化工学报 ›› 2025, Vol. 76 ›› Issue (5): 1943-1959.DOI: 10.11949/0438-1157.20241432

• 综述与专论 • 上一篇

王金月1,2( ), 谢恩泽1,2(

), 谢恩泽1,2( ), 马翰泽1,2, 袁晟1,2, 何光伟1,2,3(

), 马翰泽1,2, 袁晟1,2, 何光伟1,2,3( ), 姜忠义1,2,3(

), 姜忠义1,2,3( )

)

收稿日期:2024-12-10

修回日期:2025-01-24

出版日期:2025-05-25

发布日期:2025-06-13

通讯作者:

何光伟,姜忠义

作者简介:王金月(1999—),女,硕士研究生,wjy0829@tju.edu.cn基金资助:

Jinyue WANG1,2( ), Enze XIE1,2(

), Enze XIE1,2( ), Hanze MA1,2, Sheng YUAN1,2, Guangwei HE1,2,3(

), Hanze MA1,2, Sheng YUAN1,2, Guangwei HE1,2,3( ), Zhongyi JIANG1,2,3(

), Zhongyi JIANG1,2,3( )

)

Received:2024-12-10

Revised:2025-01-24

Online:2025-05-25

Published:2025-06-13

Contact:

Guangwei HE, Zhongyi JIANG

摘要:

原子级制造是在原子精度对材料结构进行精准控制,是制备高端材料的变革性新技术。在原子级别对膜材料厚度和孔结构进行精密调控,开发单原子层纳米孔膜,可显著降低传质阻力,实现分子极限渗透与分离,将为膜分离领域的发展与难分离物系的突破带来新机遇。本综述介绍了多种单层纳孔膜材料(single layer nanoporous membranes, SLNM),总结其纳米孔构筑方法及单层膜制备方法,探讨其在气体分离、液体分离、离子分离等领域的应用现状。最后,针对单层纳孔膜面临的机遇与挑战进行了剖析与总结,并对其未来发展方向进行了展望。

中图分类号:

王金月, 谢恩泽, 马翰泽, 袁晟, 何光伟, 姜忠义. 单原子层分离膜:进展与展望[J]. 化工学报, 2025, 76(5): 1943-1959.

Jinyue WANG, Enze XIE, Hanze MA, Sheng YUAN, Guangwei HE, Zhongyi JIANG. Monoatomic layer separation membrane: progress and prospect[J]. CIESC Journal, 2025, 76(5): 1943-1959.

| 构筑策略 | 自上而下 | 自下而上 |

|---|---|---|

| 原理和方法 | 通过外部能量或化学试剂在二维材料中移除原子或引入空位形成纳米孔。 • 物理轰击 • 化学蚀刻 • 高能等离子体 | 基于界面反应或分子组装,通过气/固、液/液或液/固界面化学反应自组装形成二维材料,直接构筑具有孔洞结构的单层膜。 • 气/固界面 • 液/液界面 • 液/固界面 |

| 孔径控制能力 | 精确性高:通过控制轰击能量、蚀刻剂浓度、等离子体能量等实现孔径尺寸和密度的高精度调控;如“级联压缩”可显著改善孔径分布并增加孔密度。 | 受工艺限制:孔径尺寸及均匀性取决于界面反应条件、前体性质及合成动力学的调控,需要优化工艺参数以提升孔径控制水平。 |

| 技术优势 | • 孔径分布精准 • 适配多种单层材料 • 易与其他策略耦合 | • 适合大面积制备 • 功能化设计灵活 |

| 工艺复杂性 | 中高:工艺条件苛刻,制备成本较高,但能满足高性能膜材料的需求。 | 低:工艺条件相对温和,设备要求低,适合实验室研究和大规模工业制备。 |

| 适用材料范围 | 适用于多种二维材料,尤其是对孔径分布和密度要求严格的膜分离应用。 | 可应用于有机和无机材料,适用于多种薄膜分离应用场景。 |

| 典型膜分离应用 场景 | • 气体分离:如H₂/CO₂、H₂/CH₄的高选择性分离,适用于严苛工业环境。 • 液体分离:海水淡化、渗透蒸发等高性能分离场景。 | • 气体分离:可用于一般气体分离场景。 • 液体分离:适用于纳滤、超滤及有机溶剂分离,具有大面积制备潜力。 |

