化工学报 ›› 2025, Vol. 76 ›› Issue (2): 858-867.DOI: 10.11949/0438-1157.20240654

应昕1,2( ), 杜淼4(

), 杜淼4( ), 潘鹏举2,3, 单国荣2,3(

), 潘鹏举2,3, 单国荣2,3( )

)

收稿日期:2024-06-14

修回日期:2024-07-21

出版日期:2025-02-25

发布日期:2025-03-10

通讯作者:

杜淼,单国荣

作者简介:应昕(2000—),男,硕士研究生,yingxin@zju.edu.cn

Xin YING1,2( ), Miao DU4(

), Miao DU4( ), Pengju PAN2,3, Guorong SHAN2,3(

), Pengju PAN2,3, Guorong SHAN2,3( )

)

Received:2024-06-14

Revised:2024-07-21

Online:2025-02-25

Published:2025-03-10

Contact:

Miao DU, Guorong SHAN

摘要:

聚硫氨酯作为一种高折射率光学树脂,具有优异的光学、热学和力学性能,被广泛应用于光电领域。研究了不同单体结构和单体官能团比对聚硫氨酯综合性能的影响,结果表明,聚硫氨酯的折射率和色散程度与其含硫量和芳环结构含量有较大的关系,调整官能团比可使高折射率聚硫氨酯的折射率从1.6848上升至1.6900。聚硫氨酯的热学性能和力学性能受到单体结构刚性、官能团度、交联网络均匀程度和反应程度多个方面影响。制备的大部分聚硫氨酯都可以很好地满足光学透镜、光学黏结剂等领域的要求。

中图分类号:

应昕, 杜淼, 潘鹏举, 单国荣. 高折射率聚硫氨酯的合成、结构与性能[J]. 化工学报, 2025, 76(2): 858-867.

Xin YING, Miao DU, Pengju PAN, Guorong SHAN. Synthesis, structure and properties of high refrective index polythiourethane[J]. CIESC Journal, 2025, 76(2): 858-867.

| Property | PTU1 | PTU2 | PTU3 | PTU4 | PTU5 | PTU6 |

|---|---|---|---|---|---|---|

| composition | BES-XDI | BES-TDI | BES-MDI | PETMP-XDI | PETMP-MDI | BMMD-XDI |

| sulf content/%(mass) | 29.48 | 30.66 | 25.16 | 14.80 | 12.94 | 25.87 |

| refractive index(589 nm) | 1.6560 | 1.6785 | 1.6862 | 1.5912 | 1.6261 | 1.6596 |

| Abbe’s number | 31.31 | 25.53 | 23.90 | 34.44 | 24.81 | 32.25 |

| total transmittance/% | 87.67±0.64 | 86.81±0.77 | 86.48±0.75 | 89.20±0.58 | 84.42±0.86 | 87.11±0.73 |

| haze/% | 0.22±0.08 | 4.1±0.13 | 0.06±0.02 | 2.07±0.09 | 18.78±0.20 | 0.71±0.11 |

| λUV/nm | 290 | 320 | 313 | 285 | 317 | 282 |

| Tg(DSC)/℃ | 69.6 | 122.5 | 125.3 | 70.9 | 124.3 | 98.4 |

| Tg(DMA)/℃ | 96.6 | 122.4 | 140.7 | 99.1 | 80.7/134.7 | — |

| FWHM/℃ | 14.4 | 31.8 | 23.2 | 11.6 | 46.4/29.3 | — |

| Td5%/℃ | 280 | 262.1 | 268.6 | 290.6 | 279.6 | 282.9 |

| Tdmax/℃ | 301.7 | 283.9 | 295.4 | 303.4 | 350.8 | 312.3 |

| tensile strength/MPa | 104.74±9.32 | 50.31±4.01 | 79.57±4.12 | 94.46±9.52 | 79.74±1.58 | — |

| tensile strength at break/MPa | 104.74±9.32 | 50.31±4.01 | 79.57±4.12 | 63.80±3.38 | 69.50±3.94 | — |

