化工学报 ›› 2020, Vol. 71 ›› Issue (3): 1362-1369.DOI: 10.11949/0438-1157.20190856

收稿日期:2019-07-25

修回日期:2020-01-06

出版日期:2020-03-05

发布日期:2020-03-05

通讯作者:

陆江银

基金资助:

Yuying LU1,Liming YU2,Jiake YANG1,Wusong ZENG1,Jiangyin LU1( )

)

Received:2019-07-25

Revised:2020-01-06

Online:2020-03-05

Published:2020-03-05

Contact:

Jiangyin LU

摘要:

采用熔融共混法,以克拉玛依90#沥青为原料,Mg-Al水滑石(LDHs)与废橡胶粉(CR)作为改性剂,制备了具有抗紫外老化性能的水滑石/废胶粉复合改性沥青(LDHs/CRMA),并对其软化点、针入度指数(PI)、延度进行了测试。通过Hassan数学方法将三个指标“归一化”得到总评“归一值”,采用响应面分析法建立总评“归一值”与各因素之间的Box-Behnken数学模型,得到了LDHs/CRMA的最优制备工艺条件为:剪切温度173℃、剪切时间89 min、剪切速率3500 r/min。通过紫外老化模拟实验对复合改性沥青的抗老化性能进行了评价,结果表明,引入水滑石可以减少沥青老化过程中含氧官能团的产生,抗紫外老化性能得到了明显提高。

中图分类号:

鲁玉莹, 余黎明, 杨加可, 曾武松, 陆江银. 响应面法优化制备LDHs-CRMA复合改性沥青及其表征[J]. 化工学报, 2020, 71(3): 1362-1369.

Yuying LU, Liming YU, Jiake YANG, Wusong ZENG, Jiangyin LU. Preparation of LDHs-CRMA composite modified asphalt by response surface methodology and its characterization[J]. CIESC Journal, 2020, 71(3): 1362-1369.

| Factor | Symbol | Level | ||

|---|---|---|---|---|

| -1 | 0 | 1 | ||

| shear temperature/℃ | A | 165 | 175 | 185 |

| shear time /min | B | 60 | 90 | 120 |

| shear rate/(r/min) | C | 3500 | 5000 | 6500 |

表1 响应面三因素三水平实验设计

Table 1 Experimental design of three factors and three levels of response surface method

| Factor | Symbol | Level | ||

|---|---|---|---|---|

| -1 | 0 | 1 | ||

| shear temperature/℃ | A | 165 | 175 | 185 |

| shear time /min | B | 60 | 90 | 120 |

| shear rate/(r/min) | C | 3500 | 5000 | 6500 |

| 实验号 | A | B | C | 针入度(100 g,5 s)/0.1 mm | PI | 软化 点/℃ | 5℃延度/mm | OD | ||

|---|---|---|---|---|---|---|---|---|---|---|

| 5℃ | 15℃ | 25℃ | ||||||||

| 1 | 185 | 60 | 5000 | 6.1 | 22.1 | 62.2 | -1.479 | 47.1 | 231 | 0 |

| 2 | 175 | 90 | 5000 | 11.0 | 27.7 | 69.2 | 0.008 | 50.0 | 221 | 0.4924 |

| 3 | 165 | 90 | 6500 | 11.1 | 18.4 | 45.8 | 1.816 | 49.1 | 212 | 0.5509 |

| 4 | 175 | 120 | 3500 | 12.6 | 22.9 | 46.8 | 2.461 | 49.8 | 221 | 0.6463 |

| 5 | 175 | 90 | 5000 | 10.9 | 26.0 | 63.6 | 0.292 | 50.2 | 222 | 0.5352 |

| 6 | 185 | 90 | 6500 | 11.6 | 27.2 | 73.8 | -0.030 | 48.1 | 240 | 0.3611 |

| 7 | 175 | 90 | 5000 | 11.4 | 23.4 | 67.0 | 0.263 | 49.9 | 210 | 0.4951 |

8 9 | 165 185 | 120 120 | 5000 5000 | 13.9 8.20 | 25.0 16.6 | 73.3 41.8 | 0.695 0.826 | 49.4 53.4 | 285 119 | 0.6033 0.2959 |

