化工学报 ›› 2024, Vol. 75 ›› Issue (1): 242-254.DOI: 10.11949/0438-1157.20230665

王俊男( ), 何呈祥, 王忠东, 朱春英, 马友光, 付涛涛(

), 何呈祥, 王忠东, 朱春英, 马友光, 付涛涛( )

)

收稿日期:2023-07-03

修回日期:2023-09-06

出版日期:2024-01-25

发布日期:2024-03-11

通讯作者:

付涛涛

作者简介:王俊男(2000—),男,硕士研究生,w2045768173@163.com

基金资助:

Junnan WANG( ), Chengxiang HE, Zhongdong WANG, Chunying ZHU, Youguang MA, Taotao FU(

), Chengxiang HE, Zhongdong WANG, Chunying ZHU, Youguang MA, Taotao FU( )

)

Received:2023-07-03

Revised:2023-09-06

Online:2024-01-25

Published:2024-03-11

Contact:

Taotao FU

摘要:

采用计算流体力学方法(CFD)对三种不同类型的T型微混合器的被动式混合进行了数值模拟。分析了简单微混合器内混合指数和压降与入口速度、扩散系数和管径之间的关系,同时研究了含有内构件混合器中结构参数对混合的影响。研究结果表明,层流状态下,在简单混合器中,混合指数随着Reynolds数Re、Schmidt数Sc和Peclet数Pe的增大而增大,同时压降随Re的增大而增大、随Pe的增大而减小。在T型混合器内加入肋板和障碍物后,混合指数随Re的增大先增大后减小;肋板长度越长,障碍物内径越大,混合效果越好,但相应的压降也越大。

中图分类号:

王俊男, 何呈祥, 王忠东, 朱春英, 马友光, 付涛涛. T型微混合器内均相混合的数值模拟[J]. 化工学报, 2024, 75(1): 242-254.

Junnan WANG, Chengxiang HE, Zhongdong WANG, Chunying ZHU, Youguang MA, Taotao FU. Numerical simulation of homogeneous mixing in T-junction micromixers[J]. CIESC Journal, 2024, 75(1): 242-254.

