化工学报 ›› 2024, Vol. 75 ›› Issue (S1): 223-234.DOI: 10.11949/0438-1157.20240676

李匡奚1,2( ), 于佩潜1, 王江云2,3,4, 魏浩然2,3, 郑志刚1, 冯留海1,4(

), 于佩潜1, 王江云2,3,4, 魏浩然2,3, 郑志刚1, 冯留海1,4( )

)

收稿日期:2024-06-17

修回日期:2024-06-27

出版日期:2024-12-25

发布日期:2024-12-17

通讯作者:

冯留海

作者简介:李匡奚(1999—),男,硕士研究生,2756540694@qq.com

基金资助:

Kuangxi LI1,2( ), Peiqian YU1, Jiangyun WANG2,3,4, Haoran WEI2,3, Zhigang ZHENG1, Liuhai FENG1,4(

), Peiqian YU1, Jiangyun WANG2,3,4, Haoran WEI2,3, Zhigang ZHENG1, Liuhai FENG1,4( )

)

Received:2024-06-17

Revised:2024-06-27

Online:2024-12-25

Published:2024-12-17

Contact:

Liuhai FENG

摘要:

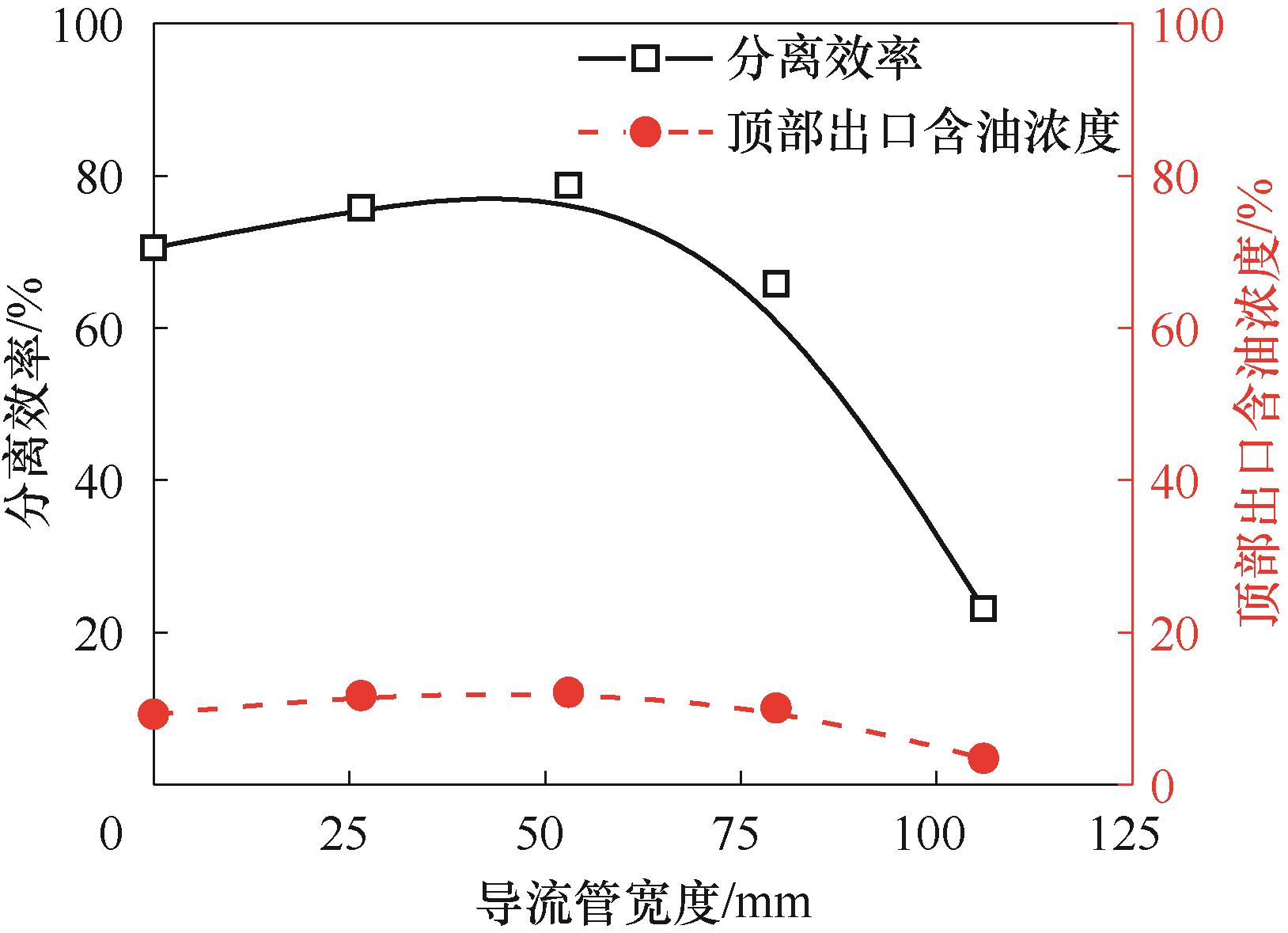

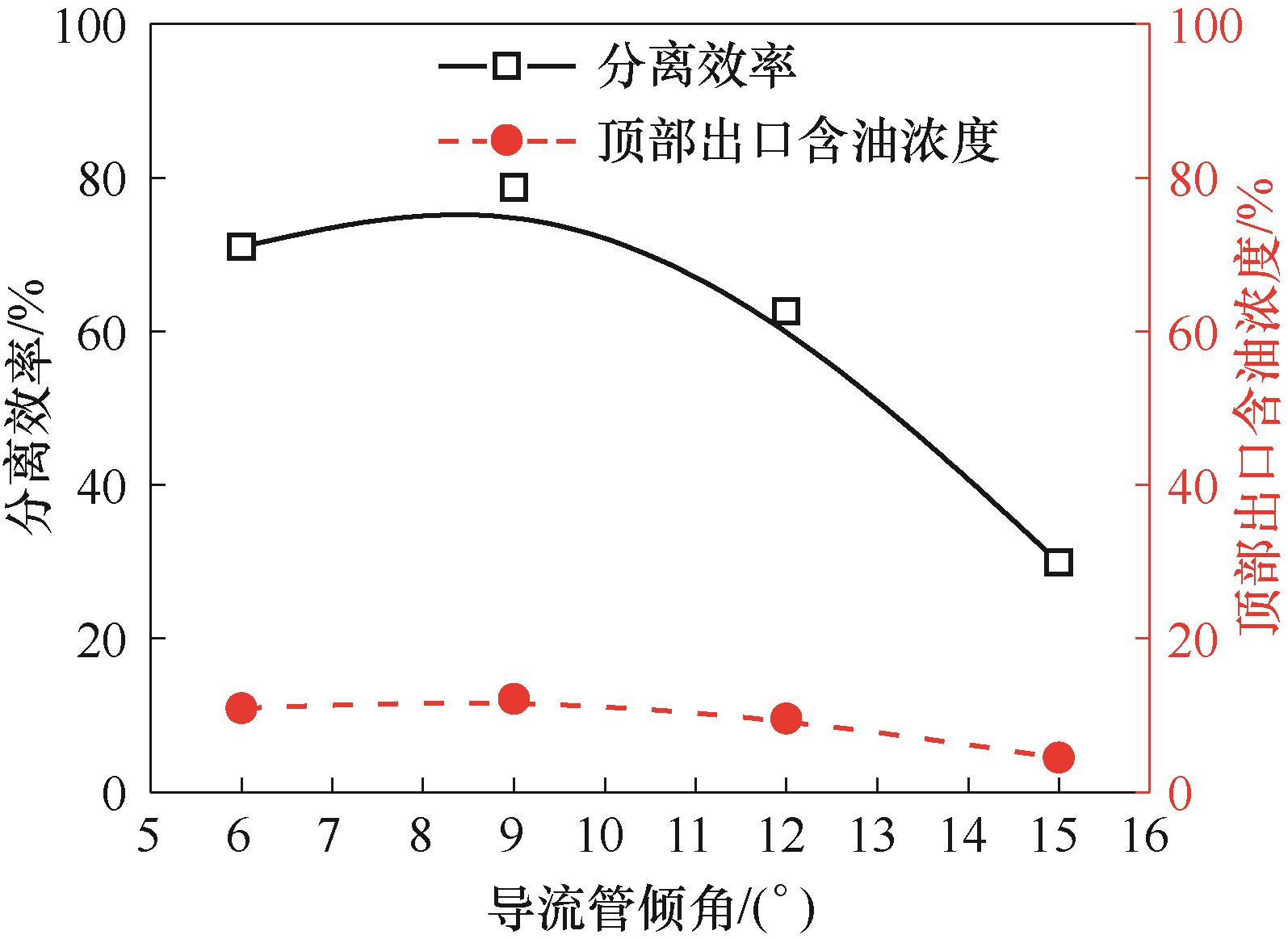

