化工学报 ›› 2023, Vol. 74 ›› Issue (10): 4087-4096.DOI: 10.11949/0438-1157.20230603

李猛1,2( ), 陶乐仁1,2(

), 陶乐仁1,2( ), 黄理浩1,2, 金程1,2

), 黄理浩1,2, 金程1,2

收稿日期:2023-06-21

修回日期:2023-09-15

出版日期:2023-10-25

发布日期:2023-12-22

通讯作者:

陶乐仁

作者简介:李猛(1996—),男,博士研究生,limeng19960607@163.com

基金资助:

Meng LI1,2( ), Leren TAO1,2(

), Leren TAO1,2( ), Lihao HUANG1,2, Cheng JIN1,2

), Lihao HUANG1,2, Cheng JIN1,2

Received:2023-06-21

Revised:2023-09-15

Online:2023-10-25

Published:2023-12-22

Contact:

Leren TAO

摘要:

采用数值和实验相结合的方法研究了齿状翅片管周围的冷凝流动和传热特性。利用经过验证的计算模型,分析了齿状翅片管在周向和轴向上的膜流动特性和冷凝传热系数,提供了有关高性能管中冷凝过程的信息。结果表明,齿状翅片管的周向和轴向薄膜厚度随着肋密度的增加而增加。对齿状翅片管特殊的传热结构进行了研究,发现复杂的传热结构导致表面张力的变化,从而改变了液膜的分布。齿状翅片管的局部冷凝传热系数对液膜分布非常敏感。得到了与最大总传热系数相对应的最佳肋密度,表明齿状翅片管的强化传热机理是传热面积和液膜厚度的共同作用。

中图分类号:

李猛, 陶乐仁, 黄理浩, 金程. 肋密度对齿状翅片管外冷凝换热和流动的影响[J]. 化工学报, 2023, 74(10): 4087-4096.

Meng LI, Leren TAO, Lihao HUANG, Cheng JIN. Effect of fin density on condensing heat transfer and flow outside dentate-fin tubes[J]. CIESC Journal, 2023, 74(10): 4087-4096.

图1 实验系统流程图1—液压隔膜泵;2—前端过热板式换热器;3—后端过冷板式换热器;4—实验测试部分;5—膨胀电磁阀;6—板式换热器;7—脉冲阻尼器;8—质量流量计;9—电加热器;10—蓄水池;11—恒温水箱;12—膨胀箱;13—电磁流量计;14—水泵;15—阀;16—差压传感器;17—液体反射镜;18—压力传感器;19—温度传感器

Fig.1 Schematic diagram of the experimental apparatus

| 管道名称 | 外径/mm | 翅片 间距/mm | 肋密度/ fpi | 周向 齿数/个 | 管道 长度/mm |

|---|---|---|---|---|---|

| 光管 | 15.88 | — | — | — | 40.00 |

| TLC-1 | 15.88 | 0.45 | 32 | 50 | 2.55 |

| TLC-2 | 15.88 | 0.35 | 36 | 50 | 2.10 |

| TLC-3 | 15.88 | 0.25 | 42 | 50 | 1.65 |

| TLC-4 | 15.88 | 0.15 | 51 | 50 | 1.35 |

表1 管道的具体结构参数

Table 1 Specifications of the tubes

| 管道名称 | 外径/mm | 翅片 间距/mm | 肋密度/ fpi | 周向 齿数/个 | 管道 长度/mm |

|---|---|---|---|---|---|

| 光管 | 15.88 | — | — | — | 40.00 |

| TLC-1 | 15.88 | 0.45 | 32 | 50 | 2.55 |

| TLC-2 | 15.88 | 0.35 | 36 | 50 | 2.10 |

| TLC-3 | 15.88 | 0.25 | 42 | 50 | 1.65 |

| TLC-4 | 15.88 | 0.15 | 51 | 50 | 1.35 |

图5 光滑管外冷凝传热系数实验结果、模拟结果和Nusselt理论值的对比

Fig.5 Comparison of experimental results, numerical results and Nusselt analytical solution of condensing heat transfer coefficient outside the plain tube

图6 齿状翅片管外传热系数模拟值与实验值的对比

Fig.6 Comparison of numerical results and experimental results of condensing heat transfer coefficient outside dentate-fin tubes

