化工学报 ›› 2023, Vol. 74 ›› Issue (4): 1433-1445.DOI: 10.11949/0438-1157.20221678

王荣1( ), 王永洪1,2(

), 王永洪1,2( ), 张新儒1,2, 李晋平1,2

), 张新儒1,2, 李晋平1,2

收稿日期:2022-12-30

修回日期:2023-03-15

出版日期:2023-04-05

发布日期:2023-06-02

通讯作者:

王永洪

作者简介:王荣(1997—),女,硕士研究生,wr2215706965@163.com

基金资助:

Rong WANG1( ), Yonghong WANG1,2(

), Yonghong WANG1,2( ), Xinru ZHANG1,2, Jinping LI1,2

), Xinru ZHANG1,2, Jinping LI1,2

Received:2022-12-30

Revised:2023-03-15

Online:2023-04-05

Published:2023-06-02

Contact:

Yonghong WANG

摘要:

高分子气体分离膜具有价格低和易加工等优点,但存在气体分离性能难以满足工业要求,以及耐老化性能和结构稳定性差等问题。炭分子筛膜不仅具有高力学性能,高耐热、耐化学腐蚀性能,而且存在适合气体传递的路径、对气体分子亲和性好的杂原子结构,以及分子辨识能力强的孔尺寸,表现出优异的气体分离性能,因而受到广泛的关注,被认为是最具应用前景的气体分离膜。6FDA型聚酰亚胺不仅具有较大的刚性和受限制的构象,且自由体积较大、分子结构可调、成孔性好和残炭量高,制备的炭分子筛膜的气体分离性能优于其他前体,受到学术界和工业部门的青睐。本文主要介绍了炭分子筛膜前体的结构设计原理,在热解过程中的炭化机理和微观结构的控制,炭结构对气体分离性能的影响,气体在膜中的传递机理,以及由6FDA型聚酰亚胺制备的炭分子筛膜在气体分离中的应用。结合科研实际,提出了6FDA型聚酰亚胺炭分子筛膜结构设计和制备的想法,为未来炭分子筛膜在气体分离中应用提供新的思路。

中图分类号:

王荣, 王永洪, 张新儒, 李晋平. 6FDA型聚酰亚胺炭分子筛气体分离膜的构筑及其应用[J]. 化工学报, 2023, 74(4): 1433-1445.

Rong WANG, Yonghong WANG, Xinru ZHANG, Jinping LI. Construction of 6FDA-based polyimide carbon molecular sieve membranes for gas separation and its application[J]. CIESC Journal, 2023, 74(4): 1433-1445.

| 聚酰亚胺 | 密度/(g/cm3) | Tg/℃ | 链间距/nm | 自由体积/(cm3/g) | 文献 |

|---|---|---|---|---|---|

| 6FDA-ODA | 1.432 | 304 | 0.56 | 0.1142 | [ |

| 6FDA-MDA | 1.400 | 304 | 0.56 | 0.1143 | [ |

| 6FDA-m-PD | 1.474 | 298 | — | 0.160 | [ |

| 6FDA-p-PD | 1.473 | 351 | — | 0.161 | [ |

| 6FDA-DABA | 1.590 | 327 | 0.53 | 0.153 | [ |

表1 不同二胺制备的6FDA型聚酰亚胺的物理化学性质

Table 1 Physicochemical properties of 6FDA-based polyimides with different diamine

