化工学报 ›› 2022, Vol. 73 ›› Issue (7): 3262-3272.DOI: 10.11949/0438-1157.20220141

收稿日期:2022-01-19

修回日期:2022-04-09

出版日期:2022-07-05

发布日期:2022-08-01

通讯作者:

杨兴富

作者简介:杨兴富(1988—),男,硕士,工程师,

Xingfu YANG1( ),Wen CHEN1,Jie XIAO2,Xiaodong CHEN2

),Wen CHEN1,Jie XIAO2,Xiaodong CHEN2

Received:2022-01-19

Revised:2022-04-09

Online:2022-07-05

Published:2022-08-01

Contact:

Xingfu YANG

摘要:

锂离子电池注液之前的真空干燥,对于电芯的循环性能、安全性、稳定性有极其重要的影响。电芯结构设计、材料体系、烘箱尺寸等的不同会导致真空干燥过程存在差异。反应工程方法(REA)在常压、高初始水含量的对流干燥模拟预测上已有广泛应用,本研究将REA干燥理论应用于真空、低初始水含量的干燥过程仿真,发现与实验结果匹配良好。同时考虑了电芯气袋与烘箱环境湿度变化对干燥过程的影响,水含量预测偏差小于10%,利用单因子仿真实验所总结的规律能用于指导锂电池真空干燥工艺的改善。介绍了该模型在生产中的应用情况,也表明REA将在锂电池真空干燥预测上有很好的工业应用前景。

中图分类号:

杨兴富, 陈文, 肖杰, 陈晓东. 反应工程方法在锂电池真空干燥模拟上的应用[J]. 化工学报, 2022, 73(7): 3262-3272.

Xingfu YANG, Wen CHEN, Jie XIAO, Xiaodong CHEN. Application of reaction engineering approach in modelling vacuum baking of lithium battery[J]. CIESC Journal, 2022, 73(7): 3262-3272.

