化工学报 ›› 2019, Vol. 70 ›› Issue (6): 2117-2128.DOI: 10.11949/j.issn.0438-1157.20181368

曲江源1( ),齐娜娜1(

),齐娜娜1( ),关彦军1,滕阳1,徐文青2,朱廷钰2,张锴1

),关彦军1,滕阳1,徐文青2,朱廷钰2,张锴1

收稿日期:2018-11-18

修回日期:2019-03-10

出版日期:2019-06-05

发布日期:2019-06-05

通讯作者:

齐娜娜

作者简介:<named-content content-type="corresp-name">曲江源</named-content>(1993-),男,博士研究生,<email>qujy_ncepu@163.com</email>

基金资助:

Jiangyuan QU1( ),Nana QI1(

),Nana QI1( ),Yanjun GUAN1,Yang TENG1,Wenqing XU2,Tingyu ZHU2,Kai ZHANG1

),Yanjun GUAN1,Yang TENG1,Wenqing XU2,Tingyu ZHU2,Kai ZHANG1

Received:2018-11-18

Revised:2019-03-10

Online:2019-06-05

Published:2019-06-05

Contact:

Nana QI

摘要:

以某330 MW燃煤发电机组湿法烟气脱硫塔为研究对象,采用欧拉-拉格朗日方法建立了塔内气-液两相流动、热质交换模型,以溶解平衡、质量守恒及电荷守恒描述浆液内13种溶质组分瞬时化学反应特性,通过用户自定义函数实现流动模型与传质模型、化学反应模型的耦合。基于上述模型预测了脱硫塔内气-液两相流动、液滴蒸发与SO2化学吸收过程,获得了SO2浓度与浆液pH的径向分布特性,详细分析了气-液流动对化学吸收特性的影响,结果表明局部液气比分布特性是影响SO2径向分布的关键因素之一,可通过调控近壁区及主管道区的两相流动状态提高脱硫塔的吸收性能;随着气相侧SO2浓度提高或液滴粒径减小,浆液pH下降速率增大且各化学组分浓度达到稳定状态用时缩短。

中图分类号:

曲江源, 齐娜娜, 关彦军, 滕阳, 徐文青, 朱廷钰, 张锴. 湿法烟气脱硫塔内传递与化学反应过程CFD模拟[J]. 化工学报, 2019, 70(6): 2117-2128.

Jiangyuan QU, Nana QI, Yanjun GUAN, Yang TENG, Wenqing XU, Tingyu ZHU, Kai ZHANG. CFD simulation of transfer and chemical reaction process in wet flue gas desulfurization tower[J]. CIESC Journal, 2019, 70(6): 2117-2128.

