化工学报 ›› 2023, Vol. 74 ›› Issue (6): 2382-2390.DOI: 10.11949/0438-1157.20230122

王光宇1,2( ), 张锴1,2(

), 张锴1,2( ), 张凯华1,2, 张东柯3

), 张凯华1,2, 张东柯3

收稿日期:2023-02-17

修回日期:2023-05-11

出版日期:2023-06-05

发布日期:2023-07-27

通讯作者:

张锴

作者简介:王光宇(1991—),男,博士研究生,guangyu15@163.com

基金资助:

Guangyu WANG1,2( ), Kai ZHANG1,2(

), Kai ZHANG1,2( ), Kaihua ZHANG1,2, Dongke ZHANG3

), Kaihua ZHANG1,2, Dongke ZHANG3

Received:2023-02-17

Revised:2023-05-11

Online:2023-06-05

Published:2023-07-27

Contact:

Kai ZHANG

摘要:

采用微波加热方法考察了煤泥干燥过程基本特征及其热量和质量传递特性,阐述了不同阶段动力学和能耗变化基本规律。结果表明煤泥微波干燥可以分为预热升温、恒速干燥和降速干燥三个阶段,其中自由水主要在预热升温和恒速阶段去除,而结合水则在降速阶段去除。恒速和降速干燥阶段的动力学特征可以采用线性模型和修正的Page模型(Ⅰ)分别描述,进而获得所选样品在降速阶段的表观活化能为3.23 W/g。样品在恒速干燥阶段脱水能耗(2.94~5.90 kJ/g)明显低于预热升温和降速干燥阶段,且脱水能耗随着微波功率(500~800 W)增大或初始质量(150~300 g)增加而逐渐降低。

中图分类号:

王光宇, 张锴, 张凯华, 张东柯. 微波加热干燥煤泥热质传递及其能耗特性分析[J]. 化工学报, 2023, 74(6): 2382-2390.

Guangyu WANG, Kai ZHANG, Kaihua ZHANG, Dongke ZHANG. Heat and mass transfer and energy consumption for microwave drying of coal slime[J]. CIESC Journal, 2023, 74(6): 2382-2390.

| 样品 | 工业分析/%(质量) | 元素分析/%(质量) | 热值Qb.ad/(MJ/kg) | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Mar | Mad | Aad | Vad | FCad | Cad | Had | Nad | Sad | O*ad | ||

| 煤泥 | 27.82 | 1.35 | 26.46 | 12.31 | 59.88 | 61.76 | 2.86 | 1.28 | 0.40 | 5.89 | 24.94 |

表1 煤泥样品工业分析和元素分析

Table 1 Proximate and ultimate analysis of coal slime

| 样品 | 工业分析/%(质量) | 元素分析/%(质量) | 热值Qb.ad/(MJ/kg) | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Mar | Mad | Aad | Vad | FCad | Cad | Had | Nad | Sad | O*ad | ||

| 煤泥 | 27.82 | 1.35 | 26.46 | 12.31 | 59.88 | 61.76 | 2.86 | 1.28 | 0.40 | 5.89 | 24.94 |