| 组别 | 温度/℃ | 真空度/kPa |

|---|---|---|

| 1 | 85 | -97 |

| 2 | 95 | -97 |

| 3 | 85 | -101 |

| 4 | 95 | -101 |

表1 真空干燥实验组别

Table 1 Experimental conditions of vacuum drying

| 组别 | 温度/℃ | 真空度/kPa |

|---|---|---|

| 1 | 85 | -97 |

| 2 | 95 | -97 |

| 3 | 85 | -101 |

| 4 | 95 | -101 |

| 项目 | 组1 | 组2 | 组3 | 组4 |

|---|---|---|---|---|

| 相关系数平方R2 | 0.99909 | 0.99950 | 0.99889 | 0.99893 |

| 均方根误差RMSE | 9.99408 | 10.69929 | 13.09409 | 9.70212 |

| 平均相对误差MRE | 0.04018 | 0.07066 | 0.08872 | 0.07039 |

表2 偏差分析

Table 2 Deviation analysis

| 项目 | 组1 | 组2 | 组3 | 组4 |

|---|---|---|---|---|

| 相关系数平方R2 | 0.99909 | 0.99950 | 0.99889 | 0.99893 |

| 均方根误差RMSE | 9.99408 | 10.69929 | 13.09409 | 9.70212 |

| 平均相对误差MRE | 0.04018 | 0.07066 | 0.08872 | 0.07039 |

| 变量 | 数值 | 数据来源 |

|---|---|---|

| 换气 | 有/无 | 实验 |

| 传质系数 | 文献[ | |

| 多孔介质平均直径 | 15 μm | 实验 |

| 孔隙率 | 0.3 | 实验 |

| 初始水含量 | 700 mg/kg | 实验 |

表3 关键变量初始值

Table 3 Initial value of characteristic variable

| 变量 | 数值 | 数据来源 |

|---|---|---|

| 换气 | 有/无 | 实验 |

| 传质系数 | 文献[ | |

| 多孔介质平均直径 | 15 μm | 实验 |

| 孔隙率 | 0.3 | 实验 |

| 初始水含量 | 700 mg/kg | 实验 |

| 温度/℃ | 平衡干基含水率Xb |

|---|---|

| 20 | 0.000300 |

| 75 | 0.000105 |

| 85 | 0.000086 |

| 95 | 0.000080 |

| 105 | 0.000070 |

表4 钴酸锂电芯的平衡干基含水率

Table 4 Equilibrium moisture content(dry basis) of lithium cobalt oxide battery

| 温度/℃ | 平衡干基含水率Xb |

|---|---|

| 20 | 0.000300 |

| 75 | 0.000105 |

| 85 | 0.000086 |

| 95 | 0.000080 |

| 105 | 0.000070 |

| 实验条件 | 实测水含量/ (mg/kg) | 预测水含量/ (mg/kg) | 偏差/ (mg/kg) |

|---|---|---|---|

| 85℃&干燥200 min | 73.4 | 79.9 | 6.5 |

| 85℃&干燥150 min | 88.0 | 85.4 | -2.6 |

| 85℃&干燥90 min | 99.9 | 108.5 | 8.6 |

| 82℃&干燥90 min | 119.5 | 116.1 | -3.4 |

| 80℃&干燥85 min | 129.7 | 132.7 | 3.0 |

| 85℃&干燥65 min | 143.8 | 146.7 | 2.9 |

| 83℃&干燥65 min | 158.3 | 164.5 | 6.2 |

| 83℃&干燥60 min | 165.9 | 185.5 | 19.6 |

表5 不同实验条件下实测与预测水含量对比

Table 5 Comparison of measured and predicted moisture content under different experimental conditions

