化工学报 ›› 2025, Vol. 76 ›› Issue (4): 1513-1522.DOI: 10.11949/0438-1157.20240855

刘璐1,2( ), 万开2, 王文玥2, 王太1,2(

), 万开2, 王文玥2, 王太1,2( ), 汤建成3, 王少恒4

), 汤建成3, 王少恒4

收稿日期:2024-07-29

修回日期:2024-10-20

出版日期:2025-04-25

发布日期:2025-05-12

通讯作者:

王太

作者简介:刘璐(1984—),女,博士,教授,luliu@ncepu.edu.cn

基金资助:

Lu LIU1,2( ), Kai WAN2, Wenyue WANG2, Tai WANG1,2(

), Kai WAN2, Wenyue WANG2, Tai WANG1,2( ), Jiancheng TANG3, Shaoheng WANG4

), Jiancheng TANG3, Shaoheng WANG4

Received:2024-07-29

Revised:2024-10-20

Online:2025-04-25

Published:2025-05-12

Contact:

Tai WANG

摘要:

为探寻基于氦膨胀制冷的氢液化流程中正仲氢转化耦合流动换热特性,采用CFD数值模拟方法,以四股流板翅式换热器为研究对象,研究了氢气在填料微通道内的正仲转化反应和流动换热性能,分析了催化剂粒径和孔隙率,氢气入口Re,低压氦气与氢气质量流量比mr对流动换热性能及出口仲氢体积分数的影响。研究结果表明:孔隙率由0.3增大为0.7,换热增强因子TEF最大可以提升71.59%;粒径由390 μm增大至790 μm,TEF最大可以提升37.05%;选用较大孔隙率和催化剂粒径更有利于提升氢通道综合换热性能。氢气入口Re由1500减小为500,TEF最多可以提升147.96%,低Re运行工况的通道换热性能更优。当低压氦气与氢气质量流量比值mr为6时,氢气在翅片通道内正仲转化耦合流动传热性能达到最优。研究结果可为大型氦膨胀制冷的氢液化系统提供理论指导。

中图分类号:

刘璐, 万开, 王文玥, 王太, 汤建成, 王少恒. 基于氦膨胀制冷的正仲氢转化耦合流动换热研究[J]. 化工学报, 2025, 76(4): 1513-1522.

Lu LIU, Kai WAN, Wenyue WANG, Tai WANG, Jiancheng TANG, Shaoheng WANG. Study on orthohydrogen and parahydrogen conversion coupled flow and heat transfer based on helium expansion refrigeration[J]. CIESC Journal, 2025, 76(4): 1513-1522.

| 催化剂 | 孔隙率ε | 颗粒直径dp/μm | 密度ρ/ (kg/m3) | 比热容cp / (J/(kg∙K)) | 热导率λs/ (W/(m∙K)) |

|---|---|---|---|---|---|

| Fe2O3 | 0.5 | 590 | 5240 | 700 | 0.58 |

表1 催化层的结构和性能参数

Table 1 Structure and performance parameters of Fe2O3

| 催化剂 | 孔隙率ε | 颗粒直径dp/μm | 密度ρ/ (kg/m3) | 比热容cp / (J/(kg∙K)) | 热导率λs/ (W/(m∙K)) |

