• •

张延焱1( ), 周婷玉1(

), 周婷玉1( ), 朱慧敏2, 李海洋3(

), 朱慧敏2, 李海洋3( ), 于慧鑫1(

), 于慧鑫1( ), 张学军1

), 张学军1

收稿日期:2025-05-22

修回日期:2025-08-12

出版日期:2025-08-13

通讯作者:

李海洋,于慧鑫

作者简介:张延焱(2000—),女,硕士研究生,1647650287@qq.com基金资助:

Yanyan ZHANG1( ), Tingyu ZHOU1(

), Tingyu ZHOU1( ), Huimin ZHU2, Haiyang LI3(

), Huimin ZHU2, Haiyang LI3( ), Huixin YU1(

), Huixin YU1( ), Xuejun ZHANG1

), Xuejun ZHANG1

Received:2025-05-22

Revised:2025-08-12

Online:2025-08-13

Contact:

Haiyang LI, Huixin YU

摘要:

挥发性有机化合物(VOCs)作为二次有机气溶胶和臭氧的前驱体,对人体和动物健康构成严重威胁。本研究以甲苯为目标污染物,选择铈氧化物作为催化剂,通过调整合成技术进而影响催化剂的物化性质,旨在开发出一种制备简便且高效的催化剂。运用多种表征技术对催化剂进行分析,结果表明,优化合成方法后所得催化剂(以下简称“CeO2-Y”,其中“Y”表示采用乙酸-乙二醇体系辅助水热法制备,具有疏松球形结构的样品)展现出理想的形貌结构和物理吸附属性。富含的Ce3+能够促进氧空位的形成,从而提高氧储存能力和氧迁移效率,并改善其在低温下的氧化还原性能。原位红外测试揭示了甲苯的反应路径,其中,苯环的裂解步骤是整个反应的决速步。本研究不仅为甲苯的催化氧化提供了高效催化剂,也为催化剂的合成方法、形貌调控及反应机制提供了理论和实验依据。

中图分类号:

张延焱, 周婷玉, 朱慧敏, 李海洋, 于慧鑫, 张学军. 基于氧空位调控的CeO2催化剂催化氧化甲苯性能[J]. 化工学报, DOI: 10.11949/0438-1157.20250565.

Yanyan ZHANG, Tingyu ZHOU, Huimin ZHU, Haiyang LI, Huixin YU, Xuejun ZHANG. Catalytic performance of CeO2 catalysts for the oxidation of toluene based on oxygen vacancy modulation[J]. CIESC Journal, DOI: 10.11949/0438-1157.20250565.

