化工学报 ›› 2022, Vol. 73 ›› Issue (1): 204-212.DOI: 10.11949/0438-1157.20210875

聂璇宇1( ),陈祯1,朱春英1,付涛涛1,高习群2,马友光1(

),陈祯1,朱春英1,付涛涛1,高习群2,马友光1( )

)

收稿日期:2021-06-28

修回日期:2021-09-04

出版日期:2022-01-05

发布日期:2022-01-18

通讯作者:

马友光

作者简介:聂璇宇(1997—),女,硕士研究生,基金资助:

Xuanyu NIE1( ),Zhen CHEN1,Chunying ZHU1,Taotao FU1,Xiqun GAO2,Youguang MA1(

),Zhen CHEN1,Chunying ZHU1,Taotao FU1,Xiqun GAO2,Youguang MA1( )

)

Received:2021-06-28

Revised:2021-09-04

Online:2022-01-05

Published:2022-01-18

Contact:

Youguang MA

摘要:

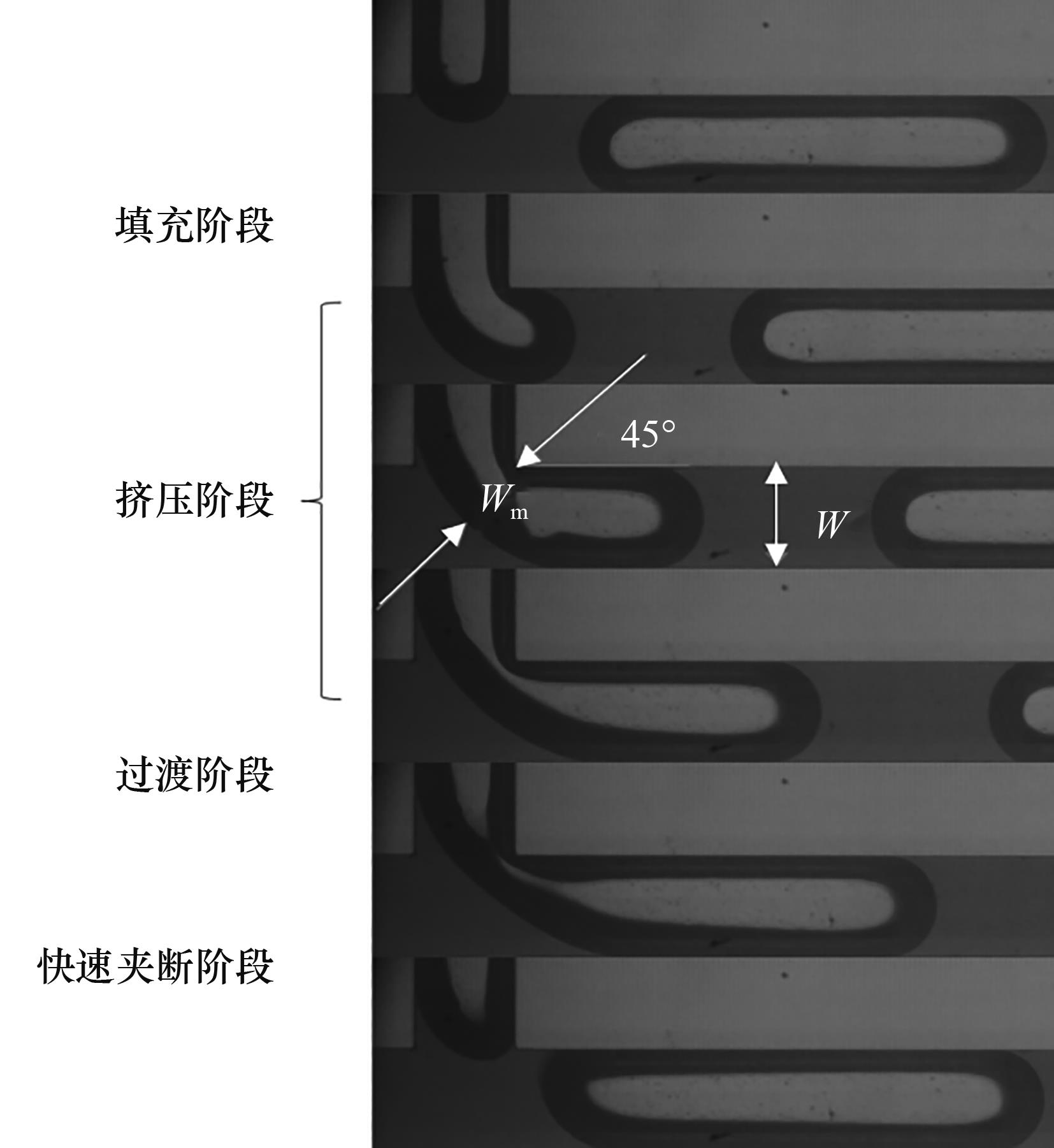

实验研究了T型微通道内浆料体系中弹状气泡的生成动力学,重点考察了颗粒粒径的影响。气泡的生成过程可划分为四个阶段:填充阶段、挤压阶段、过渡阶段和快速夹断阶段。在填充阶段、挤压阶段和快速夹断阶段,气泡最小颈部宽度与时间呈幂律关系。在过渡阶段,气泡最小颈部宽度与时间呈线性关系。浆料体系中气泡的挤压阶段和过渡阶段随颗粒粒径的减小而缩短。连续相流量及颗粒粒径对填充阶段幂律指数无显著影响;挤压阶段和快速夹断阶段的幂律指数以及过渡阶段的线性斜率均随颗粒粒径的增大而减小,随连续相流量的增大而增大。

中图分类号:

