化工学报 ›› 2024, Vol. 75 ›› Issue (9): 3103-3112.DOI: 10.11949/0438-1157.20240347

收稿日期:2024-03-28

修回日期:2024-04-30

出版日期:2024-09-25

发布日期:2024-10-10

通讯作者:

齐娜娜

作者简介:祝赫(1997—),男,博士研究生,zhuhe@ncepu.edu.cn

基金资助:

He ZHU( ), Yi ZHANG, Nana QI(

), Yi ZHANG, Nana QI( ), Kai ZHANG

), Kai ZHANG

Received:2024-03-28

Revised:2024-04-30

Online:2024-09-25

Published:2024-10-10

Contact:

Nana QI

摘要:

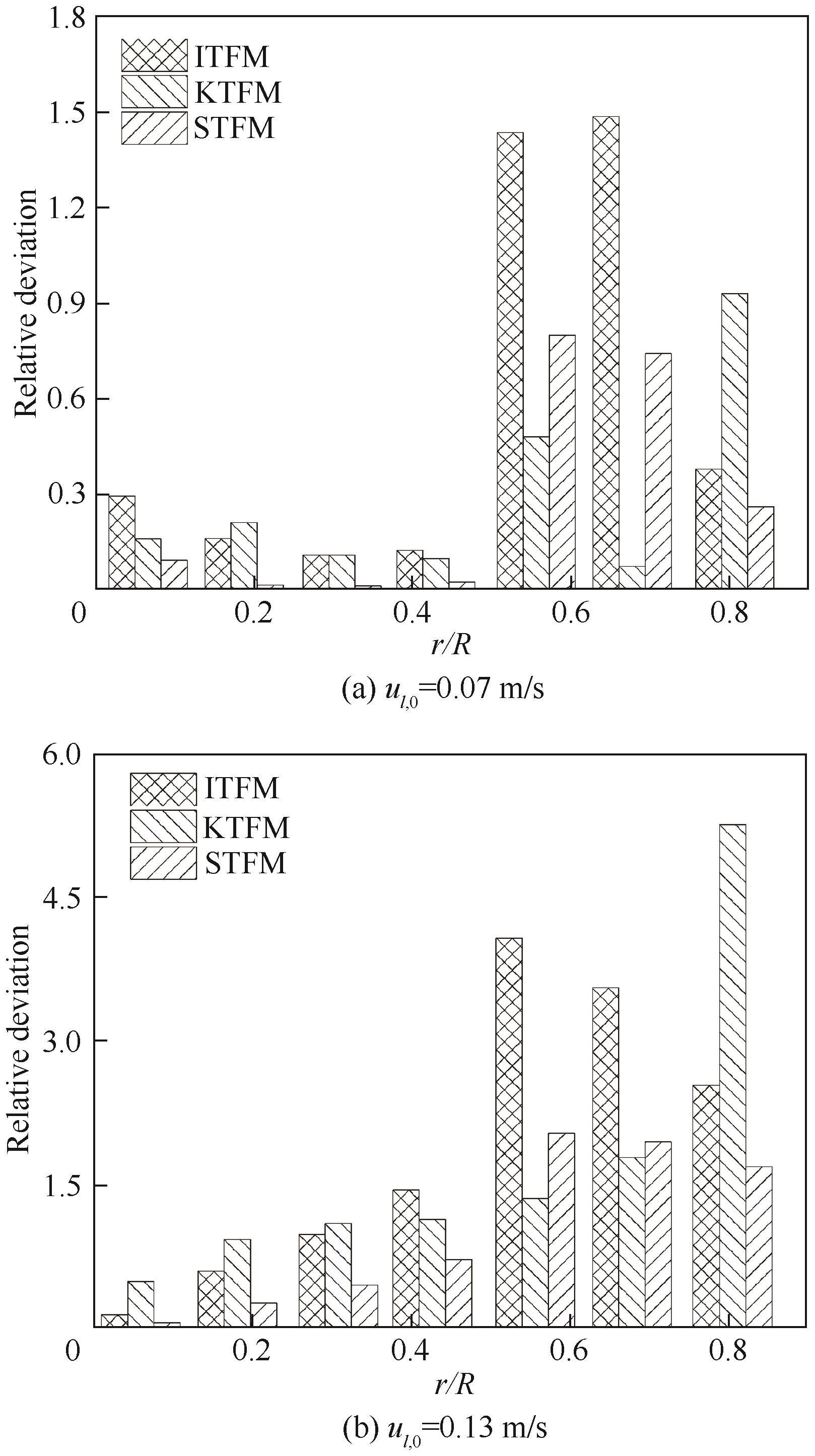

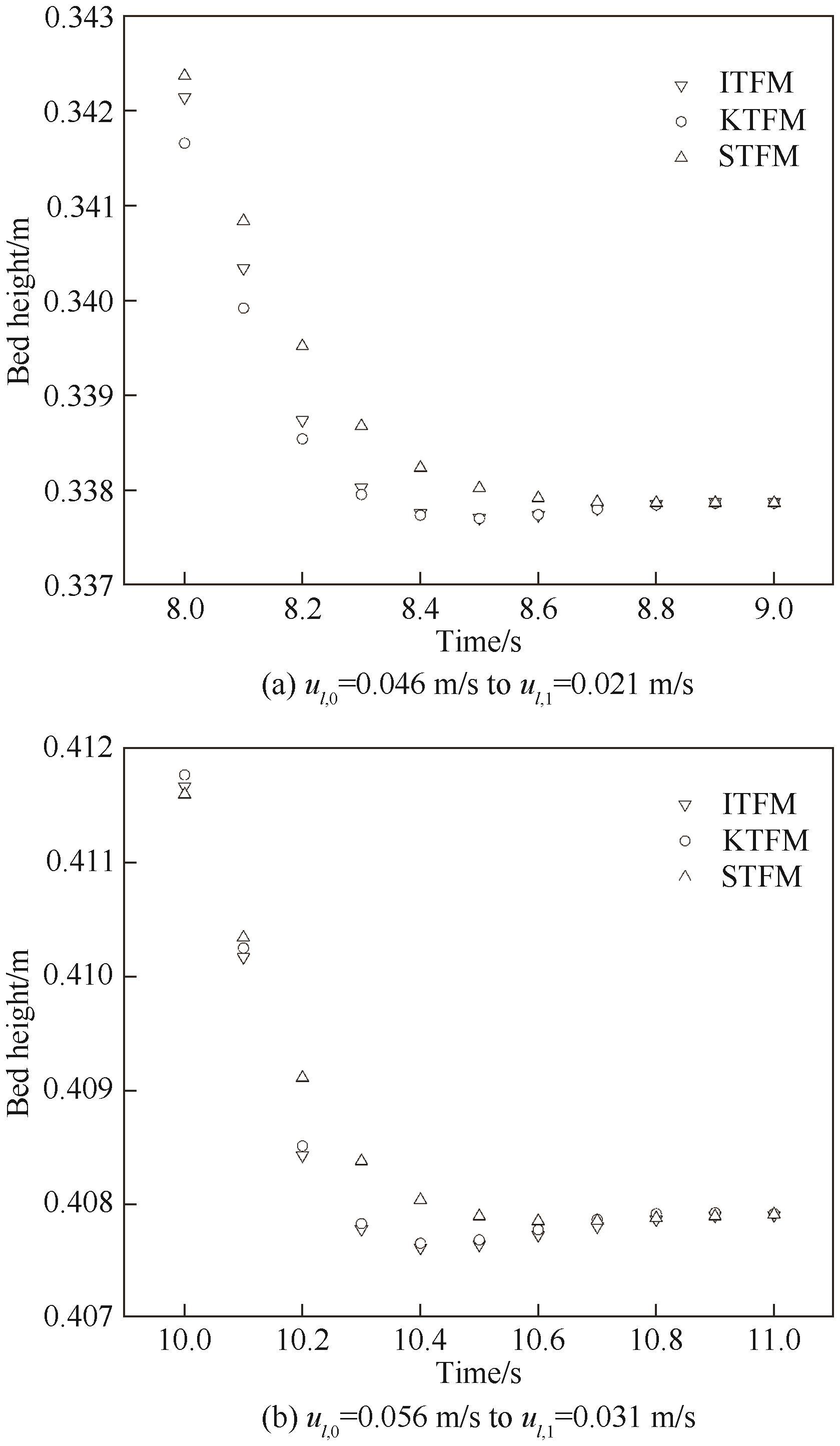

采用无黏性双流体模型、基于颗粒动理学的双流体模型以及Brandani和Zhang简化双流体模型探究了颗粒黏性对液固散式流化特性的影响规律。