| tensile strain at break/% | 10.04±1.54 | 4.78±1.37 | 13.07+2.91 | 16.55±2.27 | 27.86±3.29 | — |

| tensile yield strength/MPa | — | — | — | 94.46±9.52 | 79.74±1.58 | — |

| tensile strain at yield/% | — | — | — | 9.92±0.49 | 11.61±0.45 | — |

| pencil hardness | 2H | 2H | 2H | 2H | 2H | 3H |

| density/(g/cm3) | 1.3633 | 1.3783 | 1.3417 | 1.3958 | 1.3846 | 1.4230 |

| contact angle/(°) | 94.87±2.28 | 94.02±5.34 | 92.35±3.47 | 94.52±1.18 | 77.24±1.69 | 83.95±0.69 |

表1 不同体系聚硫氨酯的组成、光学性能、热学性能与力学性能

Table 1 Composition, optical, thermal and mechanical properties of polythiourethane of different systems

| Property | PTU1 | PTU2 | PTU3 | PTU4 | PTU5 | PTU6 |

|---|---|---|---|---|---|---|

| composition | BES-XDI | BES-TDI | BES-MDI | PETMP-XDI | PETMP-MDI | BMMD-XDI |

| sulf content/%(mass) | 29.48 | 30.66 | 25.16 | 14.80 | 12.94 | 25.87 |

| refractive index(589 nm) | 1.6560 | 1.6785 | 1.6862 | 1.5912 | 1.6261 | 1.6596 |

| Abbe’s number | 31.31 | 25.53 | 23.90 | 34.44 | 24.81 | 32.25 |

| total transmittance/% | 87.67±0.64 | 86.81±0.77 | 86.48±0.75 | 89.20±0.58 | 84.42±0.86 | 87.11±0.73 |

| haze/% | 0.22±0.08 | 4.1±0.13 | 0.06±0.02 | 2.07±0.09 | 18.78±0.20 | 0.71±0.11 |

| λUV/nm | 290 | 320 | 313 | 285 | 317 | 282 |

| Tg(DSC)/℃ | 69.6 | 122.5 | 125.3 | 70.9 | 124.3 | 98.4 |

| Tg(DMA)/℃ | 96.6 | 122.4 | 140.7 | 99.1 | 80.7/134.7 | — |

| FWHM/℃ | 14.4 | 31.8 | 23.2 | 11.6 | 46.4/29.3 | — |

| Td5%/℃ | 280 | 262.1 | 268.6 | 290.6 | 279.6 | 282.9 |

| Tdmax/℃ | 301.7 | 283.9 | 295.4 | 303.4 | 350.8 | 312.3 |

| tensile strength/MPa | 104.74±9.32 | 50.31±4.01 | 79.57±4.12 | 94.46±9.52 | 79.74±1.58 | — |

| tensile strength at break/MPa | 104.74±9.32 | 50.31±4.01 | 79.57±4.12 | 63.80±3.38 | 69.50±3.94 | — |

| tensile strain at break/% | 10.04±1.54 | 4.78±1.37 | 13.07+2.91 | 16.55±2.27 | 27.86±3.29 | — |

| tensile yield strength/MPa | — | — | — | 94.46±9.52 | 79.74±1.58 | — |

| tensile strain at yield/% | — | — | — | 9.92±0.49 | 11.61±0.45 | — |

| pencil hardness | 2H | 2H | 2H | 2H | 2H | 3H |

| density/(g/cm3) | 1.3633 | 1.3783 | 1.3417 | 1.3958 | 1.3846 | 1.4230 |

| contact angle/(°) | 94.87±2.28 | 94.02±5.34 | 92.35±3.47 | 94.52±1.18 | 77.24±1.69 | 83.95±0.69 |