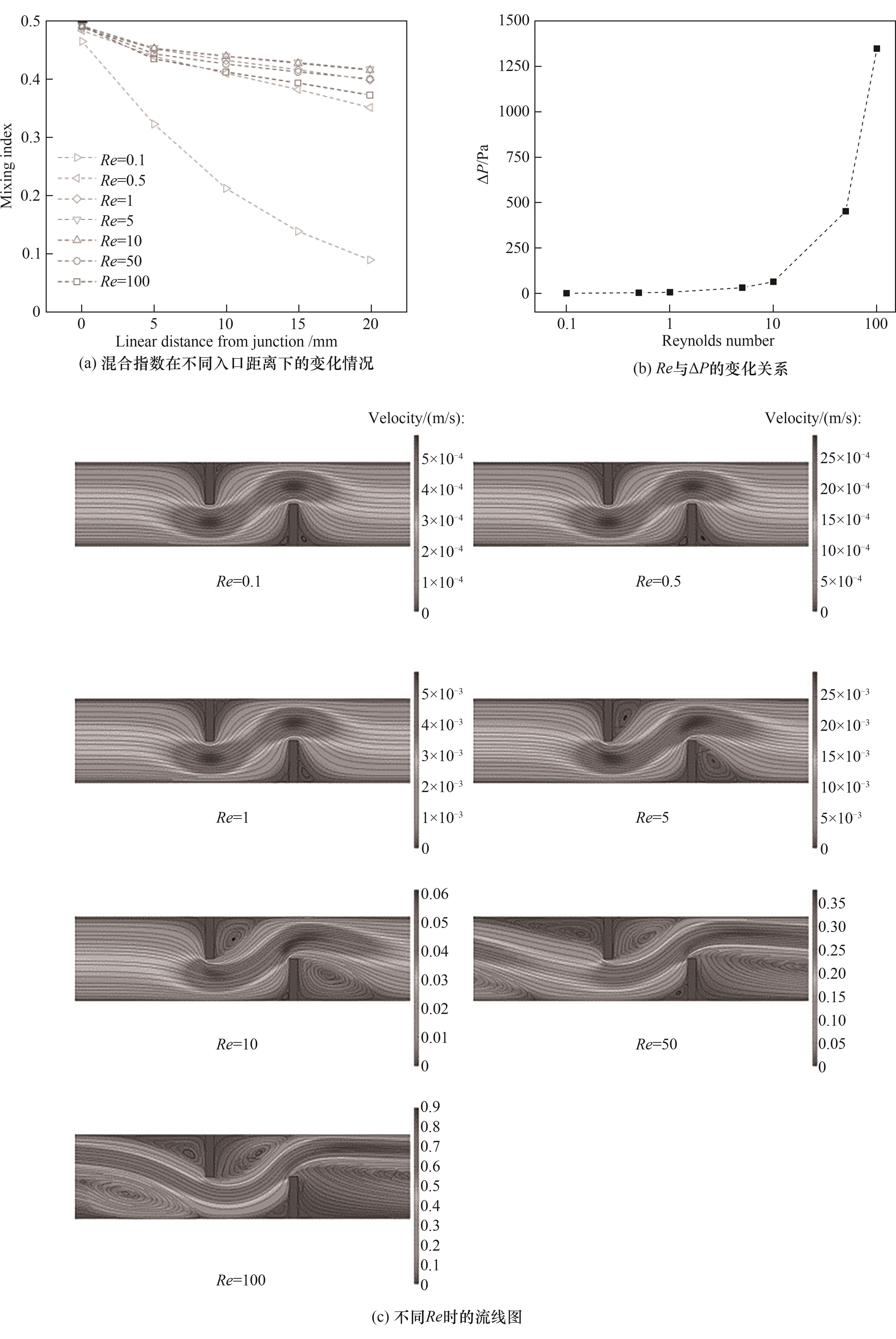

图7 加肋板后Re与混合指数和压降的关系(Sc = 2000, d = 1 mm)

Fig.7 The relationship between the Reynolds number and the mixing index and the pressure drop after adding the ribbed plate (Sc = 2000, d = 1 mm)