经与文献中实验数据和Gibilaro公式计算值对比后发现:3种双流体模型均能较好地预测整体固含率,与实验值相对偏差在3%以内,其中无黏性双流体模型和简化双流体模型对固含率预测更符合散式流态化特点;3种双流体模型对时均颗粒轴向速度预测均呈现整体环核结构的固有属性,其中简化双流体模型在较低和较高两组液速工况下预测的相对偏差平均值分别为0.277和1.028;当入口液速突然变化后,收缩过程中简化双流体模型对响应时间预测准确度略高,而膨胀过程中因低浓度区界面不稳定以及膨胀过程中床内颗粒形成的由浓到稀过渡段延长了稳定时间,3种模型预测均与理想过程存在一定偏差,其中液速较低时三者差异不明显,但液速较高时简化双流体模型准确性略高。基于颗粒动理学的双流体模型对动态过程模拟的计算耗时最长。

中图分类号:

祝赫, 张仪, 齐娜娜, 张锴. 欧拉-欧拉双流体模型中颗粒黏性对液固散式流态化的影响[J]. 化工学报, 2024, 75(9): 3103-3112.

He ZHU, Yi ZHANG, Nana QI, Kai ZHANG. Effect of particle viscosity in two-fluid model on homogeneous liquid-solid fluidization under Euler-Euler framework[J]. CIESC Journal, 2024, 75(9): 3103-3112.