聂璇宇, 陈祯, 朱春英, 付涛涛, 高习群, 马友光. T型微通道内浆料体系中气泡的生成动力学[J]. 化工学报, 2022, 73(1): 204-212.

Xuanyu NIE, Zhen CHEN, Chunying ZHU, Taotao FU, Xiqun GAO, Youguang MA. Dynamic of bubble formation in slurry system in T-junction microchannel[J]. CIESC Journal, 2022, 73(1): 204-212.

| 颗粒粒径dp/μm | 界面张力σ/(mN·m-1) | 密度ρ/(kg·m-3) | 稠度系数K/(mPa·sn) | 流动指数n |

|---|---|---|---|---|

| 0 | 42.02 | 998.87 | ||

| 0.1 | 42.96 | 998.84 | 49.31 | 0.44 |

| 5 | 42.92 | 999.84 | 39.6 | 0.45 |

| 20 | 42.51 | 999.84 | 30.1 | 0.50 |

表1 浆料的物性参数 (φ=2%)

Table 1 Physical parameters of slurries (φ=2%)

| 颗粒粒径dp/μm | 界面张力σ/(mN·m-1) | 密度ρ/(kg·m-3) | 稠度系数K/(mPa·sn) | 流动指数n |

|---|---|---|---|---|

| 0 | 42.02 | 998.87 | ||

| 0.1 | 42.96 | 998.84 | 49.31 | 0.44 |

| 5 | 42.92 | 999.84 | 39.6 | 0.45 |

| 20 | 42.51 | 999.84 | 30.1 | 0.50 |

图4 T型微通道中气泡的生成过程 (φ=2%, dp=0.1 μm, QC=100 ml·h-1, QD=180 ml·h-1)