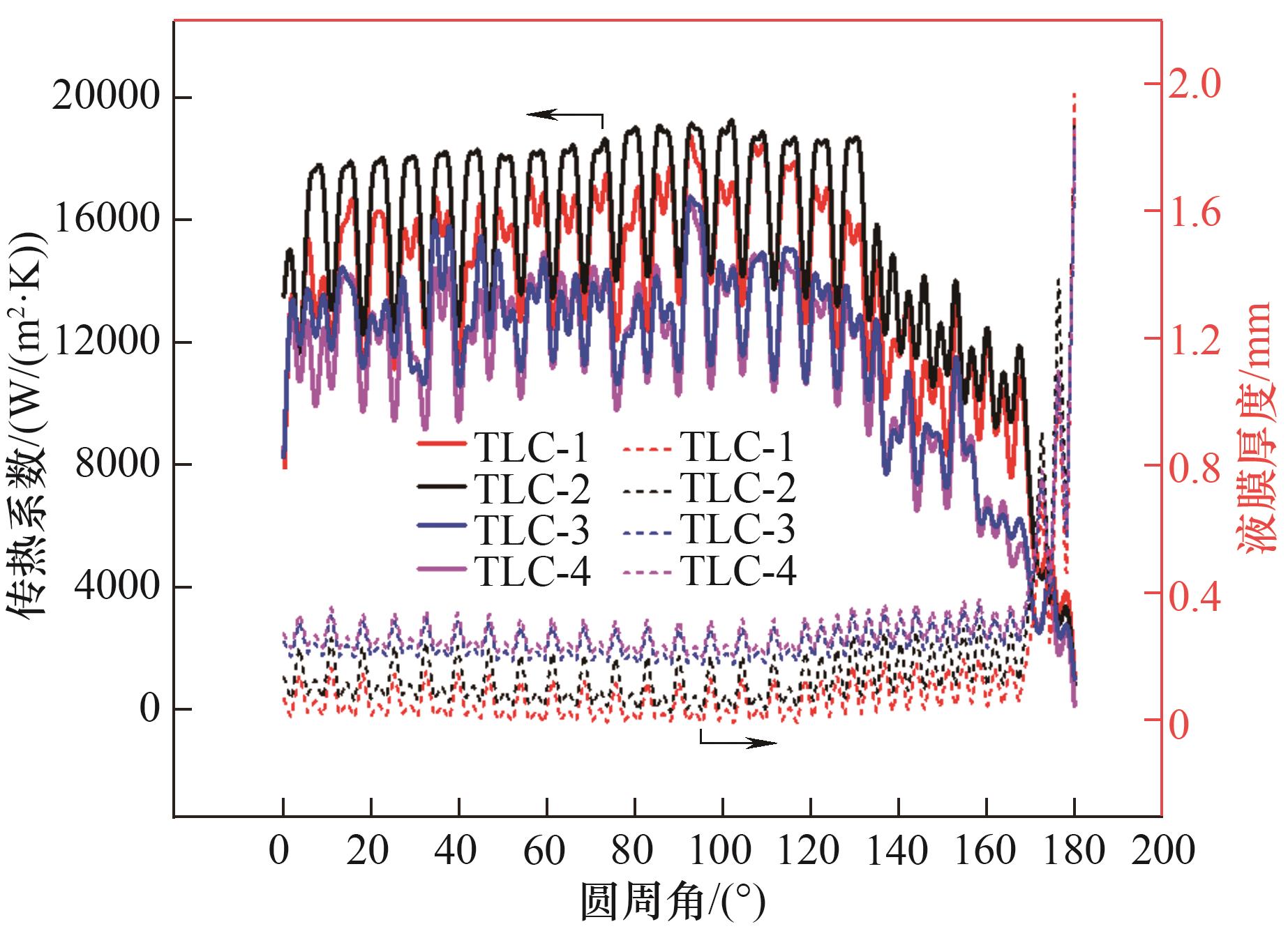

图11 局部冷凝传热系数和薄膜厚度的周向分布

Fig.11 Local condensing heat transfer coefficient and film thickness distribution at the circumferential section of the fin tip

| 1 | Company BP. BP Statistical Review of World Energy 2021[M]. London: BP, 2021. |

| 2 | Ji W T, Zhao C Y, Zhang D C, et al. Influence of condensate inundation on heat transfer of R134a condensing on three dimensional enhanced tubes and integral-fin tubes with high fin density[J]. Applied Thermal Engineering, 2012, 38: 151-159. |

| 3 | Ji W T, Zhao C Y, Zhang D C, et al. Condensation of R134a outside single horizontal titanium, cupronickel (B10 and B30), stainless steel and copper tubes[J]. International Journal of Heat and Mass Transfer, 2014, 77: 194-201. |

| 4 | Zhao C Y, Ji W T, Jin P H, et al. The influence of surface structure and thermal conductivity of the tube on the condensation heat transfer of R134a and R404A over single horizontal enhanced tubes[J]. Applied Thermal Engineering, 2017, 125: 1114-1122. |

| 5 | Zhang Z, Li Q, Xu T, et al. Effect of fin pitch, fin height, and bundle depth on condensation of R134a, R1234yf, and R1234ze in bundles of integral finned tubes[C]//Proceedings of the DKV-Conference. Duesseldorf, Germany, 2014. |