基于Euler-Euler多相流模型,对一种微气泡旋流气浮装置内的油水分离多相流动过程进行了数值计算。实际生产过程中,装置内油滴会与注入的旋流气碰撞并黏附形成油滴-气泡黏附体,因此计算过程中将微气泡旋流气浮装置内油-气-水三相流动过程简化为油气混合相和水相的两相流动过程,并依据工业生产中实际的油水分离效率确定数值计算中油气混合相的表观密度,然后考察了微气泡旋流气浮装置中导流管宽度和倾角对旋流强度及分离效率的影响规律。模拟结果表明,随导流管宽度增加,装置分离效率及出油口含油浓度先增加后迅速降低,导流管宽度为53 mm时装置的分离效果达到最优;随着导流管倾角增加,装置分离效率及顶部出油口含油浓度先上升再下降,导流管倾角为9°时装置的分离效果达到最优。

中图分类号:

李匡奚, 于佩潜, 王江云, 魏浩然, 郑志刚, 冯留海. 微气泡旋流气浮装置内流动分析与结构优化[J]. 化工学报, 2024, 75(S1): 223-234.

Kuangxi LI, Peiqian YU, Jiangyun WANG, Haoran WEI, Zhigang ZHENG, Liuhai FENG. Flow analysis and structure optimization of micro-bubble swirling air flotation device[J]. CIESC Journal, 2024, 75(S1): 223-234.

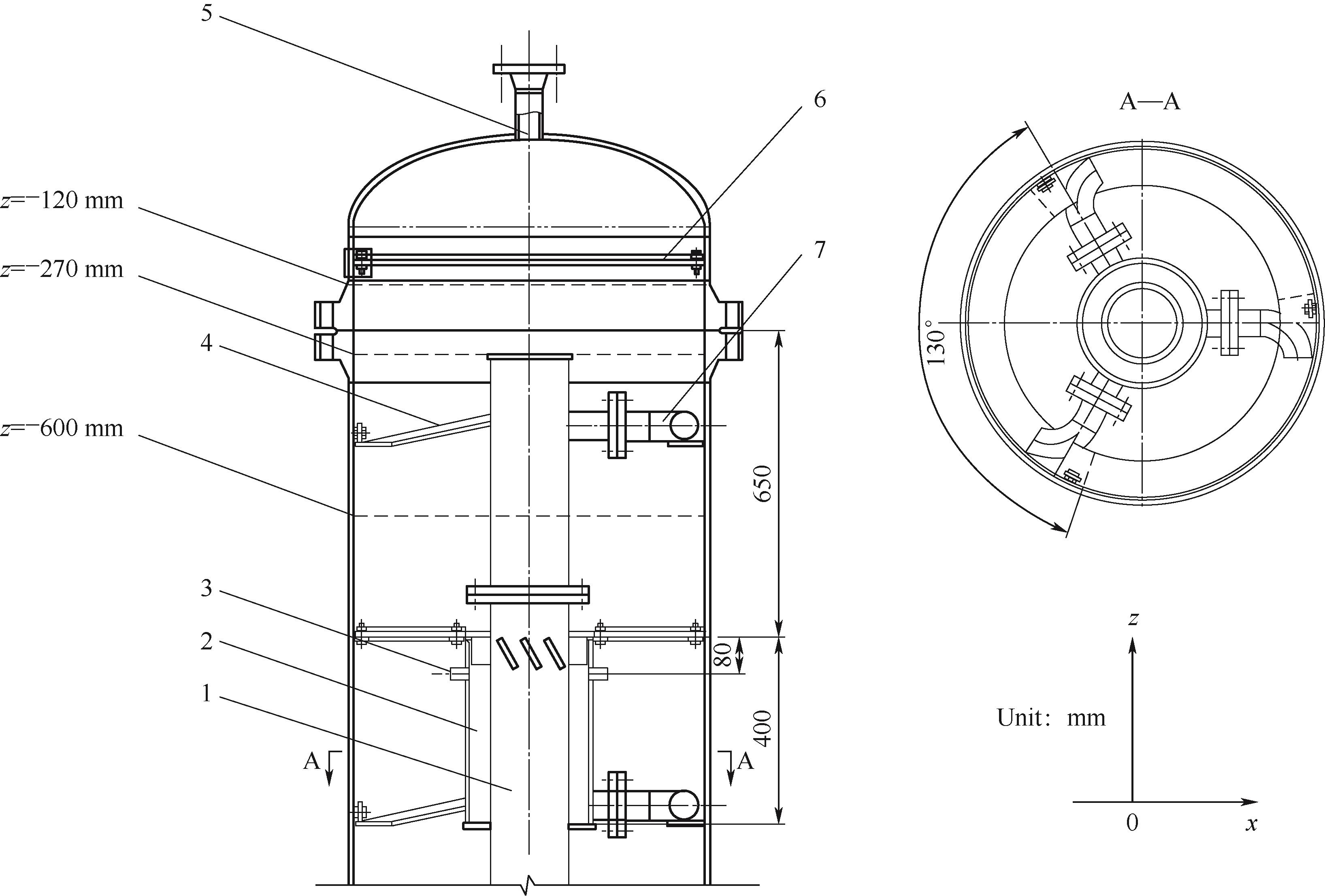

图1 微气泡旋流气浮装置几何结构及监测面位置1—污水入口管;2—净化水出口管;3—旋流气入口;4—导流板;5—油相出口;6—多孔板;7—三分支旋流管

Fig.1 Geometric structure and monitoring surface position of micro-bubble swirling air flotation device

