化工学报 ›› 2025, Vol. 76 ›› Issue (3): 1006-1017.DOI: 10.11949/0438-1157.20240862

收稿日期:2024-07-29

修回日期:2024-09-11

出版日期:2025-03-25

发布日期:2025-03-28

通讯作者:

屈健

作者简介:孙芹(1990—),女,博士,讲师,sunqin@ujs.edu.cn

基金资助:

Qin SUN( ), Guoqing ZHOU, Wanling ZHAI, Shan GAO, Qianqian LUO, Jian QU(

), Guoqing ZHOU, Wanling ZHAI, Shan GAO, Qianqian LUO, Jian QU( )

)

Received:2024-07-29

Revised:2024-09-11

Online:2025-03-25

Published:2025-03-28

Contact:

Jian QU

摘要:

借助湿刻技术在合金铜材上制作了传统蛇形结构和拓扑结构平板脉动热管,以R141b为工质,比较了上述两种热管在局部加热(加热面积15 mm×15 mm,20 mm×20 mm和25 mm×25 mm)情况下的启动与传热性能差异及变化规律。实验结果表明,传统型和拓扑型脉动热管的启动和传热性能均随着局部加热面积的增大而增强。相比于传统平板脉动热管,拓扑优化设计能够将热管通道集中分布在局部热源内,有效增大加热段蒸发/沸腾区域的面积,从而弱化热源面积对其启动和传热性能的影响。传统型脉动热管在多局部热源加热条件下的启动可分为“突变”和“平缓变化”两种方式,与单一均匀热源加热的启动方式相似,但拓扑型脉动热管在所有工况下的启动过程中均无温度突变行为。拓扑结构设计能够有效提高热管整体的均温性和传热极限,尤其是可以改善较小热源面积和中低加热功率下脉动热管的传热性能,在热源面积为15 mm×15 mm和加热功率约为75 W时,其有效热导率比传统热管提高约41.8%。具有拓扑优化通道的脉动热管能够弥补传统脉动热管在局部多热源散热应用中的不足,并表现出良好的均温性和传热极限,从而拓宽脉动热管的应用领域。

中图分类号:

孙芹, 周国庆, 翟万领, 高山, 罗倩倩, 屈健. 局部多热源下拓扑优化通道平板脉动热管的传热特性[J]. 化工学报, 2025, 76(3): 1006-1017.

Qin SUN, Guoqing ZHOU, Wanling ZHAI, Shan GAO, Qianqian LUO, Jian QU. Heat transfer characteristics of topology optimized channel flat-plate pulsating heat pipe under local multiple heat sources[J]. CIESC Journal, 2025, 76(3): 1006-1017.