| 6 | Ji W T, Lu X D, Yu Q N, et al. Film-wise condensation of R-134a, R-1234ze(E) and R-1233zd(E) outside the finned tubes with different fin thickness[J]. International Journal of Heat and Mass Transfer, 2020, 146: 118829. |

| 7 | Briggs A, Rose J W. Effect of fin efficiency on a model for condensation heat transfer on a horizontal, integral-fin tube[J]. International Journal of Heat and Mass Transfer, 1994, 37: 457-463. |

| 8 | Al-Badri A R, Gebauer T, Leipertz A, et al. Element by element prediction model of condensation heat transfer on a horizontal integral finned tube[J]. International Journal of Heat and Mass Transfer, 2013, 62: 463-472. |

| 9 | Zhang Z G, Li Q X, Xu T, et al. Condensation heat transfer characteristics of zeotropic refrigerant mixture R407C on single, three-row petal-shaped finned tubes and helically baffled condenser[J]. Applied Thermal Engineering, 2012, 39: 63-69. |

| 10 | Gstoehl D, Thome J R. Film condensation of R-134a on tube arrays with plain and enhanced surfaces (Ⅰ): Experimental heat transfer coefficients[J]. Journal of Heat Transfer, 2006, 128(1): 21-32. |

| 11 | 卢雅聪,李文玲.竖直管外蒸汽冷凝传热过程的CFD模拟[J].中国安全生产科学技术,2021,17(S1):115-120. |

| Lu Y C, Li W L. CFD simulation of steam condensation heat transfer process outside the vertical tube[J]. Journal of Safety Science and Technology, 2021,17(S1):115-120. | |

| 12 | 贾利梅.小管径水平圆管管外冷凝传热数值分析[J].流体机械,2020,48(7):84-88. |

| Jia L M. Numerical analysis of condensation heat transfer for small diameter horizontal circular tubes[J]. Fluid Machinery, 2020,48(7):84-88. | |

| 13 | 张璐,刘金平.水平管内的过热冷凝传热性能数值模拟[J].工业炉,2021,43(4):1-5. |

| Zhang L, Liu J P. Numerical simulation of superheated condensation heat transfer performance in horizontal tube[J]. Industrial Furnace, 2021,43(4):1-5. | |

| 14 | 周梦,虞斌,曹宇.空气-水蒸气混合气体在换热圆管内外冷凝相变数值研究[J].石油化工设备,2019,48(1):40-47. |

| Zhou M, Yu B, Cao Y. Numerical study on condensation behaviors of air-vapor mixture within and outside of heat exchange pipes[J]. Petro-Chemical Equipment, 2019,48(1):40-47. | |

| 15 | Gebauer T, Al-Badri A R, Gotterbarm A, et al. Condensation heat transfer on single horizontal smooth and finned tubes and tube bundles for R134a and propane[J]. International Journal of Heat and Mass Transfer, 2013, 56(1/2): 516-524. |

| 16 | Kleiner T, Rehfeldt S, Klein H. CFD model and simulation of pure substance condensation on horizontal tubes using the volume of fluid method[J]. International Journal of Heat and Mass Transfer, 2019, 138: 420-431. |

| 17 | Kleiner T, Eder A, Rehfeldt S, et al. Detailed CFD simulations of pure substance condensation on horizontal annular low finned tubes including a parameter study of the fin slope[J]. International Journal of Heat and Mass Transfer, 2020, 163: 120363. |

| 18 | 蒋淳,陈振乾.水平管外降膜蒸发流动和传热特性数值模拟[J].化工学报,2018,69(10):4224-4230. |

| Jiang C, Chen Z Q. Numerical simulation of fluid flow and heat transfer characteristics of falling film evaporation outside horizontal tubes[J]. CIESC Journal, 2018, 69(10): 4224-4230. | |

| 19 | Sattari E, Delavar M A, Fattahi E, et al. Numerical investigation the effects of working parameters on nucleate pool boiling[J]. International Communications in Heat and Mass Transfer, 2014, 59: 106-113. |

| 20 | Gnielinski V. New equations for heat and mass transfer in the turbulent flow in pipes and channels[J]. NASA Sti/recon Technical Report A, 1975, 75(2):8-16. |

| 21 | Hirt C W, Nichols B D. Volume of fluid (VOF) method for the dynamics of free boundaries[J]. Journal of Computational Physics, 1981, 39(1): 201-225. |

| 22 | Hirt C W, Nichols B D. A computational method for free surface hydrodynamics[J]. Journal of Pressure Vessel Technology, 1981, 103(2): 136-141. |