| 参数 | 收缩过程 | 膨胀过程 | ||

|---|---|---|---|---|

| 案例3 | 案例4 | 案例5 | 案例6 | |

| 突变前操作液速(ul,0)/(m/s) | 0.046 | 0.056 | 0.021 | 0.031 |

| 突变后操作液速(ul,1)/(m/s) | 0.021 | 0.031 | 0.046 | 0.056 |

| 突变前床层高度/m | 0.543 | 0.663 | 0.338 | 0.408 |

| 突变前固含率 | 0.275 | 0.224 | 0.443 | 0.367 |

表1 案例3~案例6操作条件

Table 1 Operating conditions of cases 3—case 6

| 参数 | 收缩过程 | 膨胀过程 | ||

|---|---|---|---|---|

| 案例3 | 案例4 | 案例5 | 案例6 | |

| 突变前操作液速(ul,0)/(m/s) | 0.046 | 0.056 | 0.021 | 0.031 |

| 突变后操作液速(ul,1)/(m/s) | 0.021 | 0.031 | 0.046 | 0.056 |

| 突变前床层高度/m | 0.543 | 0.663 | 0.338 | 0.408 |

| 突变前固含率 | 0.275 | 0.224 | 0.443 | 0.367 |

| 操作 液速/(m/s) | 实验 | ITFM | KTFM | STFM | |||

|---|---|---|---|---|---|---|---|

| 数值 | 偏差/% | 数值 | 偏差/% | 数值 | 偏差/% | ||

| 0.07 | 0.440 | 0.443 | 0.6 | 0.435 | 1.1 | 0.443 | 0.6 |

| 0.13 | 0.260 | 0.265 | 1.9 | 0.254 | 2.3 | 0.266 | 2.3 |

表2 3种双流体模型预测的整体固含率对比

Table 2 Comparisons of overall solid holdup predicted by three two-fluid models

| 操作 液速/(m/s) | 实验 | ITFM | KTFM | STFM | |||

|---|---|---|---|---|---|---|---|

| 数值 | 偏差/% | 数值 | 偏差/% | 数值 | 偏差/% | ||

| 0.07 | 0.440 | 0.443 | 0.6 | 0.435 | 1.1 | 0.443 | 0.6 |

| 0.13 | 0.260 | 0.265 | 1.9 | 0.254 | 2.3 | 0.266 | 2.3 |

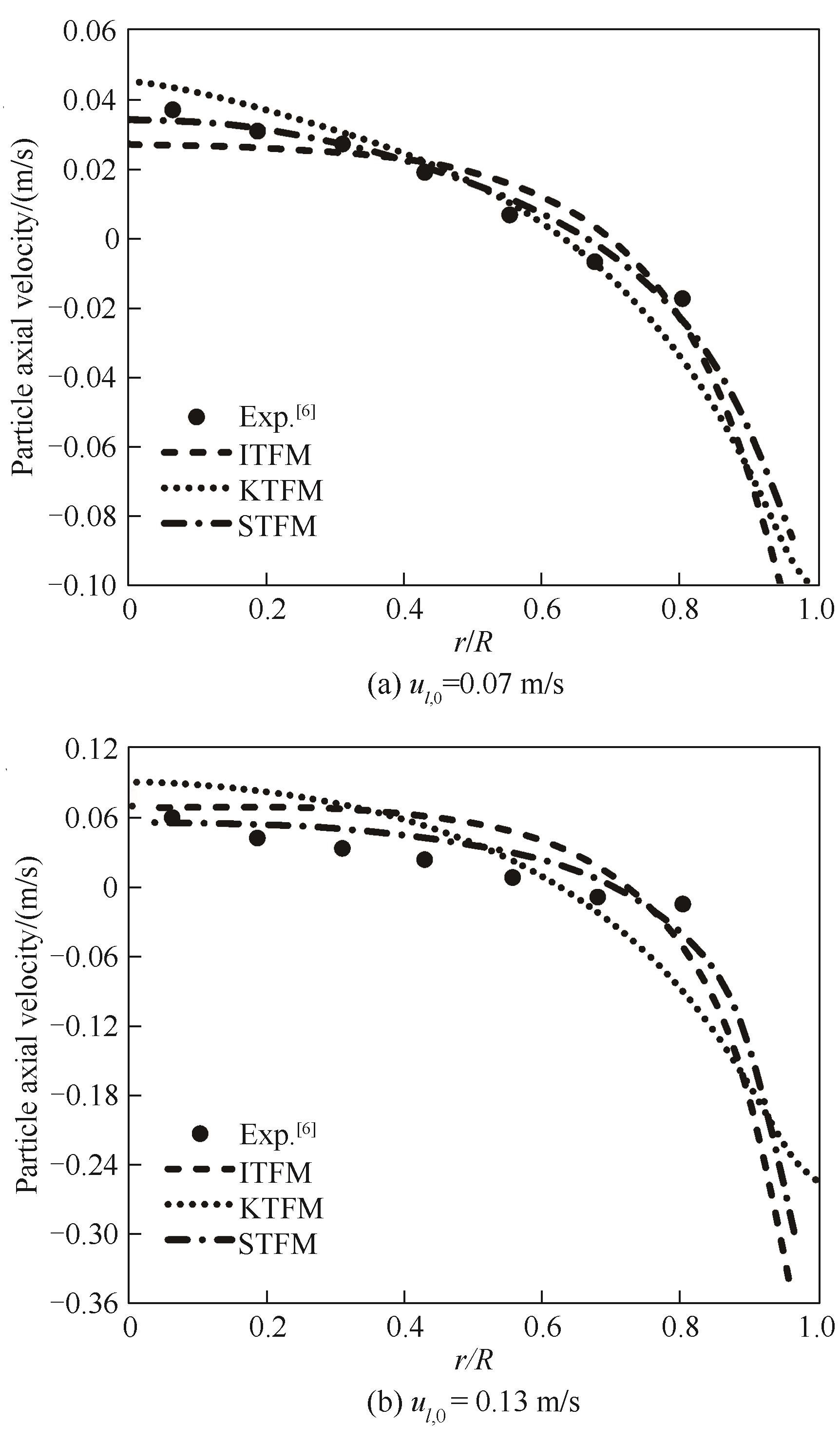

图3 3种双流体模型预测的时均颗粒轴向速度沿径向分布与实验值比较

Fig.3 Comparisons of radial profiles of time-averaged particle axial velocity predicted by three two-fluid models with experimental data