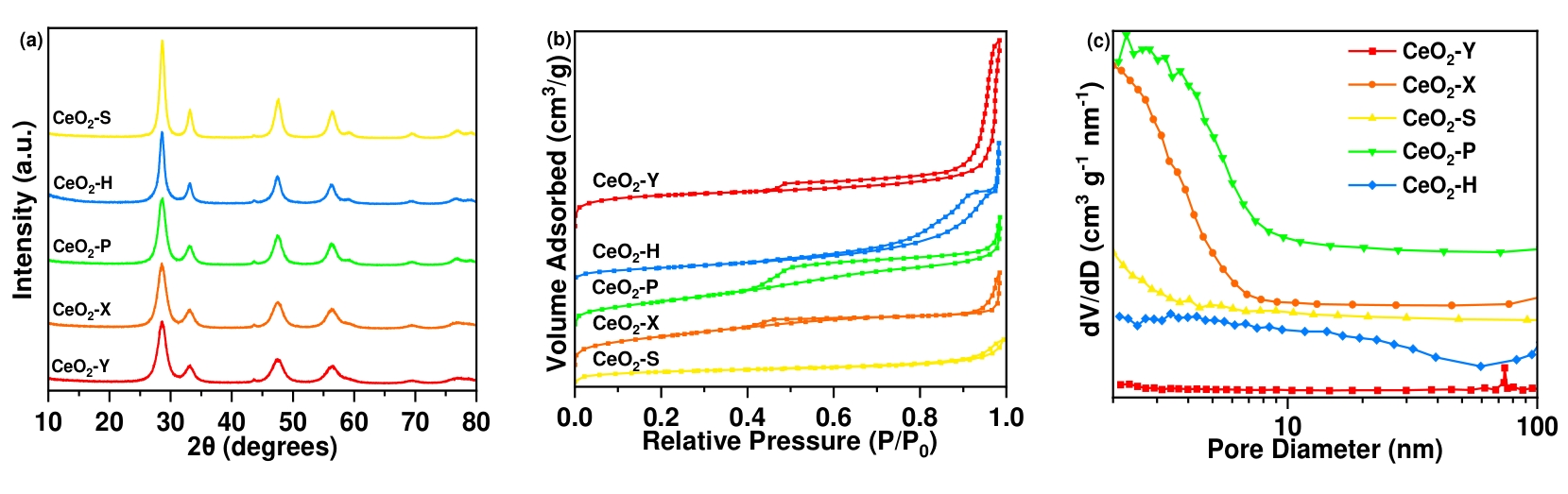

图1 所制备催化剂的(a) XRD图,(b) 氮气吸附与解吸等温曲线,以及(c) 孔径分布图

Fig. 1 (a) XRD pattern, (b) nitrogen adsorption and desorption isothermal curves, and (c) pore size distribution of the prepared catalysts

| Sample | Dp (nm) | SBET (m2 g-1) | Vp (cm3 g-1) |

|---|---|---|---|

| CeO2-Y | 8.2 | 62.4 | 0.30 |

| CeO2-X | 4.2 | 89.3 | 0.16 |

| CeO2-P | 5.8 | 90.4 | 0.18 |

| CeO2-H | 17.5 | 40.9 | 0.22 |

| CeO2-S | 12.4 | 33.3 | 0.08 |

表1 所制备催化剂的结构参数

Table 1 Structural parameters of the prepared catalysts

| Sample | Dp (nm) | SBET (m2 g-1) | Vp (cm3 g-1) |

|---|---|---|---|

| CeO2-Y | 8.2 | 62.4 | 0.30 |

| CeO2-X | 4.2 | 89.3 | 0.16 |

| CeO2-P | 5.8 | 90.4 | 0.18 |

| CeO2-H | 17.5 | 40.9 | 0.22 |

| CeO2-S | 12.4 | 33.3 | 0.08 |

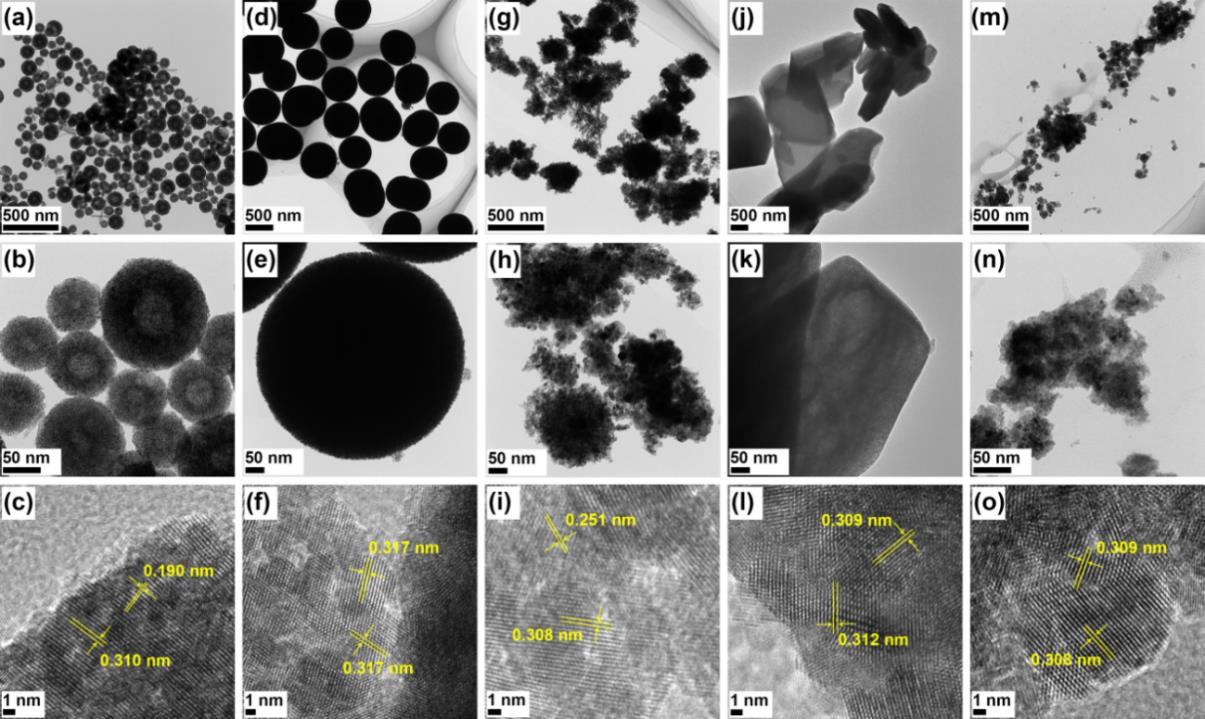

图3 CeO2-Y (a-c),CeO2-X (d-f),CeO2-S (g-i),CeO2-P (j-l)和CeO2-H (m-o)的SEM、TEM和HRTEM图像