| 23 | Hasanpour B, Irandoost M S, Hassani M, et al. Numerical investigation of saturated upward flow boiling of water in a vertical tube using VOF model: effect of different boundary conditions[J]. Heat and Mass Transfer, 2018, 54(7): 1925-1936. |

| 24 | Lee J, O'Neill L E, Lee S, et al. Experimental and computational investigation on two-phase flow and heat transfer of highly subcooled flow boiling in vertical upflow[J]. International Journal of Heat and Mass Transfer, 2019, 136: 1199-1216. |

| 25 | Lee W H. Pressure Iteration Scheme for Two-Phase Flow Modeling[M]. Washington DC, USA: Hemisphere Publishing, 1980. |

| 26 | Bahreini M, Ramiar A, Ranjbar A A. Numerical simulation of bubble behavior in subcooled flow boiling under velocity and temperature gradient[J]. Nuclear Engineering and Design, 2015, 293: 238-248. |

| 27 | Zhu H J, Li S. Numerical analysis of mitigating elbow erosion with a rib[J]. Powder Technology, 2018, 330: 445-460. |

| 28 | Li Y, Sun F, Xie G, et al. Numerical investigation on flow and thermal performance of supercritical CO2 in horizontal cylindrically concaved tubes [J].Applied Thermal Engineering, 2019, 153: 655-668. |

| 29 | Nusselt W. The surface condensation of water vapour[J]. Zeitschrift Des Vereines Deutscher Ingenieure,1916 60: 541-546. |

| [1] | 叶展羽, 山訸, 徐震原. 用于太阳能蒸发的折纸式蒸发器性能仿真[J]. 化工学报, 2023, 74(S1): 132-140. |

| [2] | 张义飞, 刘舫辰, 张双星, 杜文静. 超临界二氧化碳用印刷电路板式换热器性能分析[J]. 化工学报, 2023, 74(S1): 183-190. |

| [3] | 王志国, 薛孟, 董芋双, 张田震, 秦晓凯, 韩强. 基于裂隙粗糙性表征方法的地热岩体热流耦合数值模拟与分析[J]. 化工学报, 2023, 74(S1): 223-234. |

| [4] | 宋嘉豪, 王文. 斯特林发动机与高温热管耦合运行特性研究[J]. 化工学报, 2023, 74(S1): 287-294. |

| [5] | 张思雨, 殷勇高, 贾鹏琦, 叶威. 双U型地埋管群跨季节蓄热特性研究[J]. 化工学报, 2023, 74(S1): 295-301. |

| [6] | 何松, 刘乔迈, 谢广烁, 王斯民, 肖娟. 高浓度水煤浆管道气膜减阻两相流模拟及代理辅助优化[J]. 化工学报, 2023, 74(9): 3766-3774. |

| [7] | 邢雷, 苗春雨, 蒋明虎, 赵立新, 李新亚. 井下微型气液旋流分离器优化设计与性能分析[J]. 化工学报, 2023, 74(8): 3394-3406. |

| [8] | 韩晨, 司徒友珉, 朱斌, 许建良, 郭晓镭, 刘海峰. 协同处理废液的多喷嘴粉煤气化炉内反应流动研究[J]. 化工学报, 2023, 74(8): 3266-3278. |

| [9] | 程小松, 殷勇高, 车春文. 不同工质在溶液除湿真空再生系统中的性能对比[J]. 化工学报, 2023, 74(8): 3494-3501. |

| [10] | 刘文竹, 云和明, 王宝雪, 胡明哲, 仲崇龙. 基于场协同和 耗散的微通道拓扑优化研究[J]. 化工学报, 2023, 74(8): 3329-3341. 耗散的微通道拓扑优化研究[J]. 化工学报, 2023, 74(8): 3329-3341. |

| [11] | 洪瑞, 袁宝强, 杜文静. 垂直上升管内超临界二氧化碳传热恶化机理分析[J]. 化工学报, 2023, 74(8): 3309-3319. |

| [12] | 黄可欣, 李彤, 李桉琦, 林梅. 加装旋转叶轮T型通道流场的模态分解[J]. 化工学报, 2023, 74(7): 2848-2857. |

| [13] | 史方哲, 甘云华. 超薄热管启动特性和传热性能数值模拟[J]. 化工学报, 2023, 74(7): 2814-2823. |

| [14] | 江锦波, 彭新, 许文烜, 门日秀, 刘畅, 彭旭东. 泵出型螺旋槽油气密封泄漏特性及参数影响研究[J]. 化工学报, 2023, 74(6): 2538-2554. |

| [15] | 朱兴驰, 郭志远, 纪志永, 汪婧, 张盼盼, 刘杰, 赵颖颖, 袁俊生. 选择性电渗析镁锂分离过程模拟优化[J]. 化工学报, 2023, 74(6): 2477-2485. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号