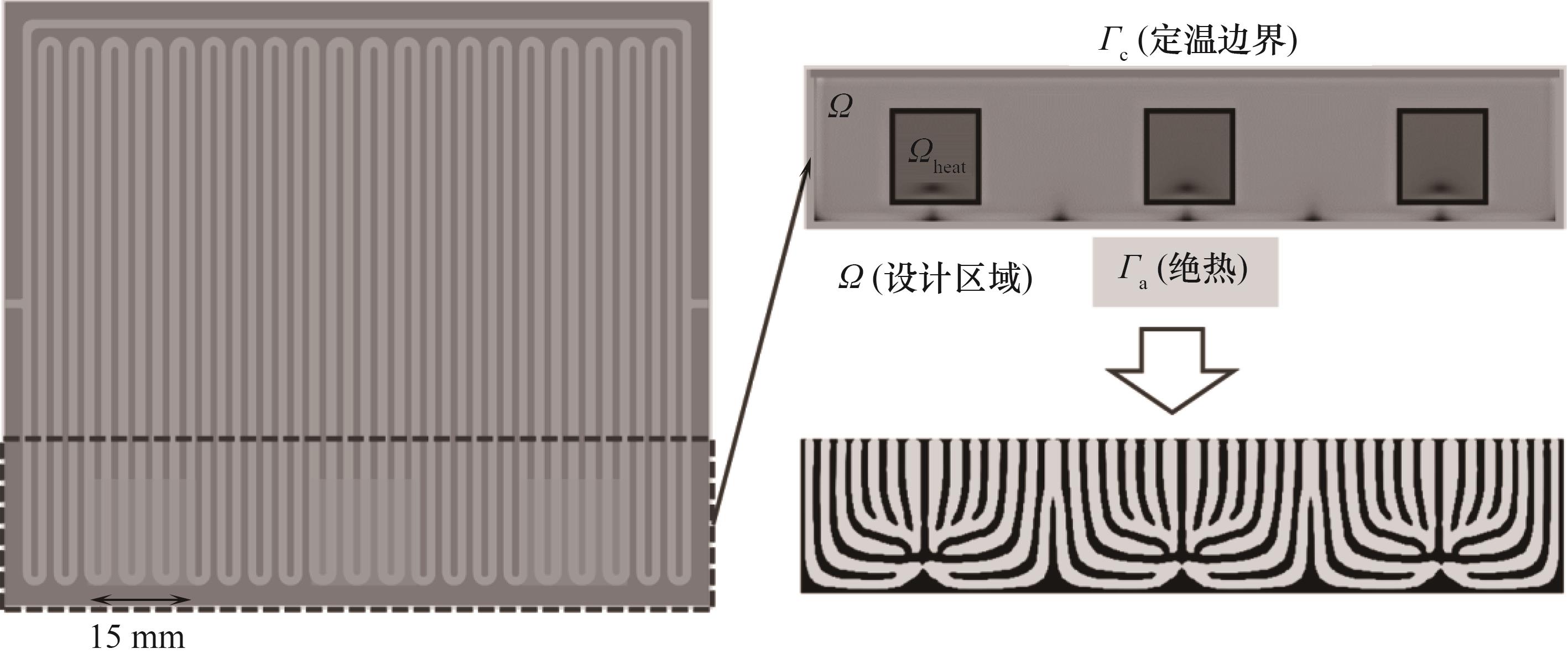

图4 三热源平板脉动热管传统通道布局和拓扑优化设计域示意图

Fig.4 Schematic diagram of traditional channel layout and topology optimization design domain of a flat plate OHP with three heat sources