| 模型 | 功率/W | R2 | χ2 | RSS |

|---|---|---|---|---|

Lewis模型 MR=exp(-kt) | 500 | 0.670 | 0.014 | 0.154 |

| 600 | 0.711 | 0.013 | 0.130 | |

| 700 | 0.638 | 0.016 | 0.115 | |

| 800 | 0.621 | 0.018 | 0.110 | |

Page模型 MR=exp(-ktn ) | 500 | 0.997 | 1.091×10-4 | 0.001 |

| 600 | 0.996 | 1.500×10-4 | 0.001 | |

| 700 | 0.999 | 5.567×10-5 | 3.340×10-4 | |

| 800 | 0.999 | 2.423×10-5 | 1.211×10-4 | |

修正Page模型(Ⅰ) MR=exp[-(kt) n ] | 500 | 0.997 | 1.091×10-4 | 0.001 |

| 600 | 0.996 | 1.500×10-4 | 0.001 | |

| 700 | 0.999 | 5.567×10-5 | 3.340×10-4 | |

| 800 | 0.999 | 2.423×10-5 | 1.211×10-4 | |

修正Page模型(Ⅱ) MR=aexp(-ktn ) | 500 | 0.997 | 1.046×10-4 | 9.419×10-4 |

| 600 | 0.996 | 1.467×10-4 | 0.001 | |

| 700 | 0.999 | 2.476×10-5 | 1.236×10-4 | |

| 800 | 0.999 | 1.375×10-5 | 5.502×10-5 | |

线性模型 MR=at+b | 500 | 0.999 | 4.985×10-5 | 4.985×10-4 |

| 600 | 0.999 | 5.872×10-5 | 5.285×10-4 | |

| 700 | 0.999 | 6.192×10-5 | 3.715×10-4 | |

| 800 | 0.998 | 1.022×10-4 | 5.108×10-4 |

表2 恒速干燥阶段不同模型的统计分析结果

Table 2 Statistical fitting results of the mathematical models in the constant-rate stage