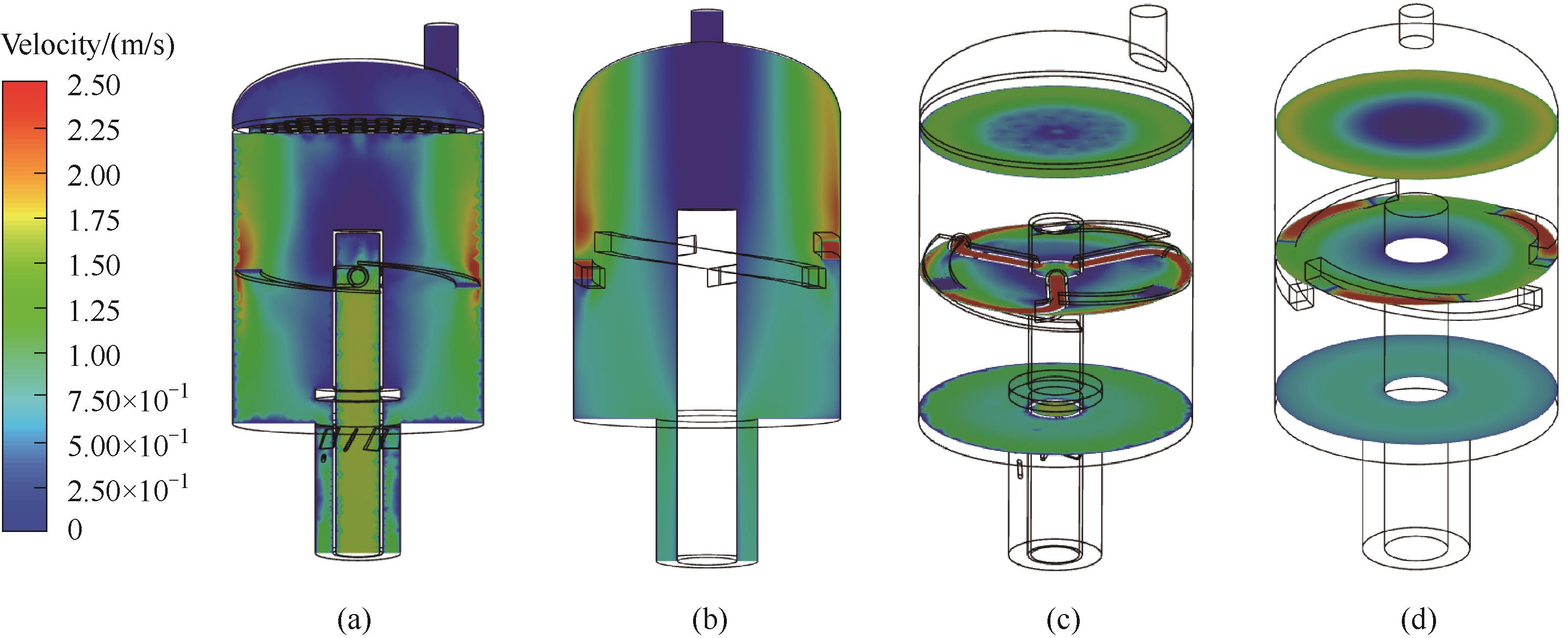

图4 原始与简化后旋流气浮装置纵截面和横截面速度对比云图

Fig.4 Velocity comparison cloud image on longitudinal and cross section of the original and simplified swirling air flotation device