图4 3种双流体模型预测的时均颗粒轴向速度与实验值的相对偏差

Fig.4 Relative deviation of time-averaged particle axial velocity between predicted by three two-fluid models and experimental data

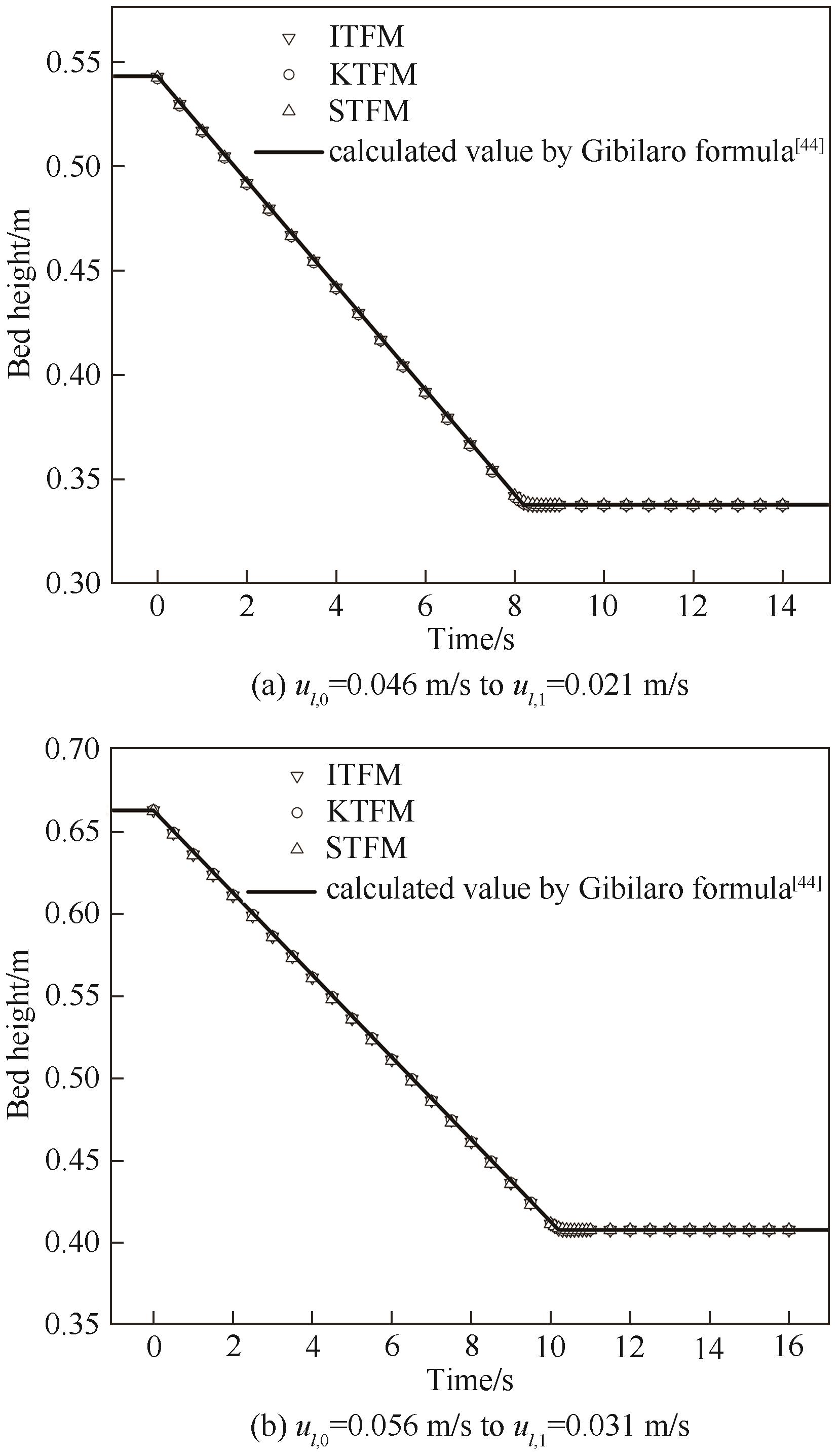

图5 3种双流体模型预测的液固流化床动态收缩过程床层高度变化与Gibilaro公式计算值比较

Fig.5 Comparisons of bed height variation predicted by three two-fluid models with Gibilaro formula in dynamic contraction process of liquid-solid fluidized bed

图6 3种双流体模型预测的液固流化床动态收缩过程床层局部放大

Fig.6 Enlarged view of local area in dynamic contraction process of liquid-solid fluidized bed predicted by three two-fluid models

