化工学报 ›› 2023, Vol. 74 ›› Issue (1): 416-427.DOI: 10.11949/0438-1157.20221014

收稿日期:2022-07-20

修回日期:2022-09-01

出版日期:2023-01-05

发布日期:2023-03-20

通讯作者:

骆广生

作者简介:盛林(1997—),男,博士研究生,shengl19@mails.tsinghua.edu.cn

基金资助:

Lin SHENG( ), Yu CHANG, Jian DENG, Guangsheng LUO(

), Yu CHANG, Jian DENG, Guangsheng LUO( )

)

Received:2022-07-20

Revised:2022-09-01

Online:2023-01-05

Published:2023-03-20

Contact:

Guangsheng LUO

摘要:

微流控技术制备微气泡因其过程可控、操作范围宽等特性而备受关注。选择阶梯式T型微通道作为微气泡生成的设备,利用高速摄像机研究了高气相含量下气泡群的自组装行为和流动特性,探索了液相体积流量、液相黏度、气相输入压力和通道宽度等因素对气泡群的影响规律。结果表明,只有当通道内的气相含量大于液相含量时才能形成有序的气泡群(气泡群晶体),且气泡群晶体在受限空间内能够沿着通道宽度或深度方向自组装成不同行数的结构。此外,系统研究了不同操作参数对气泡群晶体运动速度的影响规律。气泡群晶体运动速度随着液相体积流量变化的规律与气液两相的总体积流量变化规律一致。最后,提出了提升气液体系流动理想性的策略,并构建了预测气泡群晶体流动理想性的无量纲数学模型。

中图分类号:

盛林, 昌宇, 邓建, 骆广生. 阶梯式T型微通道内有序气泡群的形成和流动特性研究[J]. 化工学报, 2023, 74(1): 416-427.

Lin SHENG, Yu CHANG, Jian DENG, Guangsheng LUO. Formation and flow characteristics of ordered bubble swarm in a step T-junction microchannel[J]. CIESC Journal, 2023, 74(1): 416-427.

| 甘油质量 分数/% | 密度ρ/(kg·m-3) | 黏度μ/(mPa·s) | 界面张力σ/(mN·m-1) |

|---|---|---|---|

| 80 | 1206 | 45.6 | 46.12 |

| 86 | 1223 | 89.8 | 47.88 |

| 90 | 1232 | 151.9 | 49.66 |

| 93 | 1237 | 240.5 | 50.89 |

表1 气液体系的物性参数(25℃)

Table 1 Physical properties of the gas-liquid system (25℃)