| 模型 | 功率/W | R2 | χ2 | RSS |

|---|---|---|---|---|

Lewis模型 MR=exp(-kt) | 500 | 0.670 | 0.014 | 0.154 |

| 600 | 0.711 | 0.013 | 0.130 | |

| 700 | 0.638 | 0.016 | 0.115 | |

| 800 | 0.621 | 0.018 | 0.110 | |

Page模型 MR=exp(-ktn ) | 500 | 0.997 | 1.091×10-4 | 0.001 |

| 600 | 0.996 | 1.500×10-4 | 0.001 | |

| 700 | 0.999 | 5.567×10-5 | 3.340×10-4 | |

| 800 | 0.999 | 2.423×10-5 | 1.211×10-4 | |

修正Page模型(Ⅰ) MR=exp[-(kt) n ] | 500 | 0.997 | 1.091×10-4 | 0.001 |

| 600 | 0.996 | 1.500×10-4 | 0.001 | |

| 700 | 0.999 | 5.567×10-5 | 3.340×10-4 | |

| 800 | 0.999 | 2.423×10-5 | 1.211×10-4 | |

修正Page模型(Ⅱ) MR=aexp(-ktn ) | 500 | 0.997 | 1.046×10-4 | 9.419×10-4 |

| 600 | 0.996 | 1.467×10-4 | 0.001 | |

| 700 | 0.999 | 2.476×10-5 | 1.236×10-4 | |

| 800 | 0.999 | 1.375×10-5 | 5.502×10-5 | |

线性模型 MR=at+b | 500 | 0.999 | 4.985×10-5 | 4.985×10-4 |

| 600 | 0.999 | 5.872×10-5 | 5.285×10-4 | |

| 700 | 0.999 | 6.192×10-5 | 3.715×10-4 | |

| 800 | 0.998 | 1.022×10-4 | 5.108×10-4 |

| 模型 | 功率/W | R2 | χ2 | RSS |

|---|---|---|---|---|

Lewis模型 MR=exp(-kt) | 500 | 0.643 | 0.002 | 0.024 |

| 600 | 0.495 | 0.004 | 0.020 | |

| 700 | 0.557 | 0.004 | 0.022 | |

| 800 | 0.586 | 0.004 | 0.021 | |

Page模型 MR=exp(-ktn ) | 500 | 0.995 | 2.887×10-5 | 2.887×10-4 |

| 600 | 0.990 | 7.870×10-5 | 3.148×10-4 | |

| 700 | 0.990 | 8.146×10-5 | 4.073×10-4 | |

| 800 | 0.998 | 1.192×10-5 | 4.768×10-5 | |

修正Page模型(Ⅰ) MR=exp[-(kt) n ] | 500 | 0.995 | 2.883×10-5 | 2.883×10-4 |

| 600 | 0.990 | 7.574×10-5 | 3.029×10-4 | |

| 700 | 0.990 | 8.029×10-5 | 4.014×10-4 | |

| 800 | 0.998 | 1.189×10-5 | 4.756×10-5 | |

修正Page模型(Ⅱ) MR=aexp(-ktn ) | 500 | 0.995 | 3.566×10-5 | 3.209×10-4 |

| 600 | 0.978 | 1.639×10-4 | 4.918×10-4 | |

| 700 | 0.988 | 9.559×10-5 | 3.824×10-4 | |

| 800 | 0.998 | 1.456×10-5 | 4.369×10-5 | |

线性模型 MR=at+b | 500 | 0.909 | 5.728×10-4 | 0.006 |

| 600 | 0.978 | 1.679×10-4 | 6.717×10-4 | |

| 700 | 0.964 | 3.613×10-4 | 0.002 | |

| 800 | 0.953 | 5.970×10-4 | 0.002 |

表3 降速干燥阶段不同模型的统计分析结果

Table 3 Statistical fitting results of the mathematical models in the decreasing-rate stage

| 模型 | 功率/W | R2 | χ2 | RSS |

|---|---|---|---|---|

Lewis模型 MR=exp(-kt) | 500 | 0.643 | 0.002 | 0.024 |

| 600 | 0.495 | 0.004 | 0.020 | |

| 700 | 0.557 | 0.004 | 0.022 | |

| 800 | 0.586 | 0.004 | 0.021 | |

Page模型 MR=exp(-ktn ) | 500 | 0.995 | 2.887×10-5 | 2.887×10-4 |

| 600 | 0.990 | 7.870×10-5 | 3.148×10-4 | |

| 700 | 0.990 | 8.146×10-5 | 4.073×10-4 | |

| 800 | 0.998 | 1.192×10-5 | 4.768×10-5 | |

修正Page模型(Ⅰ) MR=exp[-(kt) n ] | 500 | 0.995 | 2.883×10-5 | 2.883×10-4 |

| 600 | 0.990 | 7.574×10-5 | 3.029×10-4 | |

| 700 | 0.990 | 8.029×10-5 | 4.014×10-4 | |

| 800 | 0.998 | 1.189×10-5 | 4.756×10-5 | |

修正Page模型(Ⅱ) MR=aexp(-ktn ) | 500 | 0.995 | 3.566×10-5 | 3.209×10-4 |

| 600 | 0.978 | 1.639×10-4 | 4.918×10-4 | |

| 700 | 0.988 | 9.559×10-5 | 3.824×10-4 | |

| 800 | 0.998 | 1.456×10-5 | 4.369×10-5 | |

线性模型 MR=at+b | 500 | 0.909 | 5.728×10-4 | 0.006 |

| 600 | 0.978 | 1.679×10-4 | 6.717×10-4 | |

| 700 | 0.964 | 3.613×10-4 | 0.002 | |

| 800 | 0.953 | 5.970×10-4 | 0.002 |

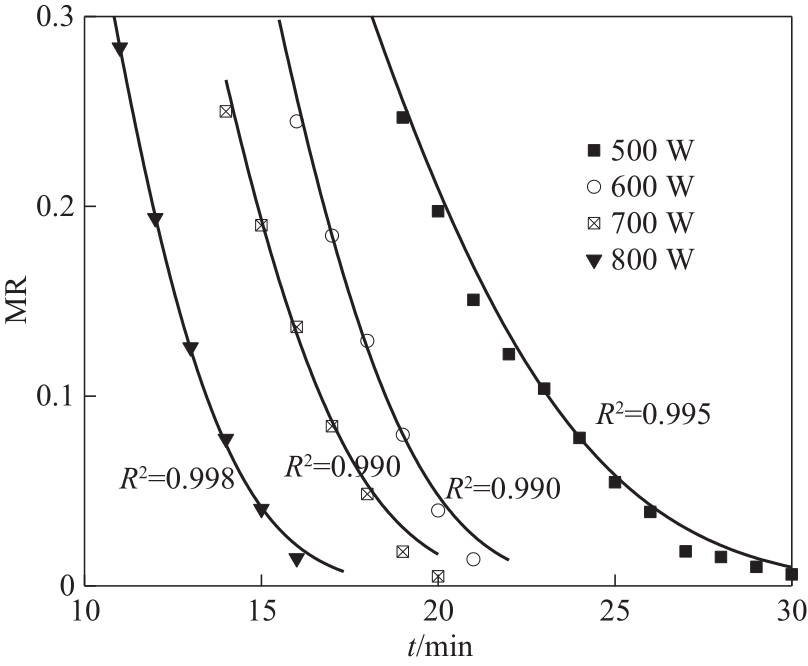

图6 降速干燥阶段含水率MR实验值与修正Page模型(Ⅰ)预测值对比

Fig.6 Comparison of experimental and predicted moisture ratios by the modified Page (Ⅰ) model in the decreasing-rate stage