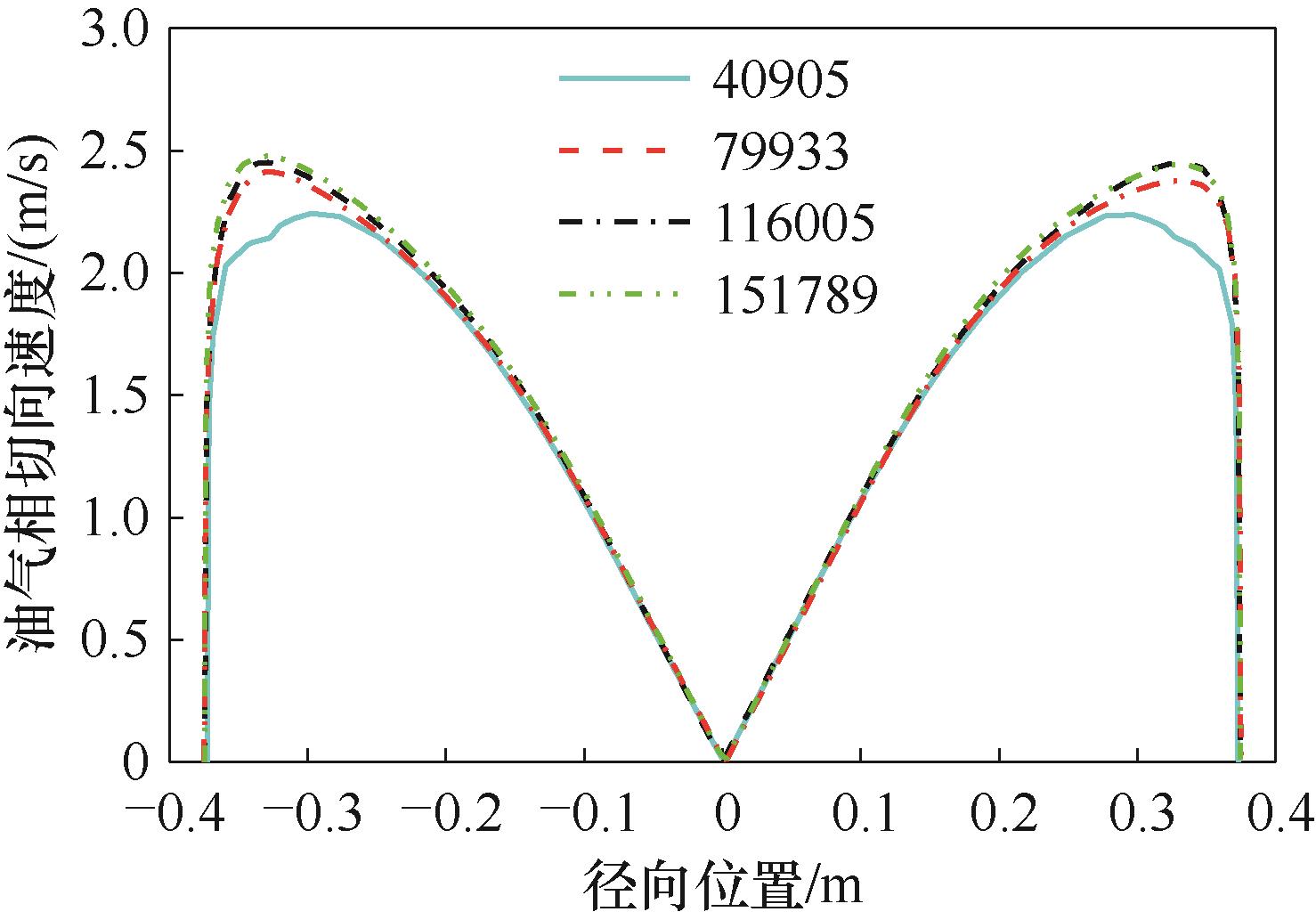

图5 z=-120 mm监测面处不同网格节点数目对应的装置内切向速度分布

Fig.5 Tangential velocity distribution in the device corresponding to the number of different grid nodes on the z=-120 mm monitoring surface

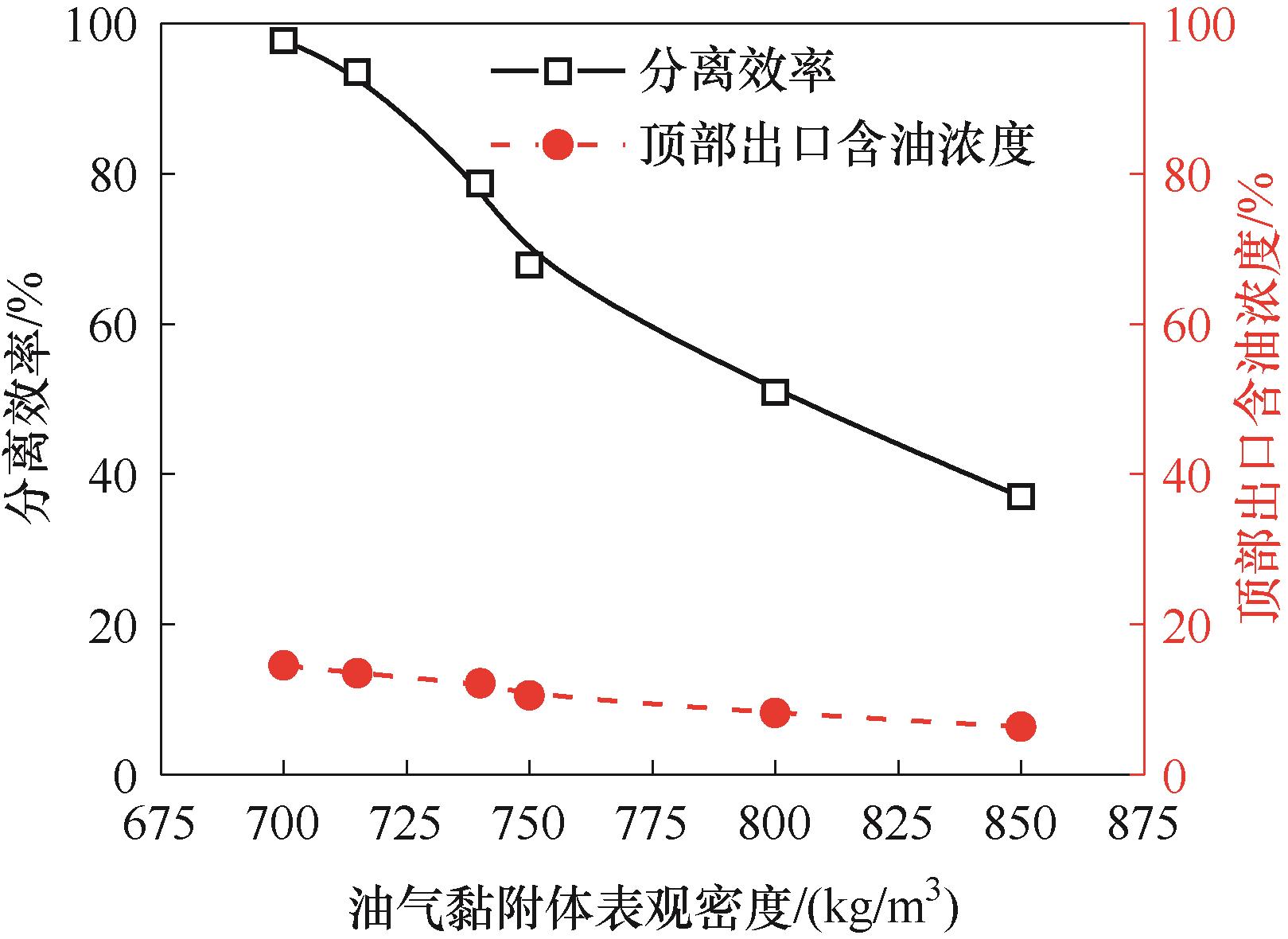

图6 分离效率及顶部出口含油浓度随油气相表观密度变化趋势

Fig.6 Variation of separation efficiency and oil concentration at the top outlet with the apparent density of oil-gas phase

图8 油气相在不同轴向高度监测面上的切向和轴向速度沿径向分布规律Ⅰ—准强制涡区;Ⅱ—准自由涡区;①—z=-120 mm;②—z=-270 mm;③—z=-600 mm

Fig.8 Tangential and axial velocity distribution of oil- gas phase on different axial height monitoring surfacesalong the radial direction