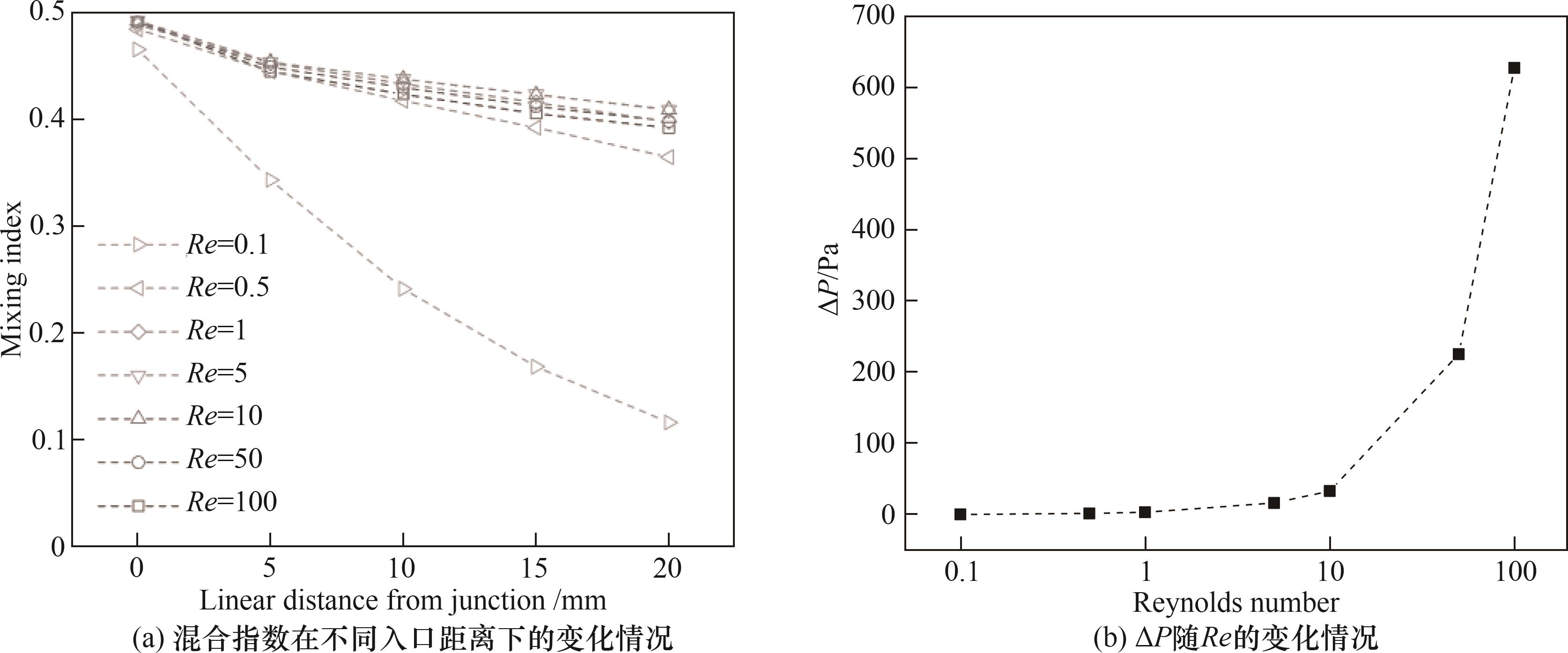

图10 加障碍物后Re与混合指数和压降的关系(Sc = 2000, d = 1 mm)

Fig.10 The relationship between Reynolds number and mixing index and pressure drop after adding obstacles (Sc = 200, d = 1 mm)