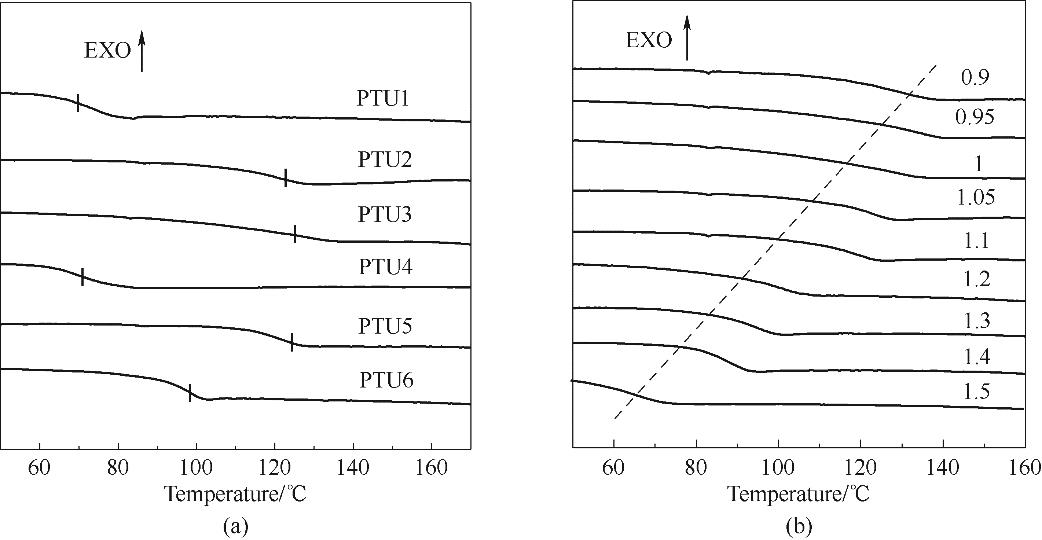

图4 不同体系聚硫氨酯(a)和不同官能团比聚硫氨酯(b)的DSC 二次升温曲线

Fig.4 DSC secondary heating curves of polythiourethane with different systems (a) and with different functional group ratios (b)

| Property | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 |

|---|---|---|---|---|---|---|---|---|---|

| —SH/—NCO | 0.90 | 0.95 | 1.00 | 1.05 | 1.10 | 1.20 | 1.30 | 1.40 | 1.50 |

| refractive index(589 nm) | 1.6848 | 1.6859 | 1.6862 | 1.6871 | 1.6880 | 1.6886 | 1.6895 | 1.6898 | 1.6900 |

| Abbe’s number | 23.48 | 23.48 | 23.90 | 23.95 | 24.00 | 24.35 | 24.05 | 24.41 | 24.46 |

| total transmittance/% | 86.62±0.83 | 86.50±0.69 | 86.48±0.75 | 86.48±0.62 | 86.35±0.87 | 86.34±0.93 | 86.50±0.76 | 86.20±0.68 | 86.36±0.91 |

| Haze/% | 0.09±0.02 | 0.17±0.04 | 0.06±0.04 | 0.04±0.03 | 0.16±0.05 | 0.50±0.08 | 0.59±0.06 | 0.47±0.09 | 1.57±0.10 |

| λUV/nm | 313 | 313 | 313 | 312 | 312 | 311 | 311 | 311 | 311 |

| Tg(DSC)/℃ | 131.3 | 127.8 | 125.3 | 119.9 | 119.4 | 101.1 | 98.0 | 89.7 | 69.4 |

| Tg(DMA)/℃ | 153.3 | 147.2 | 139.5 | 131.9 | 129.1 | 116.6 | 107.2 | 102.3 | 89.7 |

| FWHM/℃ | 33.5 | 38.7 | 36.0 | 30.0 | 28.5 | 23.3 | 19.7 | 17.5 | 19.1 |

| Td5%/℃ | 266.3 | 268.6 | 268.6 | 268.0 | 271.8 | 270.5 | 269.2 | 269.0 | 266.2 |

| Tdmax/℃ | 290.1 | 292.5 | 295.4 | 293.6 | 297.1 | 290.1 | 290.9 | 287.6 | 286.0 |

| tensile strength/MPa | 60.31±3.25 | 72.06±3.42 | 79.57±4.12 | 77.73±5.18 | 73.28±4.72 | 72.12±2.21 | 68.69±3.35 | 67.48±3.72 | 37.48±3.80 |