| Parameter | Formula | Eq. |

|---|---|---|

| | [H+][OH-] | (19) |

| | [H+][HSO3 -]/[SO2,aq] | (20) |

| | [H+][SO3 2-]/[HSO3 -] | (21) |

| | [H+][SO4 2-]/[HSO4 -] | (22) |

| | [H+][HCO3 -]/[CO2,aq] | (23) |

| | [H+][CO3 2-]/[HCO3 -] | (24) |

表1 液相内化学反应平衡常数

Table 1 Reaction equilibrium constants in droplets

| Parameter | Formula | Eq. |

|---|---|---|

| | [H+][OH-] | (19) |

| | [H+][HSO3 -]/[SO2,aq] | (20) |

| | [H+][SO3 2-]/[HSO3 -] | (21) |

| | [H+][SO4 2-]/[HSO4 -] | (22) |

| | [H+][HCO3 -]/[CO2,aq] | (23) |

| | [H+][CO3 2-]/[HCO3 -] | (24) |

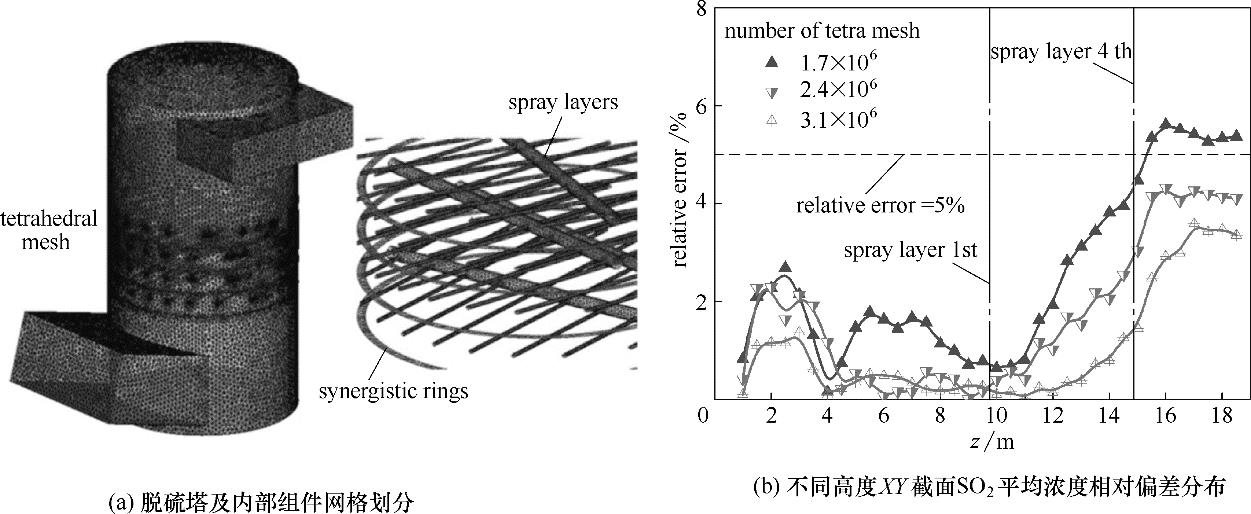

图2 网格划分与不同高度XY截面SO2平均浓度相对偏差分布

Fig.2 Schematic diagram of geometry discretization and relative errors profiles of average SO2 concentration at different XY planes

| 项目 | T g,in /℃ | T g,out /℃ | | |

|---|---|---|---|---|

| 实测 Ⅰ | 125.0 | 48.0 | 7.5 | 13.2 |

| 实测 Ⅱ | 135.0 | 50.0 | 6.2 | 13.7 |

| 实测 Ⅲ | 131.0 | 51.0 | 7.1 | 13.4 |

| 平均值 | 130.3 | 49.7 | 7.0 | 13.4 |

| 模拟值 | 130.0 | 50.0 | 7.0 | 13.8 |

| 相对误差 | — | 0.60% | — | 2.99% |

表2 温度、水蒸气体积分数实测值与计算值

Table 2 Measured values and simulation results of gas temperature and vapor volume fraction

| 项目 | T g,in /℃ | T g,out /℃ | | |

|---|---|---|---|---|

| 实测 Ⅰ | 125.0 | 48.0 | 7.5 | 13.2 |

| 实测 Ⅱ | 135.0 | 50.0 | 6.2 | 13.7 |

| 实测 Ⅲ | 131.0 | 51.0 | 7.1 | 13.4 |

| 平均值 | 130.3 | 49.7 | 7.0 | 13.4 |

| 模拟值 | 130.0 | 50.0 | 7.0 | 13.8 |

| 相对误差 | — | 0.60% | — | 2.99% |

| 1 | 史文峥, 杨萌萌, 张绪辉, 等 . 燃煤电厂超低排放技术路线与协同脱除[J]. 中国电机工程学报, 2016, 36(16): 4308-4318. |

| Shi W Z , Yang M M , Zhang X H , et al . Ultra-low emission technical route of coal-fired power plants and the cooperative removal[J]. Proceedings of the CSEE, 2016, 36(16): 4308-4318. | |

| 2 | 潘丹萍, 郭彦鹏, 黄荣廷, 等 . 石灰石-石膏法烟气脱硫过程中细颗粒物形成特性[J]. 化工学报, 2015, 66(11): 4618-4625. |