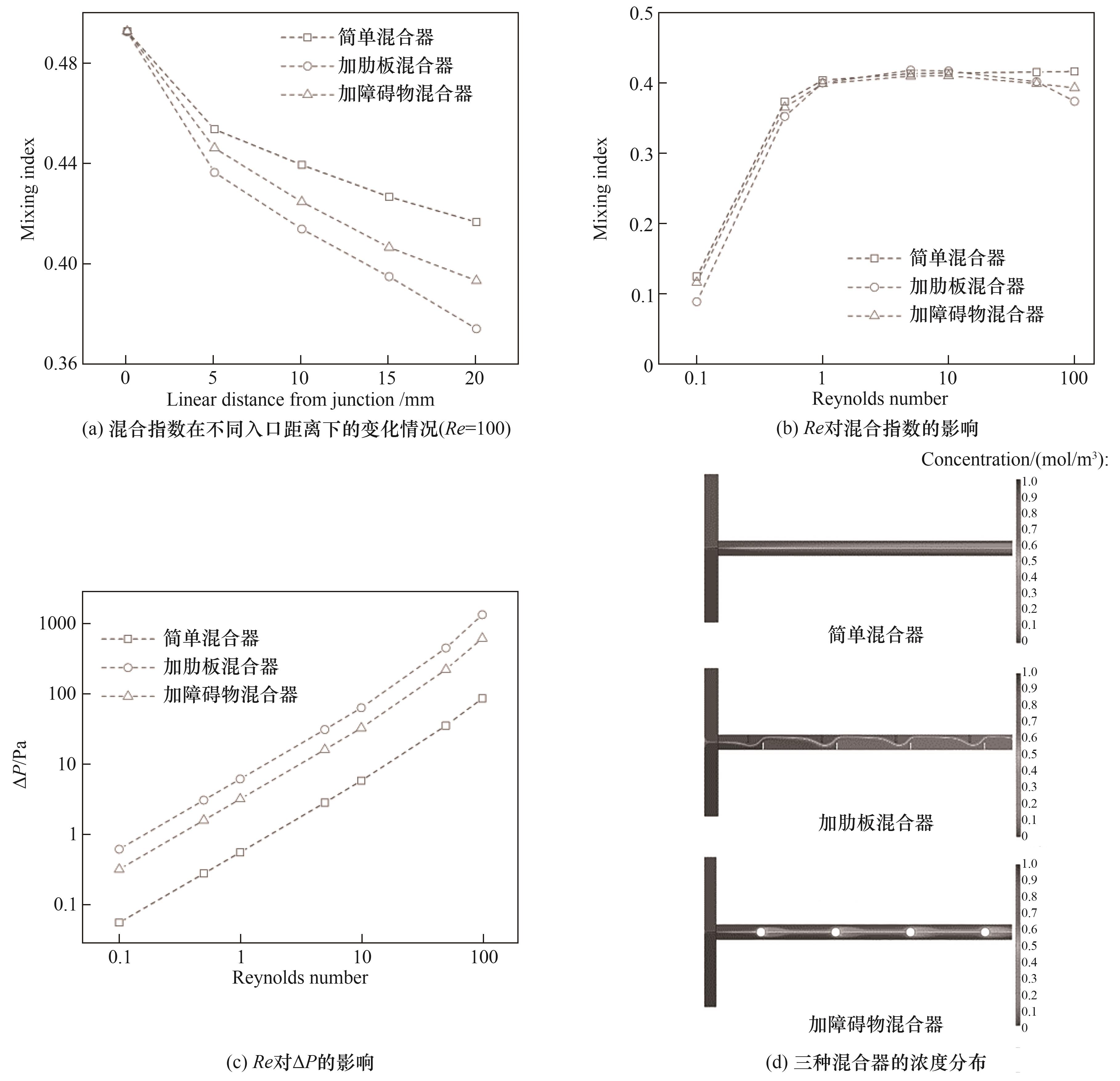

图12 不同混合器下Re与混合指数和压降的关系(Sc = 2000, d = 1 mm)

Fig.12 The relationship between Reynolds number and mixing index and pressure drop in different mixers (Sc = 2000, d = 1 mm)

