化工学报 ›› 2022, Vol. 73 ›› Issue (4): 1695-1703.DOI: 10.11949/0438-1157.20211385

收稿日期:2021-09-27

修回日期:2022-01-24

出版日期:2022-04-05

发布日期:2022-04-25

通讯作者:

孙杰

作者简介:马荣(1991—),女,博士研究生,基金资助:

Rong MA( ),Jie SUN(

),Jie SUN( ),Donghui LI,Jinjia WEI

),Donghui LI,Jinjia WEI

Received:2021-09-27

Revised:2022-01-24

Online:2022-04-05

Published:2022-04-25

Contact:

Jie SUN

摘要:

利用储量丰富且易获得的太阳能和海水资源为人类提供可持续的清洁能源是一项具有深远影响的探索。在本工作中,设计合成了一种自漂浮复合材料(Cu/TiO2/C-Wood),该材料具有高效的毛细输液、全光谱太阳能光热转化及光-热协同催化能力,可通过快速的界面相转移过程实现太阳能驱动海水汽化与水蒸气催化分解制氢的一步协同增效反应。其中,具有大量微通道和极轻质量的碳化木(C-Wood)作为漂浮载体,通过毛细作用将液态水快速输送至局部升温的C-Wood表面,借助高效光热转化过程使海水汽化脱盐,同时负载等离子金属Cu的TiO2纳米粒子作为催化活性组分触发水蒸气光-热协同催化分解制氢反应,从而实现太阳能驱动高效海水汽化催化分解制氢。实验结果表明:该复合材料在15 kW·m-2的光照条件下,产氢速率达到179 μmol·h-1·cm-2(35.8 mmol·h-1·g-1),且在循环利用5次后产氢速率仍基本保持不变。更重要的是,通过聚光太阳能和自漂浮毛细输液条件的共同作用,可以获得海水中主要成分氯化钠对产氢性能的显著促进,从而打破了海水制氢技术一直以来面临的氯离子副作用瓶颈问题,证实了聚光太阳能驱动自漂浮高效光热协同催化体系在规模化、绿色、可持续太阳能海水制氢中的应用潜力。

中图分类号:

马荣, 孙杰, 李东辉, 魏进家. 基于Cu/TiO2/C-Wood复合材料的聚光太阳能驱动自漂浮高效海水汽化催化分解制氢体系[J]. 化工学报, 2022, 73(4): 1695-1703.

Rong MA, Jie SUN, Donghui LI, Jinjia WEI. Self-floating high-efficient evaporative catalytic seawater hydrogen production system driven by concentrated solar energy based on Cu/TiO2/C-Wood composite[J]. CIESC Journal, 2022, 73(4): 1695-1703.

图1 聚光太阳能驱动自漂浮高效海水汽化催化分解制氢体系

Fig.1 Self-floating high-efficient evaporative catalytic seawater hydrogen production system driven by concentrated solar energy

图2 Cu/TiO2纳米粒子的XPS谱图全波长扫描图(a);Cu 2p谱图(b);CuLMM谱图(c)

Fig. 2 XPS spectra of Cu/TiO2 nanoparticles (a); high-resolution spectrum of Cu 2p (b); CuLMM spectrum (c)