表1 单层膜纳米孔构筑策略对比

Table 1 Comparison of nanopore construction strategies for SLNM

| 构筑策略 | 自上而下 | 自下而上 |

|---|---|---|

| 原理和方法 | 通过外部能量或化学试剂在二维材料中移除原子或引入空位形成纳米孔。 • 物理轰击 • 化学蚀刻 • 高能等离子体 | 基于界面反应或分子组装,通过气/固、液/液或液/固界面化学反应自组装形成二维材料,直接构筑具有孔洞结构的单层膜。 • 气/固界面 • 液/液界面 • 液/固界面 |

| 孔径控制能力 | 精确性高:通过控制轰击能量、蚀刻剂浓度、等离子体能量等实现孔径尺寸和密度的高精度调控;如“级联压缩”可显著改善孔径分布并增加孔密度。 | 受工艺限制:孔径尺寸及均匀性取决于界面反应条件、前体性质及合成动力学的调控,需要优化工艺参数以提升孔径控制水平。 |

| 技术优势 | • 孔径分布精准 • 适配多种单层材料 • 易与其他策略耦合 | • 适合大面积制备 • 功能化设计灵活 |

| 工艺复杂性 | 中高:工艺条件苛刻,制备成本较高,但能满足高性能膜材料的需求。 | 低:工艺条件相对温和,设备要求低,适合实验室研究和大规模工业制备。 |

| 适用材料范围 | 适用于多种二维材料,尤其是对孔径分布和密度要求严格的膜分离应用。 | 可应用于有机和无机材料,适用于多种薄膜分离应用场景。 |

| 典型膜分离应用 场景 | • 气体分离:如H₂/CO₂、H₂/CH₄的高选择性分离,适用于严苛工业环境。 • 液体分离:海水淡化、渗透蒸发等高性能分离场景。 | • 气体分离:可用于一般气体分离场景。 • 液体分离:适用于纳滤、超滤及有机溶剂分离,具有大面积制备潜力。 |

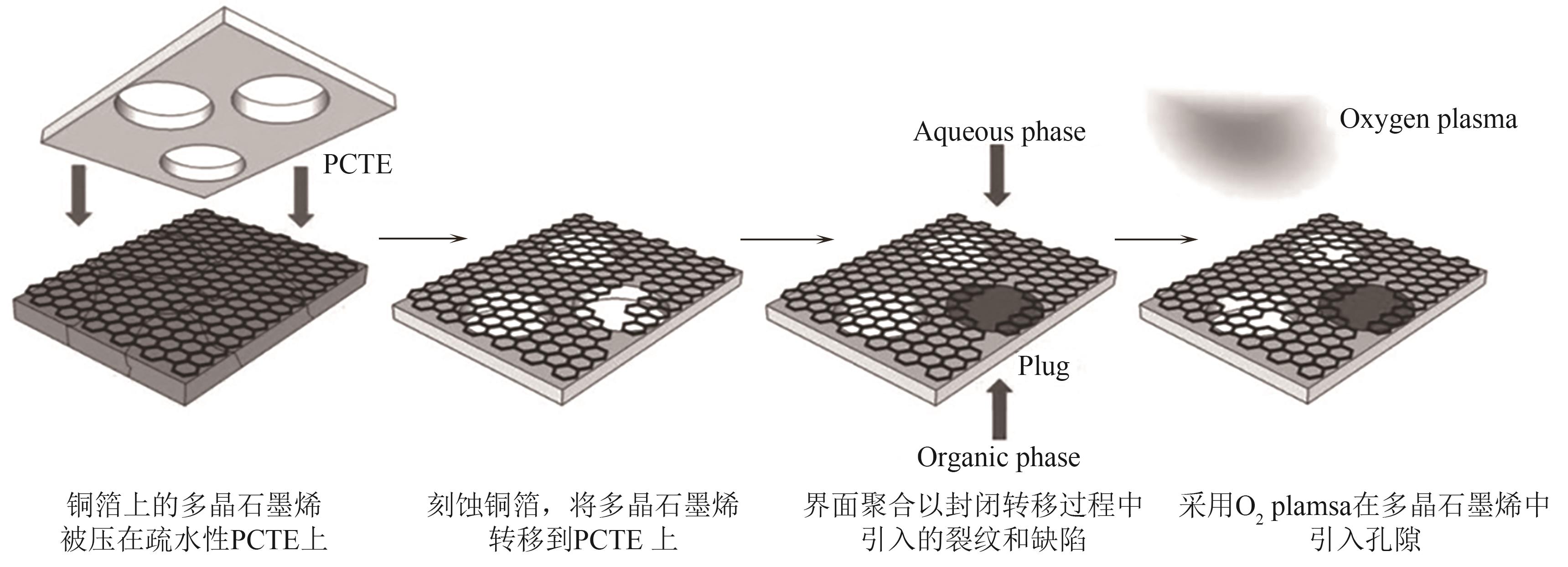

图10 采用CVD制备的单层多晶石墨烯合成大面积多孔SLG膜的过程示意图[90]