Fig. 3 SEM、TEM and HRTEM images of CeO2-Y (a-c), CeO2-X (d-f), CeO2-S(g-i), CeO2-P (j-l) and CeO2-H (m-o)

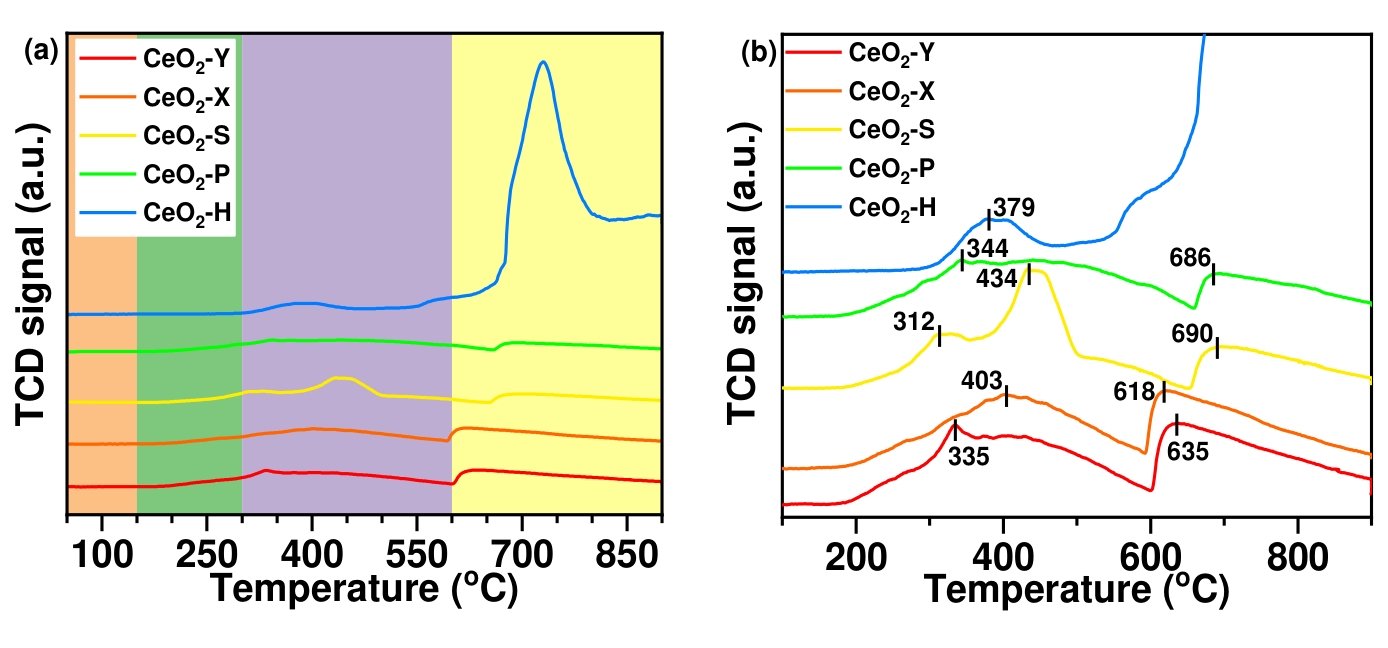

| 样品 | Ce3+/ (Ce3++Ce4+) % | Oβ/ (Oα+Oβ+Oγ) % | 氧脱附量 (μmol/g) | H2消耗量 (μmol/g) |

|---|---|---|---|---|

| CeO2-Y | 14.6 | 43.9 | 7.22 | 291.2 |

| CeO2-X | 11.1 | 27.0 | 6.41 | 213.5 |

| CeO2-S | 9.5 | 22.2 | 3.97 | 199.1 |

| CeO2-P | 10.1 | 23.7 | 4.53 | 199.3 |

| CeO2-H | 13.5 | 36.7 | 2.92 | 467.9 |

表2 所制备催化剂的XPS结果以及在O2-TPD和H2-TPR测试中涉及的参数

Table 2 XPS results and the parameters involved in the O2-TPD and H2-TPR tests of the prepared catalysts

| 样品 | Ce3+/ (Ce3++Ce4+) % | Oβ/ (Oα+Oβ+Oγ) % | 氧脱附量 (μmol/g) | H2消耗量 (μmol/g) |

|---|---|---|---|---|

| CeO2-Y | 14.6 | 43.9 | 7.22 | 291.2 |

| CeO2-X | 11.1 | 27.0 | 6.41 | 213.5 |

| CeO2-S | 9.5 | 22.2 | 3.97 | 199.1 |

| CeO2-P | 10.1 | 23.7 | 4.53 | 199.3 |

| CeO2-H | 13.5 | 36.7 | 2.92 | 467.9 |

图5 所制备催化剂的(a) O2-TPD谱图和(b) 100 - 900 oC范围的O2-TPD的放大谱图

Fig. 5 (a) O2-TPD and (b) amplified spectra of O2-TPD in the range of 100 - 900 oC for the prepared catalysts