Fig.4 Bubble formation process in T-junction microfluidics (φ=2%, dp =0.1 μm, QC=100 ml·h-1, QD=180 ml·h-1)

| 1 | Dalvand K, Ghiasvand A, Gupta V, et al. Chemotaxis-based smart drug delivery of epirubicin using a 3D printed microfluidic chip[J]. Journal of Chromatography B, 2021, 1162: 122456. |

| 2 | 赵绍磊, 王灵宇, 吴送姑. 药物多晶型的研究进展[J]. 化学工业与工程, 2018, 35(3): 12-21. |

| Zhao S L, Wang L Y, Wu S G. Progress in the research of pharmaceutical polymorph[J]. Chemical Industry and Engineering, 2018, 35(3): 12-21. | |

| 3 | Kurylo I, Gines G, Rondelez Y, et al. Spatiotemporal control of DNA-based chemical reaction network via electrochemical activation in microfluidics[J]. Scientific Reports, 2018, 8: 6396. |

| 4 | 王彦, 王靖涛. 微流控技术制备聚酰胺微胶囊的工艺研究[J]. 化学工业与工程, 2018, 35(6): 20-25. |

| Wang Y, Wang J T. Preparation of polyamide microcapsules based on microfluidics[J]. Chemical Industry and Engineering, 2018, 35(6): 20-25. | |

| 5 | Hofmann G, Tofighi G, Rinke G, et al. A microfluidic device for the investigation of rapid gold nanoparticle formation in continuous turbulent flow[J]. Journal of Physics: Conference Series, 2016, 712: 012072. |

| 6 | Aghaei E, Karimzadeh R, Godini H R, et al. Improving the physicochemical properties of Y zeolite for catalytic cracking of heavy oil via sequential steam-alkali-acid treatments[J]. Microporous and Mesoporous Materials, 2020, 294: 109854. |

| 7 | Ge B Q, Hu Y D, Zhang H W, et al. Zirconium promoter effect on catalytic activity of Pd based catalysts for heterogeneous hydrogenation of nitrile butadiene rubber[J]. Applied Surface Science, 2021, 539: 148212. |

| 8 | Gao L J, Chen L, Ren J T, et al. Mesoporous CdxZn1-xS with abundant surface defects for efficient photocatalytic hydrogen production[J]. Journal of Colloid and Interface Science, 2021, 589: 25-33. |

| 9 | Liedtke A K, Scheiff F, Bornette F, et al. Liquid-solid mass transfer for microchannel suspension catalysis in gas-liquid and liquid-liquid segmented flow[J]. Industrial & Engineering Chemistry Research, 2015, 54(17): 4699-4708. |

| 10 | Yu Y E, Khodaparast S, Stone H A. Armoring confined bubbles in the flow of colloidal suspensions[J]. Soft Matter, 2017, 13(15): 2857-2865. |

| 11 | Yu Y E, Khodaparast S, Stone H A. Separation of particles by size from a suspension using the motion of a confined bubble[J]. Applied Physics Letters, 2018, 112(18): 181604. |

| 12 | Yun J X, Zhang S H, Shen S C, et al. Continuous production of solid lipid nanoparticles by liquid flow-focusing and gas displacing method in microchannels[J]. Chemical Engineering Science, 2009, 64(19): 4115-4122. |

| 13 | Ding Y, Solvas X C, deMello A. “V-junction”: a novel structure for high-speed generation of bespoke droplet flows[J]. The Analyst, 2015, 140(2): 414-421. |

| 14 | Rahimi M, Yazdanparast S, Rezai P Y. Parametric study of droplet size in an axisymmetric flow-focusing capillary device[J]. Chinese Journal of Chemical Engineering, 2020, 28(4): 1016-1022. |

| 15 | Li P, Fan M X, Sun L X, et al. Numerical simulation of bubble formation in a co-flowing liquid in microfluidic chip[J]. Microgravity Science and Technology, 2020, 32(1): 1-9. |

| 16 | Fu T T, Ma Y G, Funfschilling D, et al. Gas-liquid flow stability and bubble formation in non-Newtonian fluids in microfluidic flow-focusing devices[J]. Microfluidics and Nanofluidics, 2011, 10(5): 1135-1140. |

| 17 | 张沁丹, 付涛涛, 朱春英, 等. 十字聚焦型微通道内弹状液滴在黏弹性流体中的生成与尺寸预测[J]. 化工学报, 2016, 67(2): 504-511. |