| 10 | 185 | 90 | 3500 | 6.80 | 20.7 | 54.8 | -0.813 | 50.0 | 208 | 0.3611 |

| 11 | 175 | 60 | 3500 | 11.3 | 22.4 | 60.3 | 0.646 | 51.4 | 261 | 0.7018 |

| 12 | 175 | 120 | 6500 | 9.20 | 17.0 | 48.2 | 0.722 | 52.6 | 112 | 0 |

| 13 | 175 | 90 | 5000 | 13.2 | 18.8 | 69.3 | 0.712 | 49.1 | 220 | 0.4935 |

| 14 | 165 | 90 | 3500 | 12.2 | 21.0 | 71.8 | 0.258 | 50.9 | 259 | 0.6269 |

| 15 | 165 | 60 | 5000 | 7.30 | 31.1 | 71.3 | -1.365 | 50.3 | 243 | 0.2298 |

| 16 | 175 | 60 | 6500 | 7.80 | 29.1 | 70.2 | -1.139 | 49.0 | 223 | 0.2633 |

| 17 | 175 | 90 | 5000 | 12.6 | 20.7 | 73.6 | 0.286 | 50.4 | 210 | 0.5253 |

表2 Box-Behnken优化实验设计与结果

Table 2 Box-Behnken response surface experimental design and results

| 实验号 | A | B | C | 针入度(100 g,5 s)/0.1 mm | PI | 软化 点/℃ | 5℃延度/mm | OD | ||

|---|---|---|---|---|---|---|---|---|---|---|

| 5℃ | 15℃ | 25℃ | ||||||||

| 1 | 185 | 60 | 5000 | 6.1 | 22.1 | 62.2 | -1.479 | 47.1 | 231 | 0 |

| 2 | 175 | 90 | 5000 | 11.0 | 27.7 | 69.2 | 0.008 | 50.0 | 221 | 0.4924 |

| 3 | 165 | 90 | 6500 | 11.1 | 18.4 | 45.8 | 1.816 | 49.1 | 212 | 0.5509 |

| 4 | 175 | 120 | 3500 | 12.6 | 22.9 | 46.8 | 2.461 | 49.8 | 221 | 0.6463 |

| 5 | 175 | 90 | 5000 | 10.9 | 26.0 | 63.6 | 0.292 | 50.2 | 222 | 0.5352 |

| 6 | 185 | 90 | 6500 | 11.6 | 27.2 | 73.8 | -0.030 | 48.1 | 240 | 0.3611 |

| 7 | 175 | 90 | 5000 | 11.4 | 23.4 | 67.0 | 0.263 | 49.9 | 210 | 0.4951 |

8 9 | 165 185 | 120 120 | 5000 5000 | 13.9 8.20 | 25.0 16.6 | 73.3 41.8 | 0.695 0.826 | 49.4 53.4 | 285 119 | 0.6033 0.2959 |

