化工学报 ›› 2025, Vol. 76 ›› Issue (2): 695-706.DOI: 10.11949/0438-1157.20240859

• 分离工程 • 上一篇

尤潇楠1( ), 范小强1,2(

), 范小强1,2( ), 杨遥1,3, 王靖岱1,3, 阳永荣1,3

), 杨遥1,3, 王靖岱1,3, 阳永荣1,3

收稿日期:2024-07-29

修回日期:2024-09-19

出版日期:2025-03-25

发布日期:2025-03-10

通讯作者:

范小强

作者简介:尤潇楠(1998—),男,硕士,youxiaonan@zju.edu.cn

基金资助:

Xiaonan YOU1( ), Xiaoqiang FAN1,2(

), Xiaoqiang FAN1,2( ), Yao YANG1,3, Jingdai WANG1,3, Yongrong YANG1,3

), Yao YANG1,3, Jingdai WANG1,3, Yongrong YANG1,3

Received:2024-07-29

Revised:2024-09-19

Online:2025-03-25

Published:2025-03-10

Contact:

Xiaoqiang FAN

摘要:

超临界乙烯和高压聚乙烯混合物的减压分离过程涉及超临界乙烯与多分散性聚乙烯的复杂两相流动和相变传质过程,现有模型不仅缺少有效的数据验证,而且并不具备准确预测多分散性聚乙烯蜡分子量分布的能力。因此,首先对高压聚乙烯及其聚乙烯蜡的分子链结构进行表征分析,然后根据分离机理提出了一种预测高压分离器气相出口聚乙烯蜡流量及其分子量分布的建模策略,最后研究了操作条件对聚乙烯蜡产量的影响。研究方法和结果不仅可为高压聚乙烯分离过程的操作优化和产品含蜡量的定向调控提供理论指导,而且可以拓展到其他溶液法工艺的聚合物分离过程,具有重要的意义。

中图分类号:

尤潇楠, 范小强, 杨遥, 王靖岱, 阳永荣. 超临界乙烯和高压聚乙烯混合物的减压分离过程建模方法[J]. 化工学报, 2025, 76(2): 695-706.

Xiaonan YOU, Xiaoqiang FAN, Yao YANG, Jingdai WANG, Yongrong YANG. Modeling method of depressurization separation process of the mixture of high-pressure polyethylene and supercritical ethylene[J]. CIESC Journal, 2025, 76(2): 695-706.

| 参数 | C2H4 | LDPE |

|---|---|---|

| kij | -0.0568708 | |

| m | 1.522416 | 0.04131746M |

| σ | 3.4882223 | 3.4750711 |

| ε/kB | 181.331214 | 267.179575 |

表1 PC-SAFT状态方程中的纯组分参数[19]

Table 1 Pure component parameters in the PC-SAFT equation of state[19]