|---|---|---|---|---|---|

| Fe2O3 | 0.5 | 590 | 5240 | 700 | 0.58 |

| 条件 | 温度/K | 温度的相对误差/% | |

|---|---|---|---|

| 文献[ | 数值模拟 | ||

| He-0.21 MPa | 214.12 | 16.06 | 0.91 |

| He-0.70 MPa | 214.09 | 214.67 | 0.27 |

表2 结果比较

Table 2 Comparsion of results

| 条件 | 温度/K | 温度的相对误差/% | |

|---|---|---|---|

| 文献[ | 数值模拟 | ||

| He-0.21 MPa | 214.12 | 16.06 | 0.91 |

| He-0.70 MPa | 214.09 | 214.67 | 0.27 |

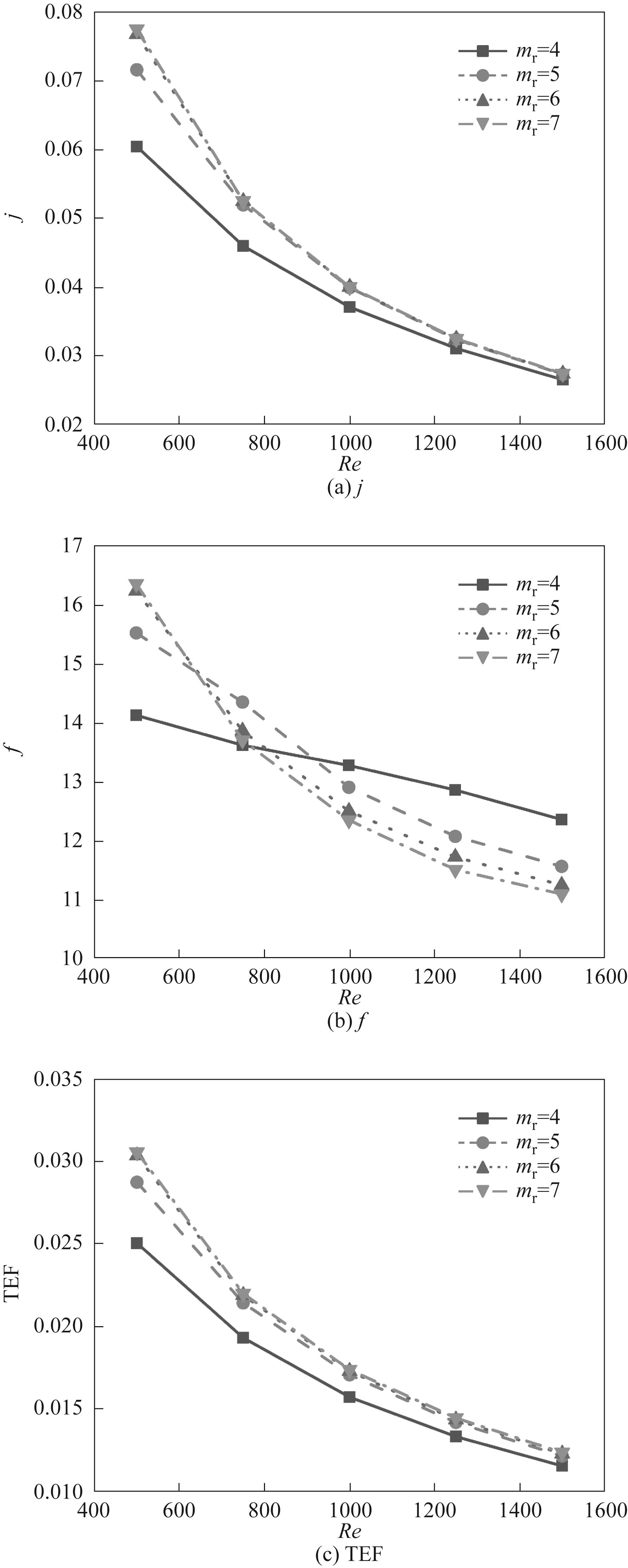

图13 流动换热性能随Re和低压氦气与氢气质量流量比mr的变化

Fig.13 Variation of flow and heat transfer performance with Re and mass flow ratio of low pressure helium to hydrogen mr

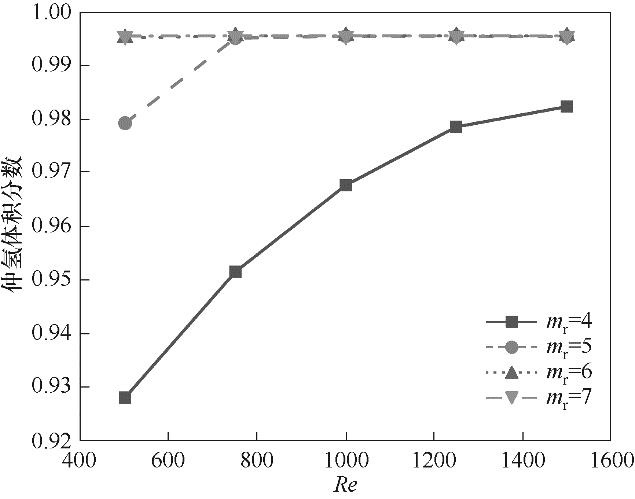

图14 出口仲氢体积分数随Re和低压氦气与氢气质量流量比mr的变化

Fig.14 Variation of volume fraction of parahydrogen at outlet with Re and mass flow ratio of low pressure helium to hydrogen mr