Fig.10 Overview of the process of synthesizing large-area nanoporous single layer graphene membranes from single-layer polycrystalline graphene prepared by CVD[90]

| 材料 | 膜制备方法 | H2渗透通量 | H2/CH4选择性 | 文献 | |

|---|---|---|---|---|---|

| GPU① | Barrer② | ||||

| PIM-EA-TB | 相转化法 | — | 7760 | 11.1 | [ |

| GO/AAO | 逐层自组装法 | 589 | — | 66.7 | [ |

| ZIF-62/AAO | 熔融淬火法 | — | 4156 | 50 | [ |

| COF-LZU1–ACOF-1 | 溶剂热法 | — | 543.6 | 105 | [ |

| 碳分子筛 | 浸渍炭化法 | 324 | — | 435 | [ |

| SLG | CVD | >4000 | — | >2000 | [ |

| SLG | O2 plasma、O3刻蚀 | 3400 | — | 25.1 | [ |

| SLG | O3、O2刻蚀 | 7200 | — | 37.5 | [ |

表2 部分二维/多孔材料的H2/CH4分离性能

Table 2 H2/CH4 separation performance of some 2D/porous materials

| 材料 | 膜制备方法 | H2渗透通量 | H2/CH4选择性 | 文献 | |

|---|---|---|---|---|---|

| GPU① | Barrer② | ||||

| PIM-EA-TB | 相转化法 | — | 7760 | 11.1 | [ |

| GO/AAO | 逐层自组装法 | 589 | — | 66.7 | [ |

| ZIF-62/AAO | 熔融淬火法 | — | 4156 | 50 | [ |

| COF-LZU1–ACOF-1 | 溶剂热法 | — | 543.6 | 105 | [ |

| 碳分子筛 | 浸渍炭化法 | 324 | — | 435 | [ |

| SLG | CVD | >4000 | — | >2000 | [ |

| SLG | O2 plasma、O3刻蚀 | 3400 | — | 25.1 | [ |

| SLG | O3、O2刻蚀 | 7200 | — | 37.5 | [ |

| 1 | Du N Y, Park H B, Dal-Cin M M, et al. Advances in high permeability polymeric membrane materials for CO2 separations[J]. Energy & Environmental Science, 2012, 5(6): 7306-7322. |

| 2 | Yampolskii Y. Polymeric gas separation membranes[J]. Macromolecules, 2012, 45(8): 3298-3311. |

| 3 | Low Z X, Budd P M, McKeown N B, et al. Gas permeation properties, physical aging, and its mitigation in high free volume glassy polymers[J]. Chemical Reviews, 2018, 118(12): 5871-5911. |

| 4 | Liu D G, Jin P W, Xu P N. Two-dimensional-material membranes: a new family of high-performance separation membranes[J]. Angewandte Chemie International Edition, 2016, 55(43): 13384-13397. |

| 5 | Yuan Z, Benck J D, Eatmon Y, et al. Stable, temperature-dependent gas mixture permeation and separation through suspended nanoporous single-layer graphene membranes[J]. Nano Letters, 2018, 18(8): 5057-5069. |

| 6 | Jiang D E, Cooper V R, Dai S. Porous graphene as the ultimate membrane for gas separation[J]. Nano Letters, 2009, 9(12): 4019-4024. |

| 7 | Celebi K, Buchheim J, Wyss R M, et al. Ultimate permeation across atomically thin porous graphene[J]. Science, 2014, 344(6181): 289-292. |

| 8 | Wang L D, Williams C M, Boutilier M S H, et al. Single-layer graphene membranes withstand ultrahigh applied pressure[J]. Nano Letters, 2017, 17(5): 3081-3088. |

| 9 | Lin L, Deng B, Sun J Y, et al. Bridging the gap between reality and ideal in chemical vapor deposition growth of graphene[J]. Chemical Reviews, 2018, 118(18): 9281-9343. |

| 10 | Fasolino A, Los J H, Katsnelson M I. Intrinsic ripples in graphene[J]. Nature Materials, 2007, 6(11): 858-861. |

| 11 | Deng B, Liu Z F, Peng H L. Toward mass production of CVD graphene films[J]. Advanced Materials, 2019, 31(9): 1800996. |

| 12 | Yang Y B, Yang X D, Liang L, et al. Large-area graphene-nanomesh/carbon-nanotube hybrid membranes for ionic and molecular nanofiltration[J]. Science, 2019, 364(6445): 1057-1062. |

| 13 | Huang S Q, Dakhchoune M, Luo W, et al. Single-layer graphene membranes by crack-free transfer for gas mixture separation[J]. Nature Communications, 2018, 9(1): 2632. |

| 14 | Safron N S, Kim M, Gopalan P, et al. Barrier-guided growth of micro- and nano-structured graphene[J]. Advanced Materials, 2012, 24(8): 1041-1045. |