| Pan D P , Guo Y P , Huang R T , et al . Formation of fine particles in flue gas desulphurization process using limestone-gypsum[J]. CIESC Journal, 2015, 66(11): 4618-4625. | |

| 3 | 张东辉, 庄烨, 朱润儒, 等 . 燃煤烟气污染物超低排放技术及经济分析[J]. 电力建设, 2015, 36(5): 125-130. |

| Zhang D H , Zhuang Y , Zhu R R , et al . Ultra-low air pollutant control technologies for coal-fired flue gas and its economic analysis[J]. Electric Power Construction, 2015, 36(5): 125-130. | |

| 4 | 张军 . 超低排放的湿法高效脱硫协同除尘的机理及模型研究[D]. 杭州: 浙江大学, 2018. |

| Zhang J . Mechanism and model study on high efficiency desulfurization and dedust based on ultra-low emission technology [D]. Hangzhou: Zhejiang University, 2018. | |

| 5 | 张军, 郑成航, 张涌新, 等 . 某1000MW燃煤机组超低排放电厂烟气污染物排放测试及其特性分析[J]. 中国电机工程学报, 2016, 36(5): 1310-1314. |

| Zhang J , Zheng C H , Zhang Y X , et al . Experimental investigation of ultra-low pollutants emission characteristics from a 1000MW coal-fired power plant[J]. Proceedings of the CSEE, 2016, 36(5): 1310-1314. | |

| 6 | 杨业, 徐超群, 朱燕群, 等 . 臭氧氧化结合硫代硫酸钠溶液喷淋同时脱硫脱硝[J]. 化工学报, 2016, 67(5): 2041-2047. |

| Yang Y , Xu C Q , Zhu Y Q , et al . Simultaneous removal of SO2 and NO x by combination of ozone oxidation and Na2S2O3 solution spray [J]. CIESC Journal, 2016, 67(5): 2041-2047. | |

| 7 | Córdoba P . Status of flue gas desulphurization (FGD) systems from coal-fired power plants: overview of the physic-chemical control processes of wet limestone FGDs [J]. Fuel, 2015, 144: 274-286. |

| 8 | Angelo J , Lightfoot E , Howard D . Generalization of the penetration theory for surface stretch: application to forming and oscillating drops[J]. AIChE Journal, 1966, 12(4): 751-760. |

| 9 | Altwicker E , Lindhjem C . Absorption of gases into drops[J]. AIChE Journal, 1988, 34(34): 329-332. |

| 10 | Hsu C , Shih S . Semiempirical equation for liquid-phase mass-transfer coefficient for drops[J]. AIChE Journal, 1993, 39(6): 1090-1092. |

| 11 | Brogren C , Karlsson H . Modeling the absorption of SO2, in a spray scrubber using the penetration theory[J]. Chemical Engineering Science, 1997, 52(18): 3085-3099. |

| 12 | Zhong Y , Gao X , Huo W , et al . A model for performance optimization of wet flue gas desulfurization systems of power plants[J]. Fuel Processing Technology, 2008, 89(11): 1025-1032. |

| 13 | 祝杰, 叶世超, 吴振元, 等 . 石灰石-石膏脱硫喷淋塔吸收区高度计算模型[J]. 化工学报, 2014, 65(8): 2896-2901. |

| Zhu J , Ye S C , Wu Z Y , et al . Mathematical modeling for height of absorption region in spray tower for limestone-gypsum wet flue gas desulfurization[J]. CIESC Journal, 2014, 65 (8): 2896-2901. | |

| 14 | Nygaard H , Kiil S , Johnsson J , et al . Full-scale measurements of SO2 gas phase concentrations and slurry compositions in a wet flue gas desulphurization spray absorber[J]. Fuel, 2004, 83(9): 1151-1164. |

| 15 | Gao X , Huo W , Luo Z Y , et al . CFD simulation with enhancement factor of sulfur dioxide absorption in the spray scrubber[J]. Journal of Zhejiang University-Science A(Applied Physics & Engineering), 2008, 9(11): 1601-1613. |