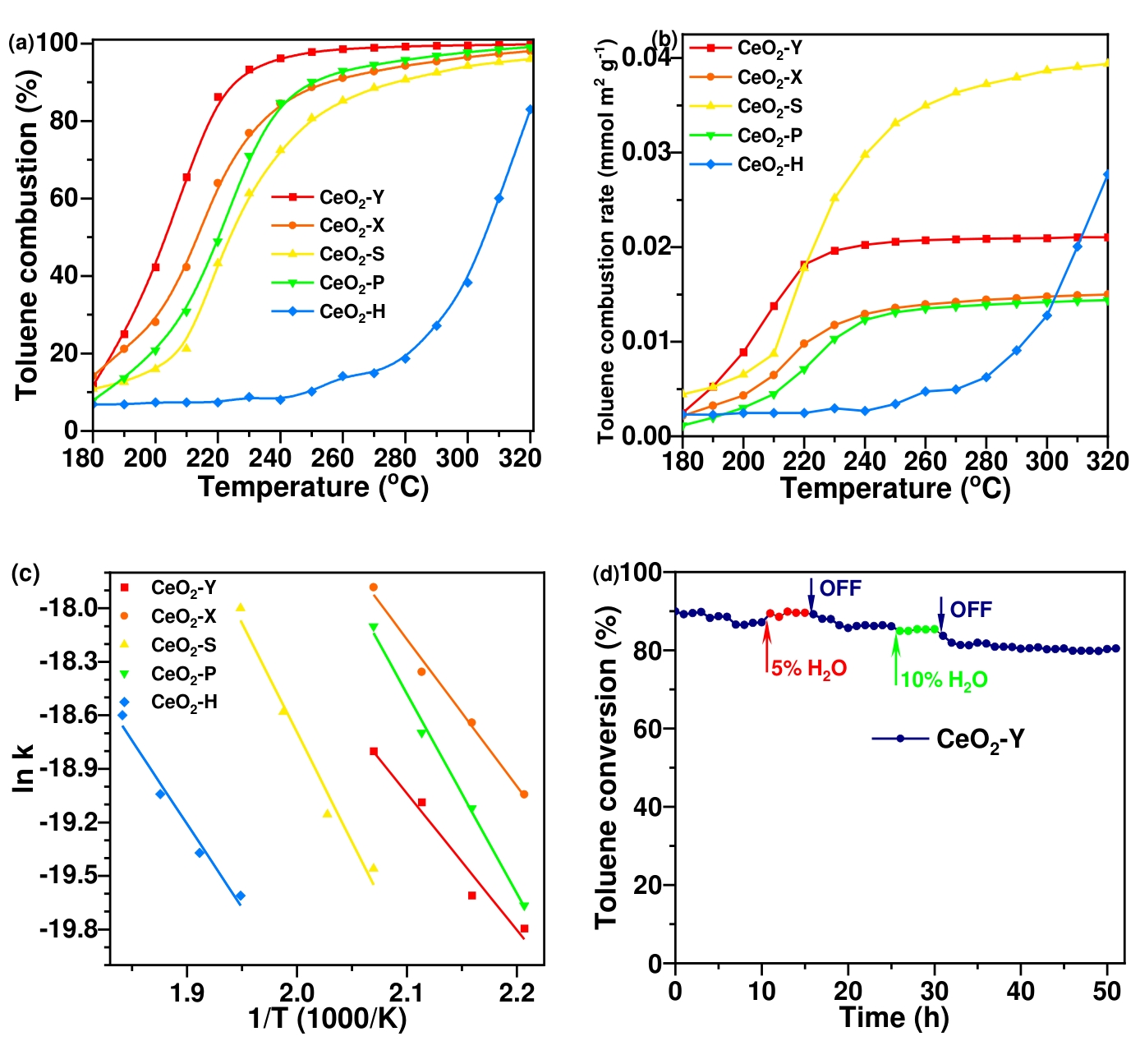

图7 所制备催化剂的(a)甲苯降解效率,(b)SBET归一化,(c)Arrhenius图和(d)CeO2-Y在225 oC的稳定性和抗水性测试

Fig. 7 (a) Toluene degradation efficiency, (b) SBET normalization, (c) Arrhenius plots and (d) CeO2-Y stability and water resistance tests at 225 oC for the prepared catalysts