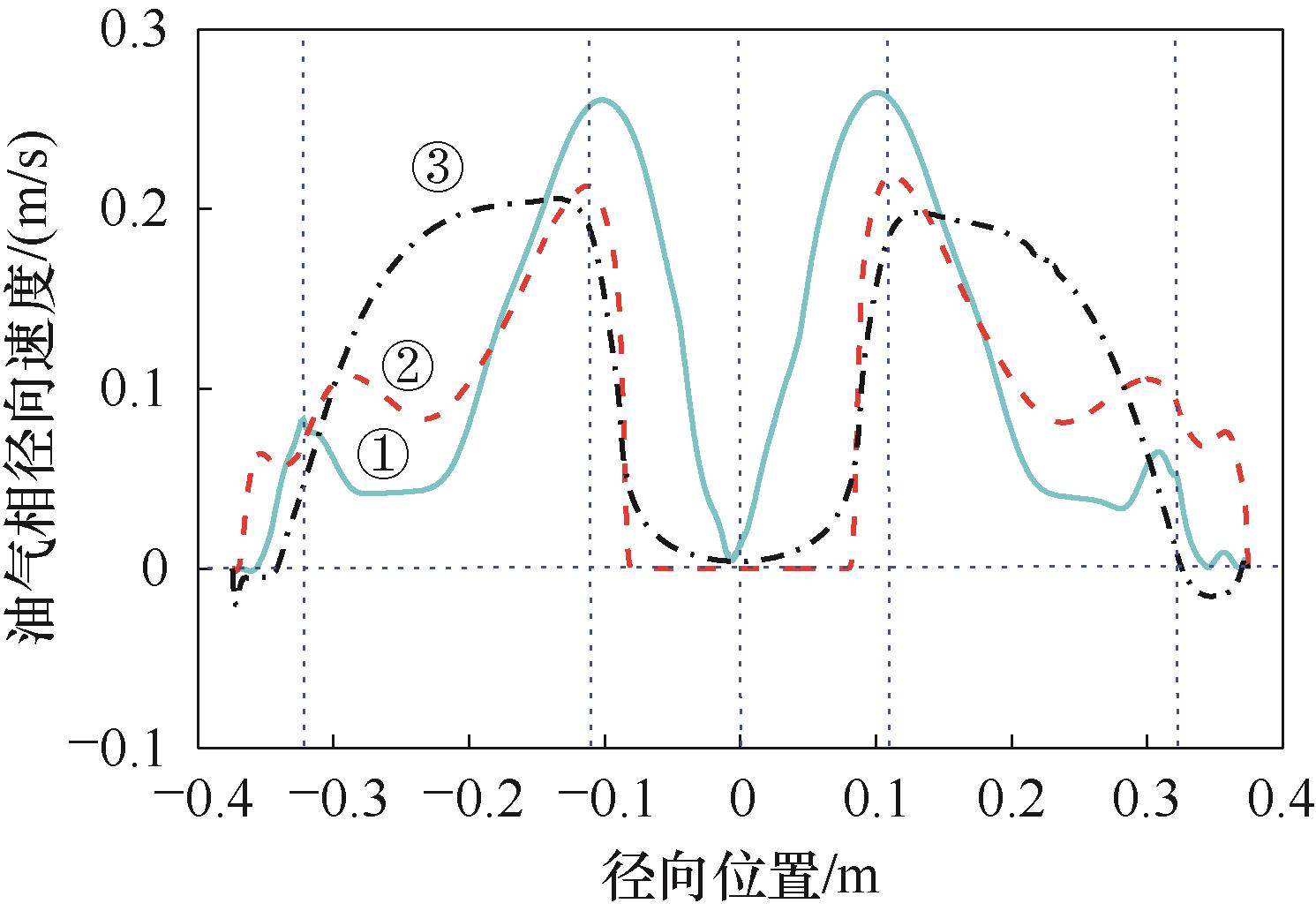

图9 油气相在不同轴向高度监测面上的径向速度沿径向分布规律①—z=-120 mm; ②—z=-270 mm; ③—z=-600 mm

Fig.9 Radial velocity distribution of oil-gas on different axial height monitoring surfaces along the radial direction

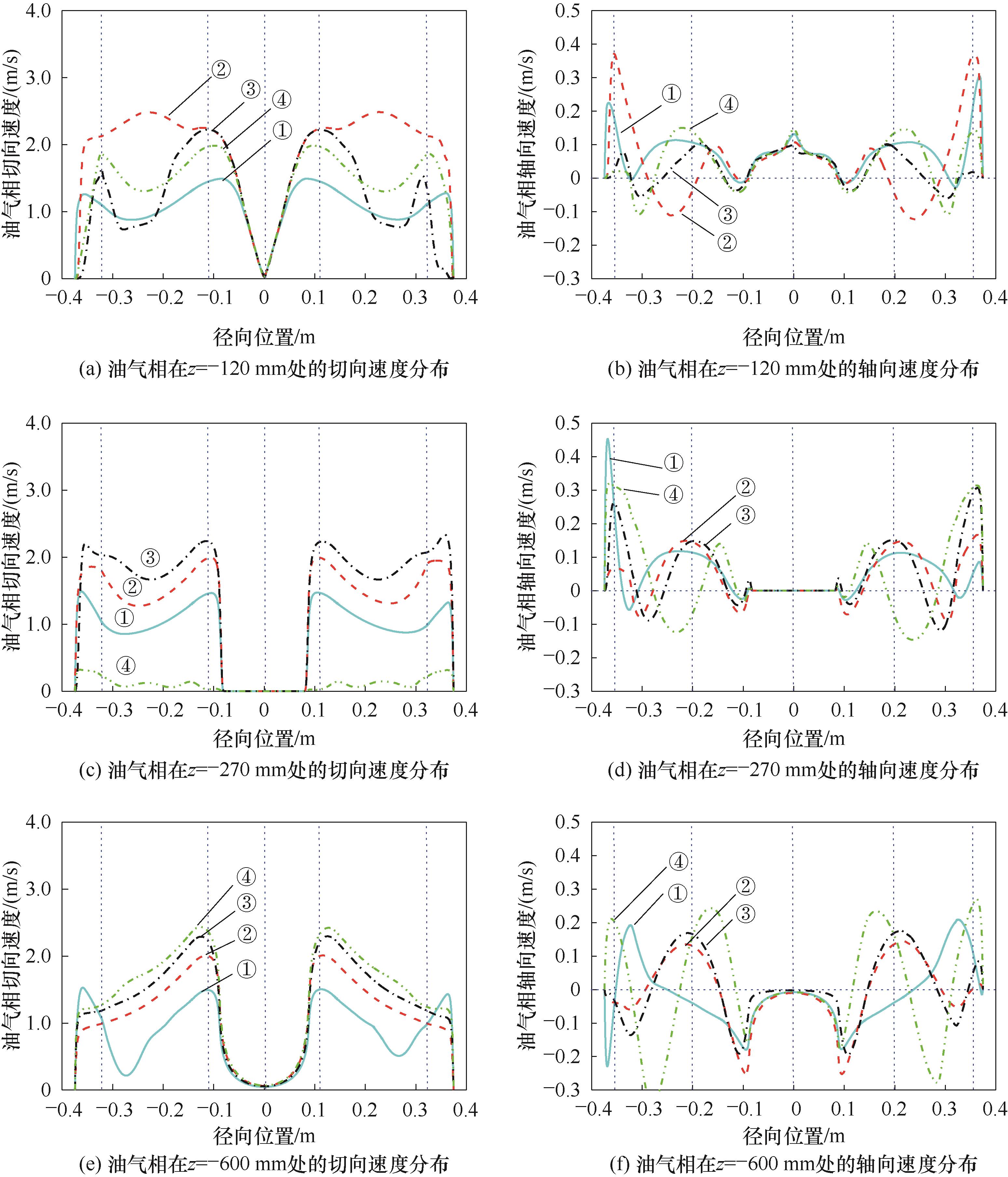

图11 不同导流管宽度时油气相速度分布① —无导流管(0 mm);② —导流管宽度26.5 mm;③—导流管宽度53 mm;④—导流管宽度106 mm

Fig.11 Oil-gas phase velocity distribution with different diversion tube widths

图12 分离效率及顶部出油口油气相浓度随导流管宽度的变化趋势

Fig.12 The variation of separation efficiency and oil-gas phase concentration at the outlet with the width of the diversion tube