| 1 | Kang D H, An J H, Lee C J. Numerical modeling and optimization of thermal insulation for liquid hydrogen storage tanks[J]. Energy, 2024, 291: 130143. |

| 2 | Ahmad A, Oko E, Ibhadon A. Comparative energy and exergy analysis of ortho-para hydrogen and non-ortho-para hydrogen conversion in hydrogen liquefaction[J]. International Journal of Hydrogen Energy, 2024, 78: 991-1003. |

| 3 | Skaugen G, Berstad D, Wilhelmsen Ø. Comparing exergy losses and evaluating the potential of catalyst-filled plate-fin and spiral-wound heat exchangers in a large-scale Claude hydrogen liquefaction process[J]. International Journal of Hydrogen Energy, 2020, 45(11): 6663-6679. |

| 4 | Cardella U, Decker L, Klein H. Roadmap to economically viable hydrogen liquefaction[J]. International Journal of Hydrogen Energy, 2017, 42(19): 13329-13338. |

| 5 | Li K Y, Zhang S G, Liu G L. Model for analyzing the energy efficiency of hydrogen liquefaction process considering the variation of hydrogen liquefaction ratio and precooling temperature[J]. International Journal of Hydrogen Energy, 2022, 47(57): 24194-24211. |

| 6 | Sun H, Xu J M, Wang C, et al. Optimization and analysis of a cascaded dual mixed refrigerant hydrogen liquefaction process considering the influence of pre-cooling stages[J]. International Journal of Hydrogen Energy, 2023, 48(81): 31653-31670. |

| 7 | Tang J H, Li Y X, Zhu J L, et al. Study on the flow and heat transfer characteristics of gaseous hydrogen in heat exchange tubes coupled with ortho-para hydrogen conversion[J]. International Journal of Hydrogen Energy, 2024, 77: 272-280. |

| 8 | Xu P, Wen J, Li K, et al. Review of the continuous catalytic ortho-para hydrogen conversion technology for hydrogen liquefaction[J]. International Journal of Hydrogen Energy, 2024, 62: 473-487. |

| 9 | 唐璐, 邱利民, 姚蕾, 等. 氢液化系统的研究进展与展望[J]. 制冷学报, 2011, 32(6): 1-8. |

| Tang L, Qiu L M, Yao L, et al. Review on research and developments of hydrogen liquefaction systems[J]. Journal of Refrigeration, 2011, 32(6): 1-8. | |

| 10 | Krasae-in S, Stang J H, Neksa P. Development of large-scale hydrogen liquefaction processes from 1898 to 2009[J]. International Journal of Hydrogen Energy, 2010, 35(10): 4524-4533. |

| 11 | Riaz A, Qyyum M A, Hussain A, et al. Significance of ortho-para hydrogen conversion in the performance of hydrogen liquefaction process[J]. International Journal of Hydrogen Energy, 2023, 48(68): 26568-26582. |

| 12 | Morales-Ospino R, Celzard A, Fierro V. Strategies to recover and minimize boil-off losses during liquid hydrogen storage[J]. Renewable and Sustainable Energy Reviews, 2023, 182: 113360. |

| 13 | O'Neill K T, Al Ghafri S, da Silva Falcão B, et al. Hydrogen ortho-para conversion: process sensitivities and optimisation[J]. Chemical Engineering and Processing - Process Intensification, 2023, 184: 109272. |

| 14 | Xu Y F, Bi Y J, Ju Y L. The thermodynamic analysis on the catalytical ortho-para hydrogen conversion during the hydrogen liquefaction process[J]. International Journal of Hydrogen Energy, 2024, 54: 1329-1342. |

