化工学报 ›› 2023, Vol. 74 ›› Issue (10): 4063-4073.DOI: 10.11949/0438-1157.20230870

收稿日期:2023-08-22

修回日期:2023-10-10

出版日期:2023-10-25

发布日期:2023-12-22

通讯作者:

刘道银

作者简介:刘道银(1982—),男,博士,副教授,dyliu@seu.edu.cn

基金资助:

Daoyin LIU( ), Zhiheng FAN, Jiliang MA, Xiaoping CHEN

), Zhiheng FAN, Jiliang MA, Xiaoping CHEN

Received:2023-08-22

Revised:2023-10-10

Online:2023-10-25

Published:2023-12-22

Contact:

Daoyin LIU

摘要:

通过耦合VOF(volume of fluid)和重叠网格的方法,对表面附着液滴的“颗粒-颗粒”倾斜碰撞进行了直接数值模拟,获得了碰撞过程中液桥演变、颗粒运动、碰撞恢复系数的变化规律。在不同碰撞角度条件下,法向碰撞是液体对碰撞恢复系数影响最显著的情况。随着液体黏度的增加,法向恢复系数和总恢复系数降低,而切向恢复系数略微增加。随着碰撞速度的增加,法向恢复系数和总恢复系数增加,而切向恢复系数降低。在倾斜碰撞中,颗粒的旋转对于颗粒分离具有促进作用,液桥可对颗粒产生剪切作用使得部分切向动能转化为法向动能。研究结果可以为发展湿颗粒碰撞简化模型提供基础数据。

中图分类号:

刘道银, 范志恒, 马吉亮, 陈晓平. 湿颗粒倾斜碰撞恢复系数的直接数值模拟[J]. 化工学报, 2023, 74(10): 4063-4073.

Daoyin LIU, Zhiheng FAN, Jiliang MA, Xiaoping CHEN. Direct numerical simulation of restitution coefficient during oblique collision of wet particles[J]. CIESC Journal, 2023, 74(10): 4063-4073.

| 参数 | 数值 |

|---|---|

| 气体密度/(kg/m3) | 1.225 |

| 气体黏度/(Pa·s) | 1.789×10-5 |

| 液体密度/(kg/m3) | 827 |

| 液体黏度/(Pa·s) | 0.185 |

| 液膜厚度/mm | 2 |

| 表面张力系数/(N/m) | 0.029 |

| 背景区域/mm | 6×6×10 |

| 前景区域/mm | 2.6 |

| 接触角(下落)/(°) | 150 |

| 接触角(返回)/(°) | 30 |

| 干颗粒碰撞恢复系数 | 0.853 |

| Courant数 | 0.12 |

表1 颗粒-液膜平板碰撞的模拟参数

Table 1 Simulation parameters of collision of the particle-plate liquid film case