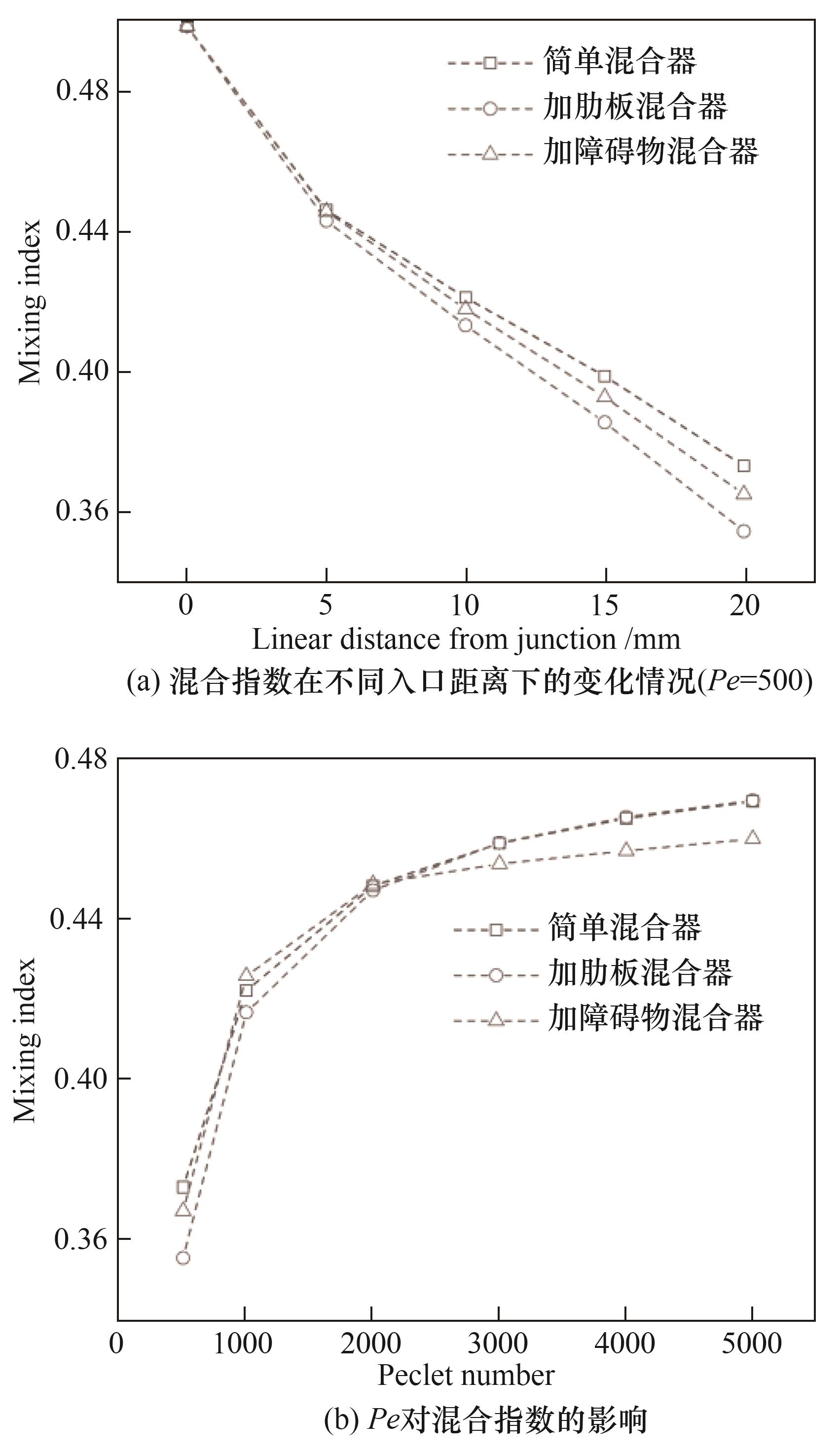

图14 不同混合器Pe与混合指数的关系(U = 0.1 mm/s, Sc = 2000)

Fig.14 The relationship between Peclet number and mixing index in different mixers (U = 0.1 mm/s, Sc = 2000)

| 1 | 荀涛, 蔡旺锋, 张旭斌. 微通道中气-液-液三相流流型及传质研究[J]. 化学工业与工程, 2017, 34(6): 81-87. |

| Xun T, Cai W F, Zhang X B. The flow pattern and mass transfer of gas-liquid-liquid three phase flow in microchannel[J]. Chemical Industry and Engineering, 2017, 34(6): 81-87. | |

| 2 | 郭戎威, 付涛涛, 朱春英, 等. 微通道内气-液两相流及并行放大的研究进展[J]. 化学工业与工程, 2021, 38(6): 74-86. |

| Guo R W, Fu T T, Zhu C Y, et al. Research progress on gas-liquid two-phase flow and numbering-up strategy in microchannel[J]. Chemical Industry and Engineering, 2021, 38(6): 74-86. | |

| 3 | Park T, Lee S, Seong G H, et al. Highly sensitive signal detection of duplex dye-labelled DNA oligonucleotides in a PDMS microfluidic chip: confocal surface-enhanced Raman spectroscopic study[J]. Lab on a Chip, 2005, 5(4): 437-442. |

| 4 | Rahman M, Rebrov E. Microreactors for gold nanoparticles synthesis: from faraday to flow[J]. Processes, 2014, 2(2): 466-493. |

