化工学报 ›› 2022, Vol. 73 ›› Issue (3): 1324-1334.DOI: 10.11949/0438-1157.20211559

收稿日期:2021-11-01

修回日期:2021-12-20

出版日期:2022-03-15

发布日期:2022-03-14

通讯作者:

俞树荣

作者简介:宋伟(1979—),男,博士,副教授,基金资助:

Wei SONG( ),Wanjia LI,Shurong YU(

),Wanjia LI,Shurong YU( ),Rongrong MA

),Rongrong MA

Received:2021-11-01

Revised:2021-12-20

Online:2022-03-15

Published:2022-03-14

Contact:

Shurong YU

摘要:

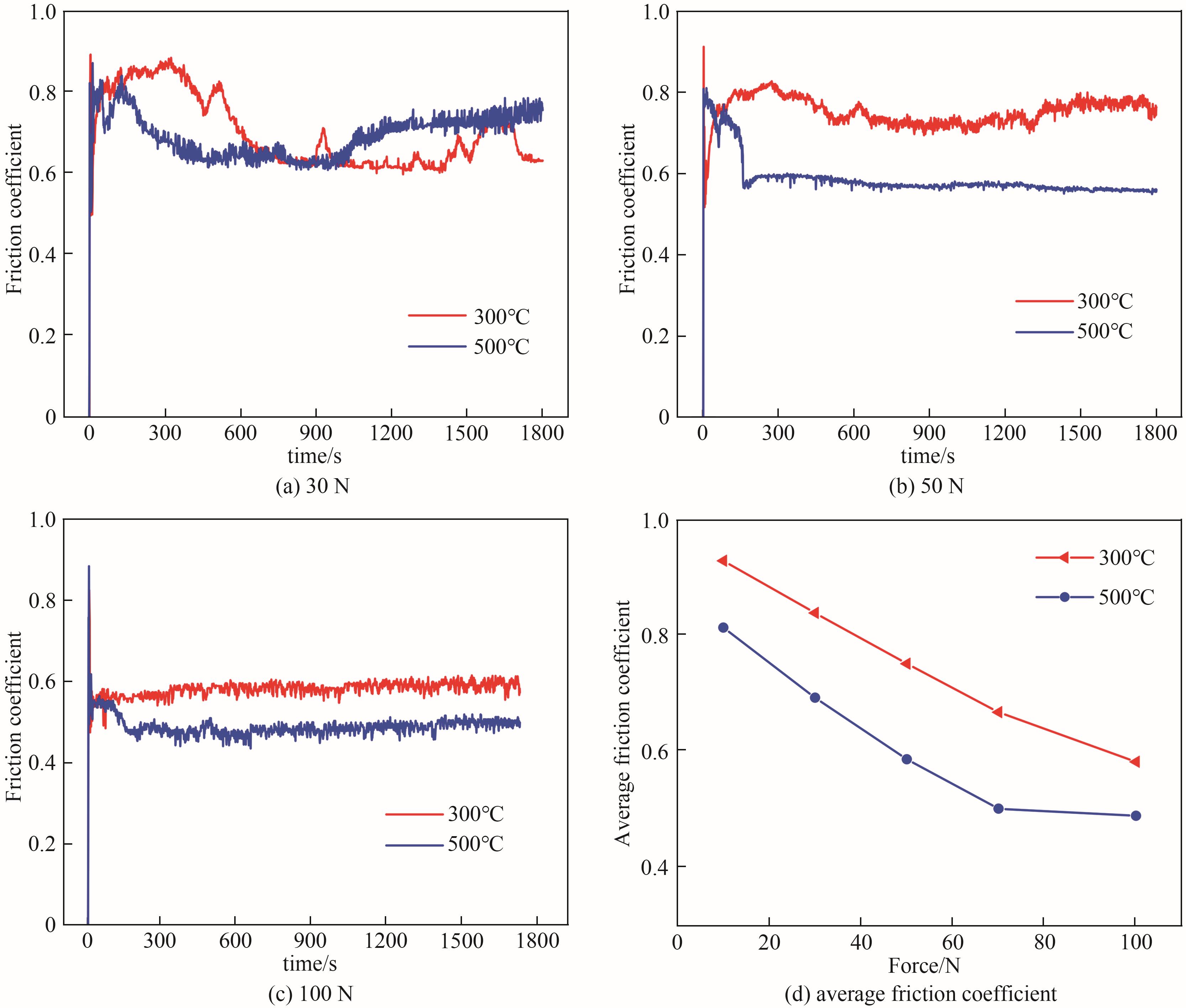