| Zhang Q D, Fu T T, Zhu C Y, et al. Formation and size prediction of slug droplet in viscoelastic fluid in flow-focusing microchannel[J]. CIESC Journal, 2016, 67(2): 504-511. | |

| 18 | Zhang Q D, Zhu C Y, Du W, et al. Formation dynamics of elastic droplets in a microfluidic T-junction[J]. Chemical Engineering Research and Design, 2018, 139: 188-196. |

| 19 | de Menech M, Garstecki P, Jousse F, et al. Transition from squeezing to dripping in a microfluidic T-shaped junction[J]. Journal of Fluid Mechanics, 2008, 595: 141-161. |

| 20 | Garstecki P, Fuerstman M J, Stone H A, et al. Formation of droplets and bubbles in a microfluidic T-junction-scaling and mechanism of break-up[J]. Lab on a Chip, 2006, 6(3): 437-446. |

| 21 | Dollet B, van Hoeve W, Raven J P, et al. Role of the channel geometry on the bubble pinch-off in flow-focusing devices[J]. Physical Review Letters, 2008, 100(3): 034504. |

| 22 | Fu T T, Ma Y G, Funfschilling D, et al. Bubble formation in non-Newtonian fluids in a microfluidic T-junction[J]. Chemical Engineering and Processing: Process Intensification, 2011, 50(4): 438-442. |

| 23 | Tang C, Liu M Y, Xu Y G. 3-D numerical simulations on flow and mixing behaviors in gas-liquid-solid microchannels[J]. AIChE Journal, 2013, 59(6): 1934-1951. |

| 24 | Chiarello E, Gupta A, Mistura G, et al. Droplet breakup driven by shear thinning solutions in a microfluidic T-junction[J]. Physical Review Fluids, 2017, 2(12): 123602. |

| 25 | van Steijn V, Kleijn C R, Kreutzer M T. Flows around confined bubbles and their importance in triggering pinch-off[J]. Physical Review Letters, 2009, 103(21): 214501. |

| 26 | Leshansky A M, Afkhami S, Jullien M C, et al. Obstructed breakup of slender drops in a microfluidic T junction[J]. Physical Review Letters, 2012, 108(26): 264502. |

| 27 | Hoang D A, Portela L M, Kleijn C R, et al. Dynamics of droplet breakup in a T-junction[J]. Journal of Fluid Mechanics, 2013, 717: R4. |

| 28 | Che Z Z, Nguyen N T, Wong T N. Hydrodynamically mediated breakup of droplets in microchannels[J]. Applied Physics Letters, 2011, 98(5): 054102. |

| 29 | Chen Y P, Deng Z L. Hydrodynamics of a droplet passing through a microfluidic T-junction[J]. Journal of Fluid Mechanics, 2017, 819: 401-434. |

| 30 | Mora A E M, de Lima e Silva A L F, de Lima e Silva S M M. Numerical study of the dynamics of a droplet in a T-junction microchannel using OpenFOAM[J]. Chemical Engineering Science, 2019, 196: 514-526. |

| 31 | Korczyk P M, van Steijn V, Blonski S, et al. Accounting for corner flow unifies the understanding of droplet formation in microfluidic channels[J]. Nature Communications, 2019, 10: 2528. |

| 32 | Liascukiene I, Amselem G, Gunes D Z, et al. Capture of colloidal particles by a moving microfluidic bubble[J]. Soft Matter, 2018, 14(6): 992-1000. |

| 33 | Ma D F, Liang D, Zhu C Y, et al. The breakup dynamics and mechanism of viscous droplets in Y-shaped microchannels[J]. Chemical Engineering Science, 2021, 231: 116300. |

| 34 | Sun X, Zhu C Y, Fu T T, et al. Dynamics of droplet breakup and formation of satellite droplets in a microfluidic T-junction[J]. Chemical Engineering Science, 2018, 188: 158-169. |

| 35 | Wang X D, Zhu C Y, Wu Y N, et al. Dynamics of bubble breakup with partly obstruction in a microfluidic T-junction[J]. Chemical Engineering Science, 2015, 132: 128-138. |

