化工学报 ›› 2021, Vol. 72 ›› Issue (6): 3228-3238.DOI: 10.11949/0438-1157.20201579

郭海军1,2,3,4( ),张海荣1,2,3,4,丁帅1,2,3,4,5,黎海龙1,2,3,4,彭芬1,2,3,4,熊莲1,2,3,4,陈新德1,2,3,4(

),张海荣1,2,3,4,丁帅1,2,3,4,5,黎海龙1,2,3,4,彭芬1,2,3,4,熊莲1,2,3,4,陈新德1,2,3,4( )

)

收稿日期:2020-11-03

修回日期:2020-12-02

出版日期:2021-06-05

发布日期:2021-06-05

通讯作者:

陈新德

作者简介:郭海军(1986—),男,博士,副研究员,基金资助:

GUO Haijun1,2,3,4( ),ZHANG Hairong1,2,3,4,DING Shuai1,2,3,4,5,LI Hailong1,2,3,4,PENG Fen1,2,3,4,XIONG Lian1,2,3,4,CHEN Xinde1,2,3,4(

),ZHANG Hairong1,2,3,4,DING Shuai1,2,3,4,5,LI Hailong1,2,3,4,PENG Fen1,2,3,4,XIONG Lian1,2,3,4,CHEN Xinde1,2,3,4( )

)

Received:2020-11-03

Revised:2020-12-02

Online:2021-06-05

Published:2021-06-05

Contact:

CHEN Xinde

摘要:

生物质作为唯一的可再生含碳资源,通过热化学液化可以实现其高附加值转化为燃料和化学品。木质纤维素多元醇液化产物富含活性羟基,具有可调变的羟值和黏度,在聚氨酯材料的生产中得到了广泛的应用。由于液化过程中同时存在缩聚、重排等副反应的发生,导致液化产物中含有醛、酮、酸、酯等羰基化合物,使用合适的催化剂对液化产物进行加氢提质是提高下游聚氨酯泡沫品质的必需步骤。为此,对木质纤维素多元醇液化工艺、液化动力学和液化机理等方面进行了总结,对液化产物的提质方法及工艺技术的选取进行了阐述,提出了“液化耦合提质”的新工艺,并对未来的研究重点及发展趋势提出了可行的建议。

中图分类号:

郭海军, 张海荣, 丁帅, 黎海龙, 彭芬, 熊莲, 陈新德. 木质纤维素多元醇液化及液化产物提质的研究进展[J]. 化工学报, 2021, 72(6): 3228-3238.

GUO Haijun, ZHANG Hairong, DING Shuai, LI Hailong, PENG Fen, XIONG Lian, CHEN Xinde. Research progress on lignocellulose liquefaction in polyhydric alcohol and upgrading of liquefaction product[J]. CIESC Journal, 2021, 72(6): 3228-3238.