| 样品 | T50 (oC) | T90 (oC) | Ea (kJ/mol) |

|---|---|---|---|

| CeO2-Y | 203 | 225 | 63.68 |

| CeO2-X | 213 | 255 | 68.49 |

| CeO2-S | 224 | 276 | 97.81 |

| CeO2-P | 220 | 250 | 93.09 |

| CeO2-H | 305 | >320 | 77.75 |

表3 所制备催化剂的T50、T90及表观活化能

Table 3 T50, T90 and apparent activation energy of the prepared catalysts

| 样品 | T50 (oC) | T90 (oC) | Ea (kJ/mol) |

|---|---|---|---|

| CeO2-Y | 203 | 225 | 63.68 |

| CeO2-X | 213 | 255 | 68.49 |

| CeO2-S | 224 | 276 | 97.81 |

| CeO2-P | 220 | 250 | 93.09 |

| CeO2-H | 305 | >320 | 77.75 |

| 催化剂 | 甲苯浓度 (ppm) | 空速 (mL g-1 h-1) | T90 (℃) | 文献 |

|---|---|---|---|---|

| CeO2 | 1000 | 30 000 | 375 | [ |

| CeO2 | 1000 | 50 000 | 363 | [ |

| CeO2 | 500 | 60 000 | >300 | [ |

| CeO2 | 500 | 60 000 | 320 | [ |

| CeO2-P | 1000 | 20 000 | 280 | [ |

| CeO2-C | 1000 | 48 000 | 296 | [ |

| CeO2-RS | 1000 | 48 000 | 249 | [ |

| CeO2-Y | 500 | 60 000 | 225 | This work |

表4 近期报道的CeO2催化剂催化氧化甲苯性能

Table 4 Recently reported catalytic oxidation performance of CeO2 catalysts on toluene

| 催化剂 | 甲苯浓度 (ppm) | 空速 (mL g-1 h-1) | T90 (℃) | 文献 |

|---|---|---|---|---|

| CeO2 | 1000 | 30 000 | 375 | [ |

| CeO2 | 1000 | 50 000 | 363 | [ |

| CeO2 | 500 | 60 000 | >300 | [ |

| CeO2 | 500 | 60 000 | 320 | [ |

| CeO2-P | 1000 | 20 000 | 280 | [ |

| CeO2-C | 1000 | 48 000 | 296 | [ |

| CeO2-RS | 1000 | 48 000 | 249 | [ |

| CeO2-Y | 500 | 60 000 | 225 | This work |

| 催化剂 | 前驱体 | 合成方法 | 溶剂体系 | 添加剂 | 反应条件 | 形貌 | 晶面暴露 | Ov |

|---|---|---|---|---|---|---|---|---|

| CeO2-Y | (NH4)2 [Ce(NO3)6] | 水热法 | 乙酸 + 乙二醇 | 无 | 180 °C 10 h | 疏松球形 | (220) | 高 |

| CeO2-X | Ce(NO3)3· 6H2O | 水热法 | 乙腈 + 三乙二醇 | 无 | 200 °C 2 h | 实心球形 | (111) | 中 |

| CeO2-S | Ce(NO3)3· 6H2O | 水热法 | 甲醇 | 尿素 | 180 °C 12 h | 不规则颗粒 | (200) | 高 |

| CeO2-P | Ce(CH3COO3·4H2O | 沉淀法 | 乙醇 + 草酸 | 草酸 | 80 °C 0.5h | 块状片层 | (111) | 中 |

| CeO2-H | Ce(SO4)2· 4H2O | 一锅法 | 水 | 尿素 | 100 °C 12 h | 团聚颗粒 | (111) | 高 |

表5 不同合成方法对催化剂结构性能的影响

Table 5 Effect of different synthesis methods on the structural properties of catalysts

| 催化剂 | 前驱体 | 合成方法 | 溶剂体系 | 添加剂 | 反应条件 | 形貌 | 晶面暴露 | Ov |

|---|---|---|---|---|---|---|---|---|

| CeO2-Y | (NH4)2 [Ce(NO3)6] | 水热法 | 乙酸 + 乙二醇 | 无 | 180 °C 10 h | 疏松球形 | (220) | 高 |

| CeO2-X | Ce(NO3)3· 6H2O | 水热法 | 乙腈 + 三乙二醇 | 无 | 200 °C 2 h | 实心球形 | (111) | 中 |