| tensile strain at break/% | 7.45±1.66 | 8.37±1.58 | 13.07±2.91 | 15.7±3.13 | 17.42±2.68 | 16.84±3.89 | 11.58±1.73 | 6.89±1.76 | 4.02±1.30 |

| pencil hardness | 2H | 2H | 2H | 2H | 2H | 2H | H | H | HB |

| density/(g/cm3) | 1.3356 | 1.3392 | 1.3417 | 1.3463 | 1.3497 | 1.3573 | 1.3625 | 1.3686 | 1.3715 |

| contact angle/(°) | 91.60±2.15 | 100.03±1.76 | 92.35±3.47 | 95.34±1.38 | 98.17±1.24 | 93.94±2.91 | 90.95±1.79 | 101.39±1.21 | 97.30±1.41 |

表2 不同官能团比聚硫氨酯的组成、光学性能、热学性能与力学性能

Table 2 Composition, optical, thermal and mechanical properties of polythiourethane with different functional group ratios

| Property | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 |

|---|---|---|---|---|---|---|---|---|---|

| —SH/—NCO | 0.90 | 0.95 | 1.00 | 1.05 | 1.10 | 1.20 | 1.30 | 1.40 | 1.50 |

| refractive index(589 nm) | 1.6848 | 1.6859 | 1.6862 | 1.6871 | 1.6880 | 1.6886 | 1.6895 | 1.6898 | 1.6900 |

| Abbe’s number | 23.48 | 23.48 | 23.90 | 23.95 | 24.00 | 24.35 | 24.05 | 24.41 | 24.46 |

| total transmittance/% | 86.62±0.83 | 86.50±0.69 | 86.48±0.75 | 86.48±0.62 | 86.35±0.87 | 86.34±0.93 | 86.50±0.76 | 86.20±0.68 | 86.36±0.91 |

| Haze/% | 0.09±0.02 | 0.17±0.04 | 0.06±0.04 | 0.04±0.03 | 0.16±0.05 | 0.50±0.08 | 0.59±0.06 | 0.47±0.09 | 1.57±0.10 |

| λUV/nm | 313 | 313 | 313 | 312 | 312 | 311 | 311 | 311 | 311 |

| Tg(DSC)/℃ | 131.3 | 127.8 | 125.3 | 119.9 | 119.4 | 101.1 | 98.0 | 89.7 | 69.4 |

| Tg(DMA)/℃ | 153.3 | 147.2 | 139.5 | 131.9 | 129.1 | 116.6 | 107.2 | 102.3 | 89.7 |

| FWHM/℃ | 33.5 | 38.7 | 36.0 | 30.0 | 28.5 | 23.3 | 19.7 | 17.5 | 19.1 |

| Td5%/℃ | 266.3 | 268.6 | 268.6 | 268.0 | 271.8 | 270.5 | 269.2 | 269.0 | 266.2 |

| Tdmax/℃ | 290.1 | 292.5 | 295.4 | 293.6 | 297.1 | 290.1 | 290.9 | 287.6 | 286.0 |

| tensile strength/MPa | 60.31±3.25 | 72.06±3.42 | 79.57±4.12 | 77.73±5.18 | 73.28±4.72 | 72.12±2.21 | 68.69±3.35 | 67.48±3.72 | 37.48±3.80 |

| tensile strain at break/% | 7.45±1.66 | 8.37±1.58 | 13.07±2.91 | 15.7±3.13 | 17.42±2.68 | 16.84±3.89 | 11.58±1.73 | 6.89±1.76 | 4.02±1.30 |

| pencil hardness | 2H | 2H | 2H | 2H | 2H | 2H | H | H | HB |

| density/(g/cm3) | 1.3356 | 1.3392 | 1.3417 | 1.3463 | 1.3497 | 1.3573 | 1.3625 | 1.3686 | 1.3715 |

| contact angle/(°) | 91.60±2.15 | 100.03±1.76 | 92.35±3.47 | 95.34±1.38 | 98.17±1.24 | 93.94±2.91 | 90.95±1.79 | 101.39±1.21 | 97.30±1.41 |