| 参数 | C2H4 | LDPE |

|---|---|---|

| kij | -0.0568708 | |

| m | 1.522416 | 0.04131746M |

| σ | 3.4882223 | 3.4750711 |

| ε/kB | 181.331214 | 267.179575 |

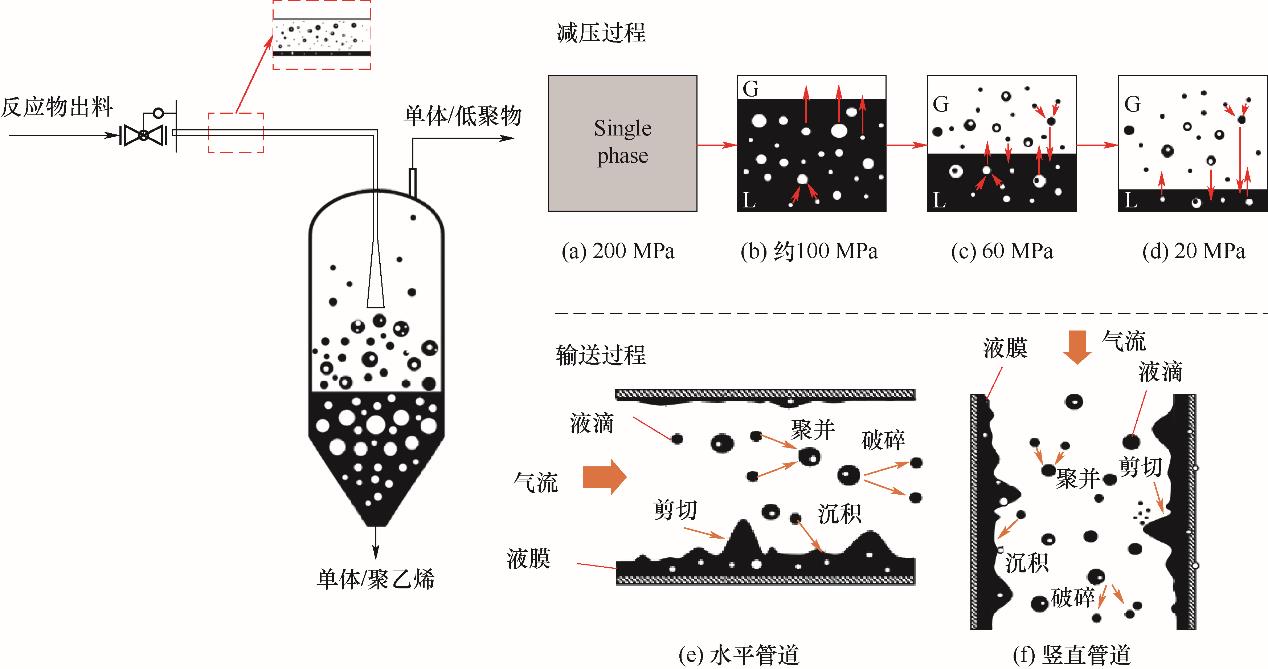

图4 超临界乙烯-聚乙烯分离机理示意图(黑色代表聚乙烯相,白色代表乙烯相,灰色代表均一相)

Fig.4 Schematic diagram of the supercritical ethylene-polyethylene separation mechanism (black represents the polyethylene phase, white represents the ethylene phase, gray represents the homogeneous phase)

| 数据 | Mn | Mw | PDI |

|---|---|---|---|

| 原始数据(PE-B) | 15390 | 106031 | 6.9 |

| 46个伪组分 | 17419 | 121314 | 7.0 |

| 91个伪组分 | 16351 | 112950 | 6.9 |

| 226个伪组分 | 15746 | 108571 | 6.9 |

表2 聚乙烯产品(PE-B)分子量分布数据处理前后对比

Table 2 Comparison of molecular weight distribution data for polyethylene product (PE-B) before and after data processing

| 数据 | Mn | Mw | PDI |

|---|---|---|---|

| 原始数据(PE-B) | 15390 | 106031 | 6.9 |

| 46个伪组分 | 17419 | 121314 | 7.0 |

| 91个伪组分 | 16351 | 112950 | 6.9 |

| 226个伪组分 | 15746 | 108571 | 6.9 |

| 相关参数 | Model A[ | Model B[ | Model C(this study Ⅰ) |

|---|---|---|---|

| 形成机理 | 相平衡 | 夹带、传质 | 相平衡、气相剪切、减压溶解 |

| 流量信息 | √ | √ | √ |

| 分子量分布 | √ | × | √ |

表3 数学模型预测能力对比

Table 3 Comparison of predictive capabilities of mathematical models

| 相关参数 | Model A[ | Model B[ | Model C(this study Ⅰ) |

|---|---|---|---|

| 形成机理 | 相平衡 | 夹带、传质 | 相平衡、气相剪切、减压溶解 |

| 流量信息 | √ | √ | √ |

| 分子量分布 | √ | × | √ |

| 1 | Pladis P, Baltsas A, Kanellopoulos V, et al. Dynamic multi-phase, multi-zone modeling of flash separators for highly viscous polymerization processes[J]. Macromolecular Reaction Engineering, 2014, 8(4): 392-405. |

| 2 | Buchelli A, Call M L, Brown A L, et al. Modeling fouling effects in LDPE tubular polymerization reactors(1): Fouling thickness determination[J]. Industrial & Engineering Chemistry Research, 2005, 44(5): 1474-1479. |

| 3 | Folie B, Radosz M. Phase equilibria in high-pressure polyethylene technology[J]. Industrial & Engineering Chemistry Research, 1995, 34(5): 1501-1516. |

| 4 | Bonner D C, Maloney D P, Prausnitz J M. Calculation of high-pressure phase equilibria and molecular-weight distribution in partial decompression of polyethylene-ethylene mixtures[J]. Industrial & Engineering Chemistry Process Design and Development, 1974, 13(1): 91-95. |

| 5 | Spahl R, Luft G. Fraktionierungserscheinungen Bei der entmischung von ethylen-polyethylen-gemischen[J]. Die Angewandte Makromolekulare Chemie, 1983, 115(1): 87-102. |

| 6 | Bogdanovic V, Tasic A, Djordjevic B. Industrial aspects of phase separation in ethylene-polyethylene system at pressures of 15—30 MPa[J]. Industrial & Engineering Chemistry Process Design and Development, 1985, 24(3): 576-581. |