| 15 | Hsu K J, Villalobos L F, Huang S Q, et al. Multipulsed millisecond ozone gasification for predictable tuning of nucleation and nucleation-decoupled nanopore expansion in graphene for carbon capture[J]. ACS Nano, 2021, 15(8): 13230-13239. |

| 16 | Zhao G K, Li X M, Huang M R, et al. The physics and chemistry of graphene-on-surfaces[J]. Chemical Society Reviews, 2017, 46(15): 4417-4449. |

| 17 | He G W, Huang S Q, Villalobos L F, et al. High-permeance polymer-functionalized single-layer graphene membranes that surpass the postcombustion carbon capture target[J]. Energy & Environmental Science, 2019, 12(11): 3305-3312. |

| 18 | Jang D, Idrobo J C, Laoui T, et al. Water and solute transport governed by tunable pore size distributions in nanoporous graphene membranes[J]. ACS Nano, 2017, 11(10): 10042-10052. |

| 19 | Surwade S P, Smirnov S N, Vlassiouk I V, et al. Water desalination using nanoporous single-layer graphene[J]. Nature Nanotechnology, 2015, 10(5): 459-464. |

| 20 | Zhou Z Y, Zhao K N, Chi H Y, et al. Electrochemical-repaired porous graphene membranes for precise ion-ion separation[J]. Nature Communications, 2024, 15(1): 4006. |

| 21 | Zhang Y Y, Pei Q X, Liu H Y, et al. Thermal conductivity of a h-BCN monolayer[J]. Physical Chemistry Chemical Physics, 2017, 19(40): 27326-27331. |

| 22 | Wang Z F, Tang Z J, Xue Q, et al. Fabrication of boron nitride nanosheets by exfoliation[J]. The Chemical Record, 2016, 16(3): 1204-1215. |

| 23 | Liu Z, Gong Y J, Zhou W, et al. Ultrathin high-temperature oxidation-resistant coatings of hexagonal boron nitride[J]. Nature Communications, 2013, 4: 2541. |

| 24 | Li L H, Cervenka J, Watanabe K, et al. Strong oxidation resistance of atomically thin boron nitride nanosheets[J]. ACS Nano, 2014, 8(2): 1457-1462. |

| 25 | Yoon S I, Seo D J, Kim G, et al. AA'-stacked trilayer hexagonal boron nitride membrane for proton exchange membrane fuel cells[J]. ACS Nano, 2018, 12(11): 10764-10771. |

| 26 | Wang L, Xu X Z, Zhang L N, et al. Epitaxial growth of a 100-square-centimetre single-crystal hexagonal boron nitride monolayer on copper[J]. Nature, 2019, 570(7759): 91-95. |

| 27 | Mouhoub O, Ricolleau C, Wang G, et al. Probing Structural and Electronic Properties of h-BN by HRTEM and STM[M]. Weinheim, Germany: Wiley-VCH Verlag GmbH & Co. KGaA, 2016. |

| 28 | Ivanovskii A L. Graphynes and graphdyines[J]. Progress in Solid State Chemistry, 2013, 41(1/2): 1-19. |

| 29 | Lin S C, Buehler M J. Mechanics and molecular filtration performance of graphyne nanoweb membranes for selective water purification[J]. Nanoscale, 2013, 5(23): 11801-11807. |

| 30 | Li G X, Li Y L, Liu H B, et al. Architecture of graphdiyne nanoscale films[J]. Chemical Communications, 2010, 46(19): 3256-3258. |

| 31 | Matsuoka R, Sakamoto R, Hoshiko K, et al. Crystalline graphdiyne nanosheets produced at a gas/liquid or liquid/liquid interface[J]. Journal of the American Chemical Society, 2017, 139(8): 3145-3152. |

| 32 | Liu R, Gao X, Zhou J Y, et al. Chemical vapor deposition growth of linked carbon monolayers with acetylenic scaffoldings on silver foil[J]. Advanced Materials, 2017, 29(18): 1604665. |

| 33 | Shen J, Cai Y C, Zhang C H, et al. Fast water transport and molecular sieving through ultrathin ordered conjugated-polymer-framework membranes[J]. Nature Materials, 2022, 21(10): 1183-1190. |

| 34 | Gao X, Liu H B, Wang D, et al. Graphdiyne: synthesis, properties, and applications[J]. Chemical Society Reviews, 2019, 48(3): 908-936. |

| 35 | Pelkowski C E, Natraj A, Malliakas C D, et al. Tuning crystallinity and stacking of two-dimensional covalent organic frameworks through side-chain interactions[J]. Journal of the American Chemical Society, 2023, 145(40): 21798-21806. |

| 36 | Fan H W, Mundstock A, Feldhoff A, et al. Covalent organic framework-covalent organic framework bilayer membranes for highly selective gas separation[J]. Journal of the American Chemical Society, 2018, 140(32): 10094-10098. |