| 参数 | 数值 |

|---|---|

| 气体密度/(kg/m3) | 1.225 |

| 气体黏度/(Pa·s) | 1.789×10-5 |

| 液体密度/(kg/m3) | 827 |

| 液体黏度/(Pa·s) | 0.185 |

| 液膜厚度/mm | 2 |

| 表面张力系数/(N/m) | 0.029 |

| 背景区域/mm | 6×6×10 |

| 前景区域/mm | 2.6 |

| 接触角(下落)/(°) | 150 |

| 接触角(返回)/(°) | 30 |

| 干颗粒碰撞恢复系数 | 0.853 |

| Courant数 | 0.12 |

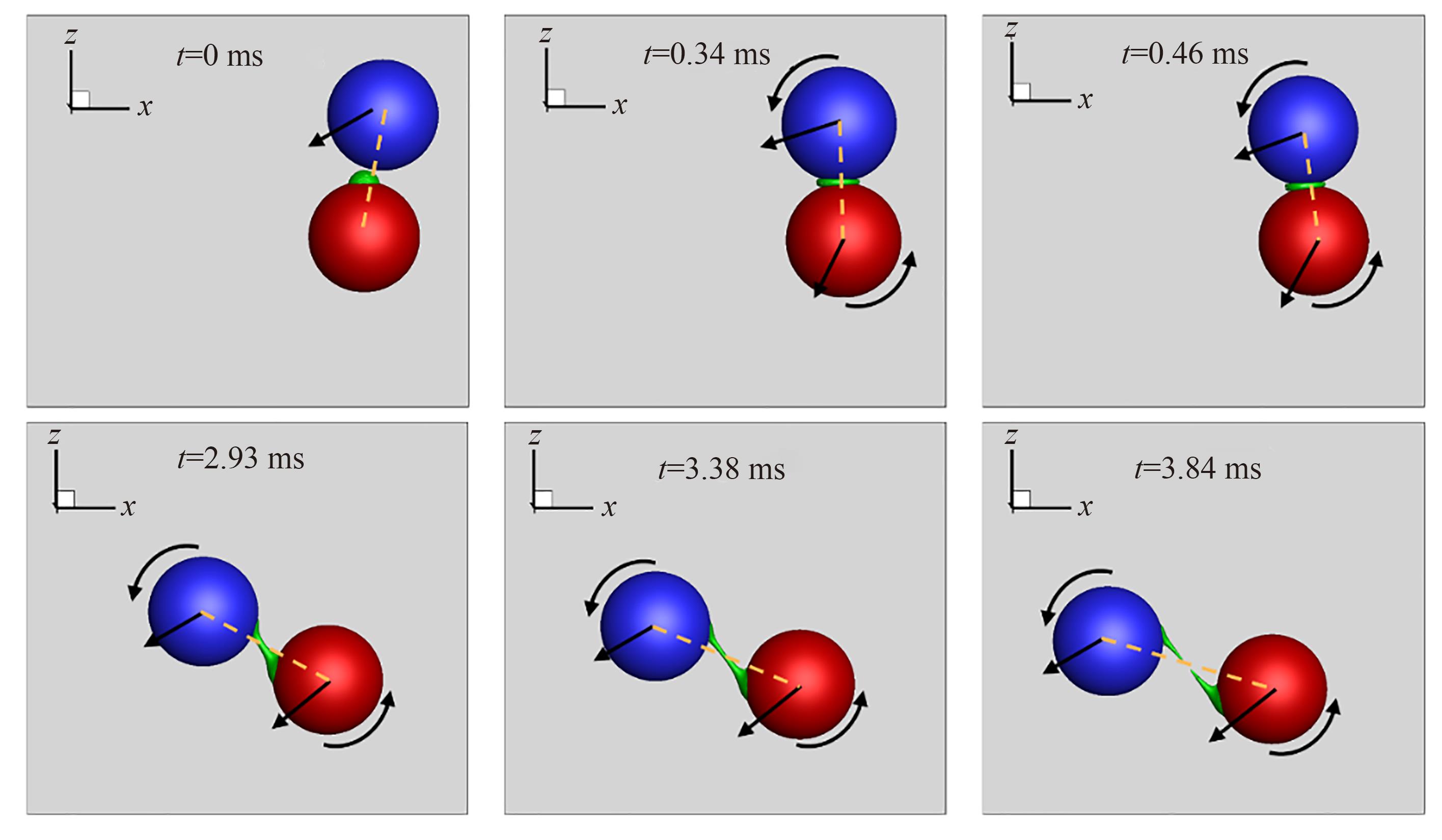

图3 基准工况条件下颗粒和液桥的动态变化(颗粒直径2 mm,液滴直径0.4 mm,液体黏度500 mPa·s,碰撞速度1.5 m/s,碰撞角60°)

Fig.3 Dynamics of particle and liquid bridge during oblique collision at the bench condition (particle diameter 2 mm, droplet diameter 0.4 mm, liquid viscosity 500 mPa·s, collision velocity 1.5 m/s, and collision angle 60°)

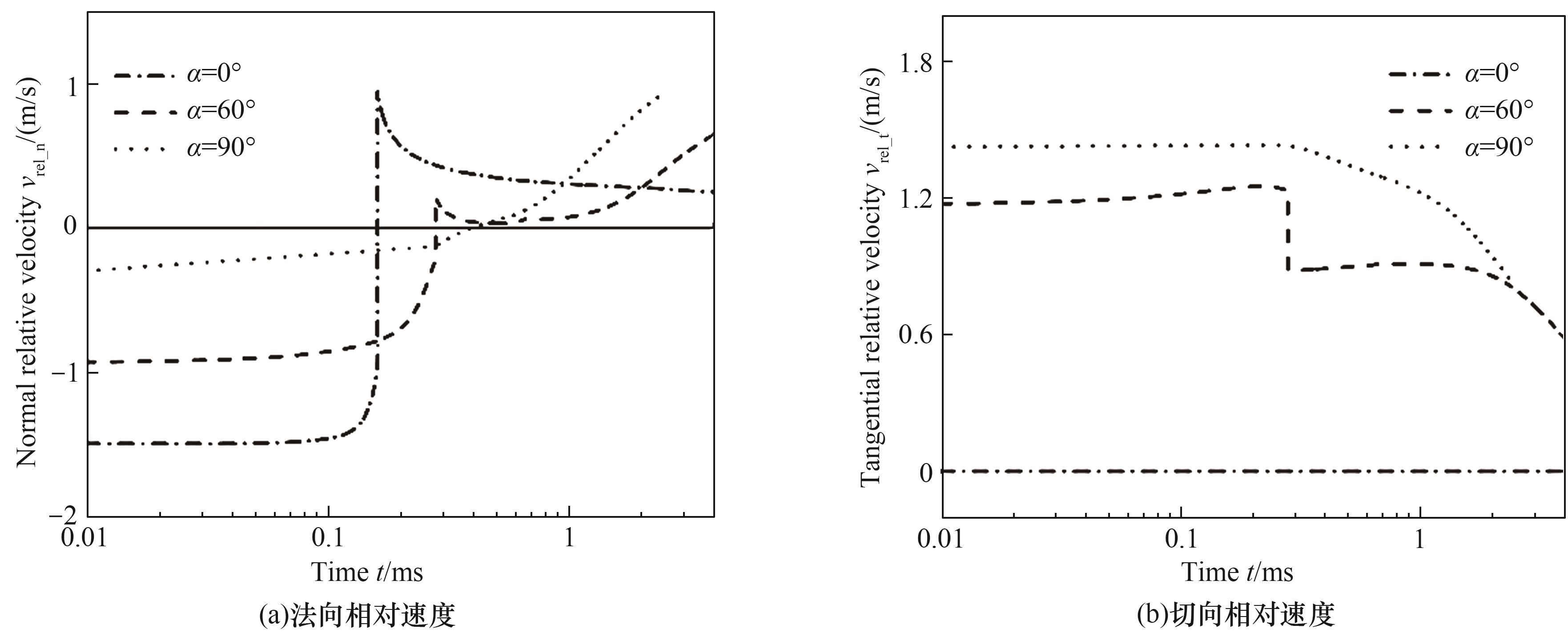

图5 不同碰撞角度下颗粒法向相对速度和切向相对速度随时间的变化(液体黏度500 mPa·s,碰撞速度1.5 m/s)