| CeO2-S | Ce(NO3)3· 6H2O | 水热法 | 甲醇 | 尿素 | 180 °C 12 h | 不规则颗粒 | (200) | 高 |

| CeO2-P | Ce(CH3COO3·4H2O | 沉淀法 | 乙醇 + 草酸 | 草酸 | 80 °C 0.5h | 块状片层 | (111) | 中 |

| CeO2-H | Ce(SO4)2· 4H2O | 一锅法 | 水 | 尿素 | 100 °C 12 h | 团聚颗粒 | (111) | 高 |

| [1] | 刘宗耀, 曾永辉, 刘俊伟, 等. 挥发性有机物末端治理技术研究进展[J]. 现代化工, 2022, 42(3): 74-78, 84. |

| Liu Z Y, Zeng Y H, Liu J W, et al. Latest advances in terminal treatment technology for volatile organic compounds[J]. Modern Chemical Industry, 2022, 42(3): 74-78, 84. | |

| [2] | Chen X, Feng Y, Liu S C, et al. Engineering lattice oxygen mobility and optimizing reaction pathway via tuning Cu-Co interactions for efficient elimination of volatile organic compounds: a metal–organic framework template approach[J].Separation and Purification Technology, 2024, 338: 126594.[] |

| [3] | Chen X, Zhang Y Y, Dai W, et al. Engineering robust oxygen vacancies towards efficient toluene purification: coupling crystal facets with Mn–Ce solid solution[J]. Journal of Materials Chemistry A, 2025, 13(15): 10561-10580.[] |

| [4] | 孙敬方, 葛成艳, 安冬琦, 等. 稀土铈基催化材料氧空位的表征方法综述[J]. 化工学报, 2020, 71(8): 3403-3415. |

| Sun J F, Ge C Y, An D Q, et al. Review on characterization methods of oxygen vacancy in rare earth cerium-based catalysts[J]. CIESC Journal, 2020, 71(8): 3403-3415. | |

| [5] | Peng H G, Dong T, Yang S Y, et al. Intra-crystalline mesoporous zeolite encapsulation-derived thermally robust metal nanocatalyst in deep oxidation of light al kanes[J]. Nature Communications, 2022, 13: 295.[] |

| [6] | Sun Y F, Liu Q H, Gao S, et al. Pits confined in ultrathin cerium (IV) oxide for studying catalytic centers in carbon monoxide oxidation[J]. Nature Communications, 2013, 4: 2899.[] |

| [7] | Zhang X J, Li H Y, Song Z X, et al. In situ DRIFT spectroscopy study into the reaction mechanism of toluene over CeMo catalysts[J]. Journal of Environmental Chemical Engineering, 2022, 10(6): 108895.[] |

| [8] | Feng Z T, Ren Q M, Peng R S, et al. Effect of CeO2 morphologies on toluene catalytic combustion[J]. Catalysis Today, 2019, 332: 177-182.[] |

| [9] | Su Z A, Yang W H, Wang C Z, et al. Roles of oxygen vacancies in the bulk and surface of CeO2 for toluene catalytic combustion[J]. Environmental Science & Technology, 2020, 54(19): 12684-12692.[] |

| [10] | Su Z A, Si W Z, Liu H, et al. Boosting the catalytic performance of CeO2 in toluene combustion via the Ce–Ce homogeneous interface[J]. Environmental Science & Technology, 2021, 55(18): 12630-12639.[] |

| [11] | Han W L, Zhao H J, Dong F, et al. Morphology-controlled synthesis of 3D, mesoporous, rosette-like CeCoO x catalysts by pyrolysis of Ce [Co(CN)6] and application for the catalytic combustion of toluene[J]. Nanoscale, 2018, 10(45): 21307-21319.[] |

| [12] | Zhang Y F, Tan X F, Han Z X, et al. Dual modification of cobalt silicate nanobelts by Co3O4 nanoparticles and phosphorization boosting oxygen evolution reaction properties[J]. Journal of Colloid and Interface Science, 2025, 679: 1036-1045.[] |

| [13] | Chen J, Chen X, Chen X, et al. Homogeneous introduction of CeOy into MnOx–based catalyst for oxidation of aromatic VOCs[J]. Applied Catalysis B: Environmental, 2018, 224: 825-835.[] |

| [14] | Ma L, Wang D S, Li J H, et al. Ag/CeO2 nanospheres: Efficient catalysts for formaldehyde oxidation[J]. Applied Catalysis B: Environmental, 2014, 148: 36-43.[] |