| 1 | 李天涛, 郭飞强, 王岩, 等. 微型流化床内松木屑和煤泥等温混合热解特性[J]. 化工学报, 2017, 68(10): 3923-3933. |

| Li T T, Guo F Q, Wang Y, et al. Characterization of co-pyrolysis of pine sawdust and coal slime under isothermal conditions in micro fluidized bed reactor[J]. CIESC Journal, 2017, 68(10): 3923-3933. | |

| 2 | Wang H, Liu S L, Li X T, et al. Morphological and structural evolution of bituminous coal slime particles during the process of combustion[J]. Fuel, 2018, 218: 49-58. |

| 3 | Guo X, Li K, Zhou P, et al. Insight into the enhanced removal of water from coal slime via solar drying technology: dewatering performance, solar thermal efficiency, and economic analysis[J]. ACS Omega, 2022, 7(8): 6710-6720. |

| 4 | Norinaga K, Kumagai H, Hayashi J I, et al. Classification of water sorbed in coal on the basis of congelation characteristics[J]. Energy & Fuels, 1998, 12(3): 574-579. |

| 5 | Allardice D J, Evans D G. The-brown coal/water system (part 2): Water sorption isotherms on bed-moist Yallourn brown coal[J]. Fuel, 1971, 50(3): 236-253. |

| 6 | Karthikeyan M, Wu Z H, Mujumdar A S. Low-rank coal drying technologies—current status and new developments[J]. Drying Technology, 2009, 27(3): 403-415. |

| 7 | Vaxelaire J, Cézac P. Moisture distribution in activated sludges: a review[J]. Water Research, 2004, 38(9): 2215-2230. |

| 8 | Chen D D, Jiang Y F, Jiang X G, et al. The effect of anionic dispersants on the moisture distribution of a coal water slurry[J]. Fuel Processing Technology, 2014, 126: 122-130. |

| 9 | Pickles C A, Gao F, Kelebek S. Microwave drying of a low-rank sub-bituminous coal[J]. Minerals Engineering, 2014, 62: 31-42. |

| 10 | 周新志, 邵伦, 崔岢, 等. 褐煤微波干燥提质生产线的多级功率控制系统研究[J]. 化工学报, 2018, 69(S2): 274-282. |

| Zhou X Z, Shao L, Cui K, et al. Research on multi-stage power control system of lignite microwave drying production line[J]. CIESC Journal, 2018, 69(S2): 274-282. | |

| 11 | Bennamoun L, Chen Z Y, Afzal M T. Microwave drying of wastewater sludge: experimental and modeling study[J]. Drying Technology, 2016, 34(2): 235-243. |

| 12 | Song Z L, Jing C M, Yao L S, et al. Microwave drying performance of single-particle coal slime and energy consumption analyses[J]. Fuel Processing Technology, 2016, 143: 69-78. |

| 13 | Song Z L, Yao L S, Jing C M, et al. Elucidation of the pumping effect during microwave drying of lignite[J]. Industrial & Engineering Chemistry Research, 2016, 55(11): 3167-3176. |

| 14 | Fu B A, Chen M Q, Song J J. Investigation on the microwave drying kinetics and pumping phenomenon of lignite spheres[J]. Applied Thermal Engineering, 2017, 124: 371-380. |

| 15 | Li L Z, Jiang X W, Qin X M, et al. Experimental study and energy analysis on microwave-assisted lignite drying[J]. Drying Technology, 2019, 37(8): 962-975. |

| 16 | Ge J, He Y, Zhu Y Q, et al. Combined conventional thermal and microwave drying process for typical Chinese lignite[J]. Drying Technology, 2019, 37(7): 813-823. |