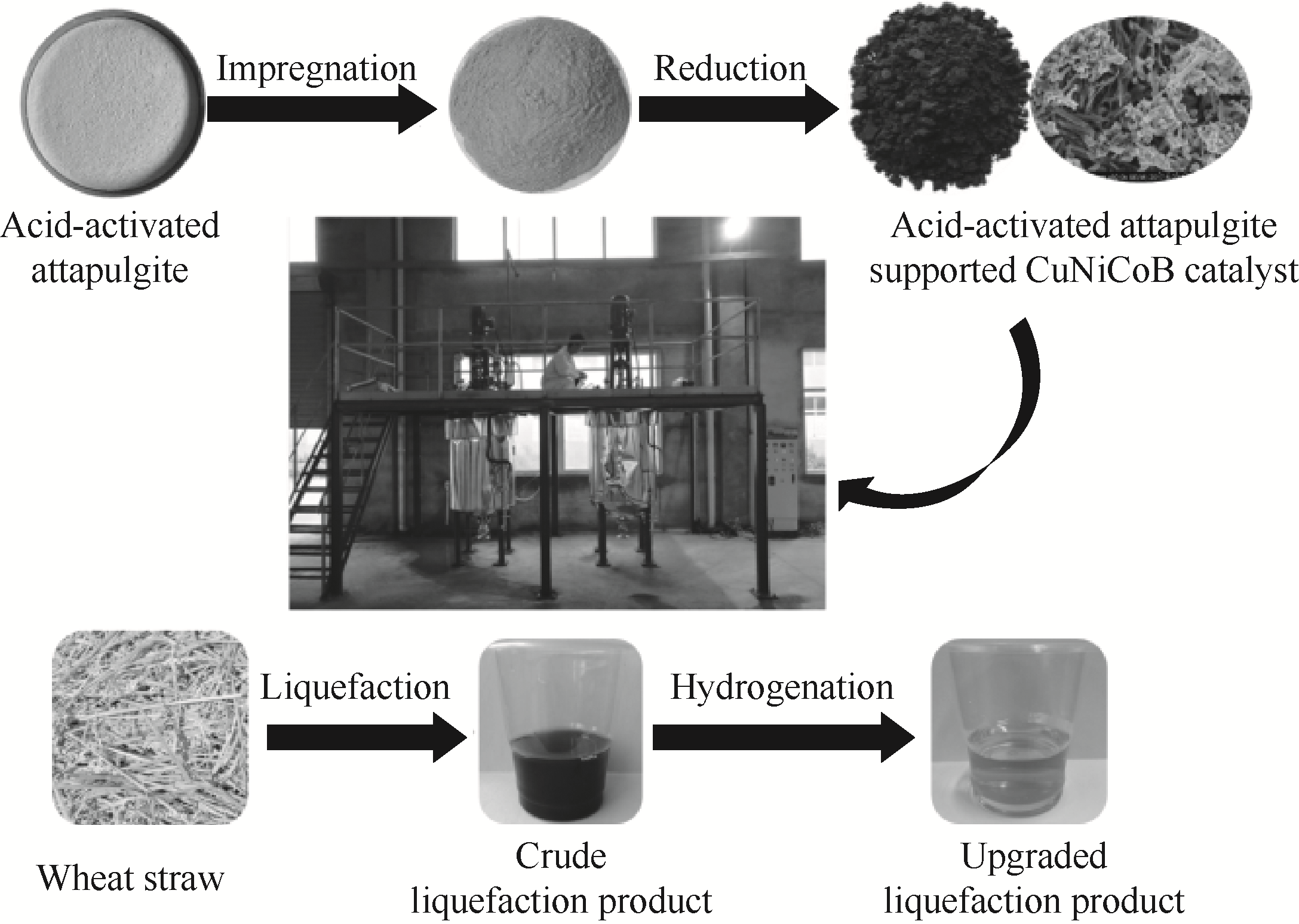

图2 酸改性凹凸棒石负载CuNiCoB非晶态合金催化剂用于麦秸液化产物加氢提质[101]

Fig.2 Hydrogenation upgrading of wheat straw liquefaction product over the acid-activated attapulgite supported CuNiCoB amorphous alloy catalyst[101]

| 97 | Zou X H, Chen T H, Zhang P, et al. High catalytic performance of Fe-Ni/palygorskite in the steam reforming of toluene for hydrogen production[J]. Applied Energy, 2018, 226: 827-837. |

| 98 | Lycourghiotis S, Kordouli E, Sygellou L, et al. Nickel catalysts supported on palygorskite for transformation of waste cooking oils into green diesel[J]. Applied Catalysis B-Environmental, 2019, 259: 118059. |

| 99 | Wang X Y, Qin G X, Li C, et al. Hydrogen production from catalytic microwave-assisted pyrolysis of corncob over transition metal (Fe, Co and Ni) modified palygorskite[J]. Journal of Biobased Materials and Bioenergy, 2020, 14(1): 126-132. |

| 100 | Wu M, Xu Y, Jang J, et al. Preparation of Pd-B/palygorskite amorphous catalyst for the selective hydrogenation of o-chloronitrobenzene to o-chloroaniline[J]. Micro & Nano Letters, 2016, 11(6): 315-318. |

| 101 | Guo H J, Zhang H R, Chen X F, et al. Catalytic upgrading of biopolyols derived from liquefaction of wheat straw over a high-performance and stable supported amorphous alloy catalyst[J]. Energy Conversion & Management, 2018, 156: 130-139. |

| 102 | Rezzoug S A, Capart R. Liquefaction of wood in two successive steps: solvolysis in ethylene-glycol and catalytic hydrotreatment[J]. Applied Energy, 2002, 72(3/4): 631-644. |

| 103 | Liu X R, Wang X C, Yao S X, et al. Recent advances in the production of polyols from lignocellulosic biomass and biomass-derived compounds[J]. RSC Advances, 2014, 4(90): 49501-49520. |

| 1 | Serrano-Ruiz J C, Dumesic J A. Catalytic routes for the conversion of biomass into liquid hydrocarbon transportation fuels[J]. Energy & Environmental Science, 2011, 4(1): 83-99. |

| 2 | Brown T R. A techno-economic review of thermochemical cellulosic biofuel pathways[J]. Bioresource Technology, 2015, 178: 166-176. |

| 104 | Cheng S Y, Wei L, Rabnawaz M. Catalytic liquefaction of pine sawdust and in-situ hydrogenation of bio-crude over bifunctional Co-Zn/HZSM-5 catalysts [J]. Fuel, 2018, 223: 252-260. |

| 105 | Wang J D, Li W Z, Wang H Z, et al. Liquefaction of kraft lignin by hydrocracking with simultaneous use of a novel dual acid-base catalyst and a hydrogenation catalyst [J]. Bioresource Technology, 2017, 243: 100-106. |

