化工学报 ›› 2024, Vol. 75 ›› Issue (10): 3815-3824.DOI: 10.11949/0438-1157.20240355

收稿日期:2024-03-29

修回日期:2024-06-11

出版日期:2024-10-25

发布日期:2024-11-04

通讯作者:

徐娜

作者简介:徐娜(1983—),女,副教授,naxu_xjtu@163.com

基金资助:

Na XU1( ), Zixuan LI1, Zilu LIU2, Yaodong LYU3, Shiwen ZHANG4

), Zixuan LI1, Zilu LIU2, Yaodong LYU3, Shiwen ZHANG4

Received:2024-03-29

Revised:2024-06-11

Online:2024-10-25

Published:2024-11-04

Contact:

Na XU

摘要:

分散剂对纳米颗粒的分散效果受溶液环境影响显著。借助粗粒化分子动力学模拟方法,研究了酸碱度、温度及分散剂浓度三个溶液环境因素对含有分散剂的液相纳米颗粒体系分散稳定性的影响。发现分散剂对纳米颗粒的分散性能主要取决于分散剂在纳米颗粒表面的吸附以及分散剂之间的聚集这两个因素,通过两个因素的协同作用实现对纳米颗粒的有效分散。在影响纳米颗粒分散的机制上,分散剂浓度影响吸附于纳米颗粒表面及相互连接形成聚集体的分散剂的相对数量;不同酸碱度会诱导分散剂水解为不同带电性质的改性结构体;温度影响分散剂之间以及分散剂与其他个体之间的连接稳定性。研究可为液相纳米颗粒体系分散稳定性控制提供理论依据。

中图分类号:

徐娜, 李子璇, 刘子璐, 吕耀东, 张释文. 溶液环境对液相纳米颗粒体系分散稳定性的影响[J]. 化工学报, 2024, 75(10): 3815-3824.

Na XU, Zixuan LI, Zilu LIU, Yaodong LYU, Shiwen ZHANG. Influence of solution environment on the dispersion stability of nanoparticle liquid system[J]. CIESC Journal, 2024, 75(10): 3815-3824.