| 聚酰亚胺 | 密度/(g/cm3) | Tg/℃ | 链间距/nm | 自由体积/(cm3/g) | 文献 |

|---|---|---|---|---|---|

| 6FDA-ODA | 1.432 | 304 | 0.56 | 0.1142 | [ |

| 6FDA-MDA | 1.400 | 304 | 0.56 | 0.1143 | [ |

| 6FDA-m-PD | 1.474 | 298 | — | 0.160 | [ |

| 6FDA-p-PD | 1.473 | 351 | — | 0.161 | [ |

| 6FDA-DABA | 1.590 | 327 | 0.53 | 0.153 | [ |

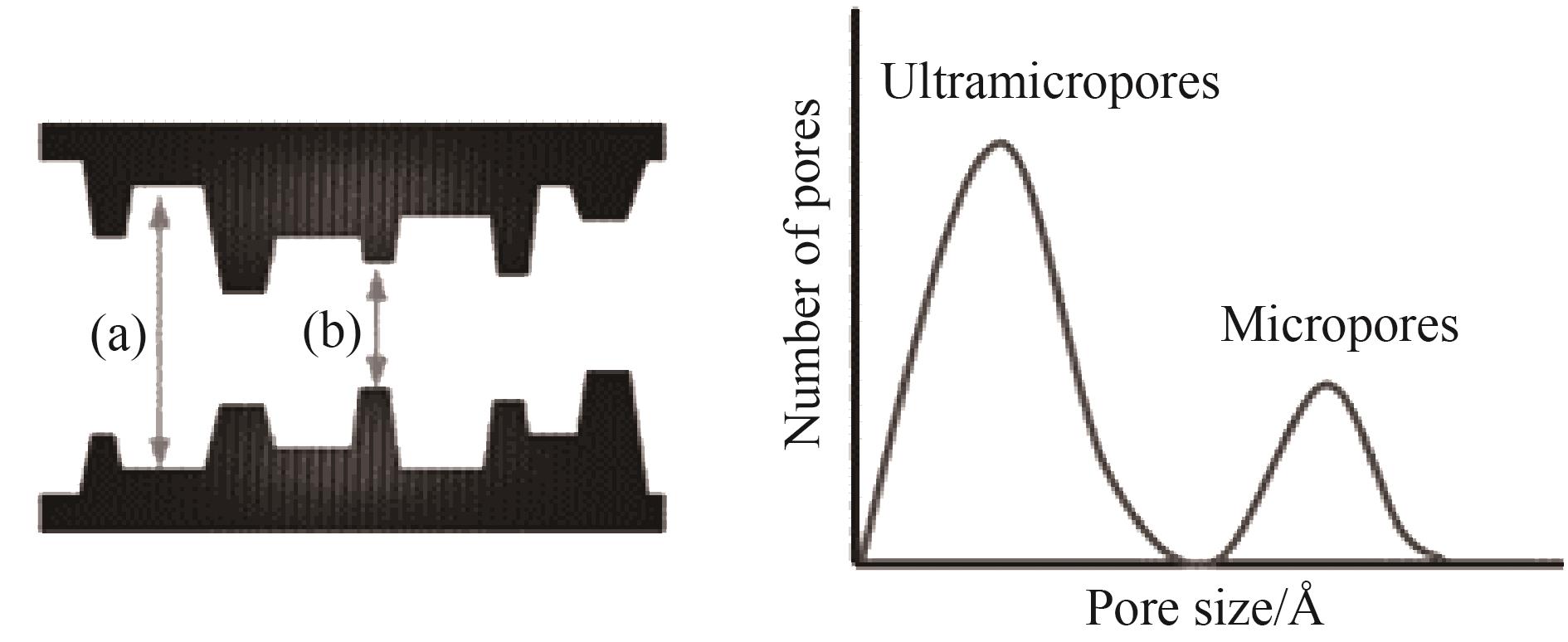

图6 炭分子筛膜的狭缝状孔结构及双峰孔径分布[22]

Fig.6 A simplified idealized slit-like pore structures and bimodal distribution of pores in carbon molecular sieve membranes[22]

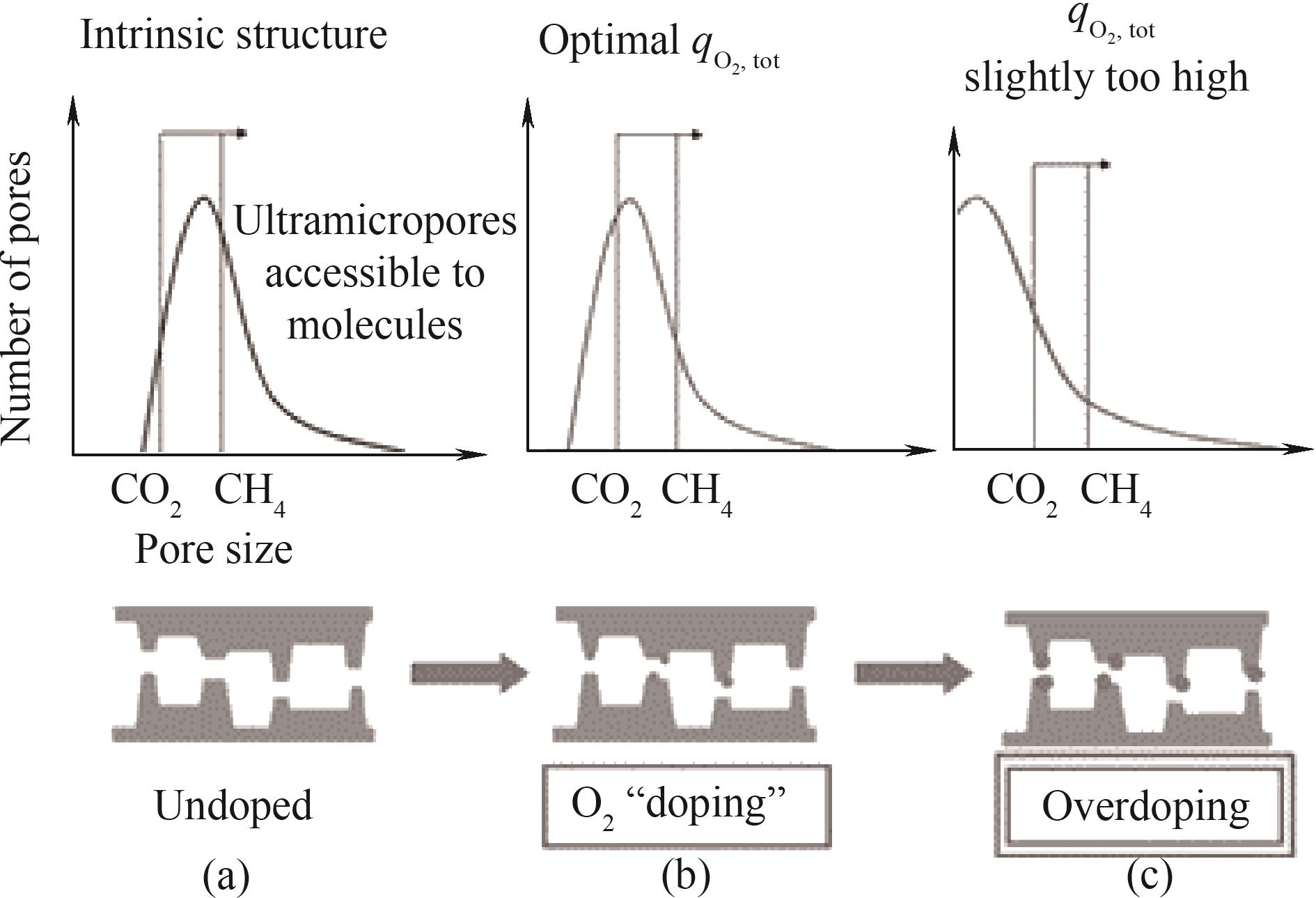

图7 (a)无氧条件下热解的未掺杂结构;(b)掺杂足够氧的最佳选择结构;(c)热解时引入高含量氧的过掺杂结构[39]