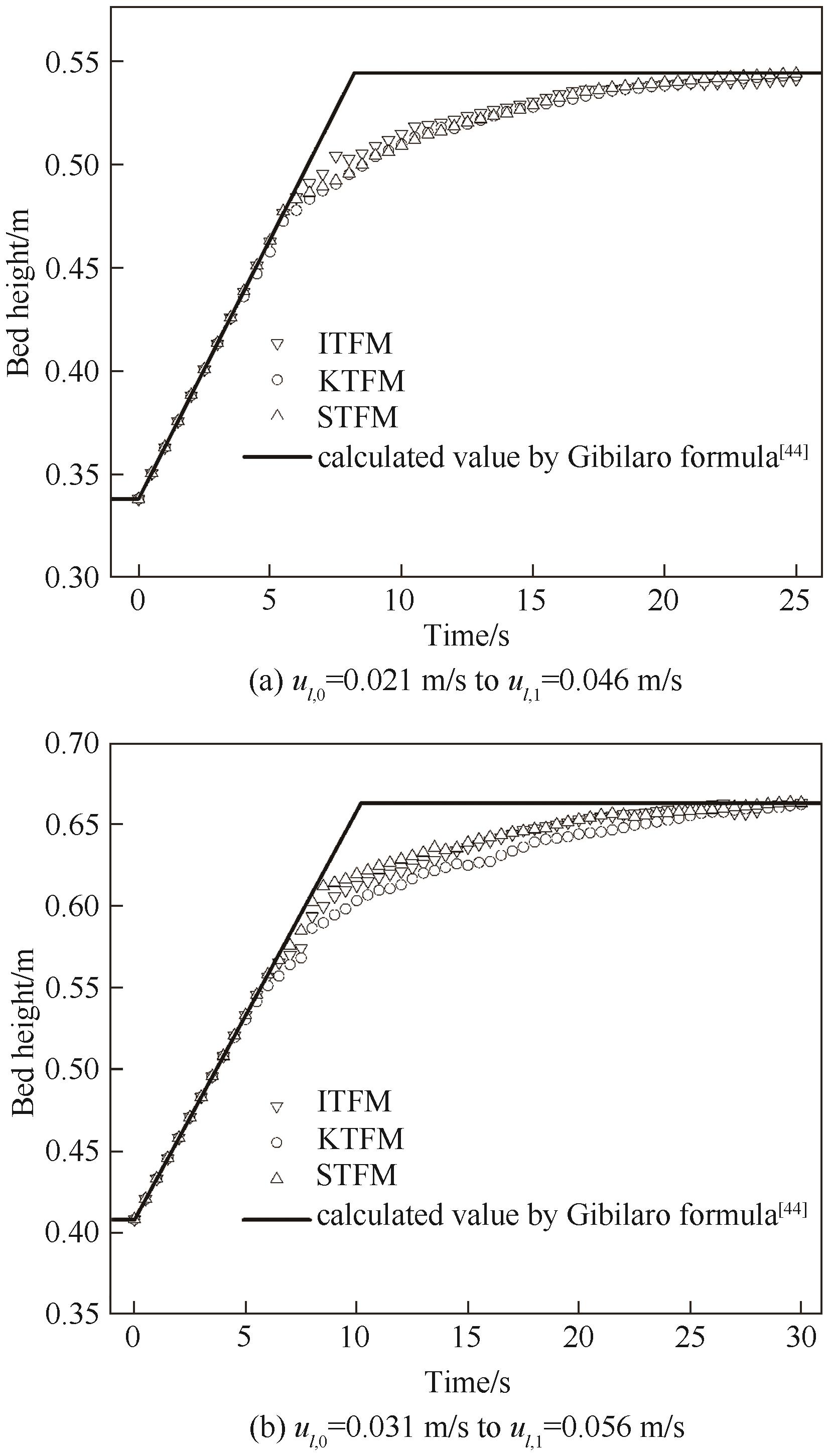

图7 3种双流体模型预测的液固流化床动态膨胀过程床层高度变化与Gibilaro公式计算值比较

Fig.7 Comparisons of bed height variation predicted by three two-fluid models with Gibilaro formula in dynamic expansion process of liquid-solid fluidized bed