| 37 | Lin S, Diercks C S, Zhang Y B, et al. Covalent organic frameworks comprising cobalt porphyrins for catalytic CO₂ reduction in water[J]. Science, 2015, 349(6253): 1208-1213. |

| 38 | Yuan S, Li X, Zhu J, et al. Covalent organic frameworks for membrane separation[J]. Chemical Society Reviews, 2019, 48(10): 2665-2681. |

| 39 | Côté A P, Benin A I, Ockwig N W, et al. Porous, crystalline, covalent organic frameworks[J]. Science, 2005, 310(5751): 1166-1170. |

| 40 | Chandra S, Roy Chowdhury D, Addicoat M, et al. Molecular level control of the capacitance of two-dimensional covalent organic frameworks: role of hydrogen bonding in energy storage materials[J]. Chemistry of Materials, 2017, 29(5): 2074-2080. |

| 41 | Zhong Y, Cheng B R, Park C, et al. Wafer-scale synthesis of monolayer two-dimensional porphyrin polymers for hybrid superlattices[J]. Science, 2019, 366(6471): 1379-1384. |

| 42 | Yang J L, Tu B, Zhang G J, et al. Advancing osmotic power generation by covalent organic framework monolayer[J]. Nature Nanotechnology, 2022, 17(6): 622-628. |

| 43 | Zhou H, Kitagawa S. Metal-organic frameworks (MOFs)[J]. Chemical Society Reviews, 2014, 43(16): 5415-5418. |

| 44 | Li X, Liu Y X, Wang J, et al. Metal-organic frameworks based membranes for liquid separation[J]. Chemical Society Reviews, 2017, 46(23): 7124-7144. |

| 45 | Ang H X, Hong L. Polycationic polymer-regulated assembling of 2D MOF nanosheets for high-performance nanofiltration[J]. ACS Applied Materials & Interfaces, 2017, 9(33): 28079-28088. |

| 46 | Zhu D X, Tian D C, Do-Thanh D C, et al. Two-dimensional materials as prospective scaffolds for mixed-matrix membrane-based CO2 separation[J]. ChemSusChem, 2017, 10(17): 3304-3316. |

| 47 | Zhao S L, Wang Y, Dong J C, et al. Ultrathin metal-organic framework nanosheets for electrocatalytic oxygen evolution[J]. Nature Energy, 2016, 1(12): 16184. |

| 48 | Huang J, Li Y, Huang R K, et al. Electrochemical exfoliation of pillared-layer metal-organic framework to boost the oxygen evolution reaction[J]. Angewandte Chemie International Edition, 2018, 57(17): 4632-4636. |

| 49 | López-Cabrelles J, Mañas-Valero S, Vitórica-Yrezábal I J, et al. Isoreticular two-dimensional magnetic coordination polymers prepared through pre-synthetic ligand functionalization[J]. Nature Chemistry, 2018, 10(10): 1001-1007. |

| 50 | Liu J X, Chen Y X, Huang X, et al. On-liquid-gallium surface synthesis of ultrasmooth thin films of conductive metal-organic frameworks[J]. Nature Synthesis, 2024, 3: 715-726. |

| 51 | Liu Q, Miao Y R, Villalobos L F, et al. Unit-cell-thick zeolitic imidazolate framework films for membrane application[J]. Nature Materials, 2023, 22(11): 1387-1393. |

| 52 | Garaj S, Hubbard W, Reina A, et al. Graphene as a subnanometre trans-electrode membrane[J]. Nature, 2010, 467(7312): 190-193. |

| 53 | Merchant C A, Healy K, Wanunu M, et al. DNA translocation through graphene nanopores[J]. Nano Letters, 2010, 10(8): 2915-2921. |

| 54 | Buchheim J, Wyss R M, Shorubalko I, et al. Understanding the interaction between energetic ions and freestanding graphene towards practical 2D perforation[J]. Nanoscale, 2016, 8(15): 8345-8354. |

| 55 | Thiruraman J P, Das P M, Drndić M. Irradiation of transition metal dichalcogenides using a focused ion beam: controlled single-atom defect creation[J]. Advanced Functional Materials, 2019, 29(52): 1904668. |

| 56 | Wang J T, Cheng C, Zheng X D, et al. Cascaded compression of size distribution of nanopores in monolayer graphene[J]. Nature, 2023, 623(7989): 956-963. |

| 57 | Chu X, Schmidt L D. Reactions of NO, O2, H2O, and CO2 with the basal plane of graphite[J]. Surface Science, 1992, 268(1/2/3): 325-332. |

| 58 | Tracz A, Wegner G, Rabe J P. Scanning tunneling microscopy study of graphite oxidation in ozone-air mixtures[J]. Langmuir, 2003, 19(17): 6807-6812. |