Fig.7 (a) Undoped structure when pyrolyzed without oxygen; (b) Optimal selective structure with adequate amount of oxygen doped; (c) Overdoped structure when slightly higher oxygen was introduced during pyrolysis[39]

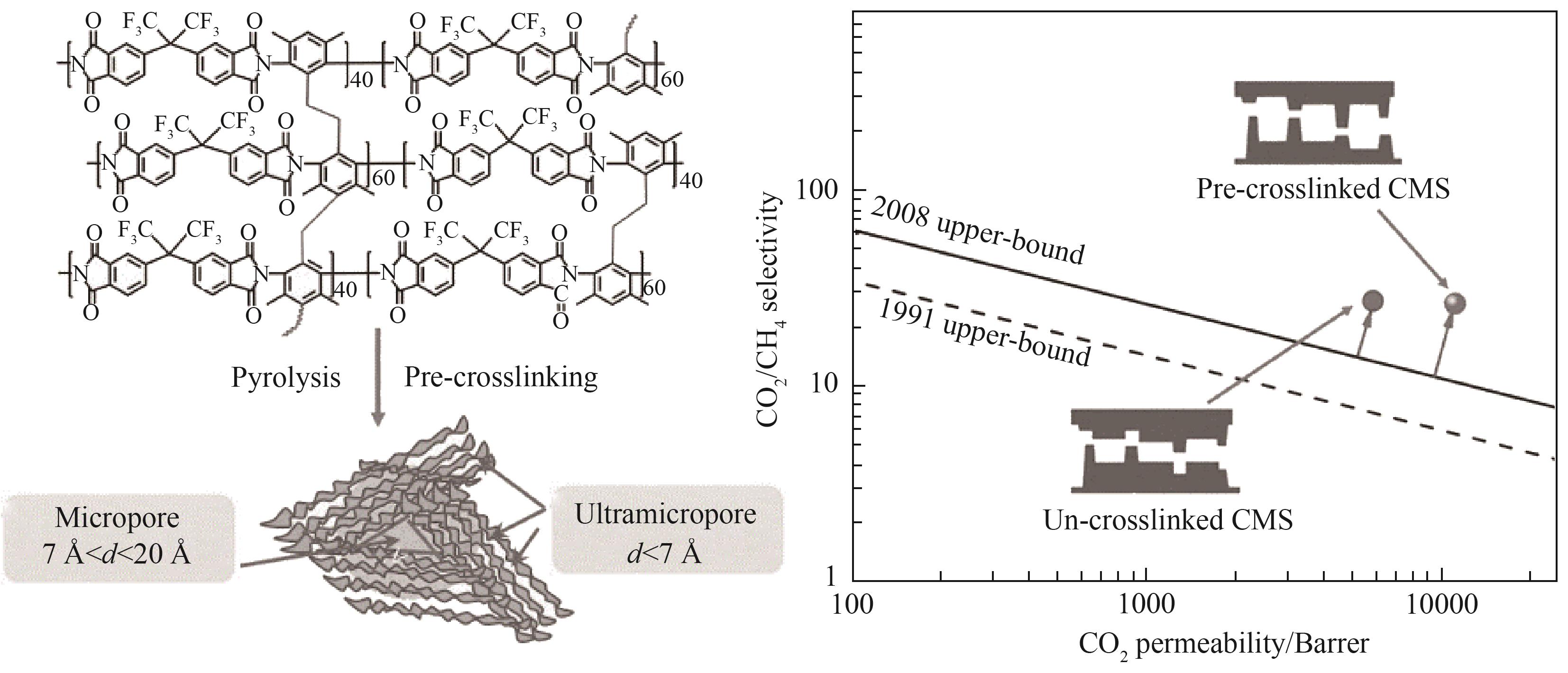

图10 热交联溴化6FDA基聚酰亚胺(BMPI)结构和炭分子筛膜对CO2/CH4的分离性能[62]

Fig.10 Structure of thermally crosslinkable brominated 6FDA-based polyimide (BMPI) and carbon molecular sieve membranes performance for CO2/CH4 separation[62]