| 1 | Zhou Y T, Zhu Z C, Zhang K, et al. Molecular structure and properties of sulfur-containing high refractive index polymer optical materials[J]. Macromolecular Rapid Communications, 2023, 44(23): e2300411. |

| 2 | Jang W, Choi K, Choi J S, et al. Transparent, ultrahigh-refractive index polymer film (n ∼1.97) with minimal birefringence (Δn <0.0010) [J]. ACS Applied Materials & Interfaces, 2021, 13(51): 61629-61637. |

| 3 | Zhang J, Bai T W, Liu W X, et al. All-organic polymeric materials with high refractive index and excellent transparency[J]. Nature Communications, 2023, 14(1): 3524. |

| 4 | Shim H, Monticone F, Miller O D. Fundamental limits to the refractive index of transparent optical materials[J]. Advanced Materials, 2021, 33(43): e2103946. |

| 5 | Huo N, Tenhaeff W E. High refractive index polymer thin films by charge-transfer complexation[J]. Macromolecules, 2023, 56(5): 2113-2122. |

| 6 | Xue S Y, Lei X F, Xiao Y Y, et al. Rapid, mild synthesis of transparent polyimides with high refractive index via thiol-Michael click reaction[J]. ACS Applied Polymer Materials, 2024, 6(4): 2315-2326. |

| 7 | Dan S M, Gu H M, Tan J J, et al. Transparent epoxy/TiO2 optical hybrid films with tunable refractive index prepared via a simple and efficient way[J]. Progress in Organic Coatings, 2018, 120: 252-259. |

| 8 | Zhang Q Y, Goh E S M, Beuerman R, et al. Development of optically transparent ZnS/poly(vinylpyrrolidone) nanocomposite films with high refractive indices and high Abbe numbers[J]. Journal of Applied Polymer Science, 2013, 129(4): 1793-1798. |

| 9 | Xia Y, Zhang C, Wang J X, et al. Synthesis of transparent aqueous ZrO2 nanodispersion with a controllable crystalline phase without modification for a high-refractive-index nanocomposite film[J]. Langmuir, 2018, 34(23): 6806-6813. |

| 10 | Mazumder K, Voit B, Banerjee S. Recent progress in sulfur-containing high refractive index polymers for optical applications[J]. ACS Omega, 2024, 9(6): 6253-6279. |

| 11 | Fang L X, Sun J, Chen X Y, et al. Phosphorus- and sulfur-containing high-refractive-index polymers with high Tg and transparency derived from a bio-based aldehyde[J]. Macromolecules, 2020, 53(1): 125-131. |

| 12 | Scheiger J M, Theato P. High Refractive Index Sulfur‐Containing Polymers (HRISPs)[M]. Germany: Wiley, 2021: 305-338. |

| 13 | Tang Y H, Pina-Hernandez C, Niu Q J, et al. A novel high-refractive index episulfide-thiol polymer for nanoimprinting optical elements[J]. Journal of Materials Chemistry C, 2018, 6(32): 8823-8831. |

| 14 |

Su Y, Filho E B D S, Peek N, et al. High refractive index polymers (n > 1.7), based on thiol-ene cross-linking of polarizable P S and P S and P Se organic/inorganic monomers[J]. Macromolecules, 2019, 52(22): 9012-9022. Se organic/inorganic monomers[J]. Macromolecules, 2019, 52(22): 9012-9022.

|

| 15 | Matsumura Y, Horikoshi H, Furukawa K, et al. Synthesis of bismuth-containing polymer films with high refractive index and X-ray shielding property by radical polymerization of styrylbismuthine derivatives[J]. ACS Macro Letters, 2022, 11(6): 723-726. |

| 16 | Badur T, Dams C, Hampp N. High refractive index polymers by design[J]. Macromolecules, 2018, 51(11): 4220-4228. |

| 17 | Yang C J, Jenekhe S A. Group contribution to molar refraction and refractive index of conjugated polymers[J]. Chemistry of Materials, 1995, 7(7): 1276-1285. |

| 18 | Xue S Y, Lei X F, Xiao Y Y, et al. Highly refractive polyimides derived from efficient catalyst-free thiol-yne click polymerization[J]. Macromolecules, 2021, 54(24): 11256-11268. |