| 16 | Gómez A , Fueyo N , Tomás A . Detailed modeling of a flue-gas desulfurization plant[J]. Computers & Chemical Engineering, 2007, 31(11): 1419-1431. |

| 17 | Crowe C , Sharma M , Stock D . The particle-source-in cell (PSI-CELL) model for gas-droplet flow[J]. Journal of Fluids Engineering, 1977, 99(2): 325-332. |

| 18 | 林永明, 高翔, 施平平, 等 . 大型湿法烟气脱硫喷淋塔内阻力特性数值模拟[J]. 中国电机工程学报, 2008, 28(5): 28-33. |

| Lin Y M , Gao X , Shi P P , et al . Numerical simulation on resistance characteristic of large scale wet flue gas desulfurization spraying scrubber[J]. Proceedings of the CSEE, 2008, 28(5): 28-33. | |

| 19 | 钟毅, 高翔, 王惠挺, 等 . 基于CFD技术的湿法烟气脱硫系统性能优化[J]. 中国电机工程学报, 2008, 28(32): 18-23. |

| Zhong Y , Gao X , Wang H T , et al . Performance optimization of wet flue gas desulphurization system based on CFD technology[J]. Proceedings of the CSEE, 2008, 28(32): 18-23. | |

| 20 | Chen Z , Wang H M , Zhuo J K , et al . Experimental and numerical study on effects of deflectors on flow field distribution and desulfurization efficiency in spray towers[J]. Fuel Processing Technology, 2017, 162: 1-12. |

| 21 | Marocco L , Inzoli F . Multiphase Euler-Lagrange CFD simulation applied to wet flue gas desulphurization technology[J]. International Journal of Multiphase Flow, 2009, 35(2): 185-194. |

| 22 | Marocco L . Modeling of the fluid dynamics and SO2 absorption in a gas-liquid reactor[J]. Chemical Engineering Journal, 2010, 162(1): 217-226. |

| 23 | Montanes C , Gomez S A , Fueyo N , et al . Computational evaluation of wall rings in wet flue-gas desulfurization plants[J]. International Journal of Energy for A Clean Environment, 2009, 10(1/2/3/4): 15-36. |

| 24 | Mors S , Alexander A . An investigation of particle trajectories in two-phase flow systems[J]. Journal of Fluid Mechanics, 1972, 55(2): 193-208. |

| 25 | Wang Y , James P . Assessment of an eddy-interaction model and its refinements using predictions of droplet deposition in a wave-plate demister[J]. Chemical Engineering Research & Design, 1999, 77(8): 692-698. |

| 26 | 林瑜, 陈德珍, 尹丽洁 . 喷淋层组合方式对大型脱硫塔内流动和热湿交换过程影响的数值模拟[J]. 中南大学学报(自然科学版), 2017, 48(10): 2572-2582. |

| Lin Y , Chen D Z , Yin L J . Numerical simulation of impact of spraying layers scheme on gas-liquid two-phases flow, heat and mass transfer in large scale desulphurization absorption tower[J]. Journal of Central South University (Science and Technology), 2017, 48(10): 2572-2582. | |

| 27 | Zhu J , Ye S C , Bai J , et al . A concise algorithm for calculating absorption height in spray tower for wet limestone-gypsum flue gas desulfurization[J]. Fuel Processing Technology, 2015, 129: 15-23. |

| 28 | Füller E N , Schettler P D , Giddings J C . New method for prediction of binary gas-phase diffusion coefficient[J]. Industrial & Engineering Chemistry, 1966, 58(5): 19-27. |

| 29 | Newton G H , Kramlich J , Payne R . Modeling the SO2-slurry droplet reaction.[J]. AIChE Journal, 1990, 36(12): 1865-1872. |

| 30 | Maurer G . On the solubility of volatile weak electrolytes in aqueous solutions—thermodynamics of aqueous systems with industrial applications[J]. ACS Symposium, 1980, 133: 139-172. |

| 31 | Neveux T , Moullec Y L . Wet industrial flue gas desulfurization unit: model development and validation on industrial data[J]. Industrial & Engineering Chemistry Research, 2011, 50(12): 7579-7592. |