| 3 | 许文茸, 张洁, 郑凤昳, 等. 纤维素与甲壳素常压酸催化液化生成小分子化学品的机理研究进展[J]. 化工学报, 2018, 69(4): 1288-1298. |

| Xu W R, Zhang J, Zheng F Y, et al. Research progress on mechanisms of acid-catalyzed cellulose and chitin liquefaction to small molecular chemicals under atmospheric pressure[J]. CIESC Journal, 2018, 69(4): 1288-1298. | |

| 106 | Ma Q H, Chen D D, Wei L F, et al. Bio-oil production from hydrogenation liquefaction of rice straw over metal (Ni, Co, Cu)-modified CeO2 catalysts [J]. Energy Sources, Part A: Recovery, Utilization, and Environmental Effects, 2017, 40(2): 200-206. |

| 4 | Pan H. Synthesis of polymers from organic solvent liquefied biomass: a review[J]. Renewable & Sustainable Energy Reviews, 2011, 15(7): 3454-3463. |

| 5 | 孟繁蓉, 李瑞松, 张玉苍. 木质类废弃物液化及其高效利用研究进展[J]. 化工进展, 2016, 35(6): 1905-1913. |

| Meng F R, Li R S, Zhang Y C. Research progress on liquefaction of lignocellulosic waste and its efficient application [J]. Chemical Industry and Engineering Progress, 2016, 35(6): 1905-1913. | |

| 6 | D'souza J, Yan N. Producing bark-based polyols through liquefaction: effect of liquefaction temperature[J]. ACS Sustainable Chemistry & Engineering, 2013, 1(5): 534-540. |

| 7 | D'souza J, Camargo R, Yan N. Biomass liquefaction and alkoxylation: a review of structural characterization methods for bio-based polyols[J]. Polymer Reviews, 2017, 57(4): 668-694. |

| 8 | Hu S J, Luo X L, Li Y B. Polyols and polyurethanes from the liquefaction of lignocellulosic biomass[J]. ChemSusChem, 2014, 7(1): 66-72. |

| 9 | van Rossum G, Zhao W, Castellvi Barnes M, et al. Liquefaction of lignocellulosic biomass: solvent, process parameter, and recycle oil screening[J]. ChemSusChem, 2014, 7(1): 253-259. |

| 10 | Zhang T, Zhou Y J, Liu D H, et al. Qualitative analysis of products formed during the acid catalyzed liquefaction of bagasse in ethylene glycol[J]. Bioresource Technology, 2007, 98(7): 1454-1459. |

| 11 | Zhang H R, Ding F, Luo C R, et al. Liquefaction and characterization of acid hydrolysis residue of corncob in polyhydric alcohols[J]. Industrial Crops and Products, 2012, 39: 47-51. |

| 12 | Yamada T, Aratani M, Kubo S, et al. Chemical analysis of the product in acid-catalyzed solvolysis of cellulose using polyethylene glycol and ethylene carbonate[J]. Journal of Wood Science, 2007, 53(6): 487-493. |

| 13 | Jo Y J, Ly H V, Kim J, et al. Preparation of biopolyol by liquefaction of palm kernel cake using PEG#400 blended glycerol [J]. Journal of Industrial and Engineering Chemistry, 2015, 29: 304-313. |

| 14 | Pan H, Zheng Z F, Hse C Y. Microwave-assisted liquefaction of wood with polyhydric alcohols and its application in preparation of polyurethane (PU) foams[J]. European Journal of Wood & Wood Products, 2012, 70(4): 461-470. |

| 15 | Kržan A, Žagar E. Microwave driven wood liquefaction with glycols[J]. Bioresource Technology, 2009, 100(12): 3143-3146. |

| 16 | 李改云, 朱显超, 邹献武, 等. 5种生物质的微波辅助多元醇液化研究[J]. 林产化学与工业, 2015, 35(1): 107-112. |

| Li G Y, Zhu X C, Zou X W, et al. Microwave-assisted liquefaction of five types of biomass in polyhydric alcohols[J]. Chemistry & Industry of Forest Products, 2015, 35(1): 107-112. | |

| 17 | Zhang H R, Yang H J, Guo H J, et al. Kinetic study on the liquefaction of wood and its three cell wall component in polyhydric alcohols[J]. Applied Energy, 2014, 113: 1596-1600. |

| 18 | Lee S H, Teramoto Y, Shiraishi N. Biodegradable polyurethane foam from liquefied waste paper and its thermal stability, biodegradability, and genotoxicity[J]. Journal of Applied Polymer Science, 2002, 83(7): 1482-1489. |

| 19 | Gong G Z, Zou X C. Preparation and characterization of biopolyol via liquefaction of rice straw[J]. Russian Journal of Applied Chemistry, 2016, 89(8): 1360-1364. |

| 20 | Zhang H R, Luo J, Li Y Y, et al. Acid-catalyzed liquefaction of bagasse in the presence of polyhydric alcohol[J]. Applied Biochemistry and Biotechnology, 2013, 170(7): 1780-1791. |