| 59 | Schlichting K P, Poulikakos D. Selective etching of graphene membrane nanopores: from molecular sieving to extreme permeance[J]. ACS Applied Materials & Interfaces, 2020, 12(32): 36468-36477. |

| 60 | Rezaei M, Villalobos L F, Hsu K J, et al. Demonstrating and unraveling a controlled nanometer-scale expansion of the vacancy defects in graphene by CO2 [J]. Angewandte Chemie International Edition, 2022, 61(18): e202200321. |

| 61 | Zhao J, He G, Huang S, et al. Etching gas-sieving nanopores in single-layer graphene with an angstrom precision for high-performance gas mixture separation[J]. Science Advances, 2019, 5(1): eaav1851. |

| 62 | Huang S Q, Li S X, Villalobos L F, et al. Millisecond lattice gasification for high-density CO2- and O2-sieving nanopores in single-layer graphene[J]. Science Advances, 2021, 7(9): eabf0116. |

| 63 | Koizumi K, Boero M, Shigeta Y, et al. Atom-scale reaction pathways and free-energy landscapes in oxygen plasma etching of graphene[J]. The Journal of Physical Chemistry Letters, 2013, 4(10): 1592-1596. |

| 64 | Harpale A, Chew H B. Hydrogen-plasma patterning of multilayer graphene: mechanisms and modeling[J]. Carbon, 2017, 117: 82-91. |

| 65 | James Claire F, Solomos M A, Kim J, et al. Structural and electronic switching of a single crystal 2D metal-organic framework prepared by chemical vapor deposition[J]. Nature Communications, 2020, 11(1): 5524. |

| 66 | Zhan Y J, Liu Z, Najmaei S, et al. Large-area vapor-phase growth and characterization of MoS2 atomic layers on a SiO2 substrate[J]. Small, 2012, 8(7): 966-971. |

| 67 | Choi K, Droudian A, Wyss R M, et al. Multifunctional wafer-scale graphene membranes for fast ultrafiltration and high permeation gas separation[J]. Science Advances, 2018, 4(11): eaau0476. |

| 68 | Wang L, Zhang X Y, Chan H L W, et al. Formation and healing of vacancies in graphene chemical vapor deposition (CVD) growth[J]. Journal of the American Chemical Society, 2013, 135(11): 4476-4482. |

| 69 | Kidambi P R, Nguyen G D, Zhang S, et al. Facile fabrication of large-area atomically thin membranes by direct synthesis of graphene with nanoscale porosity[J]. Advanced Materials, 2018, 30(49): 1804977. |

| 70 | Liu M H, Liu Y X, Dong J C, et al. Two-dimensional covalent organic framework films prepared on various substrates through vapor induced conversion[J]. Nature Communications, 2022, 13(1): 1411. |

| 71 | Colson J W, Woll A R, Mukherjee A, et al. Oriented 2D covalent organic framework thin films on single-layer graphene[J]. Science, 2011, 332(6026): 228-231. |

| 72 | Gao X, Zhu Y H, Yi D, et al. Ultrathin graphdiyne film on graphene through solution-phase van der Waals epitaxy[J]. Science Advances, 2018, 4(7): eaat6378. |

| 73 | Li X S, Cai W W, An J, et al. Large-area synthesis of high-quality and uniform graphene films on copper foils[J]. Science, 2009, 324(5932): 1312-1314. |

| 74 | Zhuang B Z, Li S Y, Li S Y, et al. Ways to eliminate PMMA residues on graphene: superclean graphene[J]. Carbon, 2021, 173: 609-636. |

| 75 | Liang X L, Sperling B A, Calizo I, et al. Toward clean and crackless transfer of graphene[J]. ACS Nano, 2011, 5(11): 9144-9153. |

| 76 | Qi P W, Huang Y N, Yao Y Z, et al. Wax-assisted crack-free transfer of monolayer CVD graphene: extending from standalone to supported copper substrates[J]. Applied Surface Science, 2019, 493: 81-86. |

| 77 | Wang Z, Liu W L, Shao J X, et al. Cyclododecane-based high-intactness and clean transfer method for fabricating suspended two-dimensional materials[J]. Nature Communications, 2024, 15(1): 6957. |

| 78 | Kim M J, Moreira G, Lisi N, et al. Solvent-free transfer of monolayer graphene with recrystallized cyclododecane[J]. Applied Physics Letters, 2023, 123(21): 211602. |

| 79 | Yang S Y, Oh J G, Jung D Y, et al. Metal-etching-free direct delamination and transfer of single-layer graphene with a high degree of freedom[J]. Small, 2015, 11(2): 175-181. |