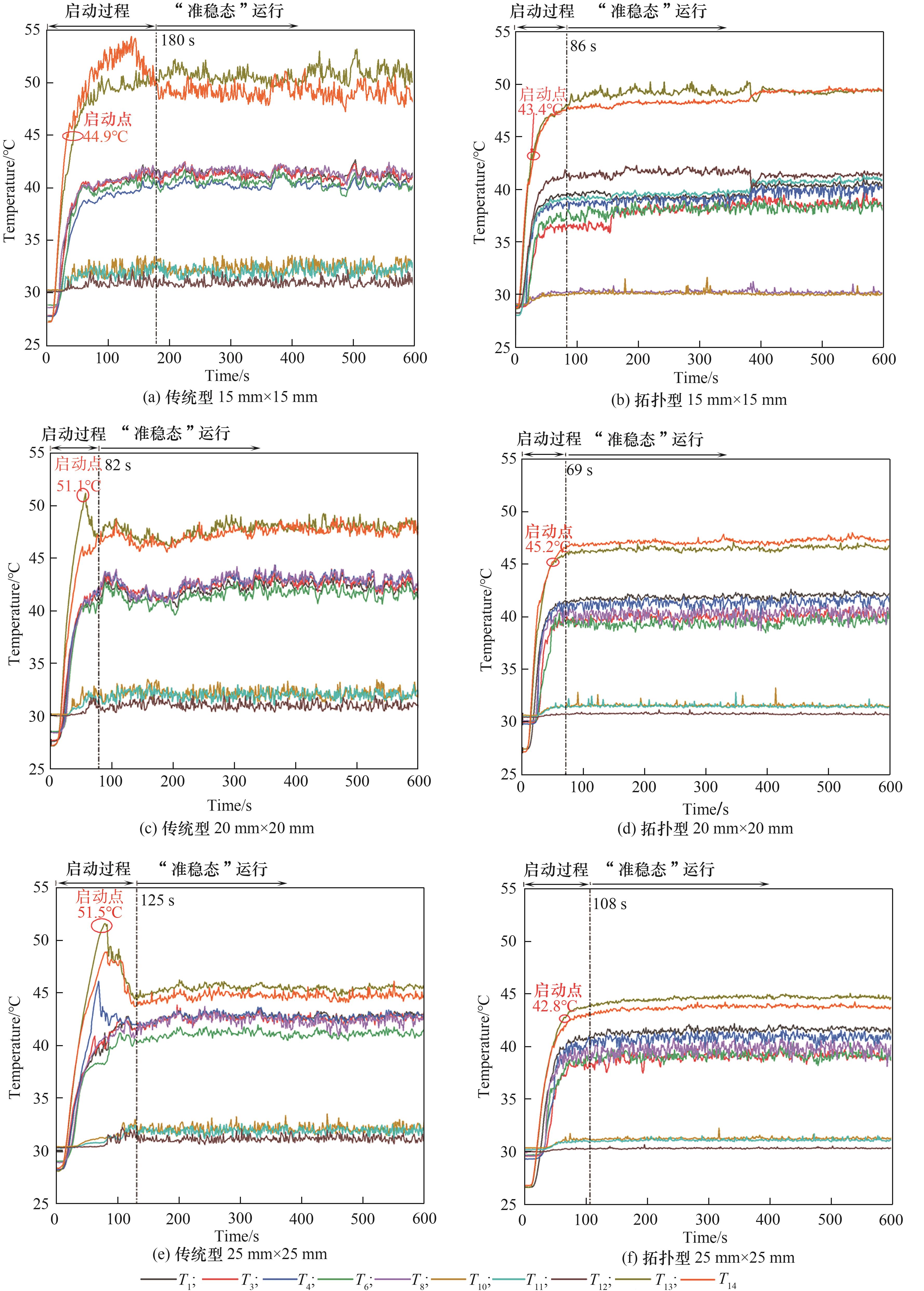

图7 加热功率约为45 W时热源面积对传统和拓扑结构脉动热管冷热段温度变化的影响

Fig.7 Effect of heat source area on the temperature variation of traditional and topologically structured OHPs at a heating power of approximately 45 W

图8 加热功率约为90 W时,传统和拓扑结构脉动热管在热源面积为20 mm×20 mm下冷热段温度变化

Fig.8 Temperature variation of traditional and topologically structured OHPs with a heat source area of 20 mm × 20 mm at a heating power of approximately 90 W