Fig.5 Variation of particle normal relative velocity and tangential relative velocity with time at different collision angles (liquid viscosity 500 mPa·s and collision velocity 1.5 m/s)

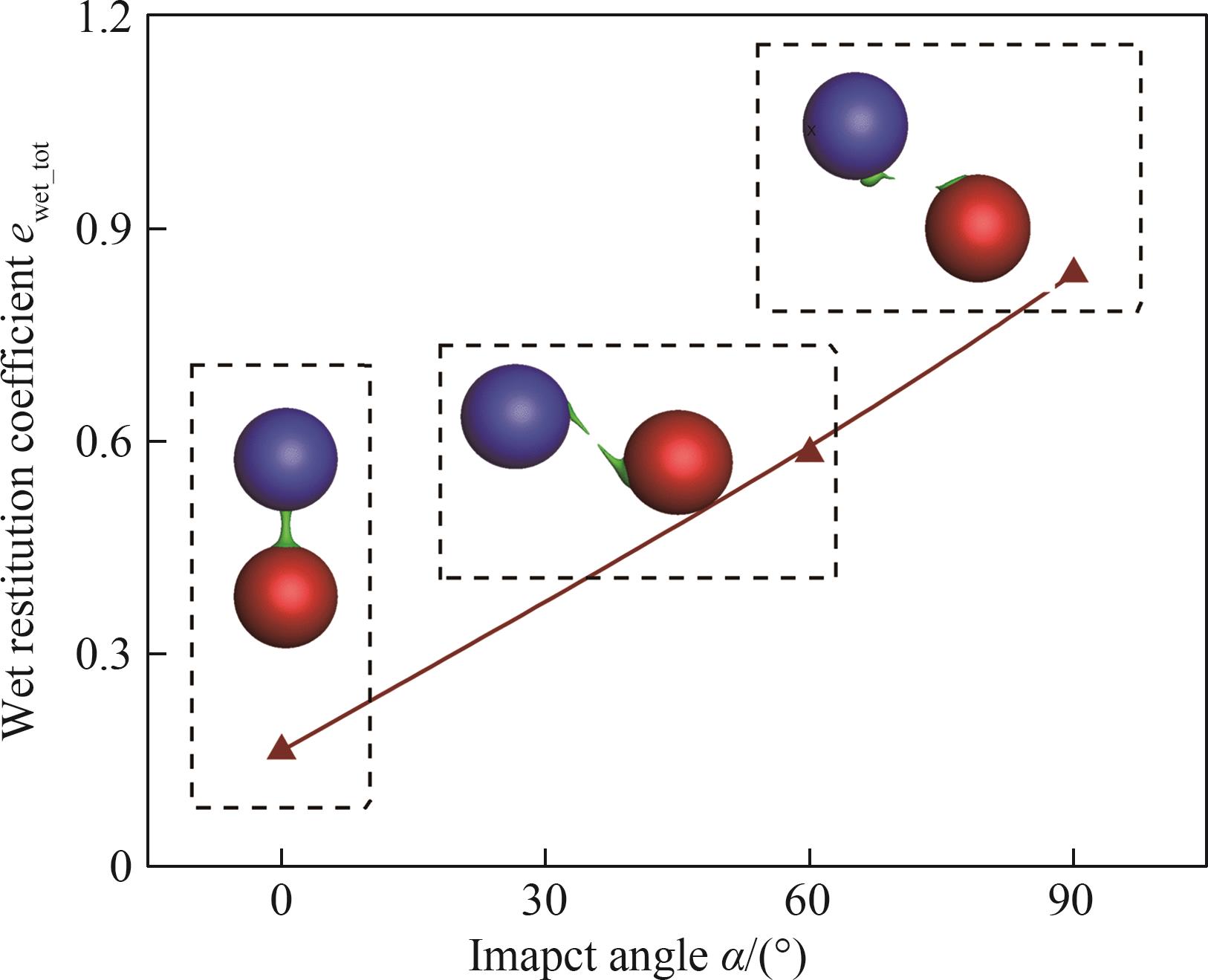

图6 碰撞角对总碰撞恢复系数的影响(液体黏度500 mPa·s,碰撞速度1.5 m/s)

Fig.6 Effects of the collision angle on the total restitution coefficient (liquid viscosity 500 mPa·s and collision velocity 1.5 m/s)