| 80 | Zhang Z K, Du J H, Zhang D D, et al. Rosin-enabled ultraclean and damage-free transfer of graphene for large-area flexible organic light-emitting diodes[J]. Nature Communications, 2017, 8: 14560. |

| 81 | Cha S, Cha M, Lee S, et al. Low-temperature, dry transfer-printing of a patterned graphene monolayer[J]. Scientific Reports, 2015, 5: 17877. |

| 82 | He G W, Huang S Q, Villalobos L F, et al. Synergistic CO2-sieving from polymer with intrinsic microporosity masking nanoporous single-layer graphene[J]. Advanced Functional Materials, 2020, 30(39): 2003979. |

| 83 | Kocaman C, Bondaz L, Rezaei M, et al. Direct synthesis of nanocrystalline single-layer porous graphene for hydrogen sieving[J]. Carbon, 2024, 221: 118866. |

| 84 | Hsu K J, Li S X, Micari M, et al. Graphene membranes with pyridinic nitrogen at pore edges for high-performance CO2 capture[J]. Nature Energy, 2024, 9: 964-974. |

| 85 | Dakhchoune M, Duan X K, Villalobos L F, et al. Rapid gas transport from block-copolymer templated nanoporous carbon films[J]. Industrial & Engineering Chemistry Research, 2021, 60(44): 16100-16108. |

| 86 | Zhao K N, Lee W C, Rezaei M, et al. Tuning pore size in graphene in the angstrom regime for highly selective ion-ion separation[J]. ACS Nano, 2024, 18(7): 5571-5580. |

| 87 | O'Hern S C, Jang D, Bose S M, et al. Nanofiltration across defect-sealed nanoporous monolayer graphene[J]. Nano Letters, 2015, 15(5): 3254-3260. |

| 88 | Kafiah F M, Khan Z, Ibrahim A, et al. Monolayer graphene transfer onto polypropylene and polyvinylidenedifluoride microfiltration membranes for water desalination[J]. Desalination, 2016, 388: 29-37. |

| 89 | Kidambi P R, Jang D, Idrobo J C, et al. Nanoporous atomically thin graphene membranes for desalting and dialysis applications[J]. Advanced Materials, 2017, 29(33): 1700277. |

| 90 | Kidambi P R, Boutilier M S H, Wang L D, et al. Selective nanoscale mass transport across atomically thin single crystalline graphene membranes[J]. Advanced Materials, 2017, 29(19): 1605896. |

| 91 | O'Hern S C, Stewart C A, Boutilier M S H, et al. Selective molecular transport through intrinsic defects in a single layer of CVD graphene[J]. ACS Nano, 2012, 6(11): 10130-10138. |

| 92 | Qin Y Z, Hu Y Y, Koehler S, et al. Ultrafast nanofiltration through large-area single-layered graphene membranes[J]. ACS Applied Materials & Interfaces, 2017, 9(11): 9239-9244. |

| 93 | Lu Y Q, Zhang L L, Shen L, et al. Monolayer graphene membranes for molecular separation in high-temperature harsh organic solvents[J]. Proceedings of the National Academy of Sciences of the United States of America, 2021, 118(37): e2111360118. |

| 94 | Carta M, Malpass-Evans R, Croad M, et al. An efficient polymer molecular sieve for membrane gas separations[J]. Science, 2013, 339(6117): 303-307. |

| 95 | Yang J J, Gong D, Li G H, et al. Self-assembly of thiourea-crosslinked graphene oxide framework membranes toward separation of small molecules[J]. Advanced Materials, 2018, 30(16): 1705775. |

| 96 | Wang Y H, Jin D H, Ma Q, et al. A MOF glass membrane for gas separation[J]. Angewandte Chemie International Edition, 2020, 59(11): 4365-4369. |

| 97 | Llosa Tanco M A, Medrano J A, Cechetto V, et al. Hydrogen permeation studies of composite supported alumina-carbon molecular sieves membranes: separation of diluted hydrogen from mixtures with methane[J]. International Journal of Hydrogen Energy, 2021, 46(37): 19758-19767. |

| 98 | Yuan Z, He G W, Faucher S, et al. Direct chemical vapor deposition synthesis of porous single-layer graphene membranes with high gas permeances and selectivities[J]. Advanced Materials, 2021, 33(44): 2104308. |

| 99 | Guo W, Mahurin S M, Unocic R R, et al. Broadening the gas separation utility of monolayer nanoporous graphene membranes by an ionic liquid gating[J]. Nano Letters, 2020, 20(11): 7995-8000. |

| 100 | Shen L, Shi Q, Zhang S P, et al. Highly porous nanofiber-supported monolayer graphene membranes for ultrafast organic solvent nanofiltration[J]. Science Advances, 2021, 7(37): eabg6263. |