| 7 | Pladis P, Baltsas A, Kiparissides C. A comprehensive investigation on high-pressure LDPE manufacturing: dynamic modelling of compressor, reactor and separation units[J]. Computer Aided Chemical Engineering, 2006, 21: 595-600. |

| 8 | Cernia E M, Mancini C. A thermodynamic approach to phase equilibria investigation of polyethylene-ethylene system at high pressure[J]. Kobunshi Kagaku, 1965, 22(248): 797-803. |

| 9 | Swelheim T, De Swaan Arons J, Diepen G A M. Fluid phase equilibria in the system polyethene-ethene[J]. Recueil Des Travaux Chimiques Des Pays-Bas, 1965, 84(2): 261-266. |

| 10 | Steiner R, Horlé K. Phasenverhalten von Äthylen/Polyäthylen-Gemischen unter hohem Druck[J]. Chemie Ingenieur Technik, 1972, 44(17): 1010-1015. |

| 11 | Maloney D P, Prausnitz J M. Solubility of ethylene in liquid, low-density polyethylene at industrial-separation pressures[J]. Industrial & Engineering Chemistry Process Design and Development, 1976, 15(1): 216-220. |

| 12 | Maloney D P, Prausnitz J M. Solubilities of ethylene and other organic solutes in liquid, low-density polyethylene in the region 124° to 300℃[J]. AIChE Journal, 1976, 22(1): 74-82. |

| 13 | Rätzsch M, Findeisen R, Sernow V S. Untersuchungen zum phasenverhalten von monomer-polymer-systemen unter hohem druck[J]. Zeitschrift Für Physikalische Chemie, 1980, 261(1): 1000-1995. |

| 14 | Luft G, Lindner A. Zum einfluß des polymermolekulargewichts auf das phasenverhalten von gas-polymer-systemen unter hochdruck[J]. Die Angewandte Makromolekulare Chemie, 1976, 56(1): 99-114. |

| 15 | Spahl R, Luft G. Einfluß von molmasse und molekülverzweigungen auf das entmischungsverhalten von ethylen/polyethylen-systemen unter hochdruck[J]. Berichte Der Bunsengesellschaft Für Physikalische Chemie, 1982, 86(7): 621-625. |

| 16 | De Loos T W, Poot W, Diepen G A M. Fluid phase equilibriums in the system polyethylene + ethylene(1): Systems of linear polyethylene + ethylene at high pressure[J]. Macromolecules, 1983, 16(1): 111-117. |

| 17 | Browarzik D, Rätzsch M T, Wohlfarth C. High pressure phase equilibrium in the system ethylene + vinylacetate + (ethylene vinylacetate) copolymer treated by continuous thermodynamics[J]. Acta Polymerica, 1989, 40(7): 457-462. |

| 18 | de Loos T W, Poot W, Lichtenthaler R N. The influence of branching on high-pressure vapor-liquid equilibria in systems of ethylene and polyethylene[J]. The Journal of Supercritical Fluids, 1995, 8(4): 282-286. |

| 19 | Buchelli A, Call M L, Brown A L, et al. Nonequilibrium behavior in ethylene/polyethylene flash separators[J]. Industrial & Engineering Chemistry Research, 2004, 43(7): 1768-1778. |

| 20 | Bogdanović V Ž, Tasić A Ž, Djordjević B D. Importance of solubility phenomena during the separation of the ethylene-polyethylene mixture in the industrial low density polyethylene process[J]. Journal of Applied Polymer Science, 1994, 51(2): 253-258. |

| 21 | Gross J, Sadowski G. Perturbed-chain SAFT: an equation of state based on a perturbation theory for chain molecules[J]. Industrial & Engineering Chemistry Research, 2001, 40(4): 1244-1260. |

| 22 | Heuer T, Peuschel G P, Rätzsch M, et al. Untersuchungen zur löslichkeit von ethen, propan, propen und but-1-en in schmelzen von oligomeren des polyethylens bzw. (Ethen-vinylacetat)-copolymeren bei temperaturen bis 473, 15 K und drücken bis 30 MPa. t e i l ( Ⅱ ) : Modellierung und vorausberechnung[J]. Acta Polymerica, 1989, 40(5): 320-324. |

| 23 | 吕海蛟. LDPE装置高压循环系统分离效果影响因素分析及优化[J]. 化工管理, 2022(31): 123-125. |

| Lyu H J. Analysis and optimization of influencing factors on separation effect of high pressure circulating system in LDPE plant[J]. Chemical Management, 2022(31): 123-125. | |

| 24 | Cheluget E L, Bokis C P, Wardhaugh L, et al. Modeling polyethylene fractionation using the perturbed-chain statistical associating fluid theory equation of state[J]. Industrial & Engineering Chemistry Research, 2002, 41(5): 968-988. |