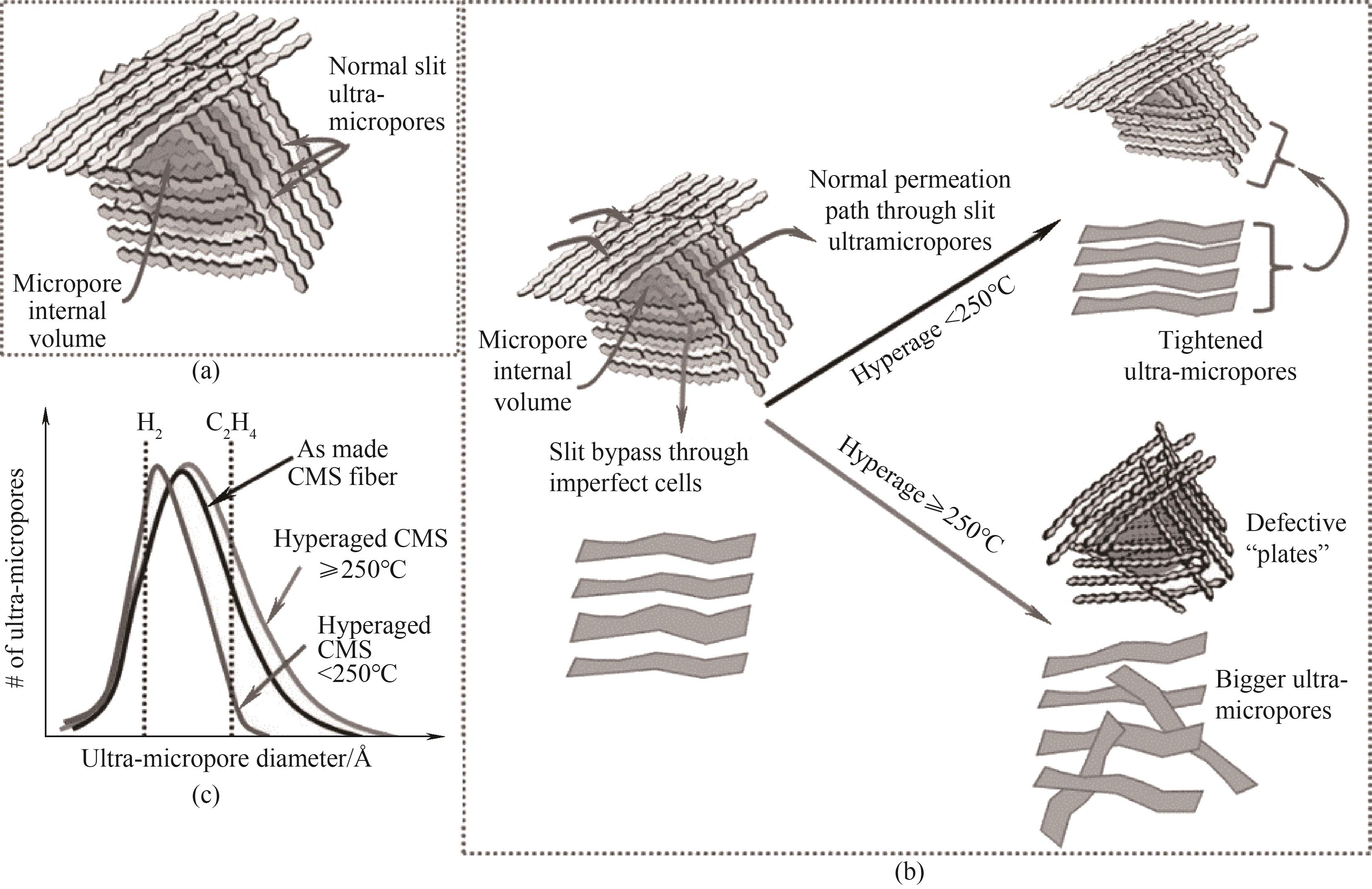

图11 (a) 炭分子筛膜的结构;(b) 250℃以上和以下强烈老化后的炭分子筛膜的结构变化;(c) 炭分子筛膜中超微孔的分布[66]

Fig.11 (a) The structure of the carbon molecular sieve membranes; (b) Structural changes in carbon molecular sieve membranes after being hyperaged below and above 250 °C; (c) Distribution of ultramicropores in carbon molecular sieve membranes[66]

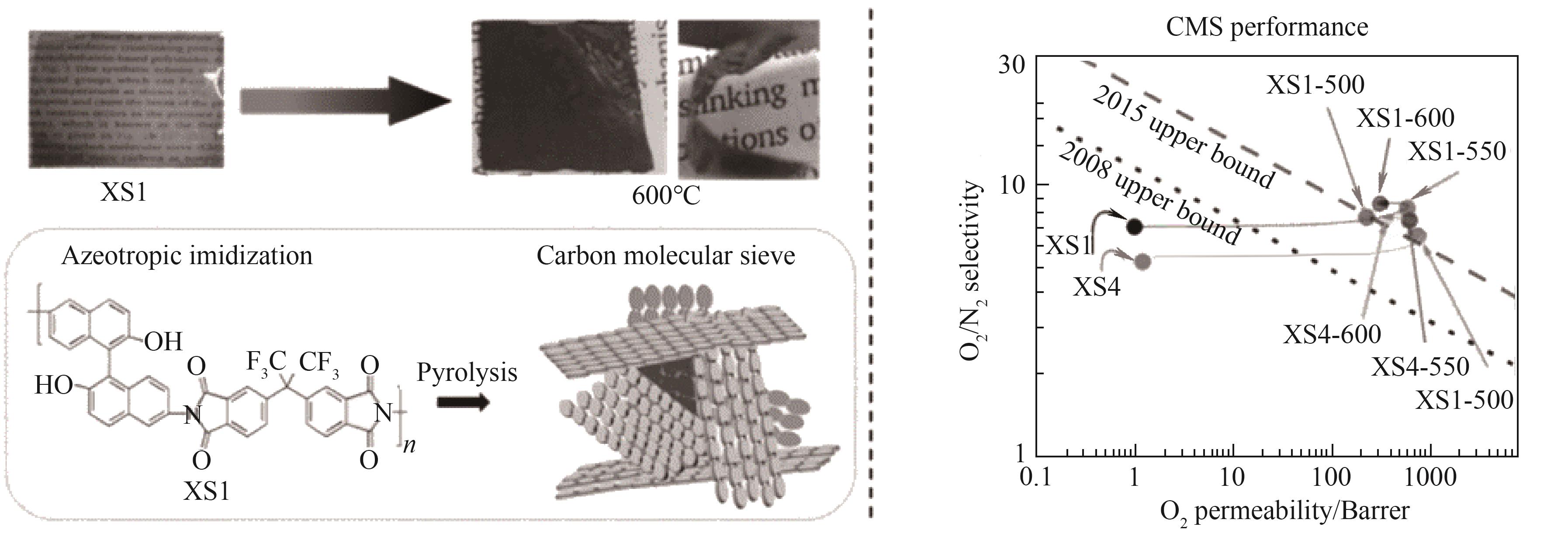

图12 XS1(共沸亚胺化)和XS4(化学亚胺化)的分离性能及与2008年和2015年Robeson上限的比较[75]

