化工学报 ›› 2019, Vol. 70 ›› Issue (S2): 169-180.DOI: 10.11949/0438-1157.20190138

收稿日期:2019-02-21

修回日期:2019-04-08

出版日期:2019-09-06

发布日期:2019-09-06

通讯作者:

周云龙

作者简介:杨宁(1989—),男,博士,讲师,基金资助:

Ning YANG1,2( ),Yunlong ZHOU1(

),Yunlong ZHOU1( ),Shusheng MA2

),Shusheng MA2

Received:2019-02-21

Revised:2019-04-08

Online:2019-09-06

Published:2019-09-06

Contact:

Yunlong ZHOU

摘要:

在重质原料液的射流阶段降低反应温度会导致液体呈现不同的黏度,促使颗粒聚集形成不同尺寸的团聚结构,阻碍了原料液的热量传递,减缓了裂化反应的速率,颗粒团聚是流体焦化反应工艺面临的一个重要而又具有挑战性的问题。选用水-沙系统模拟热态沥青-焦炭系统,利用气罩装置改进喷嘴结构,基于电导信号法测量多黏度液体射流过程的电导信号随时间的变化规律,研究不同条件下流化床内颗粒团聚过程。研究结果表明:多孔气罩装置可以为喷嘴射流创造理想的稀相环境,避免了液滴在射流空腔以及交换区域的聚集和压缩;液体射流在床层扩散过程中可以观察到不同的流化阶段,即颗粒润湿阶段、团聚形成阶段、团聚隔离阶段;较高的气液比可以有效地阻止颗粒团聚,相比于较低的流化气速,较高的气速条件允许高黏度糖水溶液参与液体射流。本研究为多黏度液体射流过程颗粒团聚现象的在线监测提供了理论研究基础,确保了流化床内射流液滴与颗粒表面的良好接触。

中图分类号:

杨宁, 周云龙, 马书生. 喷嘴结构改进及其液体射流过程颗粒团聚研究[J]. 化工学报, 2019, 70(S2): 169-180.

Ning YANG, Yunlong ZHOU, Shusheng MA. Nozzle structure improvement and study of particles agglomeration during liquid injection[J]. CIESC Journal, 2019, 70(S2): 169-180.