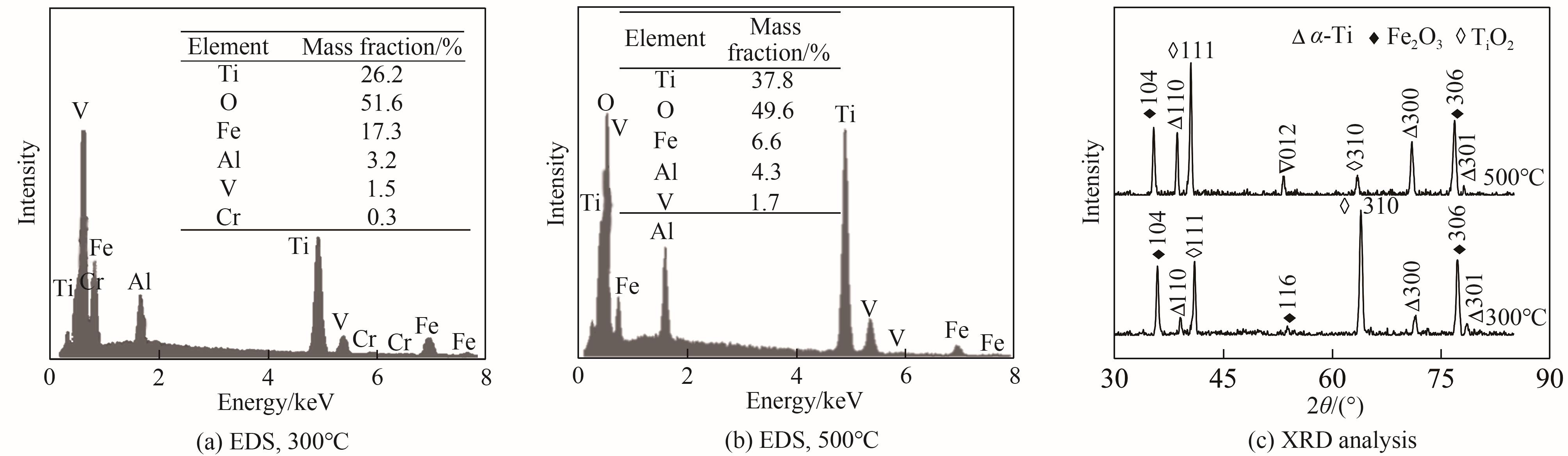

为了研究TC4合金在300℃和500℃下的微动磨损行为,利用扫描电子显微镜和激光共聚焦显微镜分别表征表面磨痕形貌、磨损体积和磨痕轮廓,探究两种温度中TC4合金不同接触载荷作用下的微动磨损机制。结果表明: 磨损体积与接触载荷呈现正相关的关系,而摩擦系数和磨损率则呈现负相关的关系。两种温度下的无润滑微动摩擦磨损过程中,小载荷作用时磨损形式表现为氧化磨损和磨粒磨损;大载荷作用时磨损形式为氧化磨损和黏着磨损。与300℃相比,500℃时合金接触表面塑性变形严重,摩擦系数小,氧化磨损加剧,疲劳裂纹扩展严重。TC4合金高温环境中微动磨损机制为黏着磨损、磨粒磨损、氧化磨损和疲劳磨损,其中氧化磨损在TC4合金高温微动磨损中占据主导地位。

中图分类号:

宋伟, 李万佳, 俞树荣, 马荣荣. 热力耦合下TC4合金微动磨损行为影响的研究[J]. 化工学报, 2022, 73(3): 1324-1334.