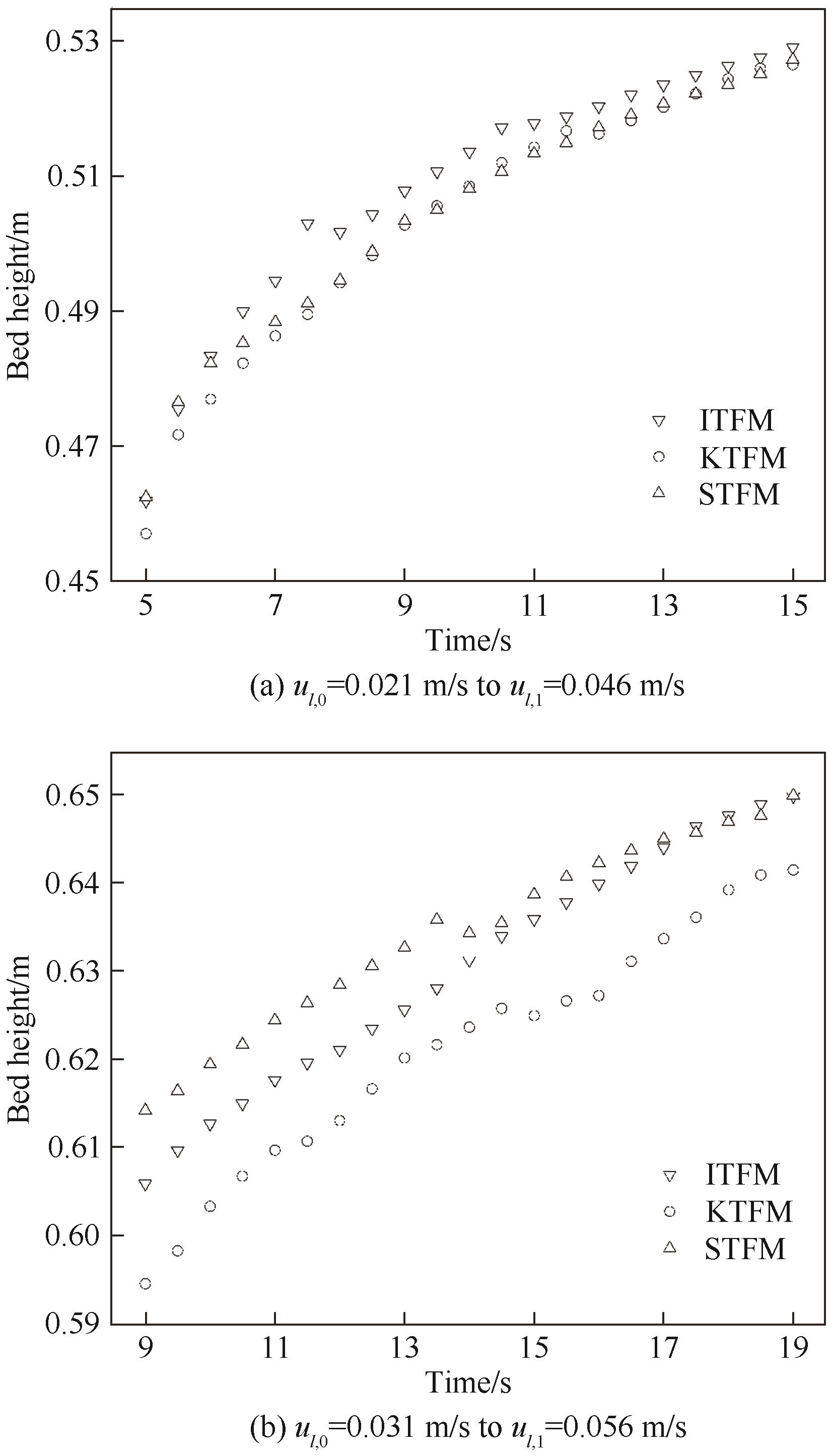

图8 3种双流体模型预测的液固流化床动态膨胀过程床层局部放大

Fig.8 Enlarged view of local area in dynamic expansion process of liquid-solid fluidized bed predicted by three two-fluid models

| 1 | 刘明言, 马永丽, 白丁荣, 等. 多相流态化[M]. 北京: 科学出版社, 2022. |

| Liu M Y, Ma Y L, Bai D R, et al. Heterogeneous Fluidization[M]. Beijing: Science Press, 2022. | |

| 2 | Epstein N. Applications of liquid-solid fluidization[J]. International Journal of Chemical Reactor Engineering, 2003, 1: 1-16. |

| 3 | 郭慕孙, 李洪钟. 流态化手册[M]. 北京: 化学工业出版社, 2008. |

| Guo M S, Li H Z. Handbook of Fluidization[M]. Beijing: Chemical Industry Press, 2008. | |

| 4 | 李洪钟, 郭慕孙. 气固流态化的散式化[M]. 北京: 化学工业出版社, 2002. |

| Li H Z, Guo M S. Particulation of Gas-Solids Fluidization[M]. Beijing: Chemical Industry Press, 2002. | |

| 5 | 金涌, 祝京旭, 汪展文, 等. 流态化工程原理[M]. 北京: 清华大学出版社, 2001. |

| Jin Y, Zhu J X, Wang Z W, et al. Fluidization Engineering Principles[M]. Beijing: Tsinghua University Press, 2001. | |

| 6 | Limtrakul S, Chen J, Ramachandran P A, et al. Solids motion and holdup profiles in liquid fluidized beds[J]. Chemical Engineering Science, 2005, 60(7): 1889-1900. |

| 7 | Cornelissen J T, Taghipour F, Escudié R, et al. CFD modelling of a liquid-solid fluidized bed[J]. Chemical Engineering Science, 2007, 62(22): 6334-6348. |

| 8 | Peng J, Sun W, Xie L, et al. An experimental study of pressure drop characteristics and flow resistance coefficient in a fluidized bed for coal particle fluidization[J]. Minerals, 2022, 12(3): 289. |

| 9 | 尤东光, 雍玉梅, 杨超, 等. 流量变化对液固流化床瞬态流化特性的影响[J]. 化工学报, 2012, 63(8): 2356-2364. |

| You D G, Yong Y M, Yang C, et al. Effect of fluidizing flux change on liquid-solids fluidization characteristics[J]. CIESC Journal, 2012, 63(8): 2356-2364. | |

| 10 | Asif M, Petersen J N, Kaufman E N, et al. A dynamic model of the hydrodynamics of a liquid fluidized bed[J]. Industrial & Engineering Chemistry Research, 1994, 33(9): 2151-2156. |

| 11 | Liu D, Fu Y. Dynamics of fine particles in liquid-solid fluidized beds[J]. Particuology, 2007, 5(6): 363-375. |

| 12 | Liu D, Jin G. Modeling two-phase flow in pulsed fluidized bed[J]. Particuology, 2003, 1(3): 95-104. |

| 13 | Huang X. CFD modeling of liquid-solid fluidization: effect of drag correlation and added mass force[J]. Particuology, 2011, 9(4): 441-445. |

| 14 | 张仪, 李兵, 白玉龙, 等. 液固流态化动态过程中相间作用力的数值模拟及实验验证[J]. 化工学报, 2020, 71(11): 5129-5139. |

| Zhang Y, Li B, Bai Y L, et al. Numerical simulation and experimental validation of inter-phase forces in dynamic process of liquid-solid fluidization[J]. CIESC Journal, 2020, 71(11): 5129-5139. | |