Fig.12 Separation performance of XS1 (azeotropic imidization) and XS4 (chemical imidization) and comparison to 2008 and 2015 Robeson upper bound[75]

| 1 | Sholl D S, Lively R P. Seven chemical separations to change the world[J]. Nature, 2016, 532(7600): 435-437. |

| 2 | Robinson S, Jubin R, Choate B. Materials for separation technologies. Energy and emission reduction opportunities[R]. Oak Ridge National Lab, 2005. |

| 3 | Brunetti A, Scura F, Barbieri G, et al. Membrane technologies for CO2 separation[J]. Journal of Membrane Science, 2010, 359(1/2): 115-125. |

| 4 | Wang Y H, Jin Z, Zhang X R, et al. Enhancing CO2 separation performance of mixed matrix membranes by incorporation of L-cysteine-functionalized MoS2 [J]. Separation and Purification Technology, 2022, 297: 121560. |

| 5 | Dai Z D, Deng J, He X Z, et al. Helium separation using membrane technology: recent advances and perspectives[J]. Separation and Purification Technology, 2021, 274: 119044. |

| 6 | Cong H L, Radosz M, Towler B F, et al. Polymer-inorganic nanocomposite membranes for gas separation[J]. Separation and Purification Technology, 2007, 55(3): 281-291. |

| 7 | Hazazi K, Ma X H, Wang Y G, et al. Ultra-selective carbon molecular sieve membranes for natural gas separations based on a carbon-rich intrinsically microporous polyimide precursor[J]. Journal of Membrane Science, 2019, 585: 1-9. |

| 8 | Koresh J, Soffer A. A molecular sieve carbon membrane for continuous process gas separation[J]. Carbon, 1984, 22(2): 225. |

| 9 | Richter H, Voss H, Kaltenborn N, et al. High-flux carbon molecular sieve membranes for gas separation[J]. Angewandte Chemie International Edition, 2017, 56(27): 7760-7763. |

| 10 | Lively R. Carbon molecular sieve membranes aim to cut energy use in hydrocarbon separations[J]. Membrane Technology, 2017, 2017(1): 9-10. |

| 11 | Yoshimune M, Fujiwara I, Haraya K. Carbon molecular sieve membranes derived from trimethylsilyl substituted poly(phenylene oxide) for gas separation[J]. Carbon, 2007, 45(3): 553-560. |

| 12 | Fu S L, Sanders E S, Kulkarni S S, et al. Carbon molecular sieve membrane structure-property relationships for four novel 6FDA based polyimide precursors[J]. Journal of Membrane Science, 2015, 487: 60-73. |

| 13 | Deng G X, Luo J Z, Liu S, et al. Molecular design and characterization of new polyimides based on binaphthyl-ether diamines for gas separation[J]. Separation and Purification Technology, 2020, 235: 116218. |

| 14 | Lively R P, Dose M E, Xu L R, et al. A high-flux polyimide hollow fiber membrane to minimize footprint and energy penalty for CO2 recovery from flue gas[J]. Journal of Membrane Science, 2012, 423/424: 302-313. |

| 15 | Sazali N, Wan Salleh W N, Ismail A F, et al. A brief review on carbon selective membranes from polymer blends for gas separation performance[J]. Reviews in Chemical Engineering, 2021, 37(3): 339-362. |

| 16 | Lei L F, Bai L, Lindbråthen A, et al. Carbon membranes for CO2 removal: status and perspectives from materials to processes[J]. Chemical Engineering Journal, 2020, 401: 126084. |

| 17 | Saufi S M, Ismail A F. Fabrication of carbon membranes for gas separation—a review[J]. Carbon, 2004, 42(2): 241-259. |

| 18 | Liu Z Y, Qiu W L, Quan W Y, et al. Fine-tuned thermally cross-linkable 6FDA-based polyimide membranes for aggressive natural gas separation[J]. Journal of Membrane Science, 2021, 635: 119474. |

| 19 | Qiu W L, Leisen J E, Liu Z Y, et al. Key features of polyimide-derived carbon molecular sieves[J]. Angewandte Chemie International Edition, 2021, 60(41): 22322-22331. |

| 20 | 王睦铿. 含氟聚酰亚胺的制备及应用[J]. 有机氟工业, 1994(2): 15-25. |

| Wang M K. Preparation and application of fluorine-containing polyimide[J]. Organo-Flnorine Industry, 1994(2): 15-25. | |

| 21 | Qiu W L, Xu L R, Chen C C, et al. Gas separation performance of 6FDA-based polyimides with different chemical structures[J]. Polymer, 2013, 54(22): 6226-6235. |

| 22 | Fu S L, Sanders E S, Kulkarni S S, et al. Temperature dependence of gas transport and sorption in carbon molecular sieve membranes derived from four 6FDA based polyimides: entropic selectivity evaluation[J]. Carbon, 2015, 95: 995-1006. |