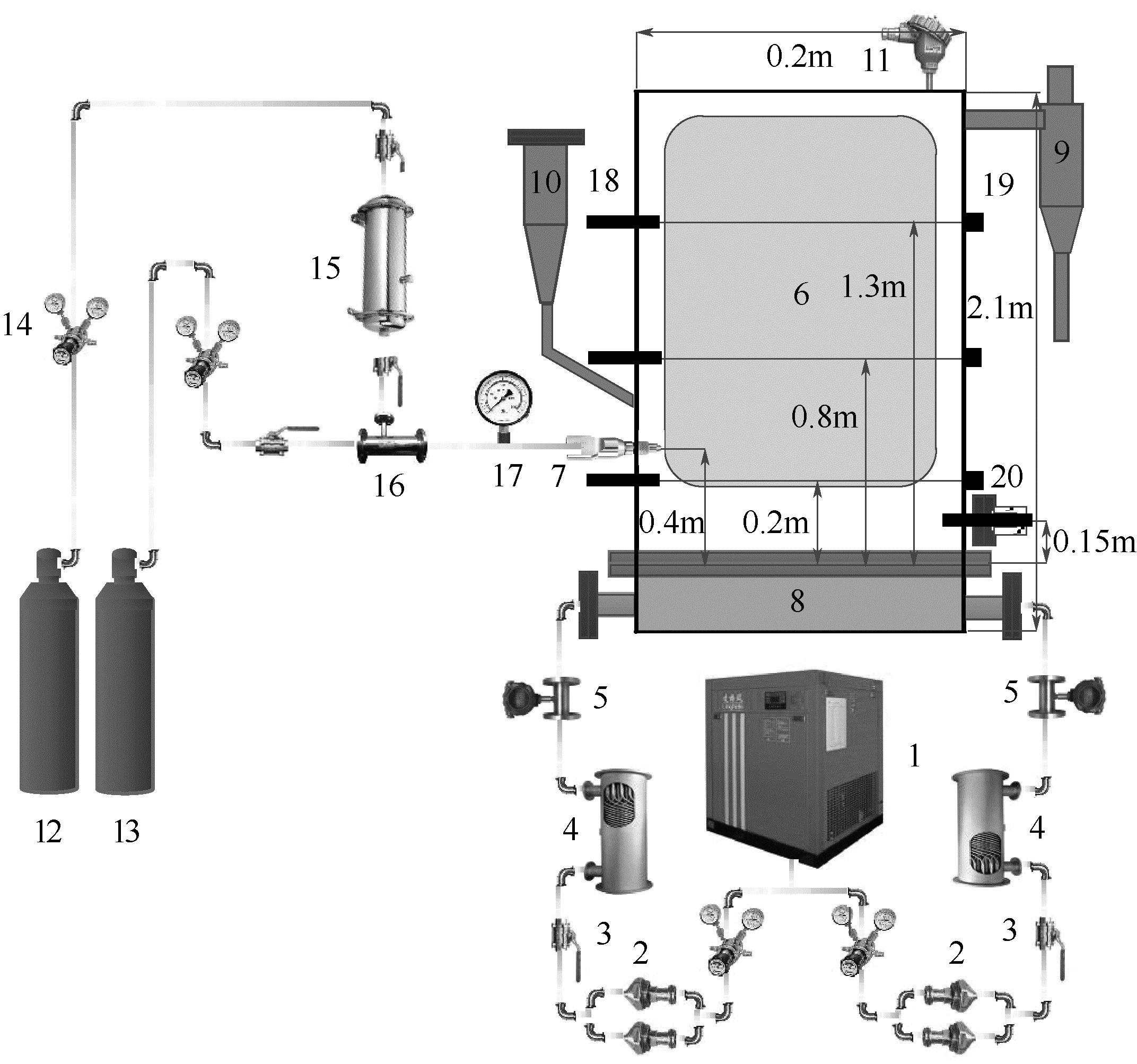

图1 实验装置流程 1—空压机;2—声速喷嘴;3—球阀;4—稳压罐;5—涡街流量计;6—流化床;7—喷嘴;8—布风板;9—布袋分离器;10—给料器;11—热电偶; 12,13—氮气瓶;14—压力调节器;15—液体储罐;16—预混器;17—压力表;18—电导探针;19—采样测点;20—压力测点

Fig.1 Experimental device for rectangular fluidized bed

| 颗粒种类 | 平均粒径/μm | 密度/(kg/m3) | 临界气速/(m/s) | Geldart颗粒类型 |

|---|---|---|---|---|

| 硅砂颗粒 | 140 | 2650 | 0.17 | B类 |

表1 颗粒的物性参数

Table 1 Physical properties of experimental particles

| 颗粒种类 | 平均粒径/μm | 密度/(kg/m3) | 临界气速/(m/s) | Geldart颗粒类型 |

|---|---|---|---|---|

| 硅砂颗粒 | 140 | 2650 | 0.17 | B类 |

| 工质种类 | 质量分数/% | 液体黏度/(mPa·s) | 表面张力/(N/m) | 沸点/℃ |

|---|---|---|---|---|

| 糖水溶液 | 0 | 1.21 | 0.0726 | 101.1 |

| 10 | 2 | 0.0758 | 103.3 | |

| 18 | 3.187 | 0.0840 | 107.2 |

表2 液体的物性参数

Table 2 Physical properties of experimental liquids

| 工质种类 | 质量分数/% | 液体黏度/(mPa·s) | 表面张力/(N/m) | 沸点/℃ |

|---|---|---|---|---|

| 糖水溶液 | 0 | 1.21 | 0.0726 | 101.1 |

| 10 | 2 | 0.0758 | 103.3 | |

| 18 | 3.187 | 0.0840 | 107.2 |

| 采样位置 | 局部自由水分 (Karl Fischer) | 平均自由水分(全床) |

|---|---|---|

| 底部位置(X 1) | 0.00025482 | 0.00027945 |

| 中间位置(X 2) | 0.00024163 | 0.00027945 |

| 顶部位置(X 3) | 0.00023911 | 0.00027699 |

表3 颗粒样本水分含量测定值与真实值比较

Table 3 Comparison between solid moistures of samples by Karl Fischer titration and real bed solid moisture contents