| 25 | Behme S, Sadowski G, Song Y H, et al. Multicomponent flash algorithm for mixtures containing polydisperse polymers[J]. AIChE Journal, 2003, 49(1): 258-268. |

| 26 | Cheng Y. Thermodynamics of phase equilibrium between ethylene and polyethylene[D]. Graduate Faculty of Texas Tech University, 1976. |

| 27 | Ishii M, Grolmes M A. Inception criteria for droplet entrainment in two-phase concurrent film flow[J]. AIChE Journal, 1975, 21(2): 308-318. |

| 28 | Berna C, Escrivá A, Muñoz-Cobo J L, et al. Review of droplet entrainment in annular flow: characterization of the entrained droplets[J]. Progress in Nuclear Energy, 2015, 79: 64-86. |

| 29 | Aliyu A M, Almabrok A A, Baba Y D, et al. Prediction of entrained droplet fraction in co-current annular gas-liquid flow in vertical pipes[J]. Experimental Thermal and Fluid Science, 2017, 85: 287-304. |

| 30 | Kwok D Y, Cheung L K, Park C B, et al. Study on the surface tensions of polymer melts using axisymmetric drop shape analysis[J]. Polymer Engineering & Science, 1998, 38(5): 757-764. |

| [1] | 戴晓宇, 徐强, 杨晨宇, 苏筱斌, 郭烈锦. 多级混流式混输泵气液两相增压特性[J]. 化工学报, 2025, 76(2): 554-563. |

| [2] | 彭子林, 周蕾, 邓庆航, 叶光华, 周兴贵. 包含偏硅酸影响的3D NAND磷酸湿法刻蚀动力学[J]. 化工学报, 2025, 76(2): 645-653. |

| [3] | 张恒, 魁殿禄, 常虹, 詹志刚. 机械应力对气体扩散层界面传输特性影响[J]. 化工学报, 2025, 76(2): 637-644. |

| [4] | 何传超, 周静红, 曹约强, 施尧, 周兴贵. Ag/SiO2催化草酸酯加氢制乙醇酸甲酯的床层-颗粒双尺度耦合模拟研究[J]. 化工学报, 2025, 76(2): 654-666. |

| [5] | 党法璐, 孙志国, 高照, 王刚, 陈政宇, 张霖宙, 连竞存, 刘美佳, 张忠东, 刘超伟. 原油一步法催化裂解制低碳烯烃:实验和反应路径研究[J]. 化工学报, 2025, 76(2): 667-685. |

| [6] | 黄云龙, 许剑, 刘通, 元昕彤, 徐强. 气藏水平井温度分布特征及流量测试实验研究[J]. 化工学报, 2025, 76(2): 612-622. |

| [7] | 张珂, 任维杰, 王梦娜, 范凯锋, 常丽萍, 李佳斌, 马涛, 田晋平. Bunsen反应产物在微通道中的液-液两相混合特性[J]. 化工学报, 2025, 76(2): 623-636. |

| [8] | 魏攀攀, 刘怿楠, 朱春英, 付涛涛, 高习群, 马友光. 改进的T型微通道内双水相液滴的制备[J]. 化工学报, 2025, 76(2): 576-583. |

| [9] | 黄鑫, 李逸龙, 李卫东, 施鸿翔, 尹鹏博, 李臻超, 滕霖, 江莉龙. 液氨-成品油混合体系相平衡及减压相变规律研究[J]. 化工学报, 2025, 76(1): 71-80. |

| [10] | 李彦, 郭红利, 苏国庆, 张建文. 加氢装置空冷器气液两相流动与冲刷腐蚀问题[J]. 化工学报, 2025, 76(1): 141-150. |

| [11] | 冯海军, 章冰璇, 周健. 图神经网络模型预测和解释离子液体毒性的研究[J]. 化工学报, 2025, 76(1): 93-106. |

| [12] | 高羡明, 杨汶轩, 卢少辉, 任晓松, 卢方财. 双槽道结构对超疏水表面液滴合并弹跳的影响[J]. 化工学报, 2025, 76(1): 208-220. |

| [13] | 贾艳萍, 马艳菊, 管文昕, 杨彬, 张健, 张兰河. 响应面法优化Fe0/H2O2体系降解染料废水的工艺条件及机理[J]. 化工学报, 2025, 76(1): 348-362. |

| [14] | 陈晗, 蔡畅, 刘红, 尹洪超. 正戊醇添加剂强化喷雾冷却传热实验研究[J]. 化工学报, 2025, 76(1): 131-140. |

| [15] | 韩志敏, 周相宇, 张宏宇, 徐志明. 不同粗糙元结构下CaCO3污垢局部沉积特性[J]. 化工学报, 2025, 76(1): 151-160. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号