| [15] | Yang P, Yang S S, Shi Z N, et al. Deep oxidation of chlorinated VOCs over CeO2-based transition metal mixed oxide catalysts[J]. Applied Catalysis B: Environmental, 2015, 162: 227-235.[] |

| [16] | Ma J, Lou Y, Cai Y F, et al. The relationship between the chemical state of Pd species and the catalytic activity for methane combustion on Pd/CeO2 [J]. Catalysis Science & Technology, 2018, 8(10): 2567-2577.[] |

| [17] | Zheng Y F, Zhao Q, Shan C P, et al. Enhanced acetone oxidation over the CeO2/Co3O4 catalyst derived from metal–organic frameworks[J]. ACS Applied Materials & Interfaces, 2020, 12(25): 28139-28147.[] |

| [18] | Cheng Z, Chen Z, Li J R, et al. Mesoporous silica-pillared clays supported nanosized Co3O4-CeO2 for catalytic combustion of toluene[J]. Applied Surface Science, 2018, 459: 32-39.[ https://doi.org/10.1016/j.apsusc.2018.07.203] |

| [19] | Li X X, Wang Y R, Chen D Y, et al. Elucidating the characteristics of palladium-anchored CeO2-modified hexagonal nanosheet Co3O4 catalysts for the complete oxidation of volatile organic compounds[J]. Industrial & Engineering Chemistry Research, 2022, 61(22): 7537-7546.[ https://doi.org/10.1021/acs.iecr.1c04823] |

| [20] | Taniguchi A, Kumabe Y, Kan K, et al. Ce3+-enriched spherical porous ceria with an enhanced oxygen storage capacity[J]. RSC Advances, 2021, 11(10): 5609-5617.[] |

| [21] | Torrente-Murciano L, Gilbank A, Puertolas B, et al. Shape-dependency activity of nanostructured CeO2 in the total oxidation of polycyclic aromatic hydrocarbons[J]. Applied Catalysis B: Environmental, 2013, 132/133: 116-122.[] |

| [22] | Zheng Y E, Li K Z, Wang H, et al. Structure dependence and reaction mechanism of CO oxidation: a model study on macroporous CeO2 and CeO2-ZrO2 catalysts[J]. Journal of Catalysis, 2016, 344: 365-377.[] |

| [23] | 朱红太, 宋丽云, 何洪, 等. CeTiOx脱硝催化剂的抗硫中毒性能[J]. 高等学校化学学报, 2019, 40(2): 350-357. |

| Zhu H T, Song L Y, He H, et al. Sulfur tolerance of the CeTiO x catalysts for selective catalytic reduction of NO with NH3 [J]. Chemical Journal of Chinese Universities, 2019, 40(2): 350-357. | |

| [24] | Xie S H, Deng J G, Zang S M, et al. Au–Pd/3DOM Co3O4: Highly active and stable nanocatalysts for toluene oxidation[J]. Journal of Catalysis, 2015, 322: 38-48.[] |

| [25] | Huang Q L, Chen X, Lv L, et al. Redox-oriented anchoring of CeO2 over nanostructured MnCo-spinel: Strong oxide-support interaction for enhanced toluene combustion[J]. Applied Catalysis B: Environment and Energy, 2025, 378: 125548.[] |

| [26] | Yu Y, Zhang M J, Shi H G, et al. Engineering surface and subsurface oxygen vacancies of Ce x Zr1- x O2 solid solution for enhanced total toluene oxidation[J]. Journal of Environmental Sciences, 2025, 158: 39-49.[] |

| [27] | Chen X, Geng J X, Feng Y, et al. Identifying the distinct influences and mechanisms of chelating agents on CoCe bimetallic oxides towards robust toluene purification[J]. Separation and Purification Technology, 2025, 367: 132861.[] |

| [28] | Jiang C L, Wang H, Wang Y Q, et al. Modifying defect States in CeO2 by Fe doping: a strategy for low-temperature catalytic oxidation of toluene with sunlight[J]. Journal of Hazardous Materials, 2020, 390: 122182.[] |

| [29] | Chen X, Chen X, Yu E Q, et al. In situ pyrolysis of Ce-MOF to prepare CeO2 catalyst with obviously improved catalytic performance for toluene combustion[J]. Chemical Engineering Journal, 2018, 344: 469-479.[] |

| [30] | Feng Z T, Zhang M Y, Ren Q M, et al. Design of 3-dimensionally self-assembled CeO2 hierarchical nanosphere as high efficiency catalysts for toluene oxidation[J]. Chemical Engineering Journal, 2019, 369: 18-25.[] |