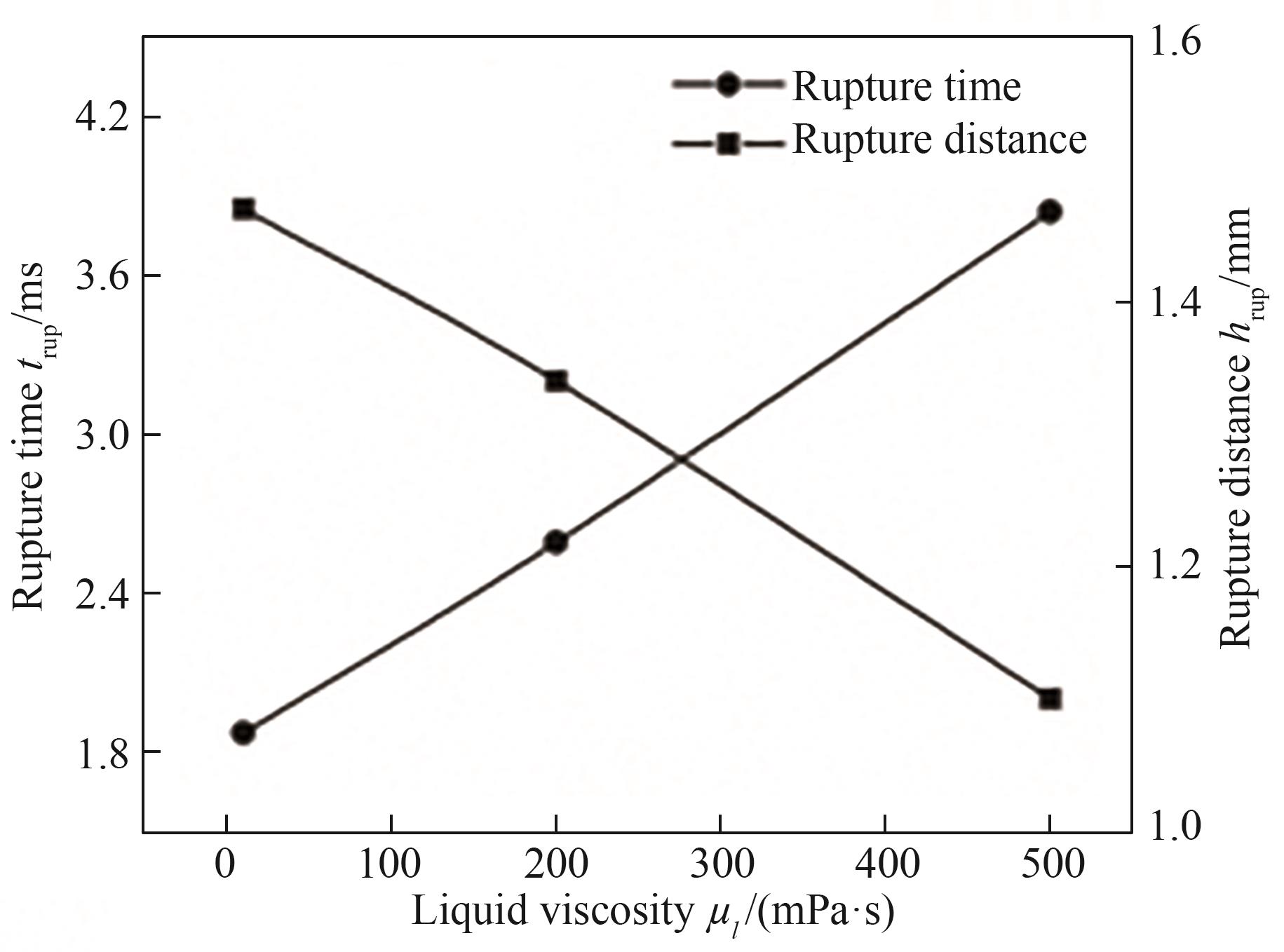

图7 倾斜碰撞中液体黏性对液桥断裂行为的影响 (碰撞速度1.5 m/s,碰撞角60°)

Fig.7 Effects of liquid viscosity on the rupture behavior of liquid bridge during the oblique collision (collision velocity 1.5 m/s and collision angle 60°)