Wei SONG, Wanjia LI, Shurong YU, Rongrong MA. Effect of thermal mechanical coupling on fretting wear behavior of TC4 alloy[J]. CIESC Journal, 2022, 73(3): 1324-1334.

| 样品 | 化学成分/%(质量) | |||||

|---|---|---|---|---|---|---|

| TC4 | Al | V | O | Fe | N | Ti |

| 6.5 | 4.3 | 0.08 | 0.06 | 0.01 | Bal. | |

| GCr15 | Cr | C | Mn | Si | Mo | Fe |

| 1.6 | 1.0 | 0.3 | 0.3 | 0.08 | Bal. | |

表1 TC4合金、GCr15轴承钢的主要化学成分

Table 1 Chemical composition of TC4 and GCr15

| 样品 | 化学成分/%(质量) | |||||

|---|---|---|---|---|---|---|

| TC4 | Al | V | O | Fe | N | Ti |

| 6.5 | 4.3 | 0.08 | 0.06 | 0.01 | Bal. | |

| GCr15 | Cr | C | Mn | Si | Mo | Fe |

| 1.6 | 1.0 | 0.3 | 0.3 | 0.08 | Bal. | |

| Materials | Rp/MPa | Rm/MPa | HRC | E/GPa |

|---|---|---|---|---|

| TC4 | ≥825 | ≥895 | 30 | 110 |

| GCr15 | 1700 | 2000 | 68 | 210 |

表2 TC4合金、GCr15轴承钢主要力学性能

Table 2 Main mechanical properties of TC4 and GCr15

| Materials | Rp/MPa | Rm/MPa | HRC | E/GPa |

|---|---|---|---|---|

| TC4 | ≥825 | ≥895 | 30 | 110 |

| GCr15 | 1700 | 2000 | 68 | 210 |

图3 TC4合金在300℃和500℃下摩擦系数随时间的变化和平均摩擦系数随着载荷的变化

Fig.3 Changes of coefficient friction with time and changes of average friction coefficient with load of TC4 alloy at 300℃ and 500℃

图8 300℃和500℃下TC4合金在不同条件下的表面微观形貌

Fig.8 The microscopic appearance of the TC4 alloy surface under different conditions at 300 and 500℃(a)~(c): Fn =50 N, 300℃; (d)~(f): Fn=50 N, 500℃; (g)~(i): Fn =100 N, 500℃

图11 TC4合金表面EDS分析及不同温度下磨坑X射线衍射结果

Fig.11 EDS analysis of surface of TC4 alloy and X-ray diffraction results of the grinding pit under different conditions

| 1 | 周仲荣, 朱旻昊. 复合微动磨损[M]. 上海: 上海交通大学出版社, 2004. |

| Zhou Z R, Zhu M H. Composite fretting wear[M]. Shanghai: Shanghai Jiao Tong University Press, 2004. | |

| 2 | 蔡建明, 弭光宝, 高帆, 等. 航空发动机用先进高温钛合金材料技术研究与发展[J]. 材料工程, 2016, 44(8): 1-10. |

| Cai J M, Mi G B, Gao F, et al. Research and development of some advanced high temperature titanium alloys for aero-engine[J]. Journal of Materials Engineering, 2016, 44(8): 1-10. | |

| 3 | Philip J T, Mathew J, Kuriachen B. Tribology of Ti6Al4V: a review[J]. Friction, 2019, 7(6): 497-536. |

| 4 | 魏世忠, 徐流杰. 钢铁耐磨材料研究进展[J]. 金属学报, 2020, 56(4): 523-538. |

| Wei S Z, Xu L J. Review on research progress of steel and iron wear-resistant materials[J]. Acta Metallurgica Sinica, 2020, 56(4): 523-538. | |

| 5 | 李海燕, 刘欢, 张秀菊, 等. HVOF喷涂用于提高锅炉换热面耐磨损耐腐蚀性能综述[J]. 化工学报, 2021, 72(4): 1833-1846. |

| Li H Y, Liu H, Zhang X J, et al. Summary of improving erosion and corrosion resistance of heat exchange surfaces in boilers through HVOF technology[J]. CIESC Journal, 2021, 72(4): 1833-1846. | |

| 6 | 杜文欣, 伍联营, 张伟涛, 等. 钢球在液体中振动磨损量的研究[J]. 化工学报, 2019, 70(4): 1505-1511. |

| Du W X, Wu L Y, Zhang W T, et al. Research on vibration attrition of steel balls in liquid[J]. CIESC Journal, 2019, 70(4): 1505-1511. | |