| 5 | Rapp B E, Gruhl F J, Länge K. Biosensors with label-free detection designed for diagnostic applications[J]. Analytical and Bioanalytical Chemistry, 2010, 398(6): 2403-2412. |

| 6 | Hessel V, Löwe H, Schönfeld F. Micromixers—a review on passive and active mixing principles[J]. Chemical Engineering Science, 2005, 60(8/9): 2479-2501. |

| 7 | Ingham C J, van Hylckama Vlieg J E T. MEMS and the microbe[J]. Lab on a Chip, 2008, 8(10): 1604. |

| 8 | Schulte T H, Bardell R L, Weigl B H. Microfluidic technologies in clinical diagnostics[J]. Clinica Chimica Acta, 2002, 321(1/2): 1-10. |

| 9 | Squires T M, Quake S R. Microfluidics: fluid physics at the nanoliter scale[J]. Reviews of Modern Physics, 2005, 77(3): 977-1026. |

| 10 | Yang A S, Chuang F C, Chen C K, et al. A high-performance micromixer using three-dimensional Tesla structures for bio-applications[J]. Chemical Engineering Journal, 2015, 263: 444-451. |

| 11 | Culbertson C T, Mickleburgh T G, Stewart-James S A, et al. Micro total analysis systems: fundamental advances and biological applications[J]. Analytical Chemistry, 2014, 86(1): 95-118. |

| 12 | Bouvier E S P, Koza S M. Advances in size-exclusion separations of proteins and polymers by UHPLC[J]. TrAC Trends in Analytical Chemistry, 2014, 63: 85-94. |

| 13 | 郭未希, 朱春英, 付涛涛, 等. 微流控技术中液滴聚并的研究进展[J]. 化学工业与工程, 2021, 38(5): 42-52. |

| Guo W X, Zhu C Y, Fu T T, et al. Research progress of droplet coalescence in microfluidic technology[J]. Chemical Industry and Engineering, 2021, 38(5): 42-52. | |

| 14 | Nguyen N T, Wu Z G. Micromixers—a review[J]. Journal of Micromechanics and Microengineering, 2005, 15(2): R1-R16. |

| 15 | Chun H G, Kim H C, Chung T D. Ultrafast active mixer using polyelectrolytic ion extractor[J]. Lab on a Chip, 2008, 8(5): 764-771. |

| 16 | Lu L H, Ryu K S, Liu C. A magnetic microstirrer and array for microfluidic mixing[J]. Journal of Microelectromechanical Systems, 2002, 11(5): 462-469. |

| 17 | Yaralioglu G G, Wygant I O, Marentis T C, et al. Ultrasonic mixing in microfluidic channels using integrated transducers[J]. Analytical Chemistry, 2004, 76(13): 3694-3698. |

| 18 | Shah I, Kim S W, Kim K, et al. Experimental and numerical analysis of Y-shaped split and recombination micro-mixer with different mixing units[J]. Chemical Engineering Journal, 2019, 358: 691-706. |

| 19 | Jeon W, Shin C B. Design and simulation of passive mixing in microfluidic systems with geometric variations[J]. Chemical Engineering Journal, 2009, 152(2/3): 575-582. |

| 20 | Mouheb N A, Malsch D, Montillet A, et al. Numerical and experimental investigations of mixing in T-shaped and cross-shaped micromixers[J]. Chemical Engineering Science, 2012, 68(1): 278-289. |

| 21 | Tripathi E, Patowari P K, Pati S. Comparative assessment of mixing characteristics and pressure drop in spiral and serpentine micromixers[J]. Chemical Engineering and Processing-Process Intensification, 2021, 162: 108335. |

| 22 | Wong S H, Bryant P, Ward M, et al. Investigation of mixing in a cross-shaped micromixer with static mixing elements for reaction kinetics studies[J]. Sensors and Actuators B: Chemical, 2003, 95(1/2/3): 414-424. |