| 采样位置 | 局部自由水分 (Karl Fischer) | 平均自由水分(全床) |

|---|---|---|

| 底部位置(X 1) | 0.00025482 | 0.00027945 |

| 中间位置(X 2) | 0.00024163 | 0.00027945 |

| 顶部位置(X 3) | 0.00023911 | 0.00027699 |

| 喷嘴形式 | 液滴Sauter平均直径/μm | |||||

|---|---|---|---|---|---|---|

| GLR=1% | GLR=1.5% | GLR=2% | GLR=2.5% | GLR=3% | GLR=3.5% | |

| 原始喷嘴 | 104 | 87 | 71 | 63 | 52 | 49 |

| 原始喷嘴+SS | 69 | 55 | 50 | 47 | 42 | 37 |

| 原始喷嘴+AS | 85 | 77 | 60 | 52 | 45 | 40 |

表4 气罩装置对糖水溶液射流Sauter(SMD) 平均直径的影响

Table 4 Effect of nozzle gas shroud attachment on Sauter mean diameter (SMD) of atomized droplets at different liquid concentrations 平均直径的影响

| 喷嘴形式 | 液滴Sauter平均直径/μm | |||||

|---|---|---|---|---|---|---|

| GLR=1% | GLR=1.5% | GLR=2% | GLR=2.5% | GLR=3% | GLR=3.5% | |

| 原始喷嘴 | 104 | 87 | 71 | 63 | 52 | 49 |

| 原始喷嘴+SS | 69 | 55 | 50 | 47 | 42 | 37 |

| 原始喷嘴+AS | 85 | 77 | 60 | 52 | 45 | 40 |

| 1 | 汪燮卿, 舒兴田 . 重质油裂解制轻烯烃[M]. 北京: 中国石化出版社, 2015: 1-10. |

| Wang X Q , Shu X T . Heavy Oil Catalytic Cracking Technology for Production of Light Olefins[M]. Beijing: China Petrochemical Press, 2015: 1-10. | |

| 2 | 张璐瑶, 赵广辉, 刘银东, 等 . 国内外劣质重油脱碳技术进展[J]. 石化技术与应用, 2014, 32(3): 259-265. |

| Zhang L Y , Zhao G H , Liu Y D , et al . Worldwide advance of carbon rejection processes for heavy oil[J]. Petrochemical Technology & Application, 2014, 32(3): 259-265. | |

| 3 | Sheng Q , Wang G , Liu Y J , et al . Pilot-scale evaluation of hydrotreating inferior coker gas oil prior to its fluid catalytic cracking[J]. Fuel, 2018, 226: 27-34. |

| 4 | 李佳, 周如金 . 我国重质油催化裂解制低碳烯烃技术现状[J]. 当代化工, 2015, 44(12): 2802-2804. |

| Li J , Zhou R J . Research progress in heavy oil catalytic cracking technology for production of light olefins[J]. Contemporary Chemical Industry, 2015, 44(12): 2802-2804. | |

| 5 | 曹春燕 . 优化原油加工轻质油收率的探索[D]. 天津: 天津大学, 2012: 1-11. |

| Cao C Y . Exploration in the optimizing of crude oil processing and improving the yield of light oil[D]. Tianjin: Tianjin University, 2012: 1-11. | |

| 6 | 王峰 . MTP工艺副产轻质油在HZSM-5上催化裂解行为的研究[J]. 现代化工, 2018, 38(9): 122-126. |

| Wang F . Catalytic cracking behavior of MTP by-product light oil over HZSM-5 catalyst[J]. Modern Chemical Industry, 2018, 38(9): 122-126. | |

| 7 | 张雅琳, 张占全, 王燕, 等 . 费托合成油和石油基油加工产品对比分析[J]. 化工进展, 2018, 37(10): 3781-3787. |

| Zhang Y L , Zhang Z Q , Wang Y , et al . Comparative analysis of products from Fischer-Tropsch oil and petroleum based oil[J]. Chemical Industry and Engineering Progress, 2018, 37(10): 3781-3787. | |

| 8 | Yang M F , Shao J G , Yang H P , et al . Enhancing the production of light olefins and aromatics from catalytic fast pyrolysis of cellulose in a dual-catalyst fixed bed reactor[J]. Bioresource Technology, 2019, 273: 77-85. |

| 9 | Weber S , Briens C , Berruti F , et al . Stability of agglomerates made from fluid coke at ambient temperature[J]. Powder Technology, 2011, 209: 53-64. |