| 23 | Dasgupta B, Sen S K, Banerjee S. Gas transport properties of fluorinated poly(ether imide) membranes containing indan moiety in the main chain[J]. Journal of Membrane Science, 2009, 345(1/2): 249-256. |

| 24 | Coleman M R, Koros W J. Isomeric polyimides based on fluorinated dianhydrides and diamines for gas separation applications[J]. Journal of Membrane Science, 1990, 50(3): 285-297. |

| 25 | Tanaka K, Okano M, Toshino H, et al. Effect of methyl substituents on permeability and permselectivity of gases in polyimides prepared from methyl-substituted phenylenediamines[J]. Journal of Polymer Science Part B: Polymer Physics, 1992, 30(8): 907-914. |

| 26 | Karunaweera C, Musselman I H, Balkus K J, et al. Fabrication and characterization of aging resistant carbon molecular sieve membranes for C3 separation using high molecular weight crosslinkable polyimide, 6FDA-DABA[J]. Journal of Membrane Science, 2019, 581: 430-438. |

| 27 | Thür R, Lemmens V, Van Havere D, et al. Tuning 6FDA-DABA membrane performance for CO2 removal by physical densification and decarboxylation cross-linking during simple thermal treatment[J]. Journal of Membrane Science, 2020, 610: 118195. |

| 28 | Weidman J R, Luo S J, Zhang Q N, et al. Structure manipulation in triptycene-based polyimides through main chain geometry variation and its effect on gas transport properties[J]. Industrial & Engineering Chemistry Research, 2017, 56(7): 1868-1879. |

| 29 | Liang J C, Wang Z G, Huang M H, et al. Effects on carbon molecular sieve membrane properties for a precursor polyimide with simultaneous flatness and contortion in the repeat unit[J]. ChemSusChem, 2020, 13(20): 5531-5538. |

| 30 | Kaneda T, Katsura T, Nakagawa K, et al. High-strength-high-modulus polyimide fibers (Ⅰ): One-step synthesis of spinnable polyimides[J]. Journal of Applied Polymer Science, 1986, 32(1): 3133-3149. |

| 31 | Mehdipour-Ataei S, Bahri-Laleh N, Amirshaghaghi A. Comparison of one-step and two-step methods of polyimidization and substitution effect in the synthesis of new poly(ester-imide)s with bulky pendent group[J]. Polymer Degradation and Stability, 2006, 91(11): 2622-2631. |

| 32 | Xiao S D, Huang R Y M, Feng X S. Synthetic 6FDA-ODA copolyimide membranes for gas separation and pervaporation: functional groups and separation properties[J]. Polymer, 2007, 48(18): 5355-5368. |

| 33 | Aristizábal S L, Habboub O S, Pulido B A, et al. One-step, room temperature synthesis of well-defined, organo-soluble multifunctional aromatic polyimides[J]. Macromolecules, 2021, 54(23): 10870-10882. |

| 34 | Huo G L, Xu S, Wu L, et al. Structural engineering on copolyimide membranes for improved gas separation performance[J]. Journal of Membrane Science, 2022, 643: 119989. |

| 35 | 汪英, 青双桂, 冯婷婷, 等. 催化剂对部分化学亚胺化法制备聚酰亚胺薄膜的影响[J]. 绝缘材料, 2020, 53(1): 30-34. |

| Wang Y, Qing S G, Feng T T, et al. Effect of catalyst on preparation of polyimide films via partly chemical imidization method[J]. Insulating Materials, 2020, 53(1): 30-34. | |

| 36 | 张兵. 分子筛炭膜的制备、微结构及气体分离性能[D]. 大连: 大连理工大学, 2007. |

| Zhang B. Preparation, microstructure and gas separation performance of molecular sieving carbon membranes[D]. Dalian: Dalian University of Technology, 2007. | |

| 37 | 李琳. 聚酰亚胺基炭膜的制备、热解机理及结构调控[D]. 大连: 大连理工大学, 2013. |

| Li L. Preparation, pyrolysis mechanism and structure modification of polyimide based carbon membrane[D]. Dalian: Dalian University of Technology, 2013. | |

| 38 | Steel K M. Carbon membranes for challenging gas separations[D]. Austin: The University of Texas at Austin, 2000. |

| 39 | Kiyono M, Williams P J, Koros W J. Effect of pyrolysis atmosphere on separation performance of carbon molecular sieve membranes[J]. Journal of Membrane Science, 2010, 359(1/2): 2-10. |

| 40 | Adams J S, Itta A K, Zhang C, et al. New insights into structural evolution in carbon molecular sieve membranes during pyrolysis[J]. Carbon, 2019, 141: 238-246. |

| 41 | Rungta M, Wenz G B, Zhang C, et al. Carbon molecular sieve structure development and membrane performance relationships[J]. Carbon, 2017, 115: 237-248. |

| 42 | 李琳, 祁文博, 王虹, 等. 聚酰亚胺的化学结构在炭膜制备过程中的变化规律及热解机理[J]. 新型炭材料, 2015, 30(5): 459-465. |

| Li L, Qi W B, Wang H, et al. Pyrolysis of polyimide membranes from the same dianhydride monomer and different diamines to form carbon membranes[J]. New Carbon Materials, 2015, 30(5): 459-465. | |

| 43 | Fu S L, Wenz G B, Sanders E S, et al. Effects of pyrolysis conditions on gas separation properties of 6FDA/DETDA∶DABA(3∶2) derived carbon molecular sieve membranes[J]. Journal of Membrane Science, 2016, 520: 699-711. |

| 44 | Qiu W L, Zhang K, Li F S, et al. Gas separation performance of carbon molecular sieve membranes based on 6FDA-mPDA/DABA (3∶2) polyimide[J]. ChemSusChem, 2014, 7(4): 1186-1194. |