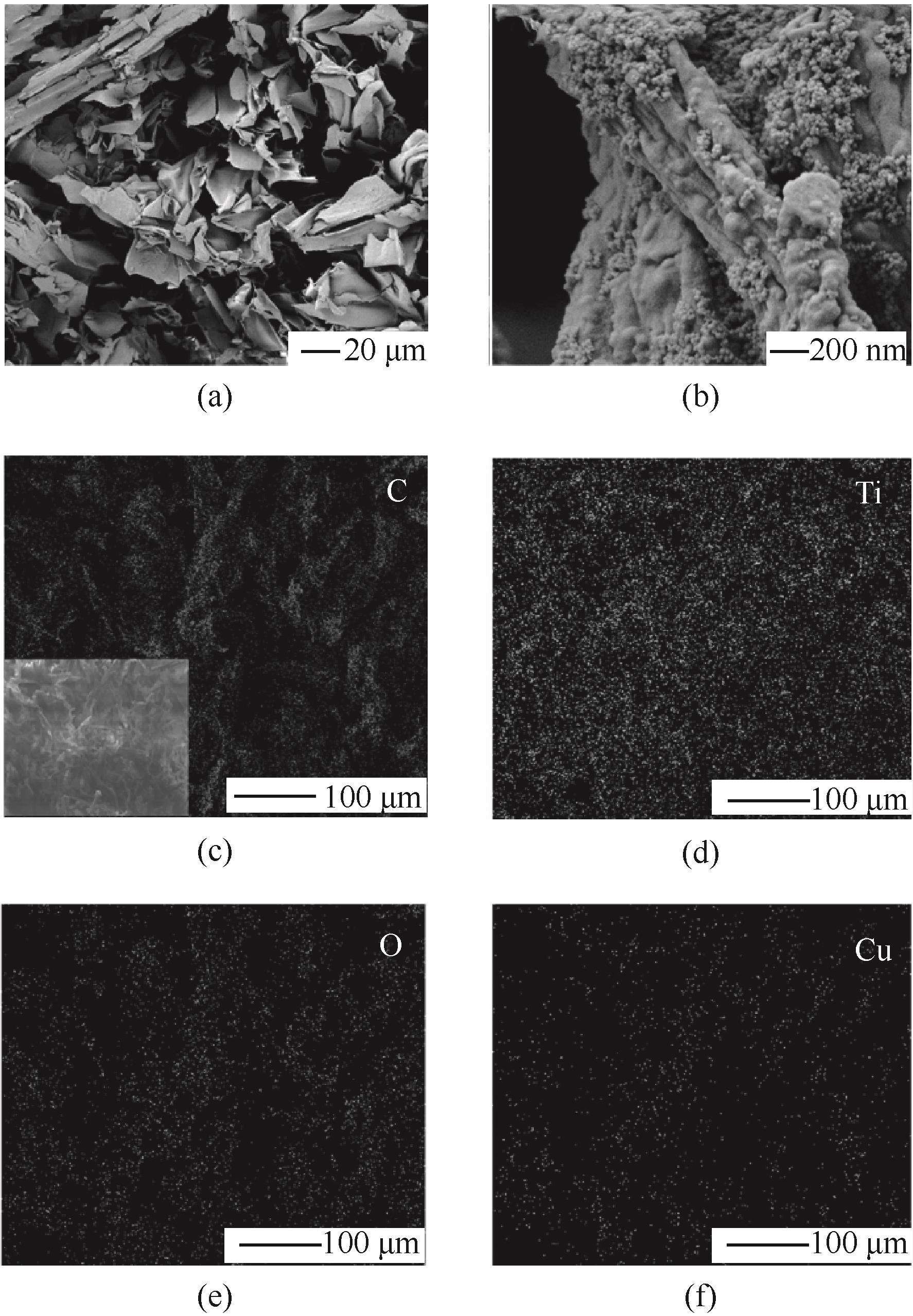

图4 C-Wood (a)和Cu/TiO2/C-Wood (b)的SEM图;Cu/TiO2/C-Wood的C、Ti、O和Cu的元素分布[(c)~(f)]

Fig.4 SEM images of C-Wood (a) and Cu/TiO2/C-Wood (b); Elemental mappings of Cu/TiO2/C-Wood for C, Ti, O and Cu elements [(c)—(f)]

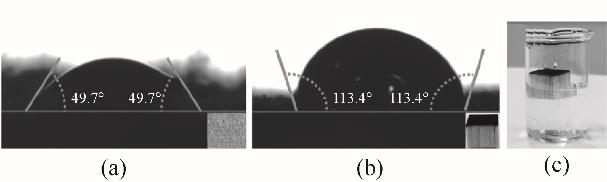

图5 Cu/TiO2/C-Wood材料的未碳化表面(a)和碳化表面(b)的接触角图像;Cu/TiO2/C-Wood材料在模拟海水中的自漂浮电子照片(c)

Fig.5 Contact angle images of Cu/TiO2/C-Wood on non-carbonized surface (a) and carbonized surface (b); Photographs of self-floating Cu/TiO2/C-Wood on synthetic seawater (c)

| 1 | Zou Z G, Ye J H, Sayama K, et al. Direct splitting of water under visible light irradiation with an oxide semiconductor photocatalyst[J]. Nature, 2001, 414(6864): 625-627. |

| 2 | Roeb M, Müller-Steinhagen H. Engineering. Concentrating on solar electricity and fuels[J]. Science, 2010, 329(5993): 773-774. |

| 3 | Luo W J, Yang Z S, Li Z S, et al. Solar hydrogen generation from seawater with a modified BiVO4 photoanode[J]. Energy & Environmental Science, 2011, 4(10): 4046. |

| 4 | Turner J A. Sustainable hydrogen production[J]. Science, 2004, 305(5686): 972-974. |

| 5 | Kumaravel V, Abdel-Wahab A. A short review on hydrogen, biofuel, and electricity production using seawater as a medium[J]. Energy & Fuels, 2018, 32(6): 6423-6437. |

| 6 | Yao Y, Gao X Y, Meng X C. Recent advances on electrocatalytic and photocatalytic seawater splitting for hydrogen evolution[J]. International Journal of Hydrogen Energy, 2021, 46(13): 9087-9100. |