| 23 | Mouza A A, Patsa C M, Schönfeld F. Mixing performance of a chaotic micro-mixer[J]. Chemical Engineering Research and Design, 2008, 86(10): 1128-1134. |

| 24 | Miranda J M, Oliveira H, Teixeira J A, et al. Numerical study of micromixing combining alternate flow and obstacles[J]. International Communications in Heat and Mass Transfer, 2010, 37(6): 581-586. |

| 25 | Lin Y C, Chung Y C, Wu C Y. Mixing enhancement of the passive microfluidic mixer with J-shaped baffles in the tee channel[J]. Biomedical Microdevices, 2007, 9(2): 215-221. |

| 26 | Jen C P, Wu C Y, Lin Y C, et al. Design and simulation of the micromixer with chaotic advection in twisted microchannels[J]. Lab on a Chip, 2003, 3(2): 77-81. |

| 27 | Chung Y C, Hsu Y L, Jen C P, et al. Design of passive mixers utilizing microfluidic self-circulation in the mixing chamber[J]. Lab on a Chip, 2004, 4(1): 70-77. |

| 28 | Stroock A D, Dertinger S K W, Ajdari A, et al. Chaotic mixer for microchannels[J]. Science, 2002, 295(5555): 647-651. |

| 29 | Viktorov V, Mahmud M, Visconte C. Comparative analysis of passive micromixers at a wide range of Reynolds numbers[J]. Micromachines, 2015, 6(8): 1166-1179. |

| 30 | Falk L, Commenge J M. Performance comparison of micromixers[J]. Chemical Engineering Science, 2010, 65(1): 405-411. |

| 31 | Rasouli M A A, Lashkaripour A. Numerical study on low Reynolds mixing of T-shaped micro-mixers with obstacles[J]. Transport Phenomena in Nano and Micro Scales, 2015, 3(2): 68-76. |

| 32 | Zare P, Talebi S. Numerical simulation of geometry effect on mixing performance in L-shaped micromixers[J]. Chemical Engineering Communications, 2020, 207(5): 585-597. |

| 33 | 王瑞金, 林建忠, 郑友取. 一种新型螺旋式微混合器及其流场的数值研究[J]. 中国机械工程, 2006(13): 1417-1420. |

| Wang R J, Lin J Z, Zheng Y Q. A new micromixer with helical microchannel and research on its numerical flow field[J]. China Mechanical Engineering, 2006(13): 1417-1420. | |

| 34 | 李艺凡, 夏国栋, 王军. 结构参数对布置窄缝和挡板的微混合器内流体流动和混合的影响[J]. 化工学报, 2015, 66(10): 3857-3865. |

| Li Y F, Xia G D, Wang J. Effect of structural parameters on fluid flow and mixing characteristics in micromixer with gaps and baffles[J]. CIESC Journal, 2015, 66(10): 3857-3865. | |

| 35 | 马广志, 沈春银, 董浩, 等. 基于协同组合的新型微混合器的数值模拟[J]. 科学技术与工程, 2021, 21(22): 9470-9478. |

| Ma G Z, Shen C Y, Dong H, et al. Numerical simulation of novel micromixer mixing performance based on synergistic combination[J]. Science Technology and Engineering, 2021, 21(22): 9470-9478. | |

| 36 | 肖水云, 李鸣, 杨大勇. T型微混合器内混合强化的数值模拟[J]. 应用数学和力学, 2016, 37(3): 301-310. |

| Xiao Y S, Li M, Yang D Y. Numerical simulation of mixing enhancement in T-shaped micromixers[J]. Applied Mathematics and Mechanics, 2016, 37(3): 301-310. | |

| 37 | Hossain S, Husain A, Kim K Y. Shape optimization of a micromixer with staggered-herringbone grooves patterned on opposite walls[J]. Chemical Engineering Journal, 2010, 162(2): 730-737. |