| 17 | Li L Z, Jiang X W, Bian Z G, et al. Microwave drying performance of lignite with the assistance of biomass-derived char[J]. Drying Technology, 2019, 37(2): 173-185. |

| 18 | Idris A, Khalid K, Omar W. Drying of silica sludge using microwave heating[J]. Applied Thermal Engineering, 2004, 24(5/6): 905-918. |

| 19 | Mawioo P M, Rweyemamu A, Garcia H A, et al. Evaluation of a microwave based reactor for the treatment of blackwater sludge[J]. Science of the Total Environment, 2016, 548/549: 72-81. |

| 20 | Zhao P F, Liu C H, Qu W W, et al. Effect of temperature and microwave power levels on microwave drying kinetics of Zhaotong lignite[J]. Processes, 2019, 7(2): 74. |

| 21 | Fu B A, Chen M Q, Huang Y W, et al. Combined effects of additives and power levels on microwave drying performance of lignite thin layer[J]. Drying Technology, 2017, 35(2): 227-239. |

| 22 | Lin B Q, Cao X A, Liu T, et al. Experimental research on water migration-damage characteristics of lignite under microwave heating[J]. Energy & Fuels, 2021, 35(2): 1058-1069. |

| 23 | 王宝和. 干燥动力学研究综述[J]. 干燥技术与设备, 2009, 7(2): 51-56. |

| Wang B H. Review of drying kinetics[J]. Drying Technology & Equipment, 2009, 7(2): 51-56. | |

| 24 | Han R, Zhou A N, Zhang N N, et al. A review of kinetic studies on evaporative dehydration of lignite[J]. Fuel, 2022, 329: 125445. |

| 25 | Zhu J F, Liu J Z, Wu J H, et al. Thin-layer drying characteristics and modeling of Ximeng lignite under microwave irradiation[J]. Fuel Processing Technology, 2015, 130: 62-70. |

| 26 | Hatibaruah D, Baruah D C, Sanyal S. Microwave drying characteristics of Assam ctc tea (Camellia assamica)[J]. Journal of Food Processing and Preservation, 2013, 37(4): 366-370. |

| 27 | Kantrong H, Tansakul A, Mittal G S. Drying characteristics and quality of shiitake mushroom undergoing microwave-vacuum drying and microwave-vacuum combined with infrared drying[J]. Journal of Food Science and Technology, 2014, 51(12): 3594-3608. |

| 28 | Arslan D, Özcan M M. Study the effect of sun, oven and microwave drying on quality of onion slices[J]. LWT-Food Science and Technology, 2010, 43(7): 1121-1127. |

| 29 | Hacifazlioglu H. Comparison of efficiencies of microwave and conventional electric ovens in the drying of slime-coal agglomerates[J]. International Journal of Coal Preparation and Utilization, 2017, 37(4): 169-178. |

| 30 | Guo J L, Zheng L, Li Z F. Microwave drying behavior, energy consumption, and mathematical modeling of sewage sludge in a novel pilot-scale microwave drying system[J]. Science of the Total Environment, 2021, 777: 146109. |

| 31 | Song Z L, Yao L S, Jing C M, et al. Drying behavior of lignite under microwave heating[J]. Drying Technology, 2017, 35(4): 433-443. |

| 32 | Li C, Liao J J, Yin Y, et al. Kinetic analysis on the microwave drying of different forms of water in lignite[J]. Fuel Processing Technology, 2018, 176: 174-181. |

| 33 | Zarein M, Samadi S H, Ghobadian B. Investigation of microwave dryer effect on energy efficiency during drying of apple slices[J]. Journal of the Saudi Society of Agricultural Sciences, 2015, 14(1): 41-47. |

| 34 | 朱炳辰, 宋维端, 房鼎业, 等. 多孔催化剂效率因子的多组分扩散模型(Ⅰ): 多组分扩散模型及数值计算方法[J]. 化工学报, 1984, 35(1): 33-40. |

| Zhu B C, Song W D, Fang D Y, et al. Multicomponent diffusion model for effectiveness factors of porous catalysts (Ⅰ): Multicomponent diffusion model and numerical computing method[J]. Journal of Chemical Industry and Engineering (China), 1984, 35(1): 33-40. | |