| 15 | 张仪, 白玉龙, 骆丁玲, 等. 液固散式流态化CFD模拟中曳力模型的影响[J]. 化工学报, 2019, 70(11): 4207-4215. |

| Zhang Y, Bai Y L, Luo D L, et al. Effect of drag models on CFD simulations for homogeneous liquid-solid fluidization[J]. CIESC Journal, 2019, 70(11): 4207-4215. | |

| 16 | Zhang K, Guan Y, Yao X, et al. Two- and three-dimensional computational studies of liquid-solid fluidization[J]. Powder Technology, 2013, 235: 180-191. |

| 17 | Zhang K, Wu G, Brandani S, et al. CFD simulation of dynamic characteristics in liquid-solid fluidized beds[J]. Powder Technology, 2012, 227: 104-110. |

| 18 | Maestri M, Salierno G, Piovano S, et al. CFD-DEM modeling of solid motion in a water-calcium alginate fluidized column and its comparison with results from radioactive particle tracking[J]. Chemical Engineering Journal, 2019, 377: 120339. |

| 19 | Liu G, Yu F, Wang S, et al. Investigation of interstitial fluid effect on the hydrodynamics of granular in liquid-solid fluidized beds with CFD-DEM[J]. Powder Technology, 2017, 322: 353-368. |

| 20 | Liu G, Yu F, Lu H, et al. CFD-DEM simulation of liquid-solid fluidized bed with dynamic restitution coefficient[J]. Powder Technology, 2016, 304: 186-197. |

| 21 | Gao Z, Liu G, Guo X, et al. A dynamic coefficient of restitution applied to two-fluid model in liquid-solid fluidized bed[J]. Powder Technology, 2022, 402: 117335. |

| 22 | Molaei E A, Yu A, Zhou Z. CFD-DEM modelling of mixing and segregation of binary mixtures of ellipsoidal particles in liquid fluidizations[J]. Journal of Hydrodynamics, 2019, 31(6): 1190-1203. |

| 23 | Han Q, Yang N, Zhu J, et al. Onset velocity of circulating fluidization and particle residence time distribution: a CFD-DEM study[J]. Particuology, 2015, 21: 187-195. |

| 24 | Hua L, Lu L, Yang N. Effects of liquid property on onset velocity of circulating fluidization in liquid-solid systems: a CFD-DEM simulation[J]. Powder Technology, 2020, 364: 622-634. |

| 25 | Michaelides E E, Sommerfeld M, Wachem B. Multiphase Flows with Droplets and Particles[M]. 3rd ed. Boca Raton: CRC Press, 2023. |

| 26 | 李静海, 欧阳洁, 高士秋, 等. 颗粒流体复杂系统的多尺度模拟[M]. 北京: 科学出版社, 2005. |

| Li J H, Ouyang J, Gao S Q, et al. Multi-scale Simulation of Particle-fluid Complex Systems[M]. Beijing: Science Press, 2005. | |

| 27 | Gidaspow D, Ettehadieh B. Fluidization in two-dimensional beds with a jet. 2. Hydrodynamic modeling[J]. Industrial & Engineering Chemistry Fundamentals, 1983, 22(2): 193-201. |

| 28 | Kuipers J A M, Prins W, Van Swaaij W P M. Theoretical and experimental bubble formation at a single orifice in a two-dimensional gas-fluidized bed[J]. Chemical Engineering Science, 1991, 46(11): 2881-2894. |

| 29 | Gidaspow D. Multiphase Flow and Fluidization: Continuum and Kinetic Theory Descriptions[M]. Boston: Academic Press, 1994. |

| 30 | Ding J, Gidaspow D. A bubbling fluidization model using kinetic theory of granular flow[J]. AIChE Journal, 1990, 36(4): 523-538. |

| 31 | Brandani S, Zhang K. A new model for the prediction of the behaviour of fluidized beds[J]. Powder Technology, 2006, 163: 80-87. |

| 32 | 祁海鹰, 戴群特, 陈程. 大型流态化多相流数值模拟的关键科学问题——曳力模型的理论分析[J]. 力学与实践, 2014, 36(3): 269-277. |

| Qi H Y, Dai Q T, Chen C. The key scientific problems in the Eulerian modeling of large-scale multi-phase flows— drag model[J]. Mechanics in Engineering, 2014, 36(3): 269-277. | |

| 33 | Wang J. Continuum theory for dense gas-solid flow: a state-of-the-art review[J]. Chemical Engineering Science, 2020, 215: 115428. |

| 34 | Di Felice R. Hydrodynamics of liquid fluidisation[J]. Chemical Engineering Science, 1995, 50(8): 1213-1245. |

| 35 | Beetstra R, van der Hoef M A, Kuipers J A M. Drag force of intermediate Reynolds number flow past mono- and bidisperse arrays of spheres[J]. AIChE Journal, 2007, 53(2): 489-501. |

| 36 | Di Felice R. The voidage function for fluid-particle interaction systems[J]. International Journal of Multiphase Flow, 1994, 20(1): 153-159. |

| 37 | Syamlal M, O’Brien T J. Simulation of granular layer inversion in liquid fluidized beds[J]. International Journal of Multiphase Flow, 1988, 14(4): 473-481. |

| 38 | Wen C Y, Yu Y H. Mechanics of fluidization[J]. Chemical Engineering Progress Symposium Series, 1966, 62: 100-111. |