| 10 | 185 | 90 | 3500 | 6.80 | 20.7 | 54.8 | -0.813 | 50.0 | 208 | 0.3611 |

| 11 | 175 | 60 | 3500 | 11.3 | 22.4 | 60.3 | 0.646 | 51.4 | 261 | 0.7018 |

| 12 | 175 | 120 | 6500 | 9.20 | 17.0 | 48.2 | 0.722 | 52.6 | 112 | 0 |

| 13 | 175 | 90 | 5000 | 13.2 | 18.8 | 69.3 | 0.712 | 49.1 | 220 | 0.4935 |

| 14 | 165 | 90 | 3500 | 12.2 | 21.0 | 71.8 | 0.258 | 50.9 | 259 | 0.6269 |

| 15 | 165 | 60 | 5000 | 7.30 | 31.1 | 71.3 | -1.365 | 50.3 | 243 | 0.2298 |

| 16 | 175 | 60 | 6500 | 7.80 | 29.1 | 70.2 | -1.139 | 49.0 | 223 | 0.2633 |

| 17 | 175 | 90 | 5000 | 12.6 | 20.7 | 73.6 | 0.286 | 50.4 | 210 | 0.5253 |

| Source | Sum of squares | df | Mean square | F | P | Significance |

|---|---|---|---|---|---|---|

| model | 0.70 | 11 | 0.063 | 126.93 | <0.0001 | significant |

| A | 0.12 | 1 | 0.12 | 246.37 | <0.0001 | |

| B | 0.025 | 1 | 0.025 | 50.78 | 0.0008 | |

| C | 0.29 | 1 | 0.29 | 588.39 | <0.0001 | |

| AB | 1.506×10-3 | 1 | 1.506×10-3 | 3.01 | 0.1432 | |

| AC | 1.440×10-3 | 1 | 1.440×10-3 | 2.88 | 0.1504 | |

| BC | 0.011 | 1 | 0.011 | 21.61 | 0.0056 | |

| A2 | 0.025 | 1 | 0.025 | 49.89 | 0.0009 | |

| B2 | 0.094 | 1 | 0.094 | 187.31 | <0.0001 | |

| C2 | 8.012×10-3 | 1 | 8.012×10-3 | 16.02 | 0.0103 | |

| A2B | 0.12 | 1 | 0.12 | 244.11 | <0.0001 | |

| A2C | 0.13 | 1 | 0.13 | 254.46 | <0.0001 | |

| residual | 2.500×10-3 | 5 | 5.000×10-4 | |||

| lack of fit | 8.315×10-4 | 1 | 8.315×10-4 | 1.99 | 0.2308 | not significant |

| pure error | 1.669×10-3 | 4 | 4.171×10-4 | |||

cor total R2=0.9964 | 0.70 CV=5.29% | 16 |

表3 回归模型的方差分析

Table 3 Analysis of variance(ANOVA)