| 19 | Qu T F, Nan G M, Ouyang Y, et al. Structure-property relationship, glass transition, and crystallization behaviors of conjugated polymers[J]. Polymers, 2023, 15(21): 4268. |

| 20 | Gamardella F, De la Flor S, Ramis X, et al. Recyclable poly(thiourethane) vitrimers with high Tg. Influence of the isocyanate structure[J]. Reactive and Functional Polymers, 2020, 151: 104574. |

| 21 | Jia Y Y, Shi B J, Jin J S, et al. High refractive index polythiourethane networks with high mechanical property via thiol-isocyanate click reaction[J]. Polymer, 2019, 180: 121746. |

| 22 | Zhang Y W, Wang Y S, Chen Y Y, et al. High-refractive index polythiourethane resin based on 2,3-bis((2-mercaptoethyl) thio)-1-propanethiol and 1,3-bis(isocyanantomethyl) cyclohexane using tertiary amine catalyst[J]. Journal of Applied Polymer Science, 2021, 138(17): e50278. |

| 23 | Liu J, Shi Y J, Li J J, et al. Closed-loop recyclable vinylogous carbamothioate-based covalent adaptable networks[J]. Macromolecules, 2023, 56(17): 6644-6654. |

| 24 | Kultys A, Puszka A. Transparent poly(thiourethane-urethane)s based on dithiol chain extender[J]. Journal of Thermal Analysis and Calorimetry, 2014, 117(3): 1427-1439. |

| 25 | Jeong J E, Lee J W, Bae M J, et al. NIR-triggered high-efficiency self-healable protective optical coating for vision systems[J]. ACS Applied Materials & Interfaces, 2023, 15(6): 8510-8520. |

| 26 | Chen Y Y, Qin Z Y, Tang G F, et al. Balancing optical property and enhancing stability for high-refractive index polythiourethane with assistance of cubic thiol-functionalized silsesquioxanes[J]. ACS Applied Polymer Materials, 2021, 3(1): 153-161. |

| 27 | Erice A, Ruiz de Luzuriaga A, Azcune I, et al. New injectable and self-healable thermoset polythiourethane based on S-aromatic thiourethane dissociative exchange mechanism[J]. Polymer, 2020, 196: 122461. |

| 28 | Zeng Y L, Fan L, Deng M, et al. Development of high refractive and high water content polythiourethane/AA hydrogels for potential artificial cornea implants[J]. International Journal of Polymeric Materials and Polymeric Biomaterials, 2020, 69(9): 580-591. |

| 29 | 慎政焕, 明正焕, 沈钟珉, 等. 聚硫氨酯类塑料镜: 111566518A[P]. 2020-08-21. |

| Shen Z H, Ming Z H, Shen Z M, et al. Polythiourethane plastic lens: 111566518A[P]. 2020-08-21. | |

| 30 | 刘洋, 张建林, 曹帅, 等. 一种高折射率超韧光学树脂材料及其制备方法: 113444247A[P]. 2021-09-28. |

| Liu Y, Zhang J L, Cao S, et al. A high refractive index ultra tough optical resin material and its preparation method: 113444247A[P]. 2021-09-28. | |

| 31 | 张建林, 曹飞羽, 易先君, 等. 光学树脂单体及其制备方法、光学树脂及其制备方法: 111763320B[P]. 2021-09-10. |

| Zhang J L, Cao F Y, Yi X J, et al. Optical resin monomer and its preparation method, optical resin and its preparation method: 111763320B[P]. 2021-09-10. | |

| 32 | 孔凡波, 梁万根, 张建林, 等. 一种高折射率光学树脂材料、其制备方法及应用: 117362565A[P]. 2024-01-09. |

| Kong F B, Liang W G, Zhang J L, et al. A high refractive index optical resin material, its preparation method and application: 117362565A[P]. 2024-01-09. | |

| 33 | 尚永华, 朱付林, 张文强, 等. 一种环己烷二亚甲基二异氰酸酯组合物、改性组合物及聚氨酯树脂和光学树脂: 117801222A[P]. 2024-04-02. |