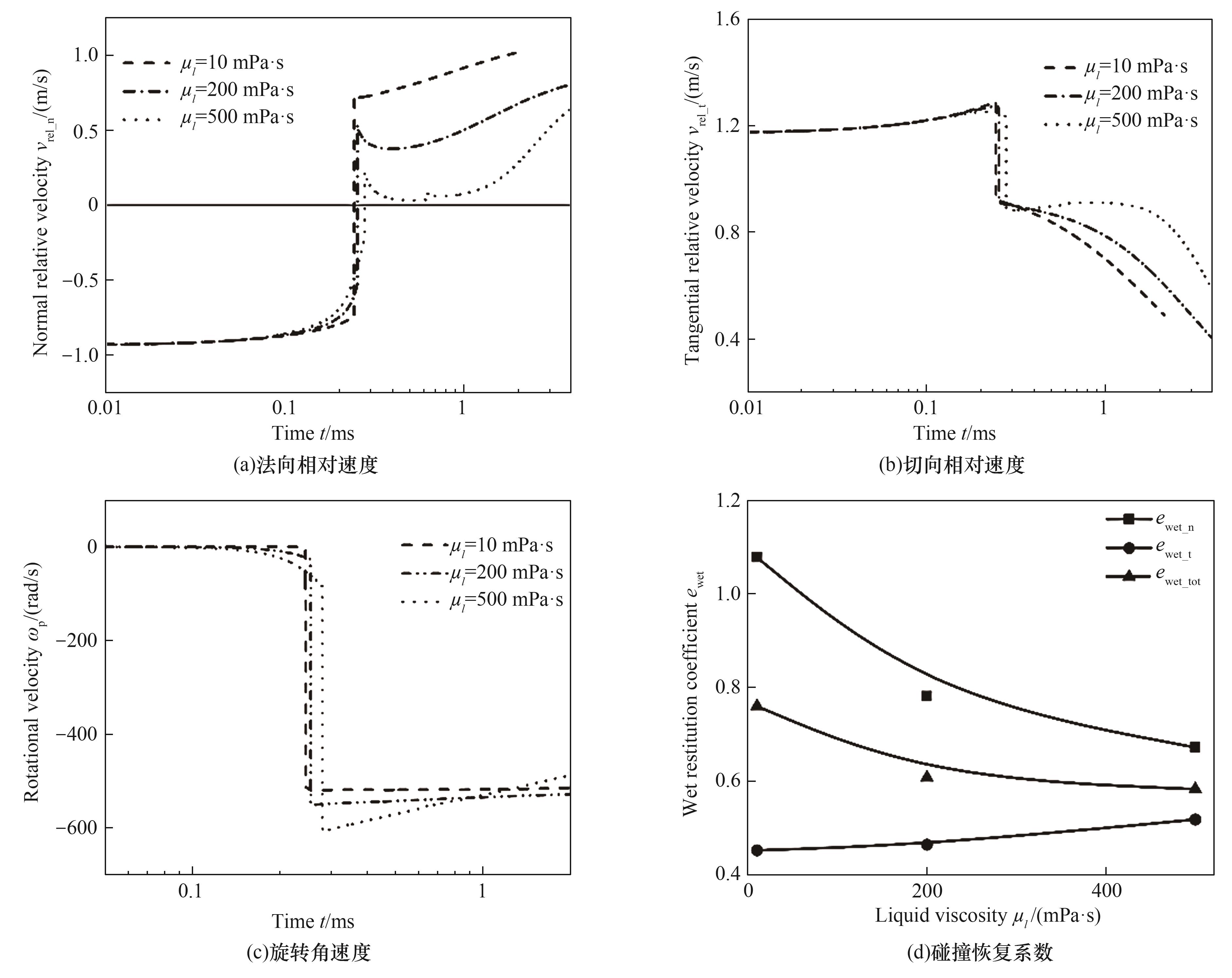

图8 不同液体黏度下倾斜碰撞中颗粒法向相对速度、切向相对速度、旋转角速度随时间的变化及液体黏度对碰撞恢复系数的影响(碰撞速度1.5 m/s,碰撞角60°)

Fig.8 Variation of particle normal relative velocity, tangential relative velocity, and rotational angular velocity with time in oblique collisions with different liquid viscosities and effect of liquid viscosity on the coefficient of restitution (collision velocity 1.5 m/s and collision angle 60°)