| 7 | 王兰, 王树奇, 李新星, 等. TC4合金干滑动磨损性能的研究[J]. 摩擦学学报, 2015, 35(5): 629-634. |

| Wang L, Wang S Q, Li X X, et al. Dry sliding wear performance of TC4 alloy[J]. Tribology, 2015, 35(5): 629-634. | |

| 8 | Ganesh B K C, Ramanaih N, Chandrasekhar Rao P V. Dry sliding wear behavior of Ti-6Al-4V implant alloy subjected to various surface treatments[J]. Transactions of the Indian Institute of Metals, 2012, 65(5): 425-434. |

| 9 | Hager C H, Sanders J H, Sharma S. Effect of high temperature on the characterization of fretting wear regimes at Ti6Al4V interfaces[J]. Wear, 2006, 260(4/5): 493-508. |

| 10 | Kermanpur A, Sepehri Amin H, Ziaei-Rad S, et al. Failure analysis of Ti6Al4V gas turbine compressor blades[J]. Engineering Failure Analysis, 2007, 15(8): 1052-1064. |

| 11 | Bhaumik S K, Rangaraju R, Venkataswamy M A, et al. Fatigue fracture of crankshaft of an aircraft engine[J]. Engineering Failure Analysis, 2002, 9(3): 255-263. |

| 12 | Zhou H Y, Shi X L, Lu G C, et al. Friction and wear behaviors of TC4 alloy with surface microporous channels filled by Sn-Ag-Cu and Al2O3 nanoparticles[J]. Surface and Coatings Technology, 2020, 387: 125552. |

| 13 | 马润梅, 赵祥, 李双喜, 等. 颗粒介质用机械密封热力耦合变形及摩擦磨损研究[J]. 化工学报, 2021, 72(11): 5726-5737, 5893. |

| Ma R M, Zhao X, Li S X, et al. Research on thermal mechanical coupling deformation and friction and wear of mechanical seal for granular medium[J]. CIESC Journal, 2021, 72(11): 5726-5737, 5893. | |

| 14 | 刘道新, 何家文. 喷丸强化因素对Ti合金微动疲劳抗力的作用[J]. 金属学报, 2001, 37(2): 156-160. |

| Liu D X, He J W. Effectof shot peening factors on fretting fatigue resistance titanium alloy[J]. Acta Metallurgica Sinica, 2001, 37(2):156-160. | |

| 15 | 蔡振兵, 朱旻昊. 扭动微动磨损的研究进展和现状[J]. 中国表面工程, 2014, 27(4): 1-11. |

| Cai Z B, Zhu M H. Research and prospect on the torsional fretting wear[J]. China Surface Engineering, 2014, 27(4): 1-11. | |

| 16 | 何燕妮, 俞树荣, 李淑欣, 等. 摩擦氧化层对TC4合金磨损行为和摩擦系数的影响[J]. 稀有金属材料与工程, 2021, 50(4): 1417-1424. |

| He Y N, Yu S R, Li S X, et al. Effect of tribo-oxide layers on wear properties and coefficient of friction of TC4 alloy in fretting[J]. Rare Metal Materials and Engineering, 2021, 50(4): 1417-1424. | |

| 17 | 俞树荣, 白利蓉, 景鹏飞, 等. 摩擦配副材料对TC4钛合金微动磨损行为的影响[J]. 润滑与密封, 2018, 43(8): 14-18. |

| Yu S R, Bai L R, Jing P F, et al. Effect of counterpart materials on fretting wear behavior of TC4 titanium alloy[J]. Lubrication Engineering, 2018, 43(8): 14-18. | |

| 18 | 王兰, 张秋阳, 李新星, 等. 温度和载荷对TC4合金磨损性能的影响[J]. 稀有金属材料与工程, 2015, 44(2): 480-484. |

| Wang L, Zhang Q Y, Li X X, et al. Effect of temperature and load on wear performance of TC4 Alloy[J]. Rare Metal Materials and Engineering, 2015, 44(2): 480-484. | |

| 19 | Guo X L, Lai P, Tang L C, et al. Effectes of sliding amplitude and normal load on the fretting wear behavior of alloy 690 tube exposed to high temperature water[J]. Tribology International, 2017, 116: 155-163. |