| 实验条件 | 实测水含量/ (mg/kg) | 预测水含量/ (mg/kg) | 偏差/ (mg/kg) |

|---|---|---|---|

| 85℃&干燥200 min | 73.4 | 79.9 | 6.5 |

| 85℃&干燥150 min | 88.0 | 85.4 | -2.6 |

| 85℃&干燥90 min | 99.9 | 108.5 | 8.6 |

| 82℃&干燥90 min | 119.5 | 116.1 | -3.4 |

| 80℃&干燥85 min | 129.7 | 132.7 | 3.0 |

| 85℃&干燥65 min | 143.8 | 146.7 | 2.9 |

| 83℃&干燥65 min | 158.3 | 164.5 | 6.2 |

| 83℃&干燥60 min | 165.9 | 185.5 | 19.6 |

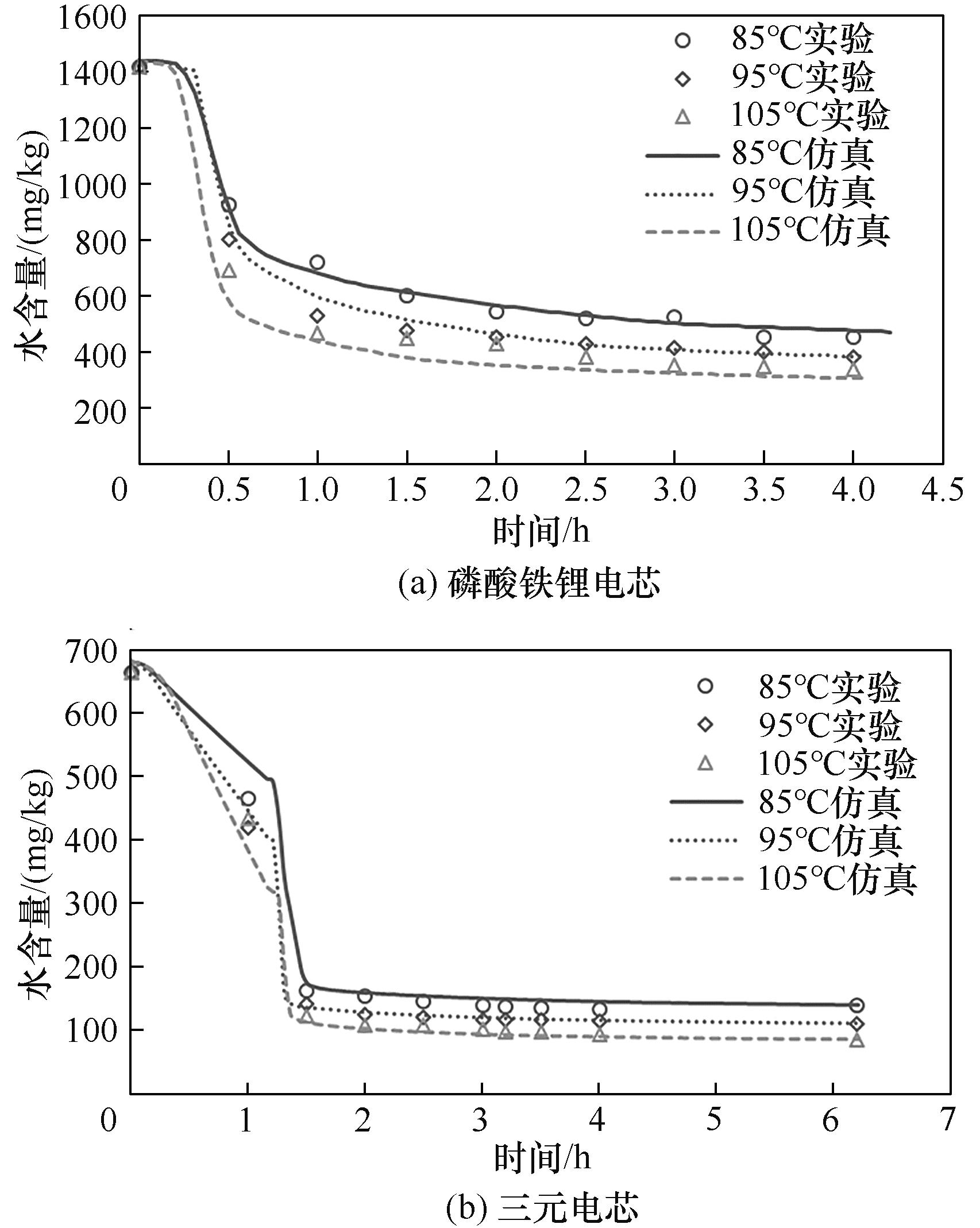

图17 磷酸铁锂电芯(a)与三元电芯(b)水含量仿真预测与实验结果对比

Fig.17 Comparison of moisture content prediction and experimental result of lithium iron phosphate (a) and ternary lithium battery (b)

| 1 | 肖顺华, 章明方. 水分对锂离子电池性能的影响[J]. 应用化学, 2005, 22(7): 764-767. |

| Xiao S H, Zhang M F. Influence of water mass fraction on performance of lithium ion batteries[J]. Chinese Journal of Applied Chemistry, 2005, 22(7): 764-767. | |

| 2 | 朱静, 于申军, 陈志奎, 等. 水分对锂离子电池性能的影响研究[J]. 华南师范大学学报(自然科学版), 2009, 41(S1): 245-247. |

| Zhu J, Yu S J, Chen Z K, et al. Effect of water contamination on the electrochemical performance of lithium-ion battery[J]. Journal of South China Normal University (Natural Science Edition), 2009, 41(S1): 245-247. | |

| 3 | 田文风. 锂电池极片真空干燥工艺仿真及优化[D]. 武汉: 华中科技大学, 2017. |

| Tian W F. Simulation and optimization of lithium battery electrode vacuum drying process[D]. Wuhan: Huazhong University of Science and Technology, 2017. | |

| 4 | 陈帅. 磷酸铁锂动力电池真空干燥过程的传热传质模拟研究[D]. 沈阳: 东北大学, 2017. |

| Chen S. Simulation of heat and mass transfer in vacuum drying process of LiFePO4 power battery[D]. Shenyang: Northeastern University, 2017. | |