| 21 | Kurimoto Y, Doi S, Tamura Y. Species effects on wood-liquefaction in polyhydric alcohols[J]. Holzforschung, 1999, 53(6): 617-622. |

| 22 | Hassan E B M, Shukry N. Polyhydric alcohol liquefaction of some lignocellulosic agricultural residues[J]. Industrial Crops and Products, 2008, 27(1): 33-38. |

| 23 | Kim K H, Jo Y J, Lee C G, et al. Solvothermal liquefaction of microalgal Tetraselmis sp. biomass to prepare biopolyols by using PEG#400-blended glycerol[J]. Algal Research-Biomass Biofuels and Bioproducts, 2015, 12: 539-544. |

| 24 | Yao Y, Yoshioka M, Shiraishi N. Combined liquefaction of wood and starch in a polyethylene glycol/glycerin blended solvent[J]. Mokuzai Gakkaishi, 1993, 39(8): 930-938. |

| 25 | Hu S J, Wan C X, Li Y B. Production and characterization of biopolyols and polyurethane foams from crude glycerol based liquefaction of soybean straw[J]. Bioresource Technology, 2012, 103(1): 227-233. |

| 26 | Hu S J, Li Y B. Polyols and polyurethane foams from acid-catalyzed biomass liquefaction by crude glycerol: effects of crude glycerol impurities[J]. Journal of Applied Polymer Science, 2014, 131(18): 40739. |

| 27 | Kosmela P, Hejna A, Formela K, et al. The study on application of biopolyols obtained by cellulose biomass liquefaction performed with crude glycerol for the synthesis of rigid polyurethane foams[J]. Journal of Polymers and the Environment, 2018, 26(6): 2546-2554. |

| 28 | Kosmela P, Hejna A, Formela K, et al. Biopolyols obtained via crude glycerol-based liquefaction of cellulose: their structural, rheological and thermal characterization[J]. Cellulose, 2016, 23(5): 2929-2942. |

| 29 | Hu S J, Li Y B. Two-step sequential liquefaction of lignocellulosic biomass by crude glycerol for the production of polyols and polyurethane foams[J]. Bioresource Technology, 2014, 161: 410-415. |

| 30 | Demirbaş A. Mechanisms of liquefaction and pyrolysis reactions of biomass[J]. Energy Conversion & Management, 2000, 41(6): 633-646. |

| 31 | Alma M H, Shiraishi N. Preparation of polyurethane-like foams from NaOH-catalyzed liquefied wood[J]. Holz als Roh-und Werkstoff, 1998, 56(4): 245-246. |

| 32 | Hu S J, Li Y B. Polyols and polyurethane foams from base-catalyzed liquefaction of lignocellulosic biomass by crude glycerol: effects of crude glycerol impurities[J]. Industrial Crops & Products, 2014, 57(2): 188-194. |

| 33 | 乐治平, 张宏, 洪立智. 固体超强酸Cl-/Fe2O3的制备及催化液化生物质[J]. 化工进展, 2007, 26(2): 246-248. |

| Le Z P, Zhang H, Hong L Z. Liquefaction of biomass by using solid superacid as catalyst[J]. Chemical Industry and Engineering Progress, 2007, 26(2): 246-248. | |

| 34 | Lu Z X, Zheng H Y, Fan L W, et al. Liquefaction of sawdust in 1-octanol using acidic ionic liquids as catalyst[J]. Bioresource Technology, 2013, 142(4): 579-584. |

| 35 | Lu Z X, Fan L W, Wu Z G, et al. Efficient liquefaction of woody biomass in polyhydric alcohol with acidic ionic liquid as a green catalyst[J]. Biomass & Bioenergy, 2015, 81: 154-161. |

| 36 | Shao Q, Li H Q, Huang C P, et al. Biopolyol preparation from liquefaction of grape seeds [J]. Journal of Applied Polymer Science, 2016, 133 (34): 43835. |

| 37 | 梁凌云. 秸秆热化学液化工艺和机理的研究 [D]. 北京: 中国农业大学, 2005. |

| Liang L Y. Research on the technique and mechanism of crop stalks thermochemical liquefaction [D]. Beijing: China Agricultural University, 2005. | |

| 38 | Liu H M, Xie X N, Ren J L, et al. 8-Lump reaction pathways of cornstalk liquefaction in sub- and super-critical ethanol [J]. Industrial Crops and Products, 2012, 35 (1): 250-256. |

| 39 | Aiouache F, McAleer L, Gan Q, et al. Path lumping kinetic model for aqueous phase reforming of sorbitol [J]. Applied Catalysis A: General, 2013, 466: 240-255. |