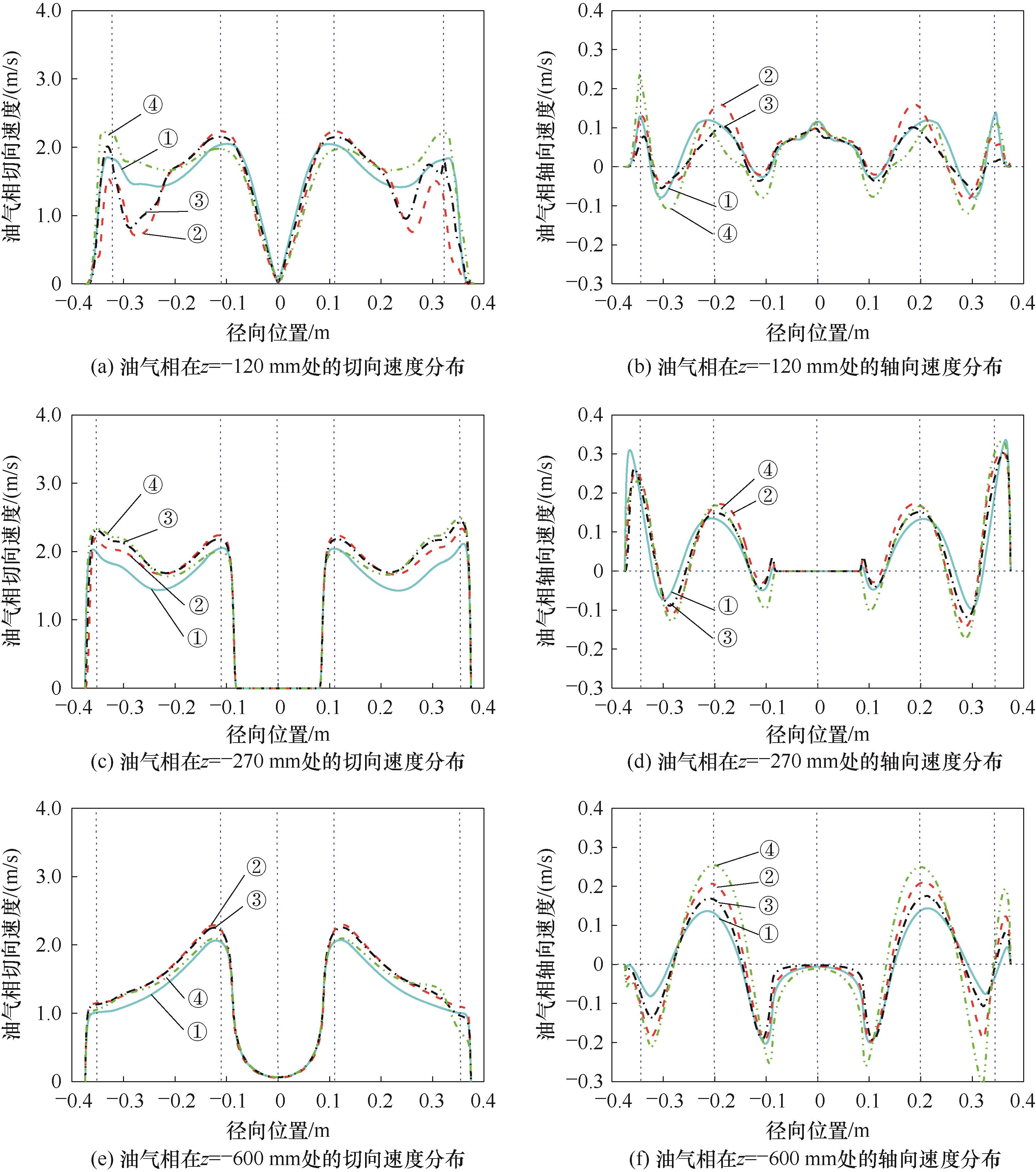

图14 不同导流管倾角时油气相速度分布①— 导流管倾角6°;②—导流管倾角9°;③—导流管倾角12°;④—导流管倾角15°

Fig.14 Velocity distribution of oil-gas phase with different inclination of diversion tube

图15 分离效率及顶部出油口油气相浓度随导流管倾角的变化趋势

Fig.15 The variation of separation efficiency and oil-gas phase concentration at the top outlet with the inclination of the diversion tube

| 1 | Sarkhel R, Ganguly P. Oil pollution and municipal wastewater treatment: issues and impact[M]//Advances in Oil-Water Separation. Amsterdam: Elsevier, 2022: 57-64. |

| 2 | Saththasivam J, Loganathan K, Sarp S. An overview of oil-water separation using gas flotation systems[J]. Chemosphere, 2016, 144: 671-680. |

| 3 | Wang L K, Shammas N K, Selke W A, et al. Flotation Technology[M]. New York: Humana Press, 2010. |

| 4 | Rawlins C. Flotation of fine oil droplets in petroleum production circuits[J]. Recent Advances in Mineral Processing Plant Design, 2009, 12 (3): 232-246. |

| 5 | 张敏, 袁惠新. 聚结分离过程的机理、方法及应用[J]. 过滤与分离, 2003, 13(1): 44-46. |

| Zhang M, Yuan H X. Methods, mechanism and application of coalescence separation[J]. Filter & Separator, 2003, 13(1): 44-46. | |

| 6 | Sarrot V, Huang Z, Legendre D, et al. Experimental determination of particles capture efficiency in flotation[J]. Chemical Engineering Science, 2007, 62(24): 7359-7369. |

| 7 | 羊衍贵, 袁惠新. 浮选过程的拓展及超重力油浮过程的分析[J]. 江南大学学报, 2004(5): 494-497. |

| Yang Y G, Yuan H X. Extension of floatation and analysis of oil-floatation in higee field[J]. Journal of Southern Yangtze University, 2004(5): 494-497. | |

| 8 | 王波, 陈家庆, 梁存珍, 等. 含油废水气浮旋流组合处理技术浅析[J]. 工业水处理, 2008, 28(4): 87-92. |

| Wang B, Chen J Q, Liang C Z, et al. Analysis on the treatment of oil-bearing wastewater by the combination of compact flotation and cyclone methods[J]. Industrial Water Treatment, 2008, 28(4): 87-92. | |