| 10 | Inagaki S , Matsunaga I , Kikuchi E , et al . 03-P-14—Influence of nano-particle agglomeration on the catalytic properties of MFI zeolite[J]. Studies in Surface Science and Catalysis, 2001, 135: 332. |

| 11 | Mcdougall S , Saberian M , Briens C , et al . Effect of liquid properties on the agglomerating tendency of a wet gas-solid fluidized bed[J]. Powder Technology, 2005, 149(23): 61-67. |

| 12 | Kolkman T , van Sint Annaland M , Kuipers J A M . Development of anon-invasive optical technique to study liquid evaporation in gas-solid fluidized beds[J]. Chemical Engineering Science, 2016, 155, 277-293. |

| 13 | Pore M , Chandrasekera T C , Holland D J , et al . Magnetic resonance studies of jets in a gas-solid fluidised bed[J]. Particuology, 2012, 10(2): 161-169. |

| 14 | Berruti F , Dawe M , Briens C . Study of gas-liquid jet boundaries in a gas-solid fluidized bed[J]. Powder Technology, 2009, 192: 250-259. |

| 15 | McMillan J , Zhou D , Saberian M , et al . Measurement techniques to characterize the contact between injected liquid and circulating solids in a downer mixing chamber[J]. Powder Technology, 2006, 161(3): 175-184. |

| 16 | Leach A , Portoghese F , Briens C , et al . A new and rapid method for the evaluation of the liquid-solid contact resulting from liquid injection into a fluidized bed[J]. Powder Technology, 2008, 184: 44-51. |

| 17 | Portoghese F , Berruti F , Briens C , et al . Novel triboelectric method for characterizing the performance of nozzles injecting gas-atomized liquid into a fluidized bed[J]. Chemical Engineering and Processing: Process Intensification, 2007, 46: 924-934. |

| 18 | House P K , Briens C , Berruti F , et al . Effect of spray nozzle design on liquid-solid contact in fluidized beds[J]. Powder Technology, 2008, 186: 89-98. |

| 19 | Ariyapadi S , Berruti F , Briens C , et al . Stability of horizontal gas-liquid sprays in open-air and in a gas-solid fluidized bed[J]. Powder Technology, 2005, 155(3): 161-174. |

| 20 | McMillan J , Zhou D , Ariyapadi S , et al . Characterization of the contact between liquid spray droplets and particles in a fluidized bed[J]. Industrial and Engineering Chemistry Research, 2005, 44: 4931-4939. |

| 21 | Portoghese F , Berruti F , Briens C . Continuous on-line monitoring of solid moisture content during fluidized bed drying using triboelectric probes[J]. Powder Technology, 2008, 181: 169-177. |

| 22 | House P K , Saberian M , Briens C , et al . Injection of a liquid spray into a fluidized bed: particle-liquid mixing and impact on fluid coker yields[J]. Industrial and Engineering Chemistry Research, 2004, 43: 5663-5669. |

| 23 | Prociw N , Briens C , Berruti F , et al . Effect of spray nozzle attachment geometry on rate of liquid released from agglomerates produced by gas-atomized liquid injection into a fluidized bed[J]. Powder Technology, 2018, 325: 280-288. |

| 24 | Castañeda L C , Muñoz J A D , Ancheyta J . Combined process schemes for upgrading of heavy petroleum [J]. Fuel, 2012, 100: 110-127. |

| 25 | Valle B , Aramburu B , Martin Olazar , et al . Steam reforming of raw bio-oil over Ni/La2O3-αAl2O3: influence of temperature on product yields and catalyst deactivation[J]. Fuel, 2018, 216: 463-474. |

| 26 | Radmanesh R , Chan E R , Gray M . Modeling of mass transfer and thermal cracking during the coking of Athabasca residues[J]. Chemical Engineering Science, 2008, 63(6): 1683-1691. |

| 27 | McDougall S , Saberian M , Briens C , et al . Effect of liquid properties on the agglomerating tendency of a wet gas-solid fluidized bed[J]. Powder Technology, 2005, 149(23): 61-67. |

| 28 | Weber S , Briens C , Berruti F , et al . Effect of agglomerate properties on agglomerate stability in fluidized beds[J]. Chemical Engineering Science, 2008, 63(17): 4245-4256. |