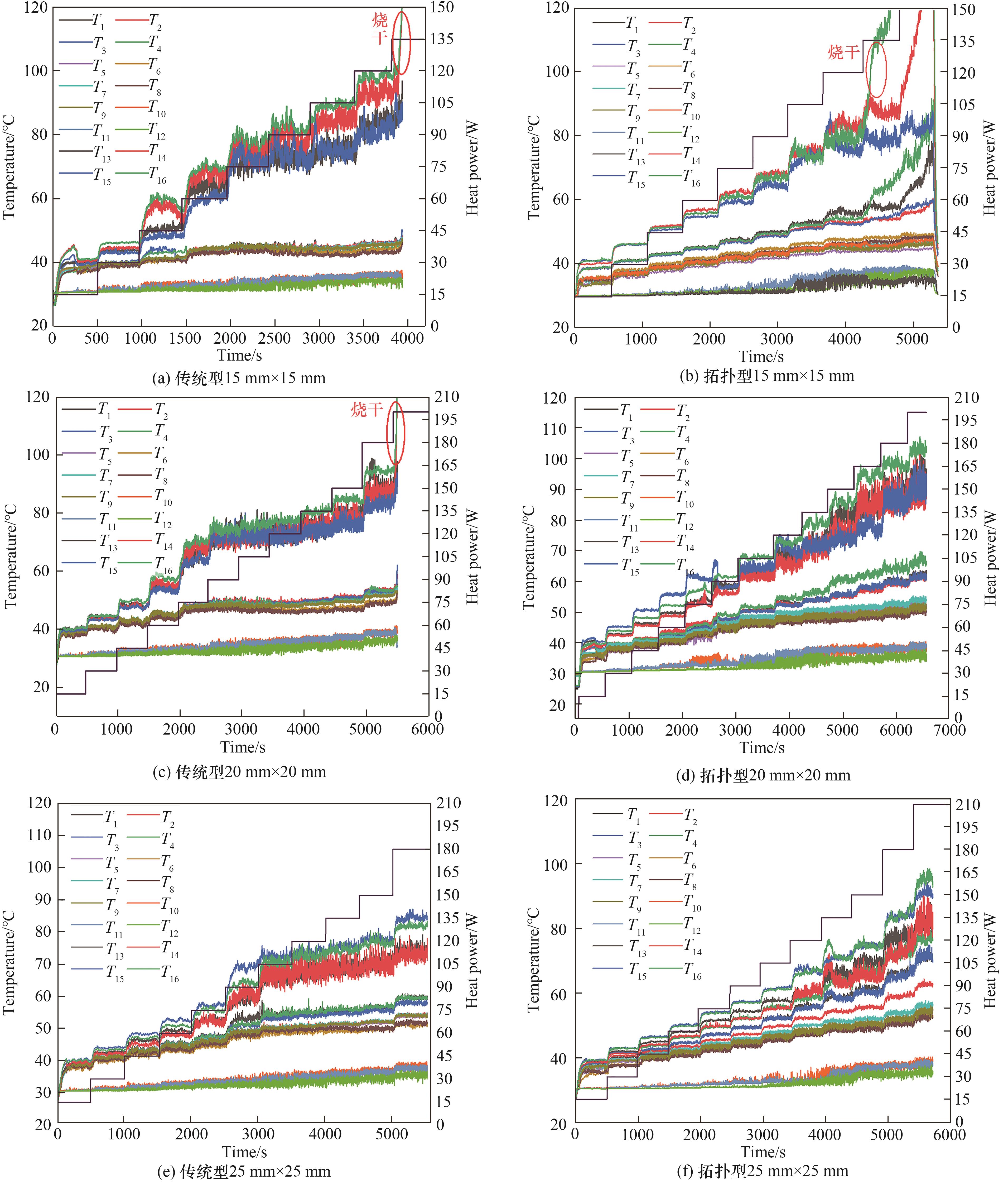

图9 竖直放置时传统和拓扑结构平板脉动热管冷热段壁面温度随加热功率的变化

Fig.9 Variation of the wall temperature of traditional and topologically structured flat plate OHPs with heating power in the vertical orientation