| 40 | Grilc M, Likozar B, Levec J. Hydrodeoxygenation and hydrocracking of solvolysed lignocellulosic biomass by oxide, reduced and sulphide form of NiMo, Ni, Mo and Pd catalysts [J]. Applied Catalysis B: Environmental, 2014, 150/151: 275-287. |

| 41 | 王娅莉, 战晓青, 解新安, 等. 秸秆纤维素亚/超临界液化中平台化合物的5集总动力学研究 [J]. 造纸科学与技术, 2016, 35 (3): 22-27. |

| Wang Y L, Zhan X Q, Xie X A, et al. 5-Lumps kinetics of platform chemical compounds from cellulose liquefaction in sub- and supercritical ethanol [J]. Paper Science & Technology, 2016, 35 (3): 22-27. | |

| 42 | Chen F G, Lu Z M. Liquefaction of wheat straw and preparation of rigid polyurethane foam from the liquefaction products[J]. Journal of Applied Polymer Science, 2009, 111(1): 508-516. |

| 43 | Meng F R, Zhang X X, Yu W F, et al. Kinetic analysis of cellulose extraction from banana pseudo-stem by liquefaction in polyhydric alcohols[J]. Industrial Crops and Products, 2019, 137: 377-385. |

| 44 | 张海荣, 计红果, 石锦志, 等. 桉树木粉的有机磺酸催化热化学液化研究[J]. 林产化学与工业, 2010, 30(6): 35-39. |

| Zhang H R, Ji H G, Shi J Z, et al. Study on liquefaction of eucalyptus wood powder in polyhydric alcohol catalyzed by organic sulfonic acid[J]. Chemistry and Industry of Forest Products, 2010, 30(6): 35-39. | |

| 45 | Remón J, Broust F, Valette J, et al. Production of a hydrogen-rich gas from fast pyrolysis bio-oils: comparison between homogeneous and catalytic steam reforming routes[J]. International Journal of Hydrogen Energy, 2014, 39(1): 171-182. |

| 46 | Widayatno W B, Guan G, Rizkiana J, et al. Selective catalytic conversion of bio-oil over high-silica zeolites[J]. Bioresource Technology, 2015, 179: 518-523. |

| 47 | Wu Q H, Wang Y P, Jiang L, et al. Microwave-assisted catalytic upgrading of co-pyrolysis vapor using HZSM-5 and MCM-41 for bio-oil production: co-feeding of soapstock and straw in a downdraft reactor[J]. Bioresource Technology, 2020, 299: 122611. |

| 48 | Kumar R, Strezov V, Lovell E, et al. Bio-oil upgrading with catalytic pyrolysis of biomass using copper/zeolite-nickel/zeolite and copper-nickel/zeolite catalysts[J]. Bioresource Technology, 2019, 279: 404-409. |

| 49 | Sanna A, Vispute T P, Huber G W. Hydrodeoxygenation of the aqueous fraction of bio-oil with Ru/C and Pt/C catalysts[J]. Applied Catalysis B Environmental, 2015, 165(10): 446-456. |

| 50 | Yang Y X, Hao J S, Lv G Q. Comparative study of catalytic hydrodeoxygenation performance over SBA-15 and TiO2 supported 20 wt% Ni for bio-oil upgrading[J]. Fuel, 2019, 253: 630-636. |

| 51 | Li Z Y, Jiang E C, Xu X W, et al. Hydrodeoxygenation of phenols, acids, and ketones as model bio-oil for hydrocarbon fuel over Ni-based catalysts modified by Al, La and Ga[J]. Renewable Energy, 2020, 146: 1991-2007. |

| 52 | Auersvald M, Shumeiko B, Stas M, et al. Quantitative study of straw bio-oil hydrodeoxygenation over a sulfided NiMo catalyst[J]. ACS Sustainable Chemistry & Engineering, 2019, 7(7): 7080-7093. |

| 53 | Huber G W, Dumesic J A. An overview of aqueous-phase catalytic processes for production of hydrogen and alkanes in a biorefinery[J]. Catalysis Today, 2006, 111(1): 119-132. |

| 54 | Huber G W, Iborra S, Corma A. Synthesis of transportation fuels from biomass: chemistry, catalysts, and engineering[J]. Chemical Reviews, 2006, 106(9): 4044-4098. |

| 55 | 郑小娟, 周娅芬, 付海燕, 等. 酯加氢反应中影响羧基活化的因素[J]. 物理化学学报, 2010, 26(10): 2699-2704. |

| Zheng X J, Zhou Y F, Fu H Y, et al. Activation factors for the carboxyl group in the hydrogenation of carboxylic esters[J]. Acta Physico-Chimica Sinica, 2010, 26(10): 2699-2704. | |

| 56 | Chen J H, Wang S R, Lu L, et al. Improved catalytic upgrading of simulated bio-oil via mild hydrogenation over bimetallic catalysts[J]. Fuel Processing Technology, 2018, 179: 135-142. |