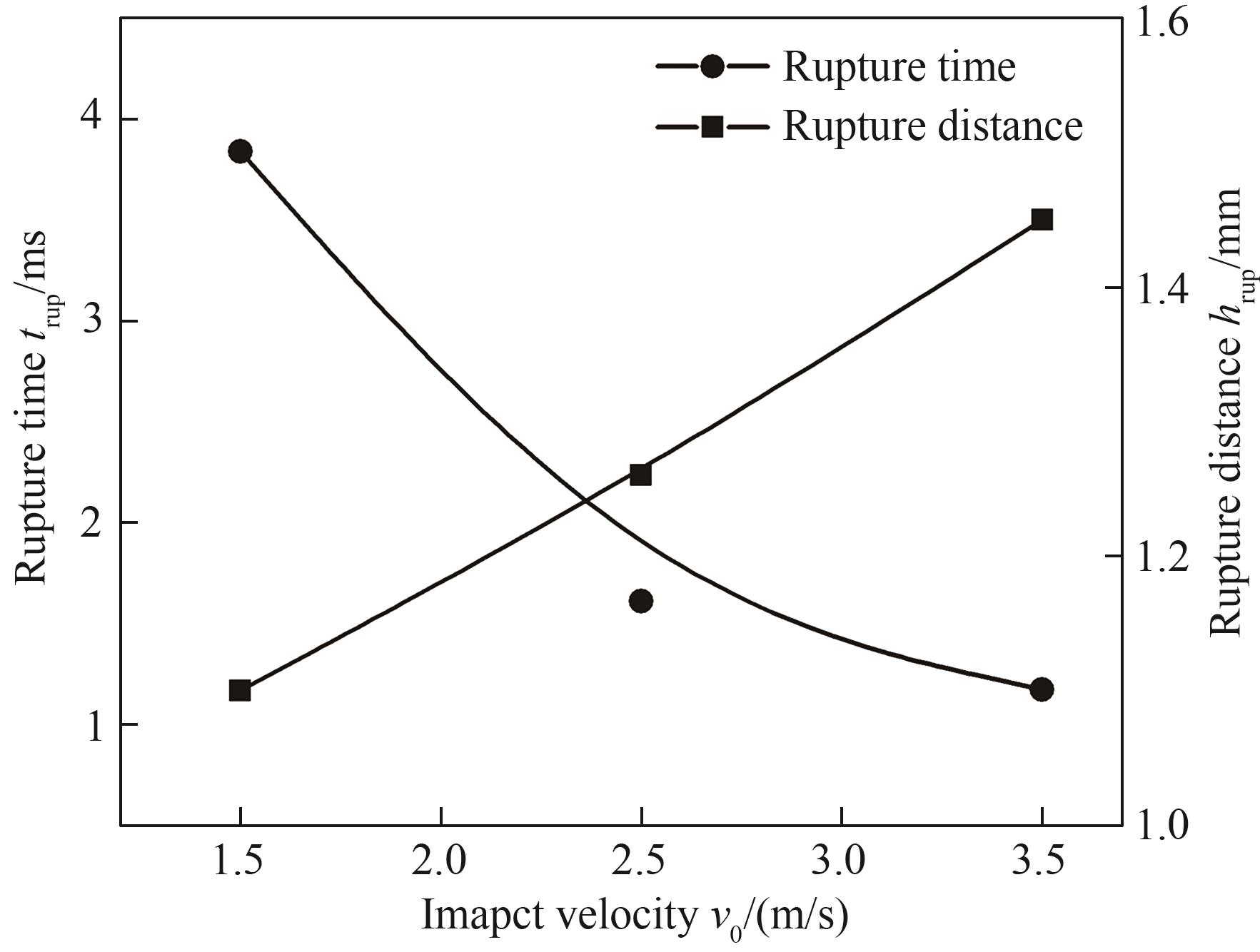

图9 倾斜碰撞中碰撞速度对液桥断裂行为的影响(液体黏度500 mPa·s,碰撞角60°)

Fig.9 Effect of collision velocity on the rupture behavior of liquid bridge during the oblique collision (liquid viscosity 500 mPa·s and collision angle 60°)

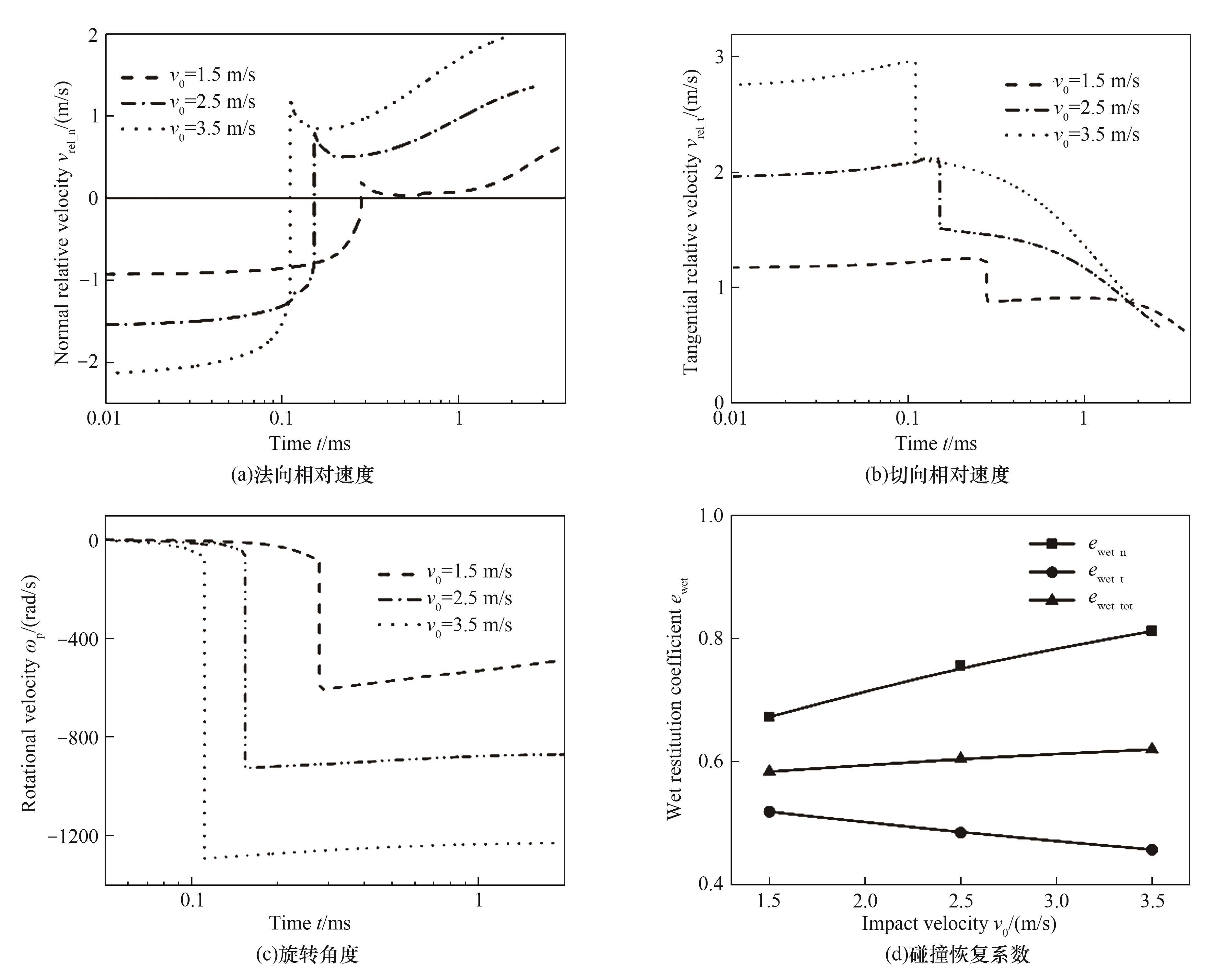

图10 不同碰撞速度下倾斜碰撞中颗粒法向相对速度、切向相对速度、旋转角速度随时间的变化及碰撞速度对碰撞恢复系数的影响(液体黏度500 mPa·s,碰撞角60°)