| 36 | Jiang X F, Zhu C Y, Li H Z. Bubble pinch-off in Newtonian and non-Newtonian fluids[J]. Chemical Engineering Science, 2017, 170: 98-104. |

| 37 | Lu Y, Fu T, Zhu C, et al. Dynamics of bubble breakup at a T junction[J]. Physical Review E, 2016, 93(2): 022802. |

| [1] | 金正浩, 封立杰, 李舒宏. 氨水溶液交叉型再吸收式热泵的能量及 分析[J]. 化工学报, 2023, 74(S1): 53-63. 分析[J]. 化工学报, 2023, 74(S1): 53-63. |

| [2] | 程成, 段钟弟, 孙浩然, 胡海涛, 薛鸿祥. 表面微结构对析晶沉积特性影响的格子Boltzmann模拟[J]. 化工学报, 2023, 74(S1): 74-86. |

| [3] | 肖明堃, 杨光, 黄永华, 吴静怡. 浸没孔液氧气泡动力学数值研究[J]. 化工学报, 2023, 74(S1): 87-95. |

| [4] | 毕丽森, 刘斌, 胡恒祥, 曾涛, 李卓睿, 宋健飞, 吴翰铭. 粗糙界面上纳米液滴蒸发模式的分子动力学研究[J]. 化工学报, 2023, 74(S1): 172-178. |

| [5] | 江河, 袁俊飞, 王林, 邢谷雨. 均流腔结构对微细通道内相变流动特性影响的实验研究[J]. 化工学报, 2023, 74(S1): 235-244. |

| [6] | 于宏鑫, 邵双全. 水结晶过程的分子动力学模拟分析[J]. 化工学报, 2023, 74(S1): 250-258. |

| [7] | 范孝雄, 郝丽芳, 范垂钢, 李松庚. LaMnO3/生物炭催化剂低温NH3-SCR催化脱硝性能研究[J]. 化工学报, 2023, 74(9): 3821-3830. |

| [8] | 郑佳丽, 李志会, 赵新强, 王延吉. 离子液体催化合成2-氰基呋喃反应动力学研究[J]. 化工学报, 2023, 74(9): 3708-3715. |

| [9] | 汪林正, 陆俞冰, 张睿智, 罗永浩. 基于分子动力学模拟的VOCs热氧化特性分析[J]. 化工学报, 2023, 74(8): 3242-3255. |

| [10] | 杨越, 张丹, 郑巨淦, 涂茂萍, 杨庆忠. NaCl水溶液喷射闪蒸-掺混蒸发的实验研究[J]. 化工学报, 2023, 74(8): 3279-3291. |

| [11] | 曾如宾, 沈中杰, 梁钦锋, 许建良, 代正华, 刘海峰. 基于分子动力学模拟的Fe2O3纳米颗粒烧结机制研究[J]. 化工学报, 2023, 74(8): 3353-3365. |

| [12] | 李锦潼, 邱顺, 孙文寿. 煤浆法烟气脱硫中草酸和紫外线强化煤砷浸出过程[J]. 化工学报, 2023, 74(8): 3522-3532. |

| [13] | 郑玉圆, 葛志伟, 韩翔宇, 王亮, 陈海生. 中高温钙基材料热化学储热的研究进展与展望[J]. 化工学报, 2023, 74(8): 3171-3192. |

| [14] | 刘文竹, 云和明, 王宝雪, 胡明哲, 仲崇龙. 基于场协同和 耗散的微通道拓扑优化研究[J]. 化工学报, 2023, 74(8): 3329-3341. 耗散的微通道拓扑优化研究[J]. 化工学报, 2023, 74(8): 3329-3341. |

| [15] | 张蒙蒙, 颜冬, 沈永峰, 李文翠. 电解液类型对双离子电池阴阳离子储存行为的影响[J]. 化工学报, 2023, 74(7): 3116-3126. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号