| 57 | Tamura M, Nakagawa Y, Tomishige K. Recent developments of heterogeneous catalysts for selective hydrogenation of unsaturated carbonyl compounds to unsaturated alcohols[J]. Journal of the Japan Petroleum Institute, 2019, 62(3): 106-119. |

| 58 | Li C Z, Zhao X C, Wang A Q, et al. Catalytic transformation of lignin for the production of chemicals and fuels[J]. Chemical Reviews, 2015, 115(21): 11559-11624. |

| 59 | Attia S, Schmidt M C, Schroder C, et al. Keto-enol tautomerization as a first step in hydrogenation of carbonyl compounds[J]. Journal of Physical Chemistry C, 2019, 123(48): 29271-29277. |

| 60 | Lan X C, Wang T F. Highly selective catalysts for the hydrogenation of unsaturated aldehydes: a review[J]. ACS Catalysis, 2020, 10(4): 2764-2790. |

| 61 | Zhang X H, Wang T J, Ma L L, et al. Characterization and catalytic properties of Ni and NiCu catalysts supported on ZrO2-SiO2 for guaiacol hydrodeoxygenation[J]. Catalysis Communications, 2013, 33: 15-19. |

| 62 | 于玉肖, 徐莹, 王铁军, 等. 木质素降解模型化合物愈创木酚及苯酚原位加氢制备环己醇[J]. 燃料化学学报, 2013, 41(4): 443-448. |

| Yu Y X, Xu Y, Wang T J, et al. In-situ hydrogenation of lignin depolymerization model compounds to cyclohexanol[J]. Journal of Fuel Chemistry and Technology, 2013, 41(4): 443-448. | |

| 63 | Rodiansono, Khairi S, Hara T, et al. Highly efficient and selective hydrogenation of unsaturated carbonyl compounds using Ni-Sn alloy catalysts[J]. Catalysis Science & Technology, 2012, 2(10): 2139-2145. |

| 64 | Yao S X, Wang X C, Jiang Y J, et al. One-step conversion of biomass-derived 5-hydroxymethylfurfural to 1,2,6-hexanetriol over Ni-Co-Al mixed oxide catalysts under mild conditions[J]. ACS Sustainable Chemistry & Engineering, 2014, 2(2): 173-180. |

| 65 | 李辉, 徐烨, 乔明华, 等. 非晶态合金及其催化应用[M]. 北京:科学出版社, 2014. |

| Li H, Xu Y, Qiao M H, et al. Amorphous Alloy and their Catalytic Applications[M]. Beijing: Science Press, 2014. | |

| 66 | Smith G V, Brower W E, Matyjaszczyk M S, et al. Metallic glasses: new catalyst systems [M]//Seivama T, Tanabe K. Studies in Surface Science and Catalysis. Elsevier, 1981: 355-363. |

| 67 | Li H, Chai W M, Luo H S, et al. Hydrogenation of furfural to furfuryl alcohol over Co-B amorphous catalysts prepared by chemical reduction in variable media[J]. Chinese Journal of Chemistry, 2006, 24(12): 1704-1708. |

| 68 | Li H, Liu J, Yang H X, et al. Influence of pore structure on catalytic properties of mesoporous silica-supported Co-B amorphous alloys in hydrogenation of cinnamaldehyde to cinnamyl alcohol[J]. Chinese Journal of Chemistry, 2009, 27(12): 2316-2322. |

| 69 | Li H X, Zhang S Y, Luo H S. A Ce-promoted Ni-B amorphous alloy catalyst (Ni-Ce-B) for liquid-phase furfural hydrogenation to furfural alcohol[J]. Materials Letters, 2004, 58(22/23): 2741-2746. |

| 70 | Bai G Y, Niu L B, Zhao Z, et al. Ni-La-B amorphous alloys supported on SiO2 and gamma-Al2O3 for selective hydrogenation of benzophenone[J]. Journal of Molecular Catalysis A: Chemical, 2012, 363/364: 411-416. |

| 71 | Guo H J, Zhang H R, Tang W C, et al. Furfural hydrogenation over amorphous alloy catalysts prepared by different reducing agents[J]. BioResources, 2017, 12(4): 8755-8774. |

| 72 | Padmanaban S, Gunasekar G H, Lee M, et al. Recyclable covalent triazine framework-based Ru catalyst for transfer hydrogenation of carbonyl compounds in water[J]. ACS Sustainable Chemistry & Engineering, 2019, 7(9): 8893-8899. |

| 73 | Michel C, Gallezot P. Why is ruthenium an efficient catalyst for the aqueous-phase hydrogenation of biosourced carbonyl compounds[J]. ACS Catalysis, 2015, 5(7): 4130-4132. |

| 74 | Hu Q, Yang L, Fan G L, et al. Hydrogenation of biomass-derived compounds containing a carbonyl group over a copper-based nanocatalyst: insight into the origin and influence of surface oxygen vacancies[J]. Journal of Catalysis, 2016, 340: 184-195. |