| Source | Sum of squares | df | Mean square | F | P | Significance |

|---|---|---|---|---|---|---|

| model | 0.70 | 11 | 0.063 | 126.93 | <0.0001 | significant |

| A | 0.12 | 1 | 0.12 | 246.37 | <0.0001 | |

| B | 0.025 | 1 | 0.025 | 50.78 | 0.0008 | |

| C | 0.29 | 1 | 0.29 | 588.39 | <0.0001 | |

| AB | 1.506×10-3 | 1 | 1.506×10-3 | 3.01 | 0.1432 | |

| AC | 1.440×10-3 | 1 | 1.440×10-3 | 2.88 | 0.1504 | |

| BC | 0.011 | 1 | 0.011 | 21.61 | 0.0056 | |

| A2 | 0.025 | 1 | 0.025 | 49.89 | 0.0009 | |

| B2 | 0.094 | 1 | 0.094 | 187.31 | <0.0001 | |

| C2 | 8.012×10-3 | 1 | 8.012×10-3 | 16.02 | 0.0103 | |

| A2B | 0.12 | 1 | 0.12 | 244.11 | <0.0001 | |

| A2C | 0.13 | 1 | 0.13 | 254.46 | <0.0001 | |

| residual | 2.500×10-3 | 5 | 5.000×10-4 | |||

| lack of fit | 8.315×10-4 | 1 | 8.315×10-4 | 1.99 | 0.2308 | not significant |

| pure error | 1.669×10-3 | 4 | 4.171×10-4 | |||

cor total R2=0.9964 | 0.70 CV=5.29% | 16 |

| 技术指标 | 基质沥青 | LDHs-CRMA复合改性沥青 |

|---|---|---|

| 针入度(100 g,5 s)/0.1 mm | ||

| 5℃ | 7.6 | 9.8 |

| 15℃ | 19.7 | 21.2 |

| 25℃ | 82.4 | 66.7 |

| 软化点/℃ | 45.1 | 51.6 |

| 5℃延度/cm | 13.6 | 24.9 |

表4 最优工艺参数改性沥青的性能

Table 4 Properties of modified asphalt by optimum parameters

| 技术指标 | 基质沥青 | LDHs-CRMA复合改性沥青 |

|---|---|---|

| 针入度(100 g,5 s)/0.1 mm | ||

| 5℃ | 7.6 | 9.8 |

| 15℃ | 19.7 | 21.2 |

| 25℃ | 82.4 | 66.7 |

| 软化点/℃ | 45.1 | 51.6 |

| 5℃延度/cm | 13.6 | 24.9 |

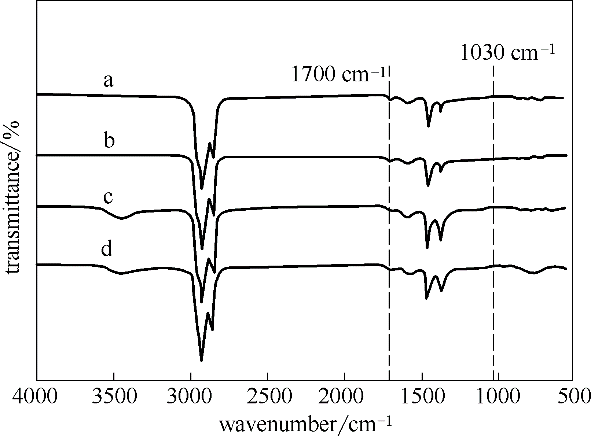

图6 紫外老化前后沥青的红外光谱图

Fig.6 Infrared spectra of CRMA and LDHs/CRMA modified asphalt before and after UV aginga—CRMA; b—CRMA-UV; c—LDHs/CRMA; d—LDHs/CRMA-UV

| 项目 | CRMA | LDHs/CRMA | ||

|---|---|---|---|---|

IC O O | IS O O | IC O O | IS O O | |

| 老化前 | 0.0028 | 0.0100 | 0.0027 | 0.0100 |

| 老化后 | 0.019 | 0.046 | 0.008 | 0.031 |

| 变化 | 0.0162 | 0.0360 | 0.0053 | 0.0210 |

表5 沥青紫外老化前后官能团指数的变化

Table 5 FTIR functional group indices change of CRMA and LDHs/CRMA modified asphalt before and after UV aging

| 项目 | CRMA | LDHs/CRMA | ||

|---|---|---|---|---|

IC O O | IS O O | IC O O | IS O O | |

| 老化前 | 0.0028 | 0.0100 | 0.0027 | 0.0100 |

| 老化后 | 0.019 | 0.046 | 0.008 | 0.031 |

| 变化 | 0.0162 | 0.0360 | 0.0053 | 0.0210 |

| 1 | Apeagyei A K.Laboratory evaluation of antioxidants for asphalt binders [J].Construction & Building Materials,2011,25(1):47-53. |

| 2 | Petersen J C.Chapter 14 chemical composition of asphalt as related to asphalt durability [J].Developments in Petroleum Science,1984,40(9):363-399. |

| 3 | Lu X,Isacsson U.Effect of ageing on bitumen chemistry and rheology [J].Construction & Building Materials,2002,16(1):15-22. |

| 4 | Fang C Q,Yu R E,Liu S L S,et al.Nanomaterials applied in asphalt modification: a review [J].Journal of Materials Science & Technology,2013,29(7):589-594. |

| 5 | Zhang H L,Yu J Y,Kuang D L.Effect of expanded vermiculite on aging properties of bitumen [J].Construction & Building Materials,2012,26(1):244-248. |

| 6 | Ouyang C F,Wang S F,Zhang Y,et al.Improving the aging resistance of styrene-butadiene-styrene tri-block copolymer modified asphalt by addition of antioxidants [J].Polymer Degradation & Stability,2006,91(4):795-804. |