| 7 | Dionigi F, Reier T, Pawolek Z, et al. Design criteria, operating conditions, and nickel-iron hydroxide catalyst materials for selective seawater electrolysis[J]. ChemSusChem, 2016, 9(9): 962-972. |

| 8 | Ayyub M M, Chhetri M, Gupta U, et al. Photochemical and photoelectrochemical hydrogen generation by splitting seawater[J]. Chemistry A European Journal, 2018, 24(69): 18455-18462. |

| 9 | Wang H L, Zhang L S, Chen Z G, et al. Semiconductor heterojunction photocatalysts: design, construction, and photocatalytic performances[J]. Chemical Society Reviews, 2014, 43(15): 5234. |

| 10 | Wang Z, Li C, Domen K. Recent developments in heterogeneous photocatalysts for solar-driven overall water splitting[J]. Chemical Society Reviews, 2019, 48(7): 2109-2125. |

| 11 | Kudo A, Miseki Y. Heterogeneous photocatalyst materials for water splitting[J]. Chemical Society Reviews, 2009, 38(1): 253-278. |

| 12 | Gust D, Moore T A, Moore A L. Solar fuels via artificial photosynthesis[J]. Accounts of Chemical Research, 2009, 42(12): 1890-1898. |

| 13 | Ma R, Sun J, Li D H, et al. Review of synergistic photo-thermo-catalysis: mechanisms, materials and applications[J]. International Journal of Hydrogen Energy, 2020, 45(55): 30288-30324. |

| 14 | Chen X B, Liu L, Yu P Y, et al. Increasing solar absorption for photocatalysis with black hydrogenated titanium dioxide nanocrystals[J]. Science, 2011, 331(6018): 746-750. |

| 15 | Yang X Y, Hu Z C, Yin Q W, et al. Water-soluble conjugated molecule for solar-driven hydrogen evolution from salt water[J]. Advanced Functional Materials, 2019, 29(13): 1808156. |

| 16 | Ma R, Sun J, Li D H, et al. Exponentially self-promoted hydrogen evolution by uni-source photo-thermal synergism in concentrating photocatalysis on co-catalyst-free P25 TiO2 [J]. Journal of Catalysis, 2020, 392: 165-174. |

| 17 | Zhang Z Y, Wang Z L, An K, et al. Ti3+ tuning the ratio of Cu+/Cu0 in the ultrafine Cu nanoparticles for boosting the hydrogenation reaction[J]. Small, 2021, 17(23): 2008052. |

| 18 | Wang L, Duan S H, Jin P X, et al. Anchored Cu(Ⅱ) tetra(4-carboxylphenyl)porphyrin to P25 (TiO2) for efficient photocatalytic ability in CO2 reduction[J]. Applied Catalysis B: Environmental, 2018, 239: 599-608.. |

| 19 | Zhang P Y, Song T, Wang T T, et al. Plasmonic Cu nanoparticle on reduced graphene oxide nanosheet support: an efficient photocatalyst for improvement of near-infrared photocatalytic H2 evolution[J]. Applied Catalysis B: Environmental, 2018, 225: 172-179. |

| 20 | Sadanandam G, Luo X, Chen X X, et al. Cu oxide quantum dots loaded TiO2 nanosheet photocatalyst for highly efficient and robust hydrogen generation[J]. Applied Surface Science, 2021, 541: 148687. |

| 21 | Li L X, Zhang J P. Highly salt-resistant and all-weather solar-driven interfacial evaporators with photothermal and electrothermal effects based on Janus graphene@silicone sponges[J]. Nano Energy, 2021, 81: 105682. |

| 22 | DeSario P A, Pitman C L, Delia D J, et al. Low-temperature CO oxidation at persistent low-valent Cu nanoparticles on TiO2 aerogels[J]. Applied Catalysis B: Environmental, 2019, 252: 205-213. |

| 23 | Linic S, Christopher P, Ingram D B. Plasmonic-metal nanostructures for efficient conversion of solar to chemical energy[J]. Nature Materials, 2011, 10(12): 911-921. |

| 24 | Marimuthu A, Zhang J W, Linic S. Tuning selectivity in propylene epoxidation by plasmon mediated photo-switching of Cu oxidation state[J]. Science, 2013, 339(6127): 1590-1593. |

| 25 | Kale M J, Avanesian T, Xin H L, et al. Controlling catalytic selectivity on metal nanoparticles by direct photoexcitation of adsorbate-metal bonds[J]. Nano Letters, 2014, 14(9): 5405-5412. |