| 35 | Özbek B, Dadali G. Thin-layer drying characteristics and modelling of mint leaves undergoing microwave treatment[J]. Journal of Food Engineering, 2007, 83(4): 541-549. |

| 36 | Song Z L, Jing C M, Yao L S, et al. Coal slime hot air/microwave combined drying characteristics and energy analysis[J]. Fuel Processing Technology, 2017, 156: 491-499. |

| 37 | Kocbek E, Garcia H A, Hooijmans C M, et al. Effects of the sludge physical-chemical properties on its microwave drying performance[J]. Science of the Total Environment, 2022, 828: 154142. |

| [1] | 杨欣, 王文, 徐凯, 马凡华. 高压氢气加注过程中温度特征仿真分析[J]. 化工学报, 2023, 74(S1): 280-286. |

| [2] | 连梦雅, 谈莹莹, 王林, 陈枫, 曹艺飞. 地下水预热新风一体化热泵空调系统制热性能研究[J]. 化工学报, 2023, 74(S1): 311-319. |

| [3] | 金正浩, 封立杰, 李舒宏. 氨水溶液交叉型再吸收式热泵的能量及 分析[J]. 化工学报, 2023, 74(S1): 53-63. 分析[J]. 化工学报, 2023, 74(S1): 53-63. |

| [4] | 程成, 段钟弟, 孙浩然, 胡海涛, 薛鸿祥. 表面微结构对析晶沉积特性影响的格子Boltzmann模拟[J]. 化工学报, 2023, 74(S1): 74-86. |

| [5] | 肖明堃, 杨光, 黄永华, 吴静怡. 浸没孔液氧气泡动力学数值研究[J]. 化工学报, 2023, 74(S1): 87-95. |

| [6] | 毕丽森, 刘斌, 胡恒祥, 曾涛, 李卓睿, 宋健飞, 吴翰铭. 粗糙界面上纳米液滴蒸发模式的分子动力学研究[J]. 化工学报, 2023, 74(S1): 172-178. |

| [7] | 王志国, 薛孟, 董芋双, 张田震, 秦晓凯, 韩强. 基于裂隙粗糙性表征方法的地热岩体热流耦合数值模拟与分析[J]. 化工学报, 2023, 74(S1): 223-234. |

| [8] | 于宏鑫, 邵双全. 水结晶过程的分子动力学模拟分析[J]. 化工学报, 2023, 74(S1): 250-258. |

| [9] | 范孝雄, 郝丽芳, 范垂钢, 李松庚. LaMnO3/生物炭催化剂低温NH3-SCR催化脱硝性能研究[J]. 化工学报, 2023, 74(9): 3821-3830. |

| [10] | 郑佳丽, 李志会, 赵新强, 王延吉. 离子液体催化合成2-氰基呋喃反应动力学研究[J]. 化工学报, 2023, 74(9): 3708-3715. |

| [11] | 吴雷, 刘姣, 李长聪, 周军, 叶干, 刘田田, 朱瑞玉, 张秋利, 宋永辉. 低阶粉煤催化微波热解制备含碳纳米管的高附加值改性兰炭末[J]. 化工学报, 2023, 74(9): 3956-3967. |

| [12] | 杨越, 张丹, 郑巨淦, 涂茂萍, 杨庆忠. NaCl水溶液喷射闪蒸-掺混蒸发的实验研究[J]. 化工学报, 2023, 74(8): 3279-3291. |

| [13] | 汪林正, 陆俞冰, 张睿智, 罗永浩. 基于分子动力学模拟的VOCs热氧化特性分析[J]. 化工学报, 2023, 74(8): 3242-3255. |

| [14] | 曾如宾, 沈中杰, 梁钦锋, 许建良, 代正华, 刘海峰. 基于分子动力学模拟的Fe2O3纳米颗粒烧结机制研究[J]. 化工学报, 2023, 74(8): 3353-3365. |

| [15] | 李锦潼, 邱顺, 孙文寿. 煤浆法烟气脱硫中草酸和紫外线强化煤砷浸出过程[J]. 化工学报, 2023, 74(8): 3522-3532. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号