| 38 | Liu R H, Stremler M A, Sharp K V, et al. Passive mixing in a three-dimensional serpentine microchannel[J]. Journal of Microelectromechanical Systems, 2000, 9(2): 190-197. |

| 39 | Sadegh Cheri M, Latifi H, Salehi Moghaddam M, et al. Simulation and experimental investigation of planar micromixers with short-mixing-length[J]. Chemical Engineering Journal, 2013, 234: 247-255. |

| 40 | Pfitzner J. Poiseuille and his law[J]. Anaesthesia, 1976, 31(2): 273-275. |

| [1] | 赵若晗, 黄蒙蒙, 朱春英, 付涛涛, 高习群, 马友光. 缩口T型微通道内纳米流体吸收CO2的流动与传质研究[J]. 化工学报, 2024, 75(1): 221-230. |

| [2] | 李亚婷, 王忠东, 董艳鹏, 朱春英, 马友光, 付涛涛. 微通道中毛细流动及其工程应用的研究进展[J]. 化工学报, 2024, 75(1): 159-170. |

| [3] | 崔怡洲, 李成祥, 翟霖晓, 刘束玉, 石孝刚, 高金森, 蓝兴英. 亚毫米气泡和常规尺寸气泡气液两相流流动与传质特性对比[J]. 化工学报, 2024, 75(1): 197-210. |

| [4] | 郑雨婷, 方冠东, 张梦波, 张浩淼, 王靖岱, 阳永荣. 微化工精馏分离技术研究进展[J]. 化工学报, 2024, 75(1): 47-59. |

| [5] | 赵碧丹, 代伊杨, 王军武, 张永民. CFD-DEM-IBM方法探究流化床倾斜挡板内构件受力特性[J]. 化工学报, 2024, 75(1): 255-267. |

| [6] | 温唯谷, 袁志宏, 王凯, 骆广生. 微分散液滴的光纤检测研究[J]. 化工学报, 2024, 75(1): 211-220. |

| [7] | 周尧, 杨小平, 倪一程, 刘继平, 魏进家, 严俊杰. 应用于新型环路热管的两相引射器数值模拟[J]. 化工学报, 2024, 75(1): 268-278. |

| [8] | 王义江, 孙莉, 刘梦涵, 杨金宏, 王国元. 基于响应面法的矿用翅片管空冷器参数优化[J]. 化工学报, 2024, 75(1): 279-291. |

| [9] | 宋嘉豪, 王文. 斯特林发动机与高温热管耦合运行特性研究[J]. 化工学报, 2023, 74(S1): 287-294. |

| [10] | 张思雨, 殷勇高, 贾鹏琦, 叶威. 双U型地埋管群跨季节蓄热特性研究[J]. 化工学报, 2023, 74(S1): 295-301. |

| [11] | 叶展羽, 山訸, 徐震原. 用于太阳能蒸发的折纸式蒸发器性能仿真[J]. 化工学报, 2023, 74(S1): 132-140. |

| [12] | 张义飞, 刘舫辰, 张双星, 杜文静. 超临界二氧化碳用印刷电路板式换热器性能分析[J]. 化工学报, 2023, 74(S1): 183-190. |

| [13] | 陈爱强, 代艳奇, 刘悦, 刘斌, 吴翰铭. 基板温度对HFE7100液滴蒸发过程的影响研究[J]. 化工学报, 2023, 74(S1): 191-197. |

| [14] | 谈莹莹, 刘晓庆, 王林, 黄鲤生, 李修真, 王占伟. R1150/R600a自复叠制冷循环开机动态特性实验研究[J]. 化工学报, 2023, 74(S1): 213-222. |

| [15] | 王志国, 薛孟, 董芋双, 张田震, 秦晓凯, 韩强. 基于裂隙粗糙性表征方法的地热岩体热流耦合数值模拟与分析[J]. 化工学报, 2023, 74(S1): 223-234. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号