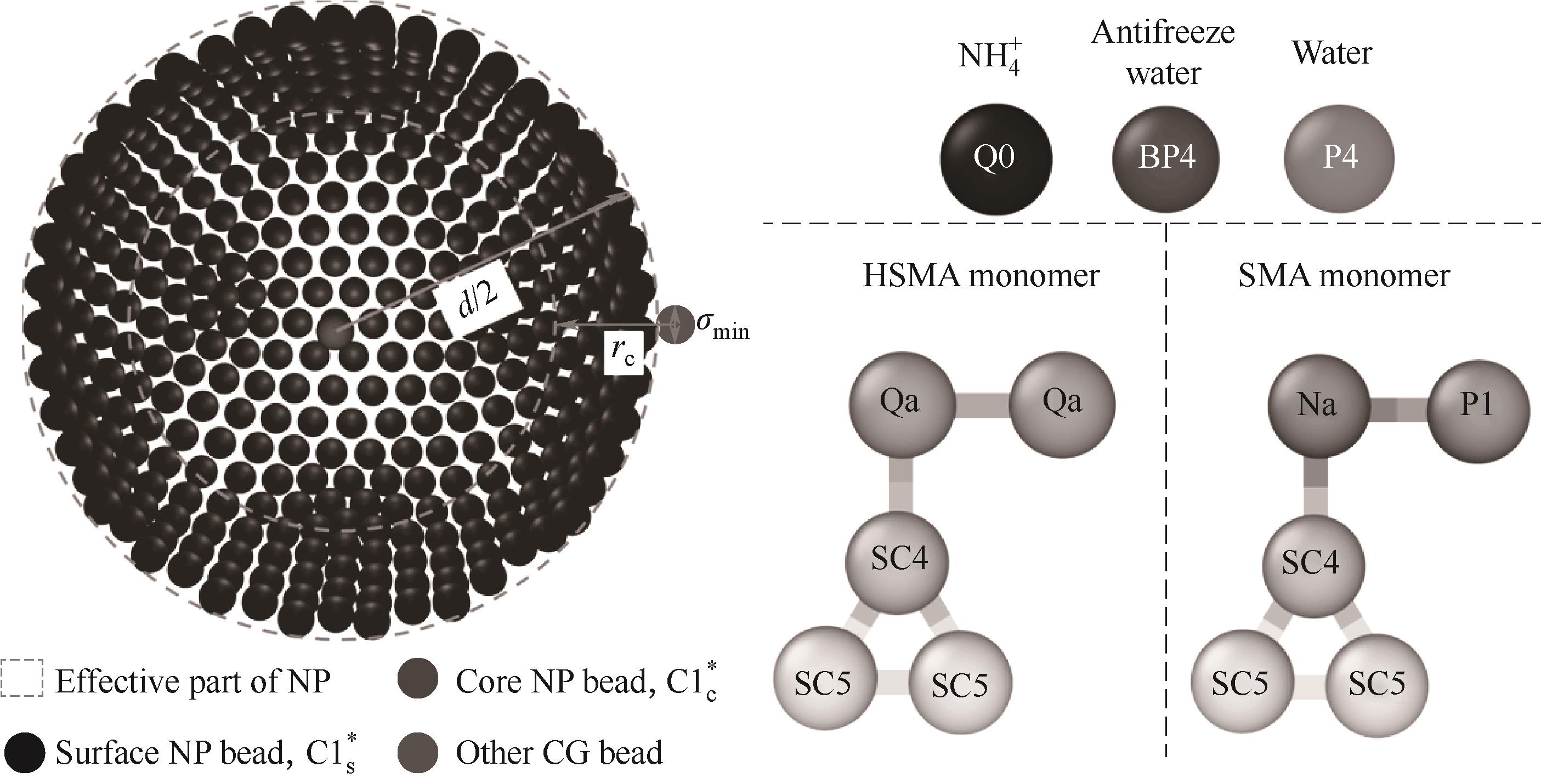

图1 基于Martini力场体系的纳米颗粒、水、SMA、HSMA、NH4+、防冻水的粗粒化计算模型

Fig.1 CG models for namoparticle, SMA, HSMA, NH4+, and water/antifreeze water molecules based on Martini force field system