| 29 | 周云龙, 杨宁 . 流化床颗粒团聚物水分分布测量新技术[J]. 化工学报, 2014, 65(10): 3878-3883. |

| Zhou Y L , Yang N . A new method for measuring moisture distribution in fluidized bed[J]. CIESC Journal, 2014, 65(10): 3878-3883. | |

| 30 | Sobrino C , Sánchez-Delgado S , García-Hernando N , et al . Standard deviation of absolute and differential pressure fluctuations in fluidized beds of group B particles[J]. Chemical Engineering Research & Design, 2008, 86: 1236-1242. |

| 31 | Vazquez A , Manasseh R , Sánchez R M , et al . Experimental comparison between acoustic and pressure signals from a bubbling flow[J]. Chemical Engineering Science, 2008, 63(24): 5860-5869. |

| [1] | 刘爽, 张霖宙, 许志明, 赵锁奇. 渣油及其组分黏度的分子层次组成关联研究[J]. 化工学报, 2023, 74(8): 3226-3241. |

| [2] | 杨峥豪, 何臻, 常玉龙, 靳紫恒, 江霞. 生物质快速热解下行式流化床反应器研究进展[J]. 化工学报, 2023, 74(6): 2249-2263. |

| [3] | 陈巨辉, 张谦, 舒崚峰, 李丹, 徐鑫, 刘晓刚, 赵晨希, 曹希峰. 基于DEM方法的旋转流化床纳米颗粒流动特性研究[J]. 化工学报, 2023, 74(6): 2374-2381. |

| [4] | 张媛媛, 曲江源, 苏欣欣, 杨静, 张锴. 循环流化床燃煤机组SNCR脱硝过程气液传质和反应特性[J]. 化工学报, 2023, 74(6): 2404-2415. |

| [5] | 雷博雯, 吴建华, 吴启航. R290低压比热泵高补气过热度循环研究[J]. 化工学报, 2023, 74(5): 1875-1883. |

| [6] | 袁子涵, 王淑彦, 邵宝力, 谢磊, 陈曦, 马一玫. 基于幂律液固曳力模型流化床内湿颗粒流动特性的研究[J]. 化工学报, 2023, 74(5): 2000-2012. |

| [7] | 周必茂, 许世森, 王肖肖, 刘刚, 李小宇, 任永强, 谭厚章. 烧嘴偏转角度对气化炉渣层分布特性的影响[J]. 化工学报, 2023, 74(5): 1939-1949. |

| [8] | 张永泉, 玄伟伟. 碱金属/(FeO+CaO+MgO)对硅酸盐灰熔渣结构和黏度的影响机理[J]. 化工学报, 2023, 74(4): 1764-1771. |

| [9] | 靳志远, 单国荣, 潘鹏举. AM/AMPS/SSS三元共聚物的制备及耐温耐盐性能[J]. 化工学报, 2023, 74(2): 916-923. |

| [10] | 张家庆, 蒋榕培, 史伟康, 武博翔, 杨超, 刘朝晖. 煤基/石油基火箭煤油高参数黏温特性与组分特性研究[J]. 化工学报, 2023, 74(2): 653-665. |

| [11] | 张东旺, 杨海瑞, 周托, 黄中, 李诗媛, 张缦. 生物质锅炉对流受热面积灰冷态模拟实验研究[J]. 化工学报, 2022, 73(8): 3731-3738. |

| [12] | 刘新华, 韩振南, 韩健, 梁斌, 张楠, 胡善伟, 白丁荣, 许光文. 基于热解与燃烧反应重构的低NO x 解耦燃烧原理与技术[J]. 化工学报, 2022, 73(8): 3355-3368. |

| [13] | 王刚, 夏志豪, 李希艳, 张虹, 韩振南, 宋兴飞, 许光文. 不同气氛下流化床菱镁矿轻烧产物特性研究[J]. 化工学报, 2022, 73(8): 3699-3707. |

| [14] | 朱莲峰, 王超, 张梦娟, 刘方正, 贾鑫, 安萍, 许光文, 韩振南. 水蒸气/氧流化床两段煤气化制备低焦油合成气工艺实验[J]. 化工学报, 2022, 73(8): 3720-3730. |

| [15] | 姚翰林, 辛忠. 液相沉淀反应在管式微通道反应器中的流动行为研究[J]. 化工学报, 2022, 73(8): 3518-3528. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号