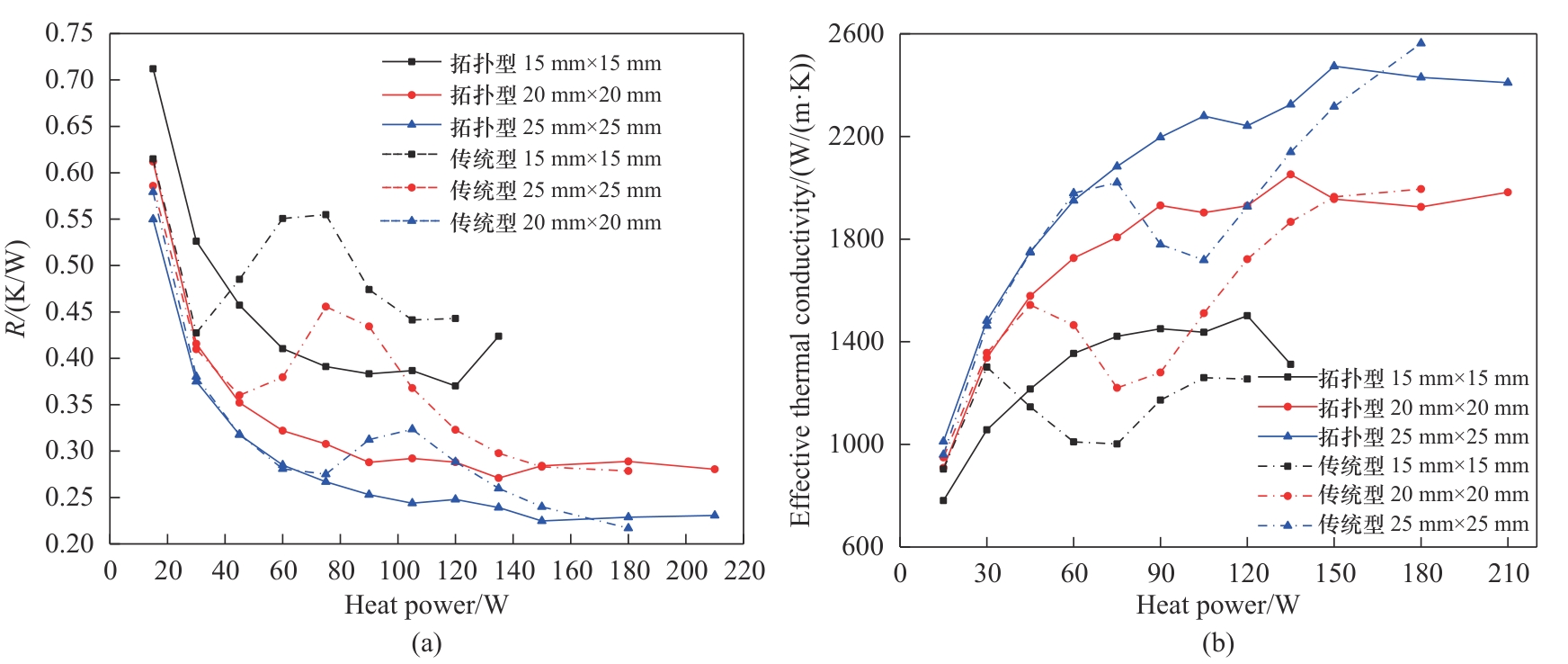

图10 不同热源面积下传统型和拓扑型脉动热管热阻(a)和等效热导率(b)随加热功率的变化情况

Fig.10 Variation of thermal resistance (a) and effective thermal conductivity (b) of traditional and topologically structured OHPs with heating power under different heat source areas

| 1 | Cho J, Goodson K E. Cool electronics[J]. Nature Materials, 2015, 14(2): 136-137. |

| 2 | Chu R C, Simons R E, Iyengar M, et al. Thermal management of flip chip packages[M]//Advanced Flip Chip Packaging. Boston, MA: Springer US, 2013: 413-469. |

| 3 | Aglawe K R, Yadav R K, Thool S B. Current technologies on electronics cooling and scope for further improvement: a typical review[M]//Lecture Notes on Multidisciplinary Industrial Engineering. Cham: Springer International Publishing, 2021: 389-408. |

| 4 | Charoensawan P, Khandekar S, Groll M, et al. Closed loop pulsating heat pipes[J]. Applied Thermal Engineering, 2003, 23(16): 2009-2020. |

| 5 | Nikolayev V S. Physical principles and state-of-the-art of modeling of the pulsating heat pipe: a review[J]. Applied Thermal Engineering, 2021, 195: 117111. |

| 6 | Ayel V, Slobodeniuk M, Bertossi R, et al. Flat plate pulsating heat pipes: a review on the thermohydraulic principles, thermal performances and open issues[J]. Applied Thermal Engineering, 2021, 197: 117200. |

| 7 | Han X H, Wang X H, Zheng H C, et al. Review of the development of pulsating heat pipe for heat dissipation[J]. Renewable and Sustainable Energy Reviews, 2016, 59: 692-709. |

| 8 | Jang D S, Kim D, Hong S H, et al. Comparative thermal performance evaluation between ultrathin flat plate pulsating heat pipe and graphite sheet for mobile electronic devices at various operating conditions[J]. Applied Thermal Engineering, 2019, 149: 1427-1434. |

| 9 | Dreiling R, Zimmermann S, Reibstirn M, et al. Experimental operating range evaluation of flat-plate pulsating heat pipes for high-heat flux automotive power electronics cooling[J]. Applied Thermal Engineering, 2023, 226: 120338. |

| 10 | 李新泽, 张双星, 杨洪海, 等. 基于电池冷却用新型脉动热管性能的实验研究[J]. 化工学报, 2024, 75(6): 2222-2232. |

| Li X Z, Zhang S X, Yang H H, et al. Experimental study on performance of new type of pulsating heat pipe for battery cooling[J]. CIESC Journal, 2024, 75(6): 2222-2232. | |

| 11 | Hao T T, Ma X H, Lan Z, et al. Effects of hydrophilic surface on heat transfer performance and oscillating motion for an oscillating heat pipe[J]. International Journal of Heat and Mass Transfer, 2014, 72: 50-65. |

| 12 | Qu J, Guan F B, Lv Y J, et al. Experimental study on the heat transport capability of micro-grooved oscillating heat pipe[J]. Case Studies in Thermal Engineering, 2021, 26: 101210. |

| 13 | Xu Y Y, Xue Y Q, Qi H, et al. An updated review on working fluids, operation mechanisms, and applications of pulsating heat pipes[J]. Renewable and Sustainable Energy Reviews, 2021, 144: 110995. |