| Shang Y H, Zhu F L, Zhang W Q, et al. A cyclohexane dimethyl diisocyanate composition, modified composition, polyurethane resin, and optical resin: 117801222A[P]. 2024-04-02. |

| [1] | 钟晓航, 许卫, 张文, 许莉, 王宇新. 碱性水电解制氢中铁杂质的影响研究进展[J]. 化工学报, 2025, 76(2): 519-531. |

| [2] | 陈弋翀, 贾星雨, 钟文宇, 施俞晖, 彭瑶, 孙嘉阳, 胡冬冬, 赵玲. 具有梯度结构的微孔热塑性聚氨酯及其性能[J]. 化工学报, 2025, 76(2): 897-908. |

| [3] | 党法璐, 孙志国, 高照, 王刚, 陈政宇, 张霖宙, 连竞存, 刘美佳, 张忠东, 刘超伟. 原油一步法催化裂解制低碳烯烃:实验和反应路径研究[J]. 化工学报, 2025, 76(2): 667-685. |

| [4] | 张珂, 任维杰, 王梦娜, 范凯锋, 常丽萍, 李佳斌, 马涛, 田晋平. Bunsen反应产物在微通道中的液-液两相混合特性[J]. 化工学报, 2025, 76(2): 623-636. |

| [5] | 贾晶宇, 孔德齐, 沈圆辉, 张东辉, 李文彬, 唐忠利. 合成氨反应器尾气变压吸附氨分离工艺的模拟与分析[J]. 化工学报, 2025, 76(2): 718-730. |

| [6] | 宫政, 高秀鲁, 赵玲, 胡冬冬. 超临界CO2发泡PBAT/PLA复合材料及其形状记忆性能[J]. 化工学报, 2025, 76(2): 888-896. |

| [7] | 徐艳焦, 楼琳瑾, 樊茁钦, 张浩淼, 王靖岱, 阳永荣. 甲基铝氧烷的改性技术研究进展[J]. 化工学报, 2025, 76(2): 454-465. |

| [8] | 翟紫航, 蒋杰, 李锦锦, 赵玲, 奚桢浩. 基于2,5-呋喃二甲酸的三元无规共聚酯PBSF的制备与性能[J]. 化工学报, 2025, 76(2): 868-878. |

| [9] | 彭子林, 周蕾, 邓庆航, 叶光华, 周兴贵. 包含偏硅酸影响的3D NAND磷酸湿法刻蚀动力学[J]. 化工学报, 2025, 76(2): 645-653. |

| [10] | 殷梦凡, 王倩, 郑涛, 姬奎, 王绍贵, 郭辉, 林志强, 张睿, 孙晖, 刘海燕, 刘植昌, 徐春明, 孟祥海, 王月平. 可再生能源电解水制氢-低温低压合成氨万吨级工业示范流程设计[J]. 化工学报, 2025, 76(2): 825-834. |

| [11] | 张闯德, 陈黎. 优势通道对多孔介质中多相反应输运过程影响的孔隙尺度研究[J]. 化工学报, 2025, 76(1): 161-172. |

| [12] | 纪之骄, 张晓方, 甘汶, 薛云鹏. 载体对单原子电催化剂合成氨性能的影响与调控策略[J]. 化工学报, 2025, 76(1): 18-39. |

| [13] | 郭珊, 田雨, 徐永滨, 王朋, 刘治明. 废旧电池再资源化制备高性能中熵合金催化剂及其性能研究[J]. 化工学报, 2025, 76(1): 231-240. |

| [14] | 王瀚彬, 胡帅, 毕丰雷, 李隽森, 贺来宾. 新型波纹翅片金属氢化物反应器的放氢性能有限元分析[J]. 化工学报, 2025, 76(1): 221-230. |

| [15] | 黄娜, 蒋云龙, 王东涵, 吴明婷, 蒋雪莉, 钟豫. 通道振动频率对超临界正癸烷裂解流动换热影响的数值研究[J]. 化工学报, 2025, 76(1): 173-183. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号