| 7 | Wu S P,Han J,Pang L,et al.Rheological properties for aged bitumen containing ultraviolate light resistant materials [J].Construction & Building Materials,2012,33(7):133-138. |

| 8 | 亢阳.高性能环氧树脂改性沥青材料的制备与性能表征[D].南京:东南大学,2006. |

| Kang Y.Preparation and characterization of high performance epoxy modified asphalt materials [D].Nanjing:Southeast University,2006. | |

| 9 | 谢玉阁,姚鸿儒,黄健.POE弹性体改性沥青的结构与性能 [J].弹性体,2013,23(3):29-34. |

| Xie Y G,Yao H R,Huang J.Structure and properties of POE elastomer modified asphalt [J].Elastomer,2013,23(3):29-34. | |

| 10 | Song X,Yu J Y,Wu W F,et al.Synthesis and characterization of layered double hydroxides intercalated by UV absorbents and their application in improving UV aging resistance of bitumen [J].Applied Clay Science,2015,114:112-129. |

| 11 | Wu H,Li L,Yu J Y,et al.Effect of layered double hydroxides on ultraviolet aging properties of different bitumens [J].Construction & Building Materials,2016,111:565-570. |

| 12 | Zhou X,Wu S,Liu Q,et al.Effect of surface active agents on the rheological properties and solubility of layered double hydroxides-modified asphalt [J].Materials Research Innovations,2015,19(sup5):S5-978-S5-982. |

| 13 | 程文静,郑成,毛桃嫣,等.十八烷基甲基二羟乙基溴化铵的微波合成及性能[J].化工学报,2011,62(2):565-572. |

| Cheng W J,Zheng C,Mao T Y,et al.Microwave synthesis and properties of dioctadecyldihydroxyethyl ammonium bromide [J].CIESC Journal,2011,62(2):565-572. | |

| 14 | Li X D,Jia R,Li P S,et al.Response surface analysis for enzymatic decolorization of Congo red by manganese peroxidase [J].Journal of Molecular Catalysis B: Enzymatic,2009,56(1):1-6. |

| 15 | 李博,屠幼英,梅鑫,等.响应面法优化超临界CO2提取茶籽多糖的工艺研究 [J].高校化学工程学报,2010,24(5):897-902. |

| Li B,Tu Y Y,Mei X,et al.Optimization of supercritical CO2 extraction process for tea seed polysaccharide by response surface method [J].Journal of Chemical Engineering of Chinese Universities,2010,24(5):897-902. | |

| 16 | Hill W J,Hunter W G.A review of response surface methodology: a literature survey [J].Technometrics,1966,8(4):571-590. |

| 17 | Hassan E E,Parish R C,Gallo J M.Optimized formulation of magnetic chitosan microspheres containing the anticancer agent, oxantrazole [J].Pharmaceutical Research,1992,9(3):390-397. |

| 18 | 曹敏娜,陆江银,薄文旻.废橡胶粉改性沥青性能及研究 [J].湖南交通科技,2012,38(4):67-70. |

| Cao M N,Lu J Y,Bo W M.Properties and research of asphalt modified by waste rubber powder [J].Hunan Transportation Technology,2012,38(4):67-70. | |

| 19 | 王晓倩,陆江银,曹敏娜.废橡胶改性沥青的储存稳定性研究 [J].石油炼制与化工,2014,45(4):27-30. |

| Wang X Q,Lu J Y,Cao M N.Study on storage stability of waste rubber modified asphalt[J].Petroleum Processing and Petrochemicals,2014,45(4):27-30. | |

| 20 | 王晓倩,陆江银,邢苗.综述WRP、SBR、SBS改性沥青制备方法和性能的比较 [J].当代化工,2014, (11):2355-2357. |

| Wang X Q,Lu J Y,Xing M.Comparison of preparation methods and properties of WRP, SBR and SBS modified asphalt [J].Contemporary Chemical Industry,2014, (11):2355-2357. | |