| 20 | 郭薇, 李健, 黄淑梅, 等. 微动幅值对Ti-6Al-4V合金摩擦特性的影响[J]. 钛工业进展, 2016, 33(5): 16-20. |

| Guo W, Li J, Huang S M, et al. Effect of fretting amplitude on friction properties of Ti-6Al-4V alloy[J]. Titanium Industry Progress, 2016, 33(5): 16-20. | |

| 21 | Zhou Y, Shen M X, Cai Z B, et al. Study on dual rotary fretting wear behavior of Ti6Al4V titanium alloy[J]. Wear, 2017, 376/377: 670-679. |

| 22 | 丁燕, 柏林, 薛超凡, 等. TC21钛合金的高温微动磨损行为研究[J]. 南京航空航天大学学报, 2018, 50(1): 126-130. |

| Ding Y, Bai L, Xue C F, et al. Fretting wear behavior of TC21 alloy materials at elevated temperature[J]. Journal of Nanjing University of Aeronautics & Astronautics, 2018, 50(1): 126-130. | |

| 23 | 柏林, 丁燕, 邓凯, 等. TC21钛合金微动磨损特性的研究[J]. 材料导报, 2013, 27(10): 79-82, 103. |

| Bai L, Ding Y, Deng K, et al. Fretting wear behavior of TC21 alloy materials[J]. Materials Review, 2013, 27(10): 79-82, 103. | |

| 24 | 黄张洪, 曲恒磊, 邓超, 等. 航空用钛及钛合金的发展及应用[J]. 材料导报, 2011, 25(1): 102-107. |

| Huang Z H, Qu H L, Deng C, et al. Development and application of aerial titanium and its alloys[J]. Materials Review, 2011, 25(1): 102-107. | |

| 25 | 李毅, 赵永庆, 曾卫东. 航空钛合金的应用及发展趋势[J].材料导报, 2020, 34(S1): 280-282. |

| Li Y, Zhao Y Q, Zeng W D. Application and development of aerial titanium alloys[J]. Materials Reports, 2020, 34(S1): 280-282. | |

| 26 | 刘世锋, 宋玺, 薛彤, 等. 钛合金及钛基复合材料在航空航天的应用和发展[J]. 航空材料学报, 2020, 40(3): 77-94. |

| Liu S F, Song X, Xue T, et al. Application and development of titanium alloy and titanium matrix composites in aerospace field[J]. Journal of Aeronautical Materials, 2020, 40(3): 77-94. | |

| 27 | Pearson S R, Shipway P H. Is the wear coefficient dependent upon slip amplitude in fretting? Vingsbo and Söderberg revisited [J]. Wear, 2015, 330/331: 93-102. |

| 28 | Wang J F, Xue W H, Gao S Y, et al. Effect of groove surface texture on the fretting wear of Ti-6Al-4V alloy[J]. Wear, 2021, 486/487: 204079. |

| 29 | Kirk A M, Shipway P H, Sun W, et al. Debris development in fretting contacts-Debris particles and debris beds[J]. Tribology International, 2020, 149: 105592. |

| 30 | Lesnevskiy L N, Lyakhovetskiy M A, Savushkina S V.Fretting wear of composite ceramic coating produced on D16 aluminum-based alloy using microarc oxidation[J]. Journal of Friction and Wear, 2016, 37(3): 268-273. |

| 31 | Cheon S, Kim N. Prediction of tool wear in the blanking process using updated geometry[J]. Wear, 2016, 352/353: 160-170. |

| 32 | 景鹏飞, 俞树荣, 张克菲,等. 载荷及位移幅值对DLC薄膜微动磨损行为[J]. 摩擦学学报, 2021, 41(2): 213-222. |

| Jing P F, Yu S R, Zhang K F, et al. Effects of load and displacement amplitude on fretting wear behavior of DLC film[J]. Tribology, 2021, 41(2): 213-222. | |

| 33 | Fouvry S, Kapsa P, Vincent L. An elastic-plastic shakedown analysis of fretting wear[J]. Wear, 2001, 247(1): 41-54. |

| 34 | 宋伟, 尘强, 俞树荣, 等. TC4合金在不同环境介质中微动磨损行为研究[J]. 稀有金属材料与工程, 2020, 49(7): 2393-2399. |