| 9 | 龚俊, 张磊, 谢勰, 等. 卧式紧凑型旋流气浮装置旋流筒结构优化数值模拟研究[J]. 工业水处理, 2023, 44(6): 179-188. |

| Gong J, Zhang L, Xie X, et al. Numerical simulation study on the structure optimization of cyclone tube of horizontal compact cyclone air flotation device[J]. Industrial Water Treatment, 2023, 44(6): 179-188. | |

| 10 | 孙志强. 海上采出污水气浮旋流一体化装置设计及其研究[D]. 荆州: 长江大学, 2020. |

| Sun Z Q. Design and research of integrated device for floating cyclone of sewage produced at sea[D]. Jingzhou: Yangtze University, 2020. | |

| 11 | 孙伯娜. 新型微气泡旋流气浮技术在某海上平台的应用[J]. 石油和化工设备, 2015, 18(11): 76-77, 80. |

| Sun B N. Application of new micro-bubble cyclone air flotation technology in an offshore platform[J]. Petro & Chemical Equipment, 2015, 18(11): 76-77, 80. | |

| 12 | 马强, 程涛, 朱梦影, 等. 旋流气浮一体化技术在油田污水处理中的应用[J]. 石油化工应用, 2018, 37(5): 47-52. |

| Ma Q, Cheng T, Zhu M Y, et al. Application of cyclonic floatation integrated technology in wastewater treatment of oilfield[J]. Petrochemical Industry Application, 2018, 37(5): 47-52. | |

| 13 | 夏福军, 武云龙, 黄宪春, 等. 微气泡旋流气浮装置处理大庆油田含聚污水[J]. 工业水处理, 2017, 37(3): 89-91. |

| Xia F J, Wu Y L, Huang X C, et al. Micro-bubble swirl current and floatation equipment for the treatment of polymer-bearing wastewater in Daqing Oilfield[J]. Industrial Water Treatment, 2017, 37(3): 89-91. | |

| 14 | 欧宇钧, 朱沫, 周艳, 等. 南海某油田紧凑型旋流气浮选器性能恢复研究[J]. 中国设备工程, 2024(8): 12-14. |

| Ou Y J, Zhu M, Zhou Y, et al. Study on performance recovery of compact cyclone gas flotation device in an oil field in South China Sea[J]. China Plant Engineering, 2024(8): 12-14. | |

| 15 | Young G A B, Wakley W D, Taggart D L, et al. Oil-water separation using hydrocyclones: an experimental search for optimum dimensions[J]. Journal of Petroleum Science and Engineering, 1994, 11(1): 37-50. |

| 16 | 魏丛达, 吴奇霖, 史仕荧, 等. 新型两级气浮旋流设备结构优化与性能研究[J]. 石油机械, 2016, 44(1): 103-107. |

| Wei C D, Wu Q L, Shi S Y, et al. Structure optimization and performance study of new two-stage air-flotation cyclone for oily water treatment[J]. China Petroleum Machinery, 2016, 44(1): 103-107. | |

| 17 | Bhatnagar M, Sverdrup C J. Advances in compact flotation units (CFUs) for produced water treatment[C]//Offshore Technology Conference. Kuala Lumpur, Malaysia. OTC, 2014: 25-28. |

| 18 | 俞接成, 陈家庆, 王春升, 等. 紧凑型气浮装置油水预分离区结构选型的数值研究[J]. 过程工程学报, 2012, 12(5): 742-747. |

| Yu J C, Chen J Q, Wang C S, et al. Numerical simulation on the structure selection of oil-water pre-separation zone in a compact flotation unit[J]. The Chinese Journal of Process Engineering, 2012, 12(5): 742-747. | |

| 19 | Maelum M, Rabe K. Improving oil separation from produced water using new compact flotation unit design[C]//Offshore Technology Conference. Oklahoma City, Oklahoma, USA. SPE, 2015: 1-5. |

| 20 | 王乐, 何庆生, 王贵宾. 气旋浮技术处理炼油企业含油污水试验研究[J]. 中外能源, 2020, 25(12): 67-70. |

| Wang L, He Q S, Wang G B. Experimental study on cyclone floatation technology for treatment of oily wastewater from oil refining enterprises[J]. Sino-Global Energy, 2020, 25(12): 67-70. | |

| 21 | 王江云, 魏浩然, 李佳奇, 等. 旋流气浮装置内流动规律数值模拟[J]. 石油学报(石油加工), 2023, 39(3): 587-598. |

| Wang J Y, Wei H R, Li J Q, et al. Numerical simulation of flow laws in swirling air flotation devices[J]. Acta Petrolei Sinica (Petroleum Processing Section), 2023, 39(3): 587-598. | |

| 22 | Bridgeman J, Jefferson B, Parsons S. Assessing floc strength using CFD to improve organics removal[J]. Chemical Engineering Research and Design, 2008, 86(8): 941-950. |

| 23 | Movafaghian S, Chen J C T. Ultra compact cyclonic flotation system: US20080006588[P]. 2008-01-10. |

| 24 | 韩严和, 陈家庆, 桑义敏, 等. 旋流气浮中气泡-颗粒碰撞效率影响因素理论分析[J]. 过程工程学报, 2013, 13(2): 186-190. |

| Han Y H, Chen J Q, Sang Y M, et al. Theoretical analysis on the influential factors of bubble-particle collision efficiency in hydrocyclone flotation[J]. The Chinese Journal of Process Engineering, 2013, 13(2): 186-190. | |

| 25 | 孔祥功, 陈家庆, 姬宜朋, 等. 大处理量紧凑型气浮装置的数值模拟[J]. 化工进展, 2016, 35(3): 733-740. |

| Kong X G, Chen J Q, Ji Y P, et al. Numerical simulation of flow field and structural and operational parameters in a large capacity compact flotation unit (CFU)[J]. Chemical Industry and Engineering Progress, 2016, 35(3): 733-740. | |

| 26 | 贺彦涛, 王玉环, 蔺爱国, 等. 旋流微气泡气浮除油过程的数值模拟[J]. 石油学报(石油加工), 2020, 36(2): 349-356. |

| He Y T, Wang Y H, Lin A G, et al. Numerical simulation of oil removal process by air flotation of swirling micro bubbles[J]. Acta Petrolei Sinica (Petroleum Processing Section), 2020, 36(2): 349-356. | |

| 27 | 杨威. 气携式液-液水力旋流器的数值模拟[D]. 大连: 大连理工大学, 2011. |

| Yang W. Numerical simulation of the gas-injected liquid-liquid hydrocyclone[D]. Dalian: Dalian University of Technology, 2011. | |

| 28 | Wang G C, Ge L H, Mitra S, et al. A review of CFD modelling studies on the flotation process[J]. Minerals Engineering, 2018, 127: 153-177. |

| 29 | 任向海, 彭振华, 丁雯, 等. 基于CFD-PBM模型的井下油水旋流分离器结构优选[J]. 石油机械, 2023, 51(6): 66-73. |

| Ren X H, Peng Z H, Ding W, et al. Structure optimization of downhole oil-water hydrocyclone based on CFD-PBM model[J]. China Petroleum Machinery, 2023, 51(6): 66-73. | |