| 21 | 云庆庆,王晓倩,曹康,等.克拉玛依改性沥青的制备及其性能研究 [J].化工新型材料,2017,45(12):190-193. |

| Yun Q Q,Wang X Q,Cao K,et al.Preparation of the Karamay modified asphalt and the performance research [J].New Chemical Materials,2017,45(12):190-193. | |

| 22 | 云庆庆,曹康,陆江银,等.废橡塑复合改性沥青的研究 [J].石油炼制与化工,2017,48(12):83-87. |

| Yun Q Q,Cao K,Lu J Y,et al.Peroperties of asphalt modified with waste rubber-plastics composite powder [J].Petroleum Processing and Petrochemicals,2017,48(12):83-87. | |

| 23 | Mohammadi I,Khabbaz H.Challenges associated with optimisation of blending, mixing and compaction temperature for asphalt mixture modified with crumb rubber modifier (CRM) [J].Applied Mechanics & Materials,2013,256-259:1837-1844. |

| 24 | Li P,Ding Z,Zou P,et al.Analysis of physico-chemical properties for crumb rubber in process of asphalt modification [J].Construction & Building Materials,2017,138:418-426. |

| 25 | Aflaki S,Memarzadeh M.Using two-way ANOVA and hypothesis test in evaluating crumb rubber modification (CRM) agitation effects on rheological properties of bitumen [J].Construction & Building Materials,2011,25(4):2094-2106. |

| 26 | Pang L,Liu K,Wu S,et al.Effect of LDHs on the aging resistance of crumb rubber modified asphalt [J].Construction & Building Materials,2014,67:239-243. |

| 27 | 蒋绍阶,冯欣蕊,李晓恩,等.响应面法优化制备PAC-PDMDAAC杂化絮凝剂及其表征 [J].化工学报,2014,65(2):731-736. |

| Jiang S J,Feng X R,Li X E,et al.Preparation of PAC-PDMDAAC hybrid flocculant by response surface method and its characterization [J].CIESC Journal,2014,65(2):731-736. | |

| 28 | 李璐,李若松,刘玲娜,等.静电纺丝技术制备PMMA纤维的分析与模型预测 [J].化工学报,2013,64(5):1869-1875. |

| Li L,Li R S,Liu L N,et al.Analysis and model prediction of PMMA fibers prepared by electrostatic spinning [J].CIESC Journal,2013,64(5):1869-1875. | |

| 29 | Zhang Z M,Zheng H L.Optimization for decolorization of azo dye acid green 20 by ultrasound and H2O2 using response surface methodology [J].Journal of Hazardous Materials,2009,172(2):1388-1393. |

| 30 | 孙志成,韩进,张明杨,等.机械转盘联合超声破解剩余污泥 [J].化工学报,2016,67(12):5229-5236. |

| Sun Z C,Han J,Zhang M Y,et al.Mechanical turntable combined with ultrasonic cracking residual sludge [J].CIESC Journal,2016,67(12):5229-5236. | |

| 31 | 丛玉凤,徐磊,黄玮,等.SBS-C-9石油树脂改性沥青的研究 [J].建筑材料学报,2016,19(3):602-605. |

| Cong Y F,Xu L,Huang W,et al.Study on SBS-C-9 modified asphalt by petroleum resin [J].Journal of Building Materials,2016,19(3):602-605. | |

| 32 | Luo W Q,Chen J C.Preparation and properties of bitumen modified by EVA graft copolymer [J].Construction & Building Materials,2011,25(4):1830-1835. |

| 33 | Yan F,Zhang D,Ma Z G,et al.Aging kinetics of Saudi Arabia paving asphalt [J].Journal of Fushun Petroleum Institute,2003,23(1):10-12. |

| 34 | Cortizo M S,Larsen D O,Bianchetto H,et al.Effect of the thermal degradation of SBS copolymers during the ageing of modified asphalts [J].Polymer Degradation & Stability,2004,86(2):275-282. |

| 35 | Zhang F,Hu C B.The research for structural characteristics and modification mechanism of crumb rubber compound modified asphalts [J].Construction & Building Materials,2015,76(76):330-342. |