| 101 | Cheng C, Iyengar S A, Karnik R. Molecular size-dependent subcontinuum solvent permeation and ultrafast nanofiltration across nanoporous graphene membranes[J]. Nature Nanotechnology, 2021, 16(9): 989-995. |

| 102 | Song Y, Fang S Q, Xu N, et al. Solar transpiration-powered lithium extraction and storage[J]. Science, 2024, 385(6716): 1444-1449. |

| 103 | Feng R Z, Zhang X, Murugesan V, et al. Reversible ketone hydrogenation and dehydrogenation for aqueous organic redox flow batteries[J]. Science, 2021, 372(6544): 836-840. |

| 104 | Zhou X C, Wang Z X, Epsztein R, et al. Intrapore energy barriers govern ion transport and selectivity of desalination membranes[J]. Science Advances, 2020, 6(48): eabd9045. |

| 105 | Zhang X P, Tu B, Cao Z W, et al. Anomalous mechanical and electrical interplay in a covalent organic framework monolayer membrane[J]. Journal of the American Chemical Society, 2023, 145(32): 17786-17794. |

| [1] | 何燎, 李俊, 高梦舒, 刘东阳, 张宇豪, 赵亮, 高金森, 徐春明. 石油烃中芳烃分离技术研究进展[J]. 化工学报, 2025, 76(5): 1909-1926. |

| [2] | 杨雅南, 常胜然, 薛松林, 潘建明, 邢卫红. 基于光、电驱动促进海水中铀和锂提取的研究进展[J]. 化工学报, 2025, 76(5): 1927-1942. |

| [3] | 赵英东, 姬沛君, 丛日尧, 付海超, 张家龙, 陈鹏忠, 彭孝军. 丙烯酸配位有机锡光刻胶的制备及高分辨光刻研究[J]. 化工学报, 2025, 76(4): 1820-1830. |

| [4] | 周印洁, 吉思蓓, 何松阳, 吉旭, 贺革. 机器学习辅助高通量筛选金属有机骨架用于富碳天然气中分离CO2[J]. 化工学报, 2025, 76(3): 1093-1101. |

| [5] | 崔家馨, 殷梦凡, 郑涛, 刘晗, 张睿, 刘植昌, 刘海燕, 徐春明, 孟祥海. 铝铜双金属离子液体在1-己烯/正己烷分离中的应用[J]. 化工学报, 2025, 76(2): 686-694. |

| [6] | 贾晶宇, 孔德齐, 沈圆辉, 张东辉, 李文彬, 唐忠利. 合成氨反应器尾气变压吸附氨分离工艺的模拟与分析[J]. 化工学报, 2025, 76(2): 718-730. |

| [7] | 尤潇楠, 范小强, 杨遥, 王靖岱, 阳永荣. 超临界乙烯和高压聚乙烯混合物的减压分离过程建模方法[J]. 化工学报, 2025, 76(2): 695-706. |

| [8] | 孟祥军, 杨林睿, 彭立培, 杨献奎, 花莹曦, 张人仁, 郑凯天, 许春建. 三氟化氮精馏分离流程的设计与控制[J]. 化工学报, 2025, 76(2): 707-717. |

| [9] | 杨林睿, 刘鉴漪, 李玲, 何永超, 郑凯天, 任建坡, 许春建. 苯/环己烷/环己烯萃取精馏过程的流程设计与节能[J]. 化工学报, 2025, 76(2): 731-743. |

| [10] | 徐子易, 席阳, 宋泽文, 周海骏. 碳纳米材料在锌离子电池中的应用研究进展[J]. 化工学报, 2025, 76(1): 40-52. |

| [11] | 李匡奚, 于佩潜, 王江云, 魏浩然, 郑志刚, 冯留海. 微气泡旋流气浮装置内流动分析与结构优化[J]. 化工学报, 2024, 75(S1): 223-234. |

| [12] | 谢慧慧, 姜佳鑫, 王鑫, 李正, 郭鑫, 吕欣然, 王凌云, 刘杨. 深共晶溶剂聚合物包覆膜传输分离铂、钯的研究[J]. 化工学报, 2024, 75(S1): 235-243. |

| [13] | 邱知, 谭明. 聚离子液体膜的制备及其在低钠高钾健康酱油中的应用[J]. 化工学报, 2024, 75(S1): 244-250. |

| [14] | 刘律, 刘洁茹, 范亮亮, 赵亮. 基于层流效应的被动式颗粒分离微流控方法研究[J]. 化工学报, 2024, 75(S1): 67-75. |

| [15] | 胡术刚, 田国庆, 刘文娟, 徐广飞, 刘华清, 张建, 王艳龙. 纳米零价铁的制备及氧化还原技术的应用进展[J]. 化工学报, 2024, 75(9): 3041-3055. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号