| 32 | Wang P H , Zhuang L W , Dai G C . Synergistic effect of droplet self-adjustment and rod bank internal on fluid distribution in a WFGD spray column[J]. Chemical Engineering Science, 2017, 162: 227-244. |

| 33 | Tseng C C , Li C J . Eulerian-Eulerian numerical simulation for a flue gas desulfurization tower with perforated sieve trays[J]. International Journal of Heat and Mass Transfer, 2018, 116: 329-345. |

| 34 | Chen Z , You C F , Liu H Z , et al . The synergetic particles collection in three different wet flue gas desulfurization towers: a pilot-scale experimental investigation[J]. Fuel Processing Technology, 2018, 179: 344-350. |

| [1] | 宋嘉豪, 王文. 斯特林发动机与高温热管耦合运行特性研究[J]. 化工学报, 2023, 74(S1): 287-294. |

| [2] | 张思雨, 殷勇高, 贾鹏琦, 叶威. 双U型地埋管群跨季节蓄热特性研究[J]. 化工学报, 2023, 74(S1): 295-301. |

| [3] | 黄琮琪, 吴一梅, 陈建业, 邵双全. 碱性电解水制氢装置热管理系统仿真研究[J]. 化工学报, 2023, 74(S1): 320-328. |

| [4] | 金正浩, 封立杰, 李舒宏. 氨水溶液交叉型再吸收式热泵的能量及 分析[J]. 化工学报, 2023, 74(S1): 53-63. 分析[J]. 化工学报, 2023, 74(S1): 53-63. |

| [5] | 叶展羽, 山訸, 徐震原. 用于太阳能蒸发的折纸式蒸发器性能仿真[J]. 化工学报, 2023, 74(S1): 132-140. |

| [6] | 张义飞, 刘舫辰, 张双星, 杜文静. 超临界二氧化碳用印刷电路板式换热器性能分析[J]. 化工学报, 2023, 74(S1): 183-190. |

| [7] | 王志国, 薛孟, 董芋双, 张田震, 秦晓凯, 韩强. 基于裂隙粗糙性表征方法的地热岩体热流耦合数值模拟与分析[J]. 化工学报, 2023, 74(S1): 223-234. |

| [8] | 江河, 袁俊飞, 王林, 邢谷雨. 均流腔结构对微细通道内相变流动特性影响的实验研究[J]. 化工学报, 2023, 74(S1): 235-244. |

| [9] | 米泽豪, 花儿. 基于DFT和COSMO-RS理论研究多元胺型离子液体吸收SO2气体[J]. 化工学报, 2023, 74(9): 3681-3696. |

| [10] | 袁佳琦, 刘政, 黄锐, 张乐福, 贺登辉. 泡状入流条件下旋流泵能量转换特性研究[J]. 化工学报, 2023, 74(9): 3807-3820. |

| [11] | 何松, 刘乔迈, 谢广烁, 王斯民, 肖娟. 高浓度水煤浆管道气膜减阻两相流模拟及代理辅助优化[J]. 化工学报, 2023, 74(9): 3766-3774. |

| [12] | 邢雷, 苗春雨, 蒋明虎, 赵立新, 李新亚. 井下微型气液旋流分离器优化设计与性能分析[J]. 化工学报, 2023, 74(8): 3394-3406. |

| [13] | 韩晨, 司徒友珉, 朱斌, 许建良, 郭晓镭, 刘海峰. 协同处理废液的多喷嘴粉煤气化炉内反应流动研究[J]. 化工学报, 2023, 74(8): 3266-3278. |

| [14] | 高燕, 伍鹏, 尚超, 胡泽君, 陈晓东. 基于双流体喷嘴的磁性琼脂糖微球的制备及其蛋白吸附性能探究[J]. 化工学报, 2023, 74(8): 3457-3471. |

| [15] | 程小松, 殷勇高, 车春文. 不同工质在溶液除湿真空再生系统中的性能对比[J]. 化工学报, 2023, 74(8): 3494-3501. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号