Fig.10 Variation of particle normal relative velocity, tangential relative velocity, and rotational angular velocity with time in oblique collisions with different collision velocities and effect of collision velocity on the coefficient of restitution (liquid viscosity 500 mPa·s and collision angle 60°)

| 1 | 谢恒来, 吴曼, 赵军, 等. 导向管喷动流化床中废弃印刷线路板的非金属颗粒包覆改性[J]. 化工学报, 2015, 66(3): 1185-1193. |

| Xie H L, Wu M, Zhao J, et al. Coating modification of non-metal particles of waste printed circuit boards in spout-fluid bed with draft tube[J]. CIESC Journal, 2015, 66(3): 1185-1193. | |

| 2 | Wang C, Liu D Y, Ma J L, et al. Characterization of coating shells in a Wurster fluidized bed under different drying conditions and solution viscosities[J]. Powder Technology, 2022, 411: 117914. |

| 3 | 唐天琪, 何玉荣. 磁场对湿颗粒流化床系统中介尺度结构影响机制研究[J]. 化工学报, 2022, 73(6): 2636-2648. |

| Tang T Q, He Y R. Effect of magnetic field on the mesoscale structure evolution process in a wet particle fluidized bed[J]. CIESC Journal, 2022, 73(6): 2636-2648. | |

| 4 | 李雪, 东明, 张璜, 等. 潮湿环境下微尺度颗粒撞击平板的动力学研究[J]. 化工学报, 2022, 73(5): 1940-1946. |

| Li X, Dong M, Zhang H, et al. Kinetic characteristics of micro-particle impact on a flat surface under humidity conditions[J]. CIESC Journal, 2022, 73(5): 1940-1946. | |

| 5 | Wu D L, Zhou P, Wang G, et al. A theoretical study of particle coalescence criteria for inelastic collisions of wet particles[J]. Chemical Engineering Science, 2021, 243: 116770. |

| 6 | 焦杨, 章新喜, 孔凡成, 等. 湿颗粒聚团碰撞解聚过程的离散元法模拟[J]. 物理学报, 2015, 64(15): 328-337. |

| Jiao Y, Zhang X X, Kong F C, et al. Discrete element simulation of impact disaggregation for wet granule agglomerate[J]. Acta Physica Sinica, 2015, 64(15): 328-337. | |

| 7 | Zhuang J D, Ju Y S. A combined experimental and numerical modeling study of the deformation and rupture of axisymmetric liquid bridges under coaxial stretching[J]. Langmuir, 2015, 31(37): 10173-10182. |

| 8 | Xiao F, Jing J Q, Kuang S B, et al. Capillary forces on wet particles with a liquid bridge transition from convex to concave[J]. Powder Technology, 2020, 363: 59-73. |

| 9 | Darabi P, Li T W, Pougatch K, et al. Modeling the evolution and rupture of stretching pendular liquid bridges[J]. Chemical Engineering Science, 2010, 65(15): 4472-4483. |

| 10 | Lian G P, Seville J. The capillary bridge between two spheres: new closed-form equations in a two century old problem[J]. Advances in Colloid and Interface Science, 2016, 227: 53-62. |

| 11 | Di Renzo A, Picarelli G, Di Maio F P. Numerical investigation of funicular liquid bridge interactions between spherical particles[J]. Chemical Engineering & Technology, 2020, 43(5): 830-837. |

| 12 | Sun X S, Sakai M. Direct numerical simulation of gas-solid-liquid flows with capillary effects: an application to liquid bridge forces between spherical particles[J]. Physical Review E, 2016, 94(6): 063301. |

| 13 | Davis R H, Serayssol J M, Hinch E J. The elastohydrodynamic collision of two spheres[J]. Journal of Fluid Mechanics, 1986, 163: 479-497. |

| 14 | Gollwitzer F, Rehberg I, Kruelle C A, et al. Coefficient of restitution for wet particles[J]. Physical Review E, 2012, 86: 011303. |

| 15 | Sutkar V S, Deen N G, Padding J T, et al. A novel approach to determine wet restitution coefficients through a unified correlation and energy analysis[J]. AIChE Journal, 2015, 61(3): 769-779. |

| 16 | Crüger B, Salikov V, Heinrich S, et al. Coefficient of restitution for particles impacting on wet surfaces: an improved experimental approach[J]. Particuology, 2016, 25: 1-9. |

| 17 | Ma J L, Liu D Y, Chen X P. Theoretical model for normal impact between dry sphere and liquid layer with considerable thickness[J]. Aerosol and Air Quality Research, 2016, 16(7): 1533-1540. |

| 18 | Buck B, Heinrich S. Collision dynamics of wet particles: comparison of literature models to new experiments[J]. Advanced Powder Technology, 2019, 30(12): 3241-3252. |

| 19 | Buck B, Lunewski J, Tang Y L, et al. Numerical investigation of collision dynamics of wet particles via force balance[J]. Chemical Engineering Research and Design, 2018, 132: 1143-1159. |

| 20 | Jain D, Deen N G, Kuipers J A M, et al. Direct numerical simulation of particle impact on thin liquid films using a combined volume of fluid and immersed boundary method[J]. Chemical Engineering Science, 2012, 69(1): 530-540. |

| 21 | Antonyuk S, Heinrich S, Deen N, et al. Influence of liquid layers on energy absorption during particle impact[J]. Particuology, 2009, 7(4): 245-259. |

| 22 | Tang Y L, Kuipers J A M H, Buck B, et al. Interface-resolved simulations of normal collisions of spheres on a wet surface[J]. AIChE Journal, 2017, 63(11): 4774-4787. |

| 23 | Kan H, Nakamura H, Watano S. Numerical simulation of particle-particle adhesion by dynamic liquid bridge[J]. Chemical Engineering Science, 2015, 138: 607-615. |