| 14 | 赵佳腾, 吴晨辉, 戴宇成, 等. 脉动热管强化传热及其应用研究进展[J]. 化工学报, 2022, 73(2): 535-565. |

| Zhao J T, Wu C H, Dai Y C, et al. Research progress on heat transfer enhancement and application of oscillating heat pipe[J]. CIESC Journal, 2022, 73(2): 535-565. | |

| 15 | Su Z P, Hu Y X, Zheng S B, et al. Recent advances in visualization of pulsating heat pipes: a review[J]. Applied Thermal Engineering, 2023, 221: 119867. |

| 16 | Kammuang-Lue N, Sakulchangsatjatai P, Terdtoon P. Effect of working fluids and internal diameters on thermal performance of vertical and horizontal closed-loop pulsating heat pipes with multiple heat sources[J]. Thermal Science, 2016, 20(1): 77-87. |

| 17 | Kammuang-Lue N, Sakulchangsatjatai P, Terdtoon P. Thermal performance of a closed-loop pulsating heat pipe with multiple heat sources[J]. Heat Transfer Engineering, 2014, 35(13): 1161-1172. |

| 18 | 谢付波. 几何结构和多热源场对脉动热管流动与传热性能影响的数值研究[D]. 合肥: 中国科学技术大学, 2020. |

| Xie F B. Numerical study on the effect of geometry and multisource heat input on flow and heat transfer in single closed-loop pulsating heat pipe[D]. Hefei: University of Science and Technology of China, 2020. | |

| 19 | Thompson S M, Ma H B. Effect of localized heating on three-dimensional flat-plate oscillating heat pipe[J]. Advances in Mechanical Engineering, 2010, 2: 465153. |

| 20 | 刘凌波. 多热源驱动气液振荡相变热沉内流动与传热特性研究[D]. 扬州: 扬州大学, 2022. |

| Liu L B. Study on flow and heat transfer characteristics of gas-liquid oscillation phase change heat sink driven by multiple heat sources[D]. Yangzhou: Yangzhou University, 2022. | |

| 21 | Liu X D, Chen X, Zhang Z W, et al. Thermal performance of a novel dual-serpentine-channel flat-plate oscillating heat pipe used for multiple heat sources and sinks[J]. International Journal of Heat and Mass Transfer, 2020, 161: 120293. |

| 22 | Chen X, Liu X D, Xu D H, et al. Thermal performance of a tandem-dual-channel flat-plate pulsating heat pipe applicable to hypergravity[J]. International Journal of Heat and Mass Transfer, 2022, 189: 122656. |

| 23 | 邹惠芬, 陈日, 刘超翔. 非均匀加热对平板脉动热管传热性能影响的实验研究[C]// 第二十届沈阳科学学术年会. 沈阳, 2023. |

| Zou H F, Chen R, Liu C X. An experimental study on the influence of non-uniform heating on the heat transfer performance of flat pulsating heat pipe[C]//Proceedings of the 20th Shenyang Annual Scientific Conference. Shenyang, 2023. | |

| 24 | Lim J, Kim S J. Effect of a channel layout on the thermal performance of a flat plate micro pulsating heat pipe under the local heating condition[J]. International Journal of Heat and Mass Transfer, 2019, 137: 1232-1240. |

| 25 | Kelly B, Hayashi Y, Kim Y J. Novel radial pulsating heat-pipe for high heat-flux thermal spreading[J]. International Journal of Heat and Mass Transfer, 2018, 121: 97-106. |

| 26 | Lim J, Kim S J. A channel layout of a micro pulsating heat pipe for an excessively localized heating condition[J]. Applied Thermal Engineering, 2021, 196: 117266. |

| 27 | 屈健, 周国庆, 李子昂, 等. 一种平板脉动热管通道的拓扑优化设计方法: 116992721A[P]. 2023-11-03. |

| Qu J, Zhou G Q, Li Z A, et al. A topology optimization method for the flat plate pulsating heat pipe: 116992721A[P]. 2023-11-03. | |

| 28 | Sun Q, Qu J, Yuan J P, et al. Start-up characteristics of MEMS-based micro oscillating heat pipe with and without bubble nucleation[J]. International Journal of Heat and Mass Transfer, 2018, 122: 515-528. |