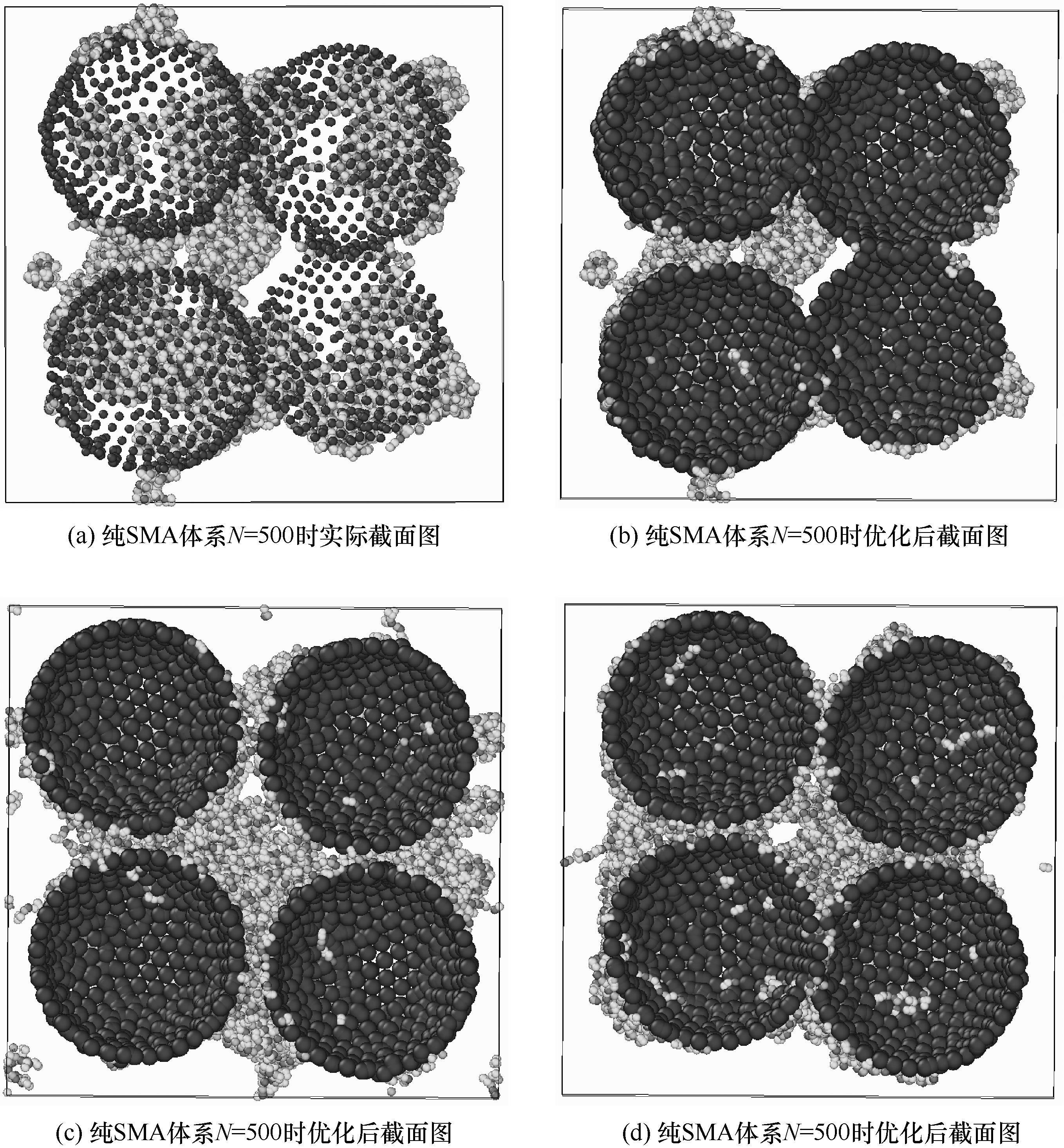

图8 不同浓度SMA体系截面图(为视图清晰,进行纳米颗粒珠子直径扩大到2倍的美化处理)

Fig.8 Cross section of SMA system with different concentrations (embellishment to expand diameter of nanoparticle bead to twice diameter was performed for clarity of view)

| 1 | Hong R Y, Li J H, Chen L L, et al. Synthesis, surface modification and photocatalytic property of ZnO nanoparticles[J]. Powder Technology, 2009, 189(3): 426-432. |

| 2 | Munkhbayar B, Tanshen M R, Jeoun J, et al. Surfactant-free dispersion of silver nanoparticles into MWCNT-aqueous nanofluids prepared by one-step technique and their thermal characteristics[J]. Ceramics International, 2013, 39(6): 6415-6425. |

| 3 | Zhu Q L, Xu Q. Immobilization of ultrafine metal nanoparticles to high-surface-area materials and their catalytic applications[J]. Chem, 2016, 1(2): 220-245. |

| 4 | Huang X H, El-Sayed M A. Gold nanoparticles: optical properties and implementations in cancer diagnosis and photothermal therapy[J]. Journal of Advanced Research, 2010, 1(1): 13-28. |

| 5 | Alatraktchi F A, Zhang Y F, Angelidaki I. Nanomodification of the electrodes in microbial fuel cell: impact of nanoparticle density on electricity production and microbial community[J]. Applied Energy, 2014, 116: 216-222. |