| 5 | Hussain M M, Dincer I. Two-dimensional heat and moisture transfer analysis of a cylindrical moist object subjected to drying: a finite-difference approach[J]. International Journal of Heat and Mass Transfer, 2003, 46(21): 4033-4039. |

| 6 | Hussain M M, Dincer I. Numerical simulation of two-dimensional heat and moisture transfer during drying of a rectangular object[J]. Numerical Heat Transfer, Part A: Applications, 2003, 43(8): 867-878. |

| 7 | Nadi F, Rahimi G H, Younsi R, et al. Numerical simulation of vacuum drying by Luikov's equations[J]. Drying Technology, 2012, 30(2): 197-206. |

| 8 | Murru M, Giorgio G, Montomoli S, et al. Model-based scale-up of vacuum contact drying of pharmaceutical compounds[J]. Chemical Engineering Science, 2011, 66(21): 5045-5054. |

| 9 | Hou L X, Zhou X, Wang S J. Numerical analysis of heat and mass transfer in kiwifruit slices during combined radio frequency and vacuum drying[J]. International Journal of Heat and Mass Transfer, 2020, 154: 119704. |

| 10 | Chen X D, Xie G Z. Fingerprints of the drying behaviour of particulate or thin layer food materials established using a reaction engineering model[J]. Food and Bioproducts Processing, 1997, 75(4): 213-222. |

| 11 | Chen X D, Lin S X Q. Air drying of milk droplet under constant and time-dependent conditions[J]. AIChE Journal, 2005, 51(6): 1790-1799. |

| 12 | Lin S X Q, Chen X D. A model for drying of an aqueous lactose droplet using the reaction engineering approach[J]. Drying Technology, 2006, 24(11): 1329-1334. |

| 13 | Patel K, Chen X D, Jeantet R, et al. One-dimensional simulation of co-current, dairy spray drying systems—pros and cons[J]. Dairy Science & Technology, 2010, 90(2/3): 181-210. |

| 14 | Putranto A, Chen X D, Xiao Z Y, et al. Mathematical modeling of intermittent and convective drying of rice and coffee using the reaction engineering approach (REA)[J]. Journal of Food Engineering, 2011, 105(4): 638-646. |

| 15 | Putranto A, Chen X D. Spatial reaction engineering approach as an alternative for nonequilibrium multiphase mass-transfer model for drying of food and biological materials[J]. AIChE Journal, 2013, 59(1): 55-67. |

| 16 | Putranto A, Chen X D. An assessment on modeling drying processes: equilibrium multiphase model and the spatial reaction engineering approach (S-REA)[J]. Chemical Engineering Research and Design, 2015, 94: 660-672. |

| 17 | Yang X F, Xiao J, Woo M W, et al. Three-dimensional numerical investigation of a mono-disperse droplet spray dryer: validation aspects and multi-physics exploration[J]. Drying Technology, 2015, 33(6): 742-756. |

| 18 | Putranto A, Chen X D. Vacuum drying of food materials modeled and explored using the reaction engineering approach (REA) framework[J]. Drying Technology, 2021: 1-9. |

| 19 | Nield D A, Bejan A. Convection in Porous Media[M]. New York: Springer, 2013. |

| 20 | Bird R B, Stewart W E, Lightfoot E N. Transport Phenomena[M]. 2nd ed. New York: Wiley, 2002. |

| 21 | 张智贤, 阴育新. 锂离子电池材料含水量测试方法研究[J]. 天津科技, 2015, 42(12): 15-17. |

| Zhang Z X, Yin Y X. On moisture testing method for lithium ion battery materials[J]. Tianjin Science & Technology, 2015, 42(12): 15-17. | |

| 22 | Peleg M. Assessment of a semi-empirical four parameter general model for sigmoid moisture sorption isotherms1[J]. Journal of Food Process Engineering, 1993, 16(1): 21-37. |