| 45 | Kiyono M, Williams P J, Koros W J. Generalization of effect of oxygen exposure on formation and performance of carbon molecular sieve membranes[J]. Carbon, 2010, 48(15): 4442-4449. |

| 46 | Vu D Q, Koros W J, Miller S J. High pressure CO2/CH4 separation using carbon molecular sieve hollow fiber membranes[J]. Industrial & Engineering Chemistry Research, 2002, 41(3): 367-380. |

| 47 | Petersen J, Matsuda M, Haraya K. Capillary carbon molecular sieve membranes derived from Kapton for high temperature gas separation[J]. Journal of Membrane Science, 1997, 131(1/2): 85-94. |

| 48 | Sazali N, Salleh W N W, Ismail A F, et al. Effect of heating rates on the microstructure and gas permeation properties of carbon membranes[J]. Malaysian Journal of Fundamental and Applied Sciences, 2018, 14(3): 378-381. |

| 49 | Pal N, Agarwal M. Advances in materials process and separation mechanism of the membrane towards hydrogen separation[J]. International Journal of Hydrogen Energy, 2021, 46(53): 27062-27087. |

| 50 | Nurwahdah F, Sazali N, Othman M. A mini review on carbon molecular sieve membrane for oxygen separation[J]. Journal of Modern Manufacturing Systems and Technology, 2020, 4(1): 23-35. |

| 51 | Gilron J, Soffer A. Knudsen diffusion in microporous carbon membranes with molecular sieving character[J]. Journal of Membrane Science, 2002, 209(2): 339-352. |

| 52 | 曾炜炜, 吴赟炎, 李毅, 等. 二维石墨相氮化碳纳米片的制备方法研究进展[J]. 化工新型材料, 2018, 46(6): 9-11, 14. |

| Zeng W W, Wu Y Y, Li Y, et al. Research process on preparation of two dimensional graphitic carbon nitride nanosheets[J]. New Chemical Materials, 2018, 46(6): 9-11, 14. | |

| 53 | Briceño K, Montané D, Garcia-Valls R, et al. Fabrication variables affecting the structure and properties of supported carbon molecular sieve membranes for hydrogen separation[J]. Journal of Membrane Science, 2012, 415/416: 288-297. |

| 54 | Fuertes A B. Adsorption-selective carbon membrane for gas separation[J]. Journal of Membrane Science, 2000, 177(1/2): 9-16. |

| 55 | Sabil K M, Partoon B. Recent advances on carbon dioxide capture through a hydrate-based gas separation process[J]. Current Opinion in Green and Sustainable Chemistry, 2018, 11: 22-26. |

| 56 | Baker R W, Lokhandwala K. Natural gas processing with membranes: an overview[J]. Industrial & Engineering Chemistry Research, 2008, 47(7): 2109-2121. |

| 57 | Parry M L, Canziani O F, Hanson C E. Climate change 2007: impacts, adaptation and vulnerability[R]. Cambridge, UK, 2007: 173-210. |

| 58 | Arnell N W, Liu C, Compagnucci R, et al. Hydrology and water resources: impacts, adaptation, and vulnerability[R]. Cambridge, UK, 2001: 191-233. |

| 59 | Sreedhar I, Vaidhiswaran R, Kamani B M, et al. Process and engineering trends in membrane based carbon capture[J]. Renewable and Sustainable Energy Reviews, 2017, 68: 659-684. |

| 60 | Joglekar M, Itta A K, Kumar R, et al. Carbon molecular sieve membranes for CO2/N2 separations: evaluating subambient temperature performance[J]. Journal of Membrane Science, 2019, 569: 1-6. |

| 61 | Wang Y H, Sheng L C, Zhang X R, et al. Hybrid carbon molecular sieve membranes having ordered Fe3O4@ZIF-8-derived microporous structure for gas separation[J]. Journal of Membrane Science, 2023, 666: 121127. |

| 62 | Xu S, Zhao N, Wu L, et al. Carbon molecular sieve gas separation membranes from crosslinkable bromomethylated 6FDA-DAM polyimide[J]. Journal of Membrane Science, 2022, 659: 120781. |

| 63 | Jiao Y, Du A J, Smith S C, et al. H2 purification by functionalized graphdiyne—role of nitrogen doping[J]. Journal of Materials Chemistry A, 2015, 3(13): 6767-6771. |

| 64 | Chen W H, Chen C Y. Water gas shift reaction for hydrogen production and carbon dioxide capture: a review[J]. Applied Energy, 2020, 258: 114078. |

| 65 | Lei L F, Lindbråthen A, Hillestad M, et al. Carbon molecular sieve membranes for hydrogen purification from a steam methane reforming process[J]. Journal of Membrane Science, 2021, 627: 119241. |

| 66 | Qiu W L, Vaughn J, Liu G P, et al. Hyperaging tuning of a carbon molecular-sieve hollow fiber membrane with extraordinary gas-separation performance and stability[J]. Angewandte Chemie International Edition, 2019, 58(34): 11700-11703. |

| 67 | Gao T, Lin W S, Gu A Z, et al. Coalbed methane liquefaction adopting a nitrogen expansion process with propane pre-cooling[J]. Applied Energy, 2010, 87(7): 2142-2147. |

| 68 | Xu M, Deng S G. Efficient screening of novel adsorbents for coalbed methane recovery[J]. Journal of Colloid and Interface Science, 2020, 565: 131-141. |