| Song W, Chen Q, Yu S R, et al. Fretting wear behavior of TC4 alloy in different environmental media[J]. Rare Metal Materials and Engineering, 2020, 49(7): 2393-2399. | |

| 35 | Fan N, Wang Y X, Wang Q F, et al. Effect of displacement amplitude on fretting wear of 304 stainless steel in air and sea water [J]. Lubrication Science, 2018, 30(3): 116-125. |

| 36 | Rigney D A. Some thoughts on sliding wear[J]. Wear, 1992, 152(1): 187-192. |

| [1] | 胡超, 董玉明, 张伟, 张红玲, 周鹏, 徐红彬. 浓硫酸活化五氧化二钒制备高浓度全钒液流电池正极电解液[J]. 化工学报, 2023, 74(S1): 338-345. |

| [2] | 宋瑞涛, 王派, 王云鹏, 李敏霞, 党超镔, 陈振国, 童欢, 周佳琦. 二氧化碳直接蒸发冰场排管内流动沸腾换热数值模拟分析[J]. 化工学报, 2023, 74(S1): 96-103. |

| [3] | 张义飞, 刘舫辰, 张双星, 杜文静. 超临界二氧化碳用印刷电路板式换热器性能分析[J]. 化工学报, 2023, 74(S1): 183-190. |

| [4] | 范孝雄, 郝丽芳, 范垂钢, 李松庚. LaMnO3/生物炭催化剂低温NH3-SCR催化脱硝性能研究[J]. 化工学报, 2023, 74(9): 3821-3830. |

| [5] | 杨百玉, 寇悦, 姜峻韬, 詹亚力, 王庆宏, 陈春茂. 炼化碱渣湿式氧化预处理过程DOM的化学转化特征[J]. 化工学报, 2023, 74(9): 3912-3920. |

| [6] | 陈哲文, 魏俊杰, 张玉明. 超临界水煤气化耦合SOFC发电系统集成及其能量转化机制[J]. 化工学报, 2023, 74(9): 3888-3902. |

| [7] | 杨学金, 杨金涛, 宁平, 王访, 宋晓双, 贾丽娟, 冯嘉予. 剧毒气体PH3的干法净化技术研究进展[J]. 化工学报, 2023, 74(9): 3742-3755. |

| [8] | 米泽豪, 花儿. 基于DFT和COSMO-RS理论研究多元胺型离子液体吸收SO2气体[J]. 化工学报, 2023, 74(9): 3681-3696. |

| [9] | 陈美思, 陈威达, 李鑫垚, 李尚予, 吴有庭, 张锋, 张志炳. 硅基离子液体微颗粒强化气体捕集与转化的研究进展[J]. 化工学报, 2023, 74(9): 3628-3639. |

| [10] | 程业品, 胡达清, 徐奕莎, 刘华彦, 卢晗锋, 崔国凯. 离子液体基低共熔溶剂在转化CO2中的应用[J]. 化工学报, 2023, 74(9): 3640-3653. |

| [11] | 李锦潼, 邱顺, 孙文寿. 煤浆法烟气脱硫中草酸和紫外线强化煤砷浸出过程[J]. 化工学报, 2023, 74(8): 3522-3532. |

| [12] | 杨菲菲, 赵世熙, 周维, 倪中海. Sn掺杂的In2O3催化CO2选择性加氢制甲醇[J]. 化工学报, 2023, 74(8): 3366-3374. |

| [13] | 洪瑞, 袁宝强, 杜文静. 垂直上升管内超临界二氧化碳传热恶化机理分析[J]. 化工学报, 2023, 74(8): 3309-3319. |

| [14] | 李凯旋, 谭伟, 张曼玉, 徐志豪, 王旭裕, 纪红兵. 富含零价钴活性位点的钴氮碳/活性炭设计及甲醛催化氧化应用研究[J]. 化工学报, 2023, 74(8): 3342-3352. |

| [15] | 孟令玎, 崇汝青, 孙菲雪, 孟子晖, 刘文芳. 改性聚乙烯膜和氧化硅固定化碳酸酐酶[J]. 化工学报, 2023, 74(8): 3472-3484. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号