| 30 | Cai X L, Chen J Q, Liu M L, et al. Numerical studies on dynamic characteristics of oil-water separation in loop flotation column using a population balance model[J]. Separation and Purification Technology, 2017, 176: 134-144. |

| 31 | Li Q, Gao J X, Lu S B, et al. Numerical studies on dynamic and oil-water separation characteristics in cyclonic flotation column[J]. Chemical Engineering Research and Design, 2023, 196: 332-341. |

| 32 | Cunha R E P, Fortuny M, Dariva C, et al. Mathematical modeling of the destabilization of crude oil emulsions using population balance equation[J]. Industrial & Engineering Chemistry Research, 2008, 47(18): 7094-7103. |

| 33 | Zeng K W, Yu Y F, Xue Y L. Effect of flow velocity of particles in flotation cellon flotation[J]. Indus. Miner. Proc, 2012, 6(1): 1-4. |

| 34 | 覃成鹏. 基于EMMS模型的CFD-PBM方法模拟液-液流动体系[D]. 北京: 中国科学院大学, 2016. |

| Qin C P. Simulation of liquid-liquid flow system by CFD-PBM method based on EMMS model[D]. Beijing: University of Chinese Academy of Sciences, 2016. | |

| 35 | Wilcox D C. Turbulence Modeling for CFD[M]. 3rd ed. California: DCW Industries Inc, 2006. |

| 36 | 冯喜平, 赵胜海, 李进贤, 等. 不同湍流模型对旋涡流动的数值模拟[J]. 航空动力学报, 2011, 26(6): 1209-1214. |

| Feng X P, Zhao S H, Li J X, et al. Numerical simulation of swirling flow with different turbulent models[J]. Journal of Aerospace Power, 2011, 26(6): 1209-1214. | |

| 37 | 王江云, 王壮, 侯琳倩, 等. 突变流道内空泡脱落特性及空蚀损伤分析[J]. 石油学报(石油加工), 2021, 37(4): 815-823. |

| Wang J Y, Wang Z, Hou L Q, et al. Cavitation shedding characteristics and cavitation damage analysis in sudden change channel[J]. Acta Petrolei Sinica (Petroleum Processing Section), 2021, 37(4): 815-823. | |

| 38 | 陈阿强, 王振波, 王晨, 等. 气浮接触区气泡聚并行为的数值模拟[J]. 化工学报, 2016, 67(6): 2300-2307. |

| Chen A Q, Wang Z B, Wang C, et al. Numerical simulation of bubble coalescence behavior in contact zone of dissolved air flotation tank[J]. CIESC Journal, 2016, 67(6): 2300-2307. | |

| 39 | Tomiyama A. Struggle with computational bubble dynamics[J]. Multiphase Science and Technology, 1998, 10(4): 369-405. |

| 40 | Lopez de Bertodano M, Lahey R T, Jones O C. Turbulent bubbly two-phase flow data in a triangular duct[J]. Nuclear Engineering and Design, 1994, 146(1/2/3): 43-52. |

| 41 | 尚超, 王春升, 张明, 等. 紧凑式气浮设备表面负荷率的分析和合理选择[C]//2015年深海能源大会. 海口, 2015: 145-149. |

| Shang C, Wang C S, Zhang M, et al. Analysis and reasonable selection of surface load rate of compact air flotation equipment[C]//Proceedings of 2015 Deepwater Energy Conference. Haikou, 2015: 145-149. |

| [1] | 任冠宇, 张义飞, 李新泽, 杜文静. 翼型印刷电路板式换热器流动传热特性数值研究[J]. 化工学报, 2024, 75(S1): 108-117. |

| [2] | 杨勇, 祖子轩, 李煜坤, 王东亮, 范宗良, 周怀荣. T型圆柱形微通道内CO2碱液吸收数值模拟[J]. 化工学报, 2024, 75(S1): 135-142. |

| [3] | 黄俊豪, 庞克亮, 孙方远, 刘福军, 谷致远, 韩龙, 段衍泉, 冯妍卉. 干熄炉料钟结构对焦炭布料粒径均匀度影响的模拟研究[J]. 化工学报, 2024, 75(S1): 158-169. |

| [4] | 董新宇, 边龙飞, 杨怡怡, 张宇轩, 刘璐, 王腾. 冷却条件下倾斜上升管S-CO2流动与传热特性研究[J]. 化工学报, 2024, 75(S1): 195-205. |

| [5] | 郭骐瑞, 任丽媛, 陈康, 黄翔宇, 马卫华, 肖乐勤, 周伟良. 用于HTPB推进剂浆料的静态混合管数值模拟[J]. 化工学报, 2024, 75(S1): 206-216. |

| [6] | 汪张洲, 唐天琪, 夏嘉俊, 何玉荣. 基于复合相变材料的电池热管理性能模拟[J]. 化工学报, 2024, 75(S1): 329-338. |

| [7] | 胡俭, 姜静华, 范生军, 刘建浩, 邹海江, 蔡皖龙, 王沣浩. 中深层U型地埋管换热器取热特性研究[J]. 化工学报, 2024, 75(S1): 76-84. |

| [8] | 李舒月, 王欢, 周少强, 毛志宏, 张永民, 王军武, 吴秀花. 基于CPFD方法的U3O8氢还原流化床反应器数值模拟[J]. 化工学报, 2024, 75(9): 3133-3151. |

| [9] | 陈巨辉, 苏潼, 李丹, 陈立伟, 吕文生, 孟凡奇. 翅形扰流片作用下的微通道换热特性[J]. 化工学报, 2024, 75(9): 3122-3132. |

| [10] | 钱啸宇, 阮璇, 李水清. 外加电场下电介质颗粒层结构重构与悬浮[J]. 化工学报, 2024, 75(8): 2756-2762. |

| [11] | 朱子良, 王爽, 姜宇昂, 林梅, 王秋旺. 欧拉-拉格朗日迭代固-液相变算法[J]. 化工学报, 2024, 75(8): 2763-2776. |

| [12] | 邓爱明, 何玉荣, 唐天琪, 胡彦伟. 导流板对喷雾流化床内颗粒生长过程影响的模拟[J]. 化工学报, 2024, 75(8): 2787-2799. |

| [13] | 金虎, 杨帆, 戴梦瑶. 基于格子Boltzmann方法的液滴在圆柱壁面上运动过程研究[J]. 化工学报, 2024, 75(8): 2897-2908. |

| [14] | 豆少军, 郝亮. PEMFC催化层耦合气体电荷传输过程的介观模拟[J]. 化工学报, 2024, 75(8): 3002-3010. |

| [15] | 韩志敏, 李江, 陈则齐, 刘威, 徐志明. 脉动流通道内不同纵向涡发生器的颗粒污垢特性[J]. 化工学报, 2024, 75(7): 2486-2496. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号