| 69 | Ning X, Koros W J. Carbon molecular sieve membranes derived from Matrimid® polyimide for nitrogen/methane separation[J]. Carbon, 2014, 66: 511-522. |

| 70 | Low B T, Chung T S. Carbon molecular sieve membranes derived from pseudo-interpenetrating polymer networks for gas separation and carbon capture[J]. Carbon, 2011, 49(6): 2104-2112. |

| 71 | Yu H J, Shin J H, Lee A S, et al. Tailoring selective pores of carbon molecular sieve membranes towards enhanced N2/CH4 separation efficiency[J]. Journal of Membrane Science, 2021, 620: 118814. |

| 72 | Fu S L, Sanders E S, Kulkarni S, et al. The significance of entropic selectivity in carbon molecular sieve membranes derived from 6FDA/DETDA∶DABA(3∶2) polyimide[J]. Journal of Membrane Science, 2017, 539: 329-343. |

| 73 | Shao L, Chung T S, Wensley G, et al. Casting solvent effects on morphologies, gas transport properties of a novel 6FDA/PMDA-TMMDA copolyimide membrane and its derived carbon membranes[J]. Journal of Membrane Science, 2004, 244(1/2): 77-87. |

| 74 | Orhan I B, Daglar H, Keskin S, et al. Prediction of O2/N2 selectivity in metal-organic frameworks via high-throughput computational screening and machine learning[J]. ACS Applied Materials & Interfaces, 2022, 14(1): 736-749. |

| 75 | Deng G X, Wang Y L, Zong X P, et al. Structure evolution in carbon molecular sieve membranes derived from binaphthol-6FDA polyimide and their gas separation performance[J]. Journal of Industrial and Engineering Chemistry, 2021, 94: 489-497. |

| [1] | 王志国, 薛孟, 董芋双, 张田震, 秦晓凯, 韩强. 基于裂隙粗糙性表征方法的地热岩体热流耦合数值模拟与分析[J]. 化工学报, 2023, 74(S1): 223-234. |

| [2] | 金伟其, 吴月荣, 王霞, 李力, 裘溯, 袁盼, 王铭赫. 化工园区工业气体泄漏气云红外成像检测技术与国产化装备进展[J]. 化工学报, 2023, 74(S1): 32-44. |

| [3] | 赵亚欣, 张雪芹, 王荣柱, 孙国, 姚善泾, 林东强. 流穿模式离子交换层析去除单抗聚集体[J]. 化工学报, 2023, 74(9): 3879-3887. |

| [4] | 陈美思, 陈威达, 李鑫垚, 李尚予, 吴有庭, 张锋, 张志炳. 硅基离子液体微颗粒强化气体捕集与转化的研究进展[J]. 化工学报, 2023, 74(9): 3628-3639. |

| [5] | 张佳怡, 何佳莉, 谢江鹏, 王健, 赵鹬, 张栋强. 渗透汽化技术用于锂电池生产中N-甲基吡咯烷酮回收的研究进展[J]. 化工学报, 2023, 74(8): 3203-3215. |

| [6] | 张瑞航, 曹潘, 杨锋, 李昆, 肖朋, 邓春, 刘蓓, 孙长宇, 陈光进. ZIF-8纳米流体天然气乙烷回收工艺的产品纯度关键影响因素分析[J]. 化工学报, 2023, 74(8): 3386-3393. |

| [7] | 邢雷, 苗春雨, 蒋明虎, 赵立新, 李新亚. 井下微型气液旋流分离器优化设计与性能分析[J]. 化工学报, 2023, 74(8): 3394-3406. |

| [8] | 刘爽, 张霖宙, 许志明, 赵锁奇. 渣油及其组分黏度的分子层次组成关联研究[J]. 化工学报, 2023, 74(8): 3226-3241. |

| [9] | 文兆伦, 李沛睿, 张忠林, 杜晓, 侯起旺, 刘叶刚, 郝晓刚, 官国清. 基于自热再生的隔壁塔深冷空分工艺设计及优化[J]. 化工学报, 2023, 74(7): 2988-2998. |

| [10] | 张缘良, 栾昕奇, 苏伟格, 李畅浩, 赵钟兴, 周利琴, 陈健民, 黄艳, 赵祯霞. 离子液体复合萃取剂选择性萃取尼古丁的研究及DFT计算[J]. 化工学报, 2023, 74(7): 2947-2956. |

| [11] | 高金明, 郭玉娇, 鄂承林, 卢春喜. 一种封闭罩内顺流多旋臂气液分离器的分离特性研究[J]. 化工学报, 2023, 74(7): 2957-2966. |

| [12] | 韩奎奎, 谭湘龙, 李金芝, 杨婷, 张春, 张永汾, 刘洪全, 于中伟, 顾学红. 四通道中空纤维MFI分子筛膜用于二甲苯异构体分离[J]. 化工学报, 2023, 74(6): 2468-2476. |

| [13] | 朱兴驰, 郭志远, 纪志永, 汪婧, 张盼盼, 刘杰, 赵颖颖, 袁俊生. 选择性电渗析镁锂分离过程模拟优化[J]. 化工学报, 2023, 74(6): 2477-2485. |

| [14] | 王光宇, 张锴, 张凯华, 张东柯. 微波加热干燥煤泥热质传递及其能耗特性分析[J]. 化工学报, 2023, 74(6): 2382-2390. |

| [15] | 蔺彩虹, 王丽, 吴瑜, 刘鹏, 杨江峰, 李晋平. 沸石中碱金属阳离子对CO2/N2O吸附分离性能的影响[J]. 化工学报, 2023, 74(5): 2013-2021. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号