| 23 | Foster K D, Bronlund J E, ( Tony) Paterson A H J. The prediction of moisture sorption isotherms for dairy powders[J]. International Dairy Journal, 2005, 15(4): 411-418. |

| 24 | Langklotz U, Schneider M, Michaelis A. Water uptake of tape-cast cathodes for lithium ion batteries[J]. Journal of Ceramic Science and Technology, 2013, 4(2): 69-76. |

| 25 | Eser J C, Wirsching T, Weidler P G, et al. Moisture adsorption behavior in anodes for Li-ion batteries[J]. Energy Technology, 2020, 8(2): 1801162. |

| [1] | 宋嘉豪, 王文. 斯特林发动机与高温热管耦合运行特性研究[J]. 化工学报, 2023, 74(S1): 287-294. |

| [2] | 张思雨, 殷勇高, 贾鹏琦, 叶威. 双U型地埋管群跨季节蓄热特性研究[J]. 化工学报, 2023, 74(S1): 295-301. |

| [3] | 晁京伟, 许嘉兴, 李廷贤. 基于无管束蒸发换热强化策略的吸附热池的供热性能研究[J]. 化工学报, 2023, 74(S1): 302-310. |

| [4] | 张化福, 童莉葛, 张振涛, 杨俊玲, 王立, 张俊浩. 机械蒸汽压缩蒸发技术研究现状与发展趋势[J]. 化工学报, 2023, 74(S1): 8-24. |

| [5] | 吴馨, 龚建英, 靳龙, 王宇涛, 黄睿宁. 超声波激励下铝板表面液滴群输运特性的研究[J]. 化工学报, 2023, 74(S1): 104-112. |

| [6] | 叶展羽, 山訸, 徐震原. 用于太阳能蒸发的折纸式蒸发器性能仿真[J]. 化工学报, 2023, 74(S1): 132-140. |

| [7] | 毕丽森, 刘斌, 胡恒祥, 曾涛, 李卓睿, 宋健飞, 吴翰铭. 粗糙界面上纳米液滴蒸发模式的分子动力学研究[J]. 化工学报, 2023, 74(S1): 172-178. |

| [8] | 张龙, 宋孟杰, 邵苛苛, 张旋, 沈俊, 高润淼, 甄泽康, 江正勇. 管翅式换热器迎风侧翅片末端霜层生长模拟研究[J]. 化工学报, 2023, 74(S1): 179-182. |

| [9] | 张义飞, 刘舫辰, 张双星, 杜文静. 超临界二氧化碳用印刷电路板式换热器性能分析[J]. 化工学报, 2023, 74(S1): 183-190. |

| [10] | 陈爱强, 代艳奇, 刘悦, 刘斌, 吴翰铭. 基板温度对HFE7100液滴蒸发过程的影响研究[J]. 化工学报, 2023, 74(S1): 191-197. |

| [11] | 王志国, 薛孟, 董芋双, 张田震, 秦晓凯, 韩强. 基于裂隙粗糙性表征方法的地热岩体热流耦合数值模拟与分析[J]. 化工学报, 2023, 74(S1): 223-234. |

| [12] | 李科, 文键, 忻碧平. 耦合蒸气冷却屏的真空多层绝热结构对液氢储罐自增压过程的影响机制研究[J]. 化工学报, 2023, 74(9): 3786-3796. |

| [13] | 何松, 刘乔迈, 谢广烁, 王斯民, 肖娟. 高浓度水煤浆管道气膜减阻两相流模拟及代理辅助优化[J]. 化工学报, 2023, 74(9): 3766-3774. |

| [14] | 刘远超, 关斌, 钟建斌, 徐一帆, 蒋旭浩, 李耑. 单层XSe2(X=Zr/Hf)的热电输运特性研究[J]. 化工学报, 2023, 74(9): 3968-3978. |

| [15] | 陈哲文, 魏俊杰, 张玉明. 超临界水煤气化耦合SOFC发电系统集成及其能量转化机制[J]. 化工学报, 2023, 74(9): 3888-3902. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号