| [31] | Dong C, Qu Z P, Qin Y, et al. Revealing the highly catalytic performance of spinel CoMn2O4 for toluene oxidation: involvement and replenishment of oxygen species using in situ designed-TP techniques[J]. ACS Catalysis, 2019, 9(8): 6698-6710.[] |

| [32] | Sun H, Liu Z G, Chen S, et al. The role of lattice oxygen on the activity and selectivity of the OMS-2 catalyst for the total oxidation of toluene[J]. Chemical Engineering Journal, 2015, 270: 58-65.[] |

| [33] | Li J, Na H B, Zeng X L, et al. In situ DRIFTS investigation for the oxidation of toluene by ozone over Mn/HZSM-5, Ag/HZSM-5 and Mn–Ag/HZSM-5 catalysts[J]. Applied Surface Science, 2014, 311: 690-696.[] |

| [1] | 裴星亮, 叶翠平, 裴赢丽, 李文英. 碱改性MIL-53(Cr)选择性吸附分离二甲苯异构体[J]. 化工学报, 2025, 76(S1): 258-267. |

| [2] | 王一非, 任婧杰, 毕明树, 叶昊天. 基于本质安全与经济性的环己烷氧化工艺参数多目标优化研究[J]. 化工学报, 2025, 76(6): 2722-2732. |

| [3] | 刘晗, 崔家馨, 殷梦凡, 郑涛, 张睿, 孟祥海, 刘植昌, 刘海燕, 徐春明. CuAlCl4-二甲苯络合物晶体结构及二元固液相平衡测定[J]. 化工学报, 2025, 76(5): 2241-2250. |

| [4] | 刘莹, 郑芳, 杨启炜, 张治国, 任其龙, 鲍宗必. 二甲苯异构体吸附分离研究进展[J]. 化工学报, 2024, 75(4): 1081-1095. |

| [5] | 陈饶, 赵鑫, 陈戴欣, 姜圣坤, 廉应江, 王金波, 杨梅, 陈光文. 微反应器内甲苯连续二硝化制备二硝基甲苯[J]. 化工学报, 2024, 75(3): 867-876. |

| [6] | 涂玉明, 邵高燕, 陈健杰, 刘凤, 田世超, 周智勇, 任钟旗. 钙基催化剂的设计合成及应用研究进展[J]. 化工学报, 2023, 74(7): 2717-2734. |

| [7] | 李盼, 马俊洋, 陈志豪, 王丽, 郭耘. Ru/α-MnO2催化剂形貌对NH3-SCO反应性能的影响[J]. 化工学报, 2023, 74(7): 2908-2918. |

| [8] | 韩奎奎, 谭湘龙, 李金芝, 杨婷, 张春, 张永汾, 刘洪全, 于中伟, 顾学红. 四通道中空纤维MFI分子筛膜用于二甲苯异构体分离[J]. 化工学报, 2023, 74(6): 2468-2476. |

| [9] | 王辰, 史秀锋, 武鲜凤, 魏方佳, 张昊虹, 车寅, 吴旭. 氧化还原法制备Mn3O4催化剂及其甲苯催化氧化性能与机理研究[J]. 化工学报, 2023, 74(6): 2447-2457. |

| [10] | 蹇建, 张嘉明, 佘祥, 周虎, 游奎一, 罗和安. V4+和V5+比例对钒磷氧催化NO2氧化环己烷性能的影响[J]. 化工学报, 2023, 74(4): 1570-1577. |

| [11] | 赵涛岩, 曹江涛, 李平, 冯琳, 商瑀. 区间二型模糊免疫PID在环己烷无催化氧化温度控制系统中的应用[J]. 化工学报, 2022, 73(7): 3166-3173. |

| [12] | 钱庆玲, 朱晴, 杨正金, 徐铜文. 微孔Noria聚合物用于二甲苯异构体吸附分离研究[J]. 化工学报, 2022, 73(12): 5438-5448. |

| [13] | 王之豪, 宋欣, 殷亚然, 张先明. 微流控纺丝中凝胶速率对螺旋纤维形貌的调控机制[J]. 化工学报, 2022, 73(11): 5158-5166. |

| [14] | 徐健元, 吴艳阳, 徐菊美, 彭阳峰. 2 kPa下均三甲苯-偏三甲苯与均三甲苯-邻甲乙苯体系二元汽液相平衡数据研究及精馏模拟[J]. 化工学报, 2021, 72(9): 4504-4510. |

| [15] | 叶凯, 刘香华, 姜月, 于颖, 赵亚飞, 庄烨, 郑进保, 陈秉辉. 低温等离子体协同CeO2/13X催化降解甲苯[J]. 化工学报, 2021, 72(7): 3706-3715. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号