| 6 | Rümenapp C, Gleich B, Haase A. Magnetic nanoparticles in magnetic resonance imaging and diagnostics[J]. Pharmaceutical Research, 2012, 29(5): 1165-1179. |

| 7 | Toshima N, Yonezawa T. Bimetallic nanoparticles—novel materials for chemical and physical applications[J]. New Journal of Chemistry, 1998, 22(11): 1179-1201. |

| 8 | Li F Y, Lu J X, Kong X Q, et al. Dynamic nanoparticle assemblies for biomedical applications[J]. Advanced Materials, 2017, 29(14): 1605897. |

| 9 | Anto R, Deshmukh S, Sanyal S, et al. Nanoparticles as flow improver of petroleum crudes: study on temperature-dependent steady-state and dynamic rheological behavior of crude oils[J]. Fuel, 2020, 275: 117873. |

| 10 | Lu J, Liu D, Yang X, et al. Molecular dynamics simulations of interfacial interactions between small nanoparticles during diffusion-limited aggregation[J]. Applied Surface Science, 2015, 357: 1114-1121. |

| 11 | Yang J J, Tang B T, Qiu W Z, et al. Controlled dispersion and precipitation of carbon black by a pH-responsive polyampholyte containing amino groups and aryl sulfonates[J]. Carbon, 2012, 50(15): 5621-5624. |

| 12 | Kamiya H, Gotoh K, Shimada M, et al. Characteristics and behavior of nanoparticles and its dispersion systems[M]//Nanoparticle Technology Handbook. Oxford: Elsevier, 2008: 113-176. |

| 13 | 白福顺, 张霞, 田安丽, 等. 苯乙烯-马来酸酐共聚物阳离子化改性及其在颜料分散中的应用[J]. 精细化工, 2011, 28(12): 1164-1168, 1172. |

| Bai F S, Zhang X, Tian A L, et al. Modification of SMA using epoxypropyl trimethyl ammonium chloride and its application for carbon black dispersing[J]. Fine Chemicals, 2011, 28(12): 1164-1168, 1172. | |

| 14 | 姜东, 王朝生, 江振林, 等. 不同结构分散剂对颜料炭黑分散稳定性的影响[J]. 过程工程学报, 2015, 15(1): 153-158. |

| Jiang D, Wang C S, Jiang Z L, et al. Influences of dispersants with different structures on the dispersibility of carbon black[J]. The Chinese Journal of Process Engineering, 2015, 15(1): 153-158. | |

| 15 | Azadgoleh J E, Kharrat R, Barati N, et al. Stability of silica nanoparticle dispersion in brine solution: an experimental study[J]. Iranian Journal of Oil & Gas Science and Technology, 2014, 3(4): 26-40. |

| 16 | Iijima M, Yamazaki M, Nomura Y, et al. Effect of structure of cationic dispersants on stability of carbon black nanoparticles and further processability through layer-by-layer surface modification[J]. Chemical Engineering Science, 2013, 85: 30-37. |

| 17 | Fatehah M O, Aziz H A, Stoll S. Stability of ZnO nanoparticles in solution. Influence of pH, dissolution, aggregation and disaggregation effects[J]. Journal of Colloid Science and Biotechnology, 2014, 3(1): 75-84. |

| 18 | 吴丽冉, 王营超, 刘姗姗, 等. 木质素纳米颗粒的可控制备及应用进展[J]. 中国造纸, 2021, 40(4): 73-84. |

| Wu L R, Wang Y C, Liu S S, et al. Controllable preparation of lignin nanoparticle and its application[J]. China Pulp & Paper, 2021, 40(4): 73-84. | |

| 19 | 卢艳敏, 崔海信, 崔金辉, 等. 磁性纳米颗粒作为基因转染载体的研究[J]. 生物技术通报, 2012(8): 199-204. |

| Lu Y M, Cui H X, Cui J H, et al. Study on magnetic nanoparticles as carriers for gene transfection[J]. Biotechnology Bulletin, 2012(8): 199-204. | |