| 29 | Qu J, Lv Y J, Zhou G Q, et al. Performance characteristics of ultra-thin flat plate oscillating heat pipes with alternate channels and auxiliary micro-grooved structures[J]. International Communications in Heat and Mass Transfer, 2024, 157: 107738. |

| 30 | Bendsøe M P, Sigmund O. Material interpolation schemes in topology optimization[J]. Archive of Applied Mechanics, 1999, 69(9): 635-654. |

| 31 | Hughes T J R. The Finite Element Method: Linear Static and Dynamic Finite Element Analysis[M]. New York: Dover Publication, 2000. |

| 32 | Svanberg K. The method of moving asymptotes—a new method for structural optimization[J]. International Journal for Numerical Methods in Engineering, 1987, 24(2): 359-373. |

| 33 | Xu J L, Zhang X M. Start-up and steady thermal oscillation of a pulsating heat pipe[J]. Heat and Mass Transfer, 2005, 41(8): 685-694. |

| [1] | 田浩辰, 马志先, 王之浩. R1234ze(E)水平三维肋管外膜状凝结特性实验研究[J]. 化工学报, 2025, 76(3): 975-984. |

| [2] | 齐珂, 王迪, 谢喆, 陈东升, 周云龙, 孙灵芳. 考虑多物理场耦合特性的固体氧化物燃料电池瞬态特性研究[J]. 化工学报, 2025, 76(3): 1264-1274. |

| [3] | 张亦鸣, 杨鹏, 纪献兵, 任纪星, 张磊, 苗政. 多回路平板式环路热管热性能[J]. 化工学报, 2025, 76(3): 1018-1028. |

| [4] | 李科, 忻碧平, 文键. 液氢储罐中耦合蒸气冷却屏的连续变密度多层绝热的序列二次规划优化[J]. 化工学报, 2025, 76(3): 985-994. |

| [5] | 禹言芳, 张埔瑜, 孟辉波, 孙雯, 李雯, 乔文龙, 张梦琼. 仿生海螺型静态混合器传热与湍流脉动特性实验研究[J]. 化工学报, 2025, 76(3): 1040-1049. |

| [6] | 张先开, 王博宇, 郭亚丽, 沈胜强. 水平圆管降膜蒸发式冷凝器热力性能计算分析[J]. 化工学报, 2025, 76(3): 995-1005. |

| [7] | 陈晗, 蔡畅, 刘红, 尹洪超. 正戊醇添加剂强化喷雾冷却传热实验研究[J]. 化工学报, 2025, 76(1): 131-140. |

| [8] | 刘萍, 邱雨生, 李世婧, 孙瑞奇, 申晨. 微通道内纳米流体传热流动特性[J]. 化工学报, 2025, 76(1): 184-197. |

| [9] | 李海东, 张奇琪, 杨路, AKRAM Naeem, 常承林, 莫文龙, 申威峰. 采用智能进化算法的管壳式换热器详细设计[J]. 化工学报, 2025, 76(1): 241-255. |

| [10] | 任冠宇, 张义飞, 李新泽, 杜文静. 翼型印刷电路板式换热器流动传热特性数值研究[J]. 化工学报, 2024, 75(S1): 108-117. |

| [11] | 李焱, 郑利军, 张恩勇, 王云飞. 深水海底管道软管内部流体渗透特性模型与试验研究[J]. 化工学报, 2024, 75(S1): 118-125. |

| [12] | 李新泽, 张双星, 任冠宇, 洪瑞, 杜文静. 大功率LED热管理用脉动热管热性能[J]. 化工学报, 2024, 75(S1): 126-134. |

| [13] | 董新宇, 边龙飞, 杨怡怡, 张宇轩, 刘璐, 王腾. 冷却条件下倾斜上升管S-CO2流动与传热特性研究[J]. 化工学报, 2024, 75(S1): 195-205. |

| [14] | 唐溯, 郑子鏖, 魏翰泽, 许晓玲, 翟晓强. PMMA/PEG600/CNT复合定型相变材料制备与导热强化[J]. 化工学报, 2024, 75(S1): 309-320. |

| [15] | 秦思宇, 刘艺佳, 杨佳成, 佟薇, 金立文, 孟祥兆. 受限蒸汽腔内气液两相传热特性研究[J]. 化工学报, 2024, 75(S1): 47-55. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号