| 24 | Ennis B J, Tardos G, Pfeffer R. A microlevel-based characterization of granulation phenomena[J]. Powder Technology, 1991, 65(1): 257-272. |

| 25 | Kan H, Nakamura H, Watano S. Effect of droplet size on particle-particle adhesion of colliding particles through droplet[J]. Powder Technology, 2017, 321: 318-325. |

| 26 | Shao L L, Liu D Y, Ma J L, et al. Normal collision between partially wetted particles by using direct numerical simulation[J]. Chemical Engineering Science, 2022, 247: 117090. |

| 27 | Donahue C M, Davis R H, Kantak A A, et al. Mechanisms for agglomeration and deagglomeration following oblique collisions of wet particles[J]. Physical Review E, 2012, 86(2): 021303. |

| 28 | Davis R H, Sitison J W. Oblique collisions of two wetted spheres[J]. Physical Review Fluids, 2020, 5(5): 054305. |

| 29 | Punch O, Danczyk M, Hawken M, et al. A comparison of pendulum experiments and discrete-element simulations of oblique collisions of wet spheres[J]. AIChE Journal, 2023, 69(3): 17989. |

| 30 | Hirt C W, Nichols B D. Volume of fluid (VOF) method for the dynamics of free boundaries[J]. Journal of Computational Physics, 1981, 39(1): 201-225. |

| 31 | Brackbill J U, Kothe D B, Zemach C. A continuum method for modeling surface tension[J]. Journal of Computational Physics, 1992, 100(2): 335-354. |

| 32 | Crowe C, Schwarzkopf J, Sommerfeld M, et al. Multiphase Flow with Droplets and Particles[M]. Boca Raton: CRC Press, 2012. |

| 33 | Ma J L, Liu D Y, Chen X P. Normal and oblique impacts between smooth spheres and liquid layers: liquid bridge and restitution coefficient[J]. Powder Technology, 2016, 301: 747-759. |

| 34 | Marshall J S, Li S Q. Adhesive Particle Flow: A Discrete-Element Approach[M]. Cambridge: Cambridge University Press, 2014. |

| [1] | 叶展羽, 山訸, 徐震原. 用于太阳能蒸发的折纸式蒸发器性能仿真[J]. 化工学报, 2023, 74(S1): 132-140. |

| [2] | 张义飞, 刘舫辰, 张双星, 杜文静. 超临界二氧化碳用印刷电路板式换热器性能分析[J]. 化工学报, 2023, 74(S1): 183-190. |

| [3] | 王志国, 薛孟, 董芋双, 张田震, 秦晓凯, 韩强. 基于裂隙粗糙性表征方法的地热岩体热流耦合数值模拟与分析[J]. 化工学报, 2023, 74(S1): 223-234. |

| [4] | 宋嘉豪, 王文. 斯特林发动机与高温热管耦合运行特性研究[J]. 化工学报, 2023, 74(S1): 287-294. |

| [5] | 张思雨, 殷勇高, 贾鹏琦, 叶威. 双U型地埋管群跨季节蓄热特性研究[J]. 化工学报, 2023, 74(S1): 295-301. |

| [6] | 何松, 刘乔迈, 谢广烁, 王斯民, 肖娟. 高浓度水煤浆管道气膜减阻两相流模拟及代理辅助优化[J]. 化工学报, 2023, 74(9): 3766-3774. |

| [7] | 邢雷, 苗春雨, 蒋明虎, 赵立新, 李新亚. 井下微型气液旋流分离器优化设计与性能分析[J]. 化工学报, 2023, 74(8): 3394-3406. |

| [8] | 程小松, 殷勇高, 车春文. 不同工质在溶液除湿真空再生系统中的性能对比[J]. 化工学报, 2023, 74(8): 3494-3501. |

| [9] | 刘文竹, 云和明, 王宝雪, 胡明哲, 仲崇龙. 基于场协同和 耗散的微通道拓扑优化研究[J]. 化工学报, 2023, 74(8): 3329-3341. 耗散的微通道拓扑优化研究[J]. 化工学报, 2023, 74(8): 3329-3341. |

| [10] | 洪瑞, 袁宝强, 杜文静. 垂直上升管内超临界二氧化碳传热恶化机理分析[J]. 化工学报, 2023, 74(8): 3309-3319. |

| [11] | 韩晨, 司徒友珉, 朱斌, 许建良, 郭晓镭, 刘海峰. 协同处理废液的多喷嘴粉煤气化炉内反应流动研究[J]. 化工学报, 2023, 74(8): 3266-3278. |

| [12] | 黄可欣, 李彤, 李桉琦, 林梅. 加装旋转叶轮T型通道流场的模态分解[J]. 化工学报, 2023, 74(7): 2848-2857. |

| [13] | 史方哲, 甘云华. 超薄热管启动特性和传热性能数值模拟[J]. 化工学报, 2023, 74(7): 2814-2823. |

| [14] | 江锦波, 彭新, 许文烜, 门日秀, 刘畅, 彭旭东. 泵出型螺旋槽油气密封泄漏特性及参数影响研究[J]. 化工学报, 2023, 74(6): 2538-2554. |

| [15] | 杨峥豪, 何臻, 常玉龙, 靳紫恒, 江霞. 生物质快速热解下行式流化床反应器研究进展[J]. 化工学报, 2023, 74(6): 2249-2263. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号