| 20 | Metin C O, Lake L W, Miranda C R, et al. Stability of aqueous silica nanoparticle dispersions[J]. Journal of Nanoparticle Research, 2011, 13(2): 839-850. |

| 21 | 王照亮, 唐大伟, 郑兴华, 等. 利用3ω法同时测量纳米流体热导率和热扩散系数[J]. 化工学报, 2007, 58(10): 2462-2468. |

| Wang Z L, Tang D W, Zheng X H, et al. Simultaneous measurements of thermal conductivity and thermal diffusivity of nanofluids using 3ω method[J]. Journal of Chemical Industry and Engineering (China), 2007, 58(10): 2462-2468. | |

| 22 | 秦睿, 郑立飞, 王力, 等. 介质pH及离子强度对纳米SiO2颗粒分散度的影响机制初探[J]. 西北农林科技大学学报(自然科学版), 2016, 44(3): 89-95. |

| Qin R, Zheng L F, Wang L, et al. Effects of aqueous pH and ion strength on dispersity of nano-SiO2 particles[J]. Journal of Northwest A & F University (Natural Science Edition), 2016, 44(3): 89-95. | |

| 23 | Doblas D, Kister T, Cano-Bonilla M, et al. Colloidal solubility and agglomeration of apolar nanoparticles in different solvents[J]. Nano Letters, 2019, 19(8): 5246-5252. |

| 24 | Lee J, Bae J, Kim W, et al. A study on aqueous dispersing of carbon black nanoparticles surface-coated with styrene maleic acid (SMA) copolymer[J]. Polymers, 2022, 14(24): 5455. |

| 25 | Dan L Y, Zhang K, Wang Q, et al. Surface modification boosts dispersion stability of nanoparticles in dielectric fluids[J]. Journal of Industrial and Engineering Chemistry, 2024, 132: 518-528. |

| 26 | Liu J, Gao Y Y, Cao D P, et al. Nanoparticle dispersion and aggregation in polymer nanocomposites: insights from molecular dynamics simulation[J]. Langmuir, 2011, 27(12): 7926-7933. |

| 27 | Koparde V N, Cummings P T. Molecular dynamics simulation of titanium dioxide nanoparticle sintering[J]. The Journal of Physical Chemistry B, 2005, 109(51): 24280-24287. |

| 28 | 生丽莎, 陈振乾. 纳米流体中纳米颗粒分散性能的分子动力学模拟[J]. 东南大学学报(自然科学版), 2021, 51(4): 700-706. |

| Sheng L S, Chen Z Q. Molecular dynamics simulation of dispersion property of nanoparticles in nanofluids[J]. Journal of Southeast University (Natural Science Edition), 2021, 51(4): 700-706. | |

| 29 | Xu N, Liu Z L, Lv Y D, et al. Improved coarse-grained model for nanoparticles based on the martini force field and its application in molecular dynamics simulation on gel ink[J]. Langmuir, 2022, 38(46): 14172-14184. |

| 30 | Marrink S J, Risselada H J, Yefimov S, et al. The MARTINI force field: coarse grained model for biomolecular simulations[J]. The Journal of Physical Chemistry B, 2007, 111(27): 7812-7824. |

| 31 | 刘子璐. 多尺度液相纳米颗粒体系分散稳定性粗粒化分子动力学模拟[D]. 太原: 太原理工大学, 2023. |

| Liu Z L. Coarse-grained molecular dynamics simulation on the dispersion stability of multi-scale nanoparticle liquid system[D]. Taiyuan: Taiyuan University of Technology, 2023. | |

| 32 | van der Spoel D, Lindahl E, Hess B, et al. GROMACS: fast, flexible, and free[J]. Journal of Computational Chemistry, 2005, 26(16): 1701-1718. |