| 75 | K S R, Enumula S S, Koppadi K S, et al. Gas phase transfer hydrogenation of α, β- unsaturated carbonyl compounds into saturated carbonyl compounds over supported Cu catalysts[J]. Molecular Catalysis, 2020, 482: 110686. |

| 76 | Mäki-Arvela P, Hájek J, Salmi T, et al. Chemoselective hydrogenation of carbonyl compounds over heterogeneous catalysts[J]. Applied Catalysis A: General, 2005, 292: 1-49. |

| 77 | Nakagawa Y, Tamura M, Tomishige K. Catalytic reduction of biomass-derived furanic compounds with hydrogen[J]. ACS Catalysis, 2013, 3(12): 2655-2668. |

| 78 | Siddqui N, Sarkar B, Pendem C, et al. Highly selective transfer hydrogenation of α,β-unsaturated carbonyl compounds using Cu-based nanocatalysts[J]. Catalysis Science & Technology, 2017, 7(13): 2828-2837. |

| 79 | 张跃, 黄波, 严生虎, 等. 丁二酸二乙酯加氢制备1,4-丁二醇的工艺研究[J]. 精细石油化工, 2008, 25(1): 21-24. |

| Zhang Y, Huang B, Yan S H, et al. Preparation of 1,4-butanediol by hydrogenation of diethyl succinate[J]. Speciality Petrochemicals, 2008, 25(1): 21-24. | |

| 80 | Wang Y, Shen Y L, Zhao Y J, et al. Insight into the balancing effect of active Cu species for hydrogenation of carbon–oxygen bonds[J]. ACS Catalysis, 2015, 5(10): 6200-6208. |

| 81 | Yao Y Q, Wu X Q, Gutiérrez O Y, et al. Roles of Cu+ and Cu0 sites in liquid-phase hydrogenation of esters on core-shell CuZnx@C catalysts[J]. Applied Catalysis B: Environmental, 2020, 267: 118698. |

| 82 | Mo M, Zheng M, Tang J S, et al. Highly active Co: B, Co: Mo(W): B amorphous nanotube catalysts for the selective hydrogenation of cinnamaldehyde[J]. Journal of Materials Science, 2014, 49(2): 877-885. |

| 83 | Zou J J, Xiong Z Q, Wang L, et al. Preparation of Pd-B/gamma-Al2O3 amorphous catalyst for the hydrogenation of tricyclopentadiene[J]. Journal of Molecular Catalysis A: Chemical, 2007, 271(1/2): 209-215. |

| 84 | Wen X, Cao Y Y, Qiao X L, et al. Significant effect of base on the improvement of selectivity in the hydrogenation of benzoic acid over NiZrB amorphous alloy supported on gamma-Al2O3[J]. Catalysis Science & Technology, 2015, 5(6): 3281-3287. |

| 85 | Villaverde M M, Bertero N M, Garetto T F, et al. Selective liquid-phase hydrogenation of furfural to furfuryl alcohol over Cu-based catalysts[J]. Catalysis Today, 2013, 213: 87-92. |

| 86 | Liu B, Qiao M H, Wang J Q, et al. Amorphous Ni-B/SiO2 catalyst prepared by microwave heating and its catalytic activity in acrylonitrile hydrogenation[J]. Journal of Chemical Technology & Biotechnology, 2003, 78(5): 512-517. |

| 87 | Wang L J, Li W, Zhang M H, et al. The interactions between the NiB amorphous alloy and TiO2 support in the NiB/TiO2 amorphous catalysts[J]. Applied Catalysis A: General, 2004, 259(2): 185-190. |

| 88 | Liu S C, Liu Z, Wang Z, et al. Characterization and study on performance of the Ru-La-B/ZrO2 amorphous alloy catalysts for benzene selective hydrogenation to cyclohexene under pilot conditions[J]. Chemical Engineering Journal, 2008, 139(1): 157-164. |

| 89 | Sun H, Jiang H, Li S, et al. Selective hydrogenation of benzene to cyclohexene over nanocomposite Ru-Mn/ZrO2 catalysts[J]. Chinese Journal of Catalysis, 2013, 34(4): 684-694. |

| 90 | 王来军, 张明慧, 李伟, 等. NiB、NiB/MgO非晶态合金催化剂的制备、表征及其加氢性能[J]. 石油化工, 2004, 33(1): 14-19. |

| Wang L J, Zhang M H, Li W, et al. Preparation, characterization and catalytic performance of NiB and NiB/MgO amorphous alloy catalysts in hydrogenation of sulfolene [J]. Petrochemical Technology, 2004, 33(1): 14-19. | |

| 91 | He Y G, Qiao M H, Hu H R, et al. Characterization and catalytic behavior of amorphous Ni-B/AC catalysts prepared in different impregnation sequences[J]. Applied Catalysis A: General, 2002, 228(1): 29-37. |