| 26 | Wang M, Zhang L, Huang M R, et al. Morphology-controlled tantalum diselenide structures as self-optimizing hydrogen evolution catalysts[J]. Energy & Environmental Materials, 2020, 3(1): 12-18. |

| 27 | Wang J, Sun Y C, Fu L J, et al. A defective g-C3N4/RGO/TiO2 composite from hydrogen treatment for enhanced visible-light photocatalytic H2 production[J]. Nanoscale, 2020, 12(43): 22030-22035. |

| 28 | Bai H Y, Liu N, Hao L, et al. Self-floating efficient solar steam generators constructed using super-hydrophilic N, O dual-doped carbon foams from waste polyester[J]. Energy & Environmental Materials, 2021, 0: 1-10. |

| 29 | Christopher P, Xin H L, Marimuthu A, et al. Singular characteristics and unique chemical bond activation mechanisms of photocatalytic reactions on plasmonic nanostructures[J]. Nature Materials, 2012, 11(12): 1044-1050. |

| 30 | Guo S H, Li X H, Li J, et al. Boosting photocatalytic hydrogen production from water by photothermally induced biphase systems[J]. Nature Communications, 2021, 12: 1343. |

| [1] | 张佳怡, 何佳莉, 谢江鹏, 王健, 赵鹬, 张栋强. 渗透汽化技术用于锂电池生产中N-甲基吡咯烷酮回收的研究进展[J]. 化工学报, 2023, 74(8): 3203-3215. |

| [2] | 陈昇, 王梦钶, 鲁波娜, 李秀峰, 刘岑凡, 刘梦溪, 范怡平, 卢春喜. 原料油汽化特性对催化裂化反应结焦过程影响的CFD模拟[J]. 化工学报, 2022, 73(7): 2982-2995. |

| [3] | 刘鑫, 潘阳, 刘公平, 方静, 李春利, 李浩. 渗透汽化-隔壁塔精馏耦合初步分离费托合成水的过程研究[J]. 化工学报, 2022, 73(5): 2020-2030. |

| [4] | 毛恒, 王月, 王森, 刘伟民, 吕静, 陈甫雪, 赵之平. APTES改性ZIF-L/PEBA混合基质膜强化渗透汽化分离苯酚研究[J]. 化工学报, 2022, 73(3): 1389-1402. |

| [5] | 许晓东, 马晨波, 孙见君, 张玉言, 於秋萍. 基于最优传质系数的槽型结构参数对液膜机械密封汽化特性影响及优化[J]. 化工学报, 2022, 73(3): 1147-1156. |

| [6] | 林恩承, 王文, 匡以武, 石玉美, 耑锐, 孙礼杰. 低温输运管道预冷过程的气液两相数值分析[J]. 化工学报, 2021, 72(S1): 153-160. |

| [7] | 丁婉月, 马晓华. 合成次数及硅铝比调控SAPO-34分子筛膜的乙醇脱水性能[J]. 化工学报, 2021, 72(8): 4410-4417. |

| [8] | 方丽君, 王景梅, 林巧靖, 陈建华, 杨谦. 二苯并-18-冠醚-6/聚醚嵌段酰胺膜富集水中苯酚性能研究[J]. 化工学报, 2021, 72(7): 3716-3727. |

| [9] | 左成业, 涂睿, 丁晓斌, 邢卫红. PDMS复合膜回收酯化反应废水中的异丁醇[J]. 化工学报, 2020, 71(9): 4189-4199. |

| [10] | 马珊宏, 叶枫, 王燕鸿, 郎雪梅, 樊栓狮, 李刚. ZSM-5沸石膜用于生物油的脱水分离及其再生过程研究[J]. 化工学报, 2020, 71(7): 3345-3353. |

| [11] | 宋思婕,姚加,李浩然. 离子液体汽化焓的测量方法[J]. 化工学报, 2020, 71(1): 26-33. |

| [12] | 陈宏霞, 肖红洋, 孙源, 刘霖. 微柱表面液滴定壁温沸腾实验研究[J]. 化工学报, 2019, 70(9): 3363-3369. |

| [13] | 田震, 成有为, 王丽军, 李希. 温度与压力对单孔气泡形成过程的影响[J]. 化工学报, 2019, 70(9): 3337-3345. |

| [14] | 万星晨, 林文胜. 螺旋管丙烷流动沸腾换热特性[J]. 化工学报, 2018, 69(S2): 135-140. |

| [15] | 金浩, 陆佳伟, 汤吉海, 张竹修, 费兆阳, 刘清, 陈献, 崔咪芬, 乔旭. 带侧线反应精馏-渗透汽化生产乙酸乙酯集成过程模拟与分析[J]. 化工学报, 2018, 69(8): 3469-3478. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号