| 33 | Stukowski A. Visualization and analysis of atomistic simulation data with OVITO — the Open Visualization Tool[J]. Modelling Simul. Mater. Sci. Eng., 2010, 18(1): 015012. |

| 34 | Wang P, Pei S, Wang M H, et al. Study on the transformation from linear to branched wormlike micelles: an insight from molecular dynamics simulation[J]. Journal of Colloid and Interface Science, 2017, 494: 47-53. |

| [1] | 王皓宇, 杨杨, 荆文婕, 杨斌, 唐雨, 刘毅. 不同旋流器作用下气液螺旋环状流动特性研究[J]. 化工学报, 2024, 75(8): 2744-2755. |

| [2] | 杨艳, 郭亚丽, 于硕文, 潘泊年, 沈胜强. 液氨喷射泵热力性能的计算分析[J]. 化工学报, 2024, 75(6): 2134-2142. |

| [3] | 张文焱, 刘浩, 宋伟龙, 赵频, 王新华. 不同粒径UiO-66混掺改性TFN-FO膜的构建及性能评价[J]. 化工学报, 2024, 75(5): 1920-1928. |

| [4] | 李静, 张方芳, 王帅帅, 徐建华, 张朋远. 凹腔结构对正丁烷部分预混火焰可燃极限的影响[J]. 化工学报, 2024, 75(5): 2081-2090. |

| [5] | 申州洋, 薛康, 刘青, 史成香, 邹吉军, 张香文, 潘伦. 吸热型纳米流体燃料研究进展[J]. 化工学报, 2024, 75(4): 1167-1182. |

| [6] | 陈好奇, 史博会, 彭琪, 康琦, 宋尚飞, 姚海元, 陈海宏, 吴海浩, 宫敬. 基于稳定性分析的含酸/醇烃水体系相平衡计算[J]. 化工学报, 2024, 75(3): 789-800. |

| [7] | 潘越, 刘相洋, 黄奕晨, 李江涛, 邱丽, 李瑞丰, 李莎, 闫晓亮. Ni/Al2O3与ZnO距离对含硫菲加氢性能的影响[J]. 化工学报, 2024, 75(10): 3548-3556. |

| [8] | 陈巨辉, 安然, 李丹, 高浩铭, 张坤. 范德华力对磁场流化纳米颗粒运动的影响[J]. 化工学报, 2024, 75(10): 3518-3527. |

| [9] | 赵文琪, 邓燕君, 朱春英, 付涛涛, 马友光. 纳米粒子稳定的Pickering乳液及其液滴聚并动力学研究进展[J]. 化工学报, 2024, 75(1): 33-46. |

| [10] | 江河, 袁俊飞, 王林, 邢谷雨. 均流腔结构对微细通道内相变流动特性影响的实验研究[J]. 化工学报, 2023, 74(S1): 235-244. |

| [11] | 孟令玎, 崇汝青, 孙菲雪, 孟子晖, 刘文芳. 改性聚乙烯膜和氧化硅固定化碳酸酐酶[J]. 化工学报, 2023, 74(8): 3472-3484. |

| [12] | 郑玉圆, 葛志伟, 韩翔宇, 王亮, 陈海生. 中高温钙基材料热化学储热的研究进展与展望[J]. 化工学报, 2023, 74(8): 3171-3192. |

| [13] | 仪显亨, 周骛, 蔡小舒, 蔡天意. 光纤后向动态光散射测量纳米颗粒的浓度适用范围研究[J]. 化工学报, 2023, 74(8): 3320-3328. |

| [14] | 毛磊, 刘冠章, 袁航, 张光亚. 可捕集CO2的纳米碳酸酐酶粒子的高效制备及性能研究[J]. 化工学报, 2023, 74(6): 2589-2598. |

| [15] | 蔡斌, 张效林, 罗倩, 党江涛, 左栗源, 刘欣梅. 导电薄膜材料的研究进展[J]. 化工学报, 2023, 74(6): 2308-2321. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号