| 92 | Chen X Y, Wang S, Zhuang J H, et al. Mesoporous silica-supported NiB amorphous alloy catalysts for selective hydrogenation of 2-ethylanthraquinone[J]. Journal of Catalysis, 2004, 227(2): 419-427. |

| 93 | Chen X Y, Hu H R, Liu B, et al. Selective hydrogenation of 2-ethylanthraquinone over an environmentally benign Ni-B/SBA-15 catalyst prepared by a novel reductant-impregnation method[J]. Journal of Catalysis, 2003, 220(1): 254-257. |

| 94 | Wang W B, Wang A Q. Recent progress in dispersion of palygorskite crystal bundles for nanocomposites [J]. Applied Clay Science, 2016, 119: 18-30. |

| 95 | Guo H J, Zhang H R, Peng F, et al. Mixed alcohols synthesis from syngas over activated palygorskite supported Cu-Fe-Co based catalysts[J]. Applied Clay Science, 2015, 111: 83-89. |

| 96 | Guo H J, Zhang H R, Peng F, et al. Effects of Cu/Fe ratio on structure and performance of attapulgite supported CuFeCo-based catalyst for mixed alcohols synthesis from syngas[J]. Applied Catalysis A: General, 2015, 503: 51-61. |

| [1] | 杨欣, 王文, 徐凯, 马凡华. 高压氢气加注过程中温度特征仿真分析[J]. 化工学报, 2023, 74(S1): 280-286. |

| [2] | 李艺彤, 郭航, 陈浩, 叶芳. 催化剂非均匀分布的质子交换膜燃料电池操作条件研究[J]. 化工学报, 2023, 74(9): 3831-3840. |

| [3] | 郑佳丽, 李志会, 赵新强, 王延吉. 离子液体催化合成2-氰基呋喃反应动力学研究[J]. 化工学报, 2023, 74(9): 3708-3715. |

| [4] | 杨学金, 杨金涛, 宁平, 王访, 宋晓双, 贾丽娟, 冯嘉予. 剧毒气体PH3的干法净化技术研究进展[J]. 化工学报, 2023, 74(9): 3742-3755. |

| [5] | 曹跃, 余冲, 李智, 杨明磊. 工业数据驱动的加氢裂化装置多工况切换过渡状态检测[J]. 化工学报, 2023, 74(9): 3841-3854. |

| [6] | 杨绍旗, 赵淑蘅, 陈伦刚, 王晨光, 胡建军, 周清, 马隆龙. Raney镍-质子型离子液体体系催化木质素平台分子加氢脱氧制备烷烃[J]. 化工学报, 2023, 74(9): 3697-3707. |

| [7] | 陈杰, 林永胜, 肖恺, 杨臣, 邱挺. 胆碱基碱性离子液体催化合成仲丁醇性能研究[J]. 化工学报, 2023, 74(9): 3716-3730. |

| [8] | 杨菲菲, 赵世熙, 周维, 倪中海. Sn掺杂的In2O3催化CO2选择性加氢制甲醇[J]. 化工学报, 2023, 74(8): 3366-3374. |

| [9] | 李凯旋, 谭伟, 张曼玉, 徐志豪, 王旭裕, 纪红兵. 富含零价钴活性位点的钴氮碳/活性炭设计及甲醛催化氧化应用研究[J]. 化工学报, 2023, 74(8): 3342-3352. |

| [10] | 陈佳起, 赵万玉, 姚睿充, 侯道林, 董社英. 开心果壳基碳点的合成及其对Q235碳钢的缓蚀行为研究[J]. 化工学报, 2023, 74(8): 3446-3456. |

| [11] | 杨欣, 彭啸, 薛凯茹, 苏梦威, 吴燕. 分子印迹-TiO2光电催化降解增溶PHE废水性能研究[J]. 化工学报, 2023, 74(8): 3564-3571. |

| [12] | 吴文涛, 褚良永, 张玲洁, 谭伟民, 沈丽明, 暴宁钟. 腰果酚生物基自愈合微胶囊的高效制备工艺研究[J]. 化工学报, 2023, 74(7): 3103-3115. |

| [13] | 余娅洁, 李静茹, 周树锋, 李清彪, 詹国武. 基于天然生物模板构建纳米材料及集成催化剂研究进展[J]. 化工学报, 2023, 74(7): 2735-2752. |

| [14] | 李盼, 马俊洋, 陈志豪, 王丽, 郭耘. Ru/α-MnO2催化剂形貌对NH3-SCO反应性能的影响[J]. 化工学报, 2023, 74(7): 2908-2918. |

| [15] | 涂玉明, 邵高燕, 陈健杰, 刘凤, 田世超, 周智勇, 任钟旗. 钙基催化剂的设计合成及应用研究进展[J]. 化工学报, 2023, 74(7): 2717-2734. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号