| 39 | Gidaspow D, Bezburuah R, Ding J. Hydrodynamics of circulating fluidized beds: kinetic theory approach[C]//Potter O E, Nicklin D J. Fluidization Ⅶ, Proceedings of the 7th Engineering Foundation Conference on Fluidization. New York: Engineering Foundation, 1992: 75-82. |

| 40 | Lun C K K, Savage S B, Jeffrey D J, et al. Kinetic theories for granular flow: inelastic particles in Couette flow and slightly inelastic particles in a general flowfield[J]. Journal of Fluid Mechanics, 1984, 140: 223-256. |

| 41 | Gibilaro L G. Fluidization-dynamics[M]. Oxford: Butterworth-Heinemann, 2001. |

| 42 | Latif B A J, Richardson J F. Circulation patterns and velocity distributions for particles in a liquid fluidised bed[J]. Chemical Engineering Science, 1972, 27(11): 1933-1949. |

| 43 | Ozel A, Brändle de Motta J C, Abbas M, et al. Particle resolved direct numerical simulation of a liquid-solid fluidized bed: comparison with experimental data[J]. International Journal of Multiphase Flow, 2017, 89: 228-240. |

| 44 | Gibilaro L G, Waldram S P, Foscolo P U. A simple mechanistic description of the unsteady state expansion of liquid fluidised beds[J]. Chemical Engineering Science, 1984, 39(3): 607-610. |

| 45 | 高晓根, 刘文东, 魏耀东, 等. 液固流化床内床层动态特性的CFD模拟[J]. 燃料化学学报, 2006, 34(4): 492-498. |

| Gao X G, Liu W D, Wei Y D, et al. CFD simulation for the kinematic characteristics of liquid-solid flow in fluidized beds[J]. Journal of Fuel Chemistry and Technology, 2006, 34(4): 492-498. | |

| 46 | 邱小平, 王利民, 杨宁. 耦合EMMS曳力与简化双流体模型的气固流动模拟[J]. 化工学报, 2018, 69(5): 1867-1872. |

| Qiu X P, Wang L M, Yang N. Simplified two-fluid model coupled with EMMS drag for simulating gas-solid flow[J]. CIESC Journal, 2018, 69(5): 1867-1872. |

| [1] | 唐昊, 胡定华, 李强, 张轩畅, 韩俊杰. 抗加速度双切线弧流道内气泡动力学行为数值与可视化研究[J]. 化工学报, 2024, 75(9): 3074-3082. |

| [2] | 黄正梁, 冯铭瑞, 宋琦, 任聪静, 杨遥, 孙婧元, 王靖岱, 阳永荣. 预混进料对废树脂流化裂解反应中颗粒团聚的抑制作用[J]. 化工学报, 2024, 75(9): 3094-3102. |

| [3] | 罗正航, 李敬宇, 陈伟雄, 种道彤, 严俊杰. 摇摆运动下低流率蒸汽冷凝换热特性和气泡受力数值模拟[J]. 化工学报, 2024, 75(8): 2800-2811. |

| [4] | 曾港, 陈林, 杨董, 袁海专, 黄彦平. 矩形通道内超临界CO2局部热流场可视化实验[J]. 化工学报, 2024, 75(8): 2831-2839. |

| [5] | 李倩, 张蓉民, 林子杰, 战琪, 蔡伟华. 基于机器学习的印刷电路板式换热器流动换热预测与仿真[J]. 化工学报, 2024, 75(8): 2852-2864. |

| [6] | 曹佳蕾, 孙立岩, 曾德望, 尹凡, 高子翔, 肖睿. 双流化床化学链制氢反应器的数值模拟[J]. 化工学报, 2024, 75(8): 2865-2874. |

| [7] | 金虎, 杨帆, 戴梦瑶. 基于格子Boltzmann方法的液滴在圆柱壁面上运动过程研究[J]. 化工学报, 2024, 75(8): 2897-2908. |

| [8] | 吕方明, 包志铭, 王博文, 焦魁. 气体扩散层侵入流道对燃料电池水管理影响研究[J]. 化工学报, 2024, 75(8): 2929-2938. |

| [9] | 周文轩, 刘珍, 张福建, 张忠强. 高通量-高截留率时间维度膜法水处理机理研究[J]. 化工学报, 2024, 75(7): 2583-2593. |

| [10] | 张香港, 常玉龙, 汪华林, 江霞. 废弃秸秆等生物质低能耗非相变秒级干燥[J]. 化工学报, 2024, 75(7): 2433-2445. |

| [11] | 吴邦汉, 林定标, 陆海峰, 郭晓镭, 刘海峰. 竖直管气动物流传输系统管道压降和传送瓶输送特性[J]. 化工学报, 2024, 75(7): 2465-2473. |

| [12] | 王芝安, 兰忠, 马学虎. 喷嘴参数对超临界水热燃烧特性影响的模拟[J]. 化工学报, 2024, 75(6): 2190-2200. |

| [13] | 师毓辉, 邢继远, 姜雪晗, 叶爽, 黄伟光. 基于PBM的离心式叶轮内气泡破碎合并数值模拟[J]. 化工学报, 2024, 75(5): 1816-1829. |

| [14] | 刘帆, 张芫通, 陶成, 胡成玉, 杨小平, 魏进家. 歧管式射流微通道液冷散热性能[J]. 化工学报, 2024, 75(5): 1777-1786. |

| [15] | 成文凯, 颜金钰, 王嘉骏, 冯连芳. 卧式捏合反应器及其在聚合工业中的研究进展[J]. 化工学报, 2024, 75(3): 768-781. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号