| 15 | Aziz M. Liquid hydrogen: a review on liquefaction, storage, transportation, and safety[J]. Energies, 2021, 14(18): 5917. |

| 16 | Cardella U, Decker L, Sundberg J, et al. Process optimization for large-scale hydrogen liquefaction[J]. International Journal of Hydrogen Energy, 2017, 42(17): 12339-12354. |

| 17 | Yang J H, Yoon Y, Ryu M, et al. Integrated hydrogen liquefaction process with steam methane reforming by using liquefied natural gas cooling system[J]. Applied Energy, 2019, 255: 113840. |

| 18 | Berstad D, Skaugen G, Wilhelmsen Ø. Dissecting the exergy balance of a hydrogen liquefier: analysis of a scaled-up Claude hydrogen liquefier with mixed refrigerant pre-cooling[J]. International Journal of Hydrogen Energy, 2021, 46(11): 8014-8029. |

| 19 | Xu P, Lei G, Xu Y Y, et al. Study on continuous cooling process coupled with ortho-para hydrogen conversion in plate-fin heat exchanger filled with catalyst[J]. International Journal of Hydrogen Energy, 2022, 47(7): 4690-4703. |

| 20 | 王昊成, 杨敬瑶, 董学强, 等. 10 t/d级氢液化装置流程热力分析与优化[J]. 化工学报, 2022, 73(11): 5106-5117. |

| Wang H C, Yang J Y, Dong X Q, et al. Thermodynamic analysis and optimization of 10 t/d hydrogen liquefaction process[J]. CIESC Journal, 2022, 73(11): 5106-5117. | |

| 21 | 赵欣, 陈强, 文键, 等. 正仲转化换热一体化大规模氢液化流程模拟[J]. 化学工程, 2023, 51(1): 36-40. |

| Zhao X, Chen Q, Wen J, et al. Simulation on large-scale hydrogen liquefaction process integrating ortho-para conversion and heat exchange[J]. Chemical Engineering (China), 2023, 51(1): 36-40. | |

| 22 | Wilhelmsen Ø, Berstad D, Aasen A, et al. Reducing the exergy destruction in the cryogenic heat exchangers of hydrogen liquefaction processes[J]. International Journal of Hydrogen Energy, 2018, 43(10): 5033-5047. |

| 23 | Donaubauer P J, Cardella U, Decker L, et al. Kinetics and heat exchanger design for catalytic ortho-para hydrogen conversion during liquefaction[J]. Chemical Engineering & Technology, 2019, 42(3): 669-679. |

| 24 | Hutchinson H L. Analysis of catalytic ortho-parahydrogen reaction mechanisms[D]. Boulder, Colorado, USA: University of Colorado, 1966: 58-122. |

| 25 | Hånde R, Wilhelmsen Ø. Minimum entropy generation in a heat exchanger in the cryogenic part of the hydrogen liquefaction process: on the validity of equipartition and disappearance of the highway[J]. International Journal of Hydrogen Energy, 2019, 44(29): 15045-15055. |

| 26 | 李启铭, 张磊, 徐攀, 等. 氢液化流程中催化换热一体化可行性研究[J]. 化学工程, 2021, 49(7): 26-30. |

| Li Q M, Zhang L, Xu P, et al. Feasibility on integration of catalysis and heat transfer in hydrogen liquefaction process[J]. Chemical Engineering (China), 2021, 49(7): 26-30. | |

| 27 | 徐攀, 文键, 厉彦忠, 等. 氢正仲转化耦合流动换热板翅式换热器研究[J]. 西安交通大学学报, 2021, 55(12): 16-24. |

| Xu P, Wen J, Li Y Z, et al. Study on hydrogen ortho-para conversion coupled with flow and heat transfer of the plate fin heat exchanger[J]. Journal of Xi'an Jiaotong University, 2021, 55(12): 16-24. | |

| 28 | Xu P, Wen J, Wang S M, et al. Study on performance comparison of different fin combinations of catalyst filled plate fin heat exchanger for hydrogen liquefaction[J]. International Journal of Hydrogen Energy, 2022, 47(56): 23661-23678. |