| 36 | Ouyang C F,Wang S F,Zhang Y,et al.Improving the aging resistance of asphalt by addition of zinc dialkyldithiophosphate [J].Fuel,2006,85(7):1060-1066. |

| [1] | 杨欣, 王文, 徐凯, 马凡华. 高压氢气加注过程中温度特征仿真分析[J]. 化工学报, 2023, 74(S1): 280-286. |

| [2] | 陈哲文, 魏俊杰, 张玉明. 超临界水煤气化耦合SOFC发电系统集成及其能量转化机制[J]. 化工学报, 2023, 74(9): 3888-3902. |

| [3] | 齐聪, 丁子, 余杰, 汤茂清, 梁林. 基于选择吸收纳米薄膜的太阳能温差发电特性研究[J]. 化工学报, 2023, 74(9): 3921-3930. |

| [4] | 何松, 刘乔迈, 谢广烁, 王斯民, 肖娟. 高浓度水煤浆管道气膜减阻两相流模拟及代理辅助优化[J]. 化工学报, 2023, 74(9): 3766-3774. |

| [5] | 邢雷, 苗春雨, 蒋明虎, 赵立新, 李新亚. 井下微型气液旋流分离器优化设计与性能分析[J]. 化工学报, 2023, 74(8): 3394-3406. |

| [6] | 张曼铮, 肖猛, 闫沛伟, 苗政, 徐进良, 纪献兵. 危废焚烧处理耦合有机朗肯循环系统工质筛选与热力学优化[J]. 化工学报, 2023, 74(8): 3502-3512. |

| [7] | 诸程瑛, 王振雷. 基于改进深度强化学习的乙烯裂解炉操作优化[J]. 化工学报, 2023, 74(8): 3429-3437. |

| [8] | 陈国泽, 卫东, 郭倩, 向志平. 负载跟踪状态下的铝空气电池堆最优功率点优化方法[J]. 化工学报, 2023, 74(8): 3533-3542. |

| [9] | 刘文竹, 云和明, 王宝雪, 胡明哲, 仲崇龙. 基于场协同和 耗散的微通道拓扑优化研究[J]. 化工学报, 2023, 74(8): 3329-3341. 耗散的微通道拓扑优化研究[J]. 化工学报, 2023, 74(8): 3329-3341. |

| [10] | 吴文涛, 褚良永, 张玲洁, 谭伟民, 沈丽明, 暴宁钟. 腰果酚生物基自愈合微胶囊的高效制备工艺研究[J]. 化工学报, 2023, 74(7): 3103-3115. |

| [11] | 汤晓玲, 王嘉瑞, 朱玄烨, 郑仁朝. 基于Pickering乳液的卤醇脱卤酶催化合成手性环氧氯丙烷[J]. 化工学报, 2023, 74(7): 2926-2934. |

| [12] | 王志龙, 杨烨, 赵真真, 田涛, 赵桐, 崔亚辉. 搅拌时间和混合顺序对锂离子电池正极浆料分散特性的影响[J]. 化工学报, 2023, 74(7): 3127-3138. |

| [13] | 文兆伦, 李沛睿, 张忠林, 杜晓, 侯起旺, 刘叶刚, 郝晓刚, 官国清. 基于自热再生的隔壁塔深冷空分工艺设计及优化[J]. 化工学报, 2023, 74(7): 2988-2998. |

| [14] | 朱风, 陈凯琳, 黄小凤, 鲍银珠, 李文斌, 刘嘉鑫, 吴玮强, 高王伟. KOH改性电石渣脱除羰基硫的性能研究[J]. 化工学报, 2023, 74(6): 2668-2679. |

| [15] | 江锦波, 彭新, 许文烜, 门日秀, 刘畅, 彭旭东. 泵出型螺旋槽油气密封泄漏特性及参数影响研究[J]. 化工学报, 2023, 74(6): 2538-2554. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号