| 29 | Marquardt E D, Le J P, Radebaugh R. Cryogenic material properties database[M]//Cryocoolers 11. Boston, MA: Springer US, 2002: 681-687. |

| 30 | Kays W M, London A L. Compact Heat Exchangers[M]. 2nd ed. New York: McGraw-Hill Book, 1964: 142-181. |

| 31 | Goyal M, Chakravarty A, Atrey M D. Two dimensional model for multistream plate fin heat exchangers[J]. Cryogenics, 2014, 61: 70-78. |

| [1] | 许成城, 邵索拉, 魏文建, 郑旭. 多工况下直凝式蓄热型铝制辐射板换热器供暖性能研究[J]. 化工学报, 2025, 76(4): 1545-1558. |

| [2] | 贾文龙, 肖欢, 冷翔宇, 黄巧竞, 刘程玮, 吴瑕. 原油储罐重质沉积物超声波空化微射流清洗实验及数值模拟[J]. 化工学报, 2025, 76(3): 1288-1296. |

| [3] | 赵丽文, 刘桂莲. 基于系统集成的复杂催化反应系统性能强化及参数优化[J]. 化工学报, 2025, 76(3): 1111-1119. |

| [4] | 万俊, 宋佳芮, 范春煌, 魏乐乐, 聂依娜, 刘琳. 高效空穴转移助力光催化碱性甲醇-水溶液制氢[J]. 化工学报, 2025, 76(3): 1064-1075. |

| [5] | 何传超, 周静红, 曹约强, 施尧, 周兴贵. Ag/SiO2催化草酸酯加氢制乙醇酸甲酯的床层-颗粒双尺度耦合模拟研究[J]. 化工学报, 2025, 76(2): 654-666. |

| [6] | 李舒月, 王欢, 周少强, 毛志宏, 张永民, 王军武, 吴秀花. 重质颗粒流态化研究现状与展望[J]. 化工学报, 2025, 76(2): 466-483. |

| [7] | 钟晓航, 许卫, 张文, 许莉, 王宇新. 碱性水电解制氢中铁杂质的影响研究进展[J]. 化工学报, 2025, 76(2): 519-531. |

| [8] | 张珂, 任维杰, 王梦娜, 范凯锋, 常丽萍, 李佳斌, 马涛, 田晋平. Bunsen反应产物在微通道中的液-液两相混合特性[J]. 化工学报, 2025, 76(2): 623-636. |

| [9] | 张泽雨, 王平, 戴凯论, 钱伟佳, Roy Subhajit, 帅瑞洋, Ferrante Antonio. 轴向双级氨/甲烷湍流预混火焰燃烧特性及NO生成[J]. 化工学报, 2025, 76(2): 835-845. |

| [10] | 姚佳逸, 张东辉, 唐忠利, 李文彬. 基于二级双回流的变压吸附捕碳工艺研究[J]. 化工学报, 2025, 76(2): 744-754. |

| [11] | 贾晶宇, 孔德齐, 沈圆辉, 张东辉, 李文彬, 唐忠利. 合成氨反应器尾气变压吸附氨分离工艺的模拟与分析[J]. 化工学报, 2025, 76(2): 718-730. |

| [12] | 邹吉军, 刘宝宏, 史成香, 潘伦, 张香文. 综纤维素衍生物转化合成生物航空燃料的非均相催化剂研究进展[J]. 化工学报, 2025, 76(1): 1-17. |

| [13] | 杨晨, 毛伟, 董兴宗, 田松, 赵锋伟, 吕剑. 选择性加氢脱氯合成烯烃研究进展[J]. 化工学报, 2025, 76(1): 53-70. |

| [14] | 刘萍, 邱雨生, 李世婧, 孙瑞奇, 申晨. 微通道内纳米流体传热流动特性[J]. 化工学报, 2025, 76(1): 184-197. |

| [15] | 韩志敏, 周相宇, 张宏宇, 徐志明. 不同粗糙元结构下CaCO3污垢局部沉积特性[J]. 化工学报, 2025, 76(1): 151-160. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号