| 甘油质量 分数/% | 密度ρ/(kg·m-3) | 黏度μ/(mPa·s) | 界面张力σ/(mN·m-1) |

|---|---|---|---|

| 80 | 1206 | 45.6 | 46.12 |

| 86 | 1223 | 89.8 | 47.88 |

| 90 | 1232 | 151.9 | 49.66 |

| 93 | 1237 | 240.5 | 50.89 |

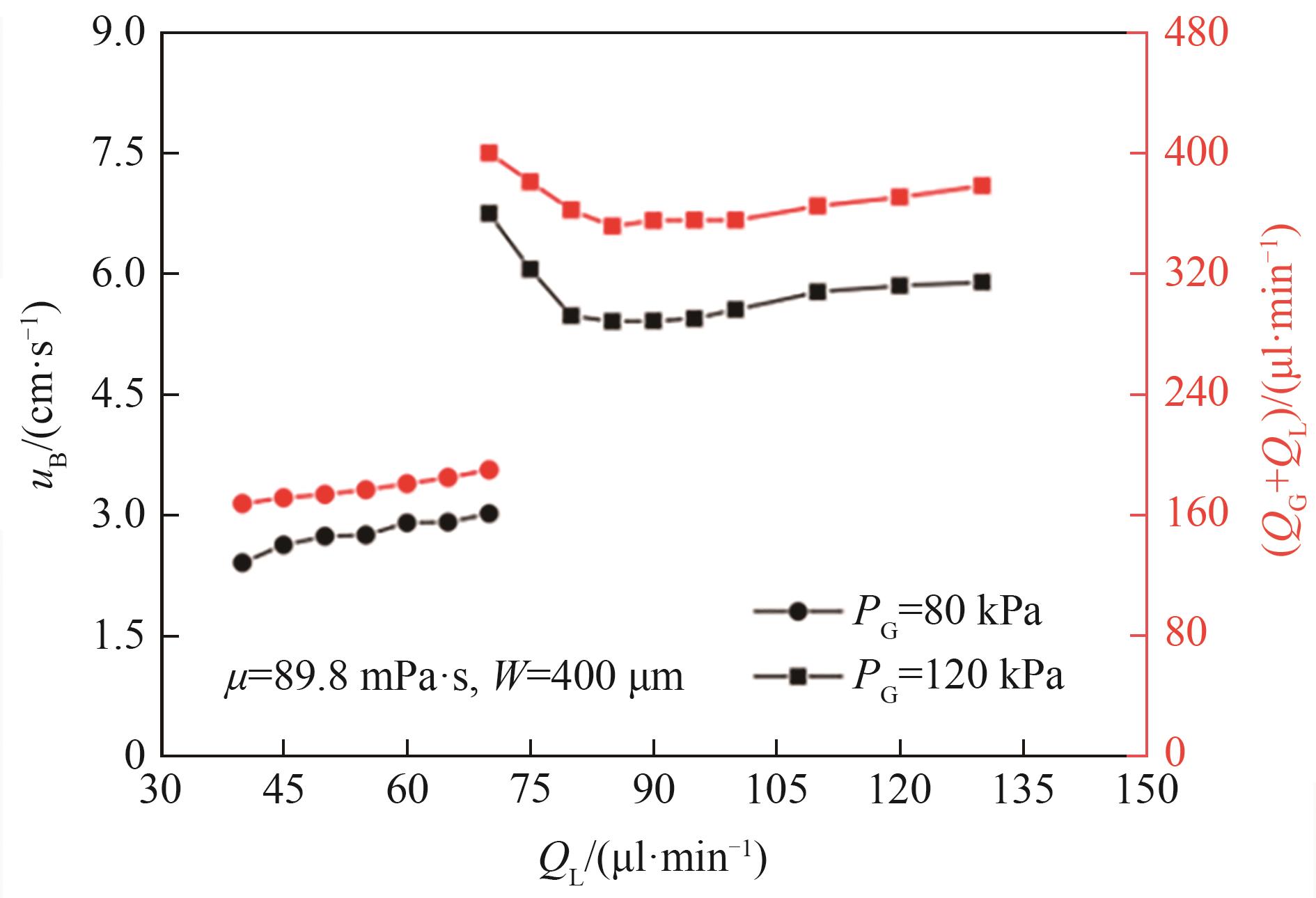

图9 气泡群晶体运动速度和气液两相的总体积流量随液相体积流量的变化规律

Fig.9 Variation of the velocity of bubble swarm crystal and total volumetric flow rate of gas-liquid two-phase with volumetric flow rate of liquid phase

| 8 | Wang K, Luo G S. Microflow extraction: a review of recent development[J]. Chemical Engineering Science, 2017, 169: 18-33. |

| 9 | Jeong H H, Chen Z, Yadavali S, et al. Large-scale production of compound bubbles using parallelized microfluidics for efficient extraction of metal ions[J]. Lab on a Chip, 2019, 19(6): 1101-1102. |

| 10 | Zheng C, Zhao B C, Wang K, et al. Determination of kinetics of CO2 absorption in solutions of 2-amino-2-methyl-1-propanol using a microfluidic technique[J]. AIChE Journal, 2015, 61(12): 4358-4366. |

| 11 | Pang Z F, Jiang S K, Zhu C Y, et al. Mass transfer of chemical absorption of CO2 in a serpentine minichannel[J]. Chemical Engineering Journal, 2021, 414: 128791. |

| 12 | Niu H N, Pan L W, Su H J, et al. Flow pattern, pressure drop, and mass transfer in a gas-liquid concurrent two-phase flow microchannel reactor[J]. Industrial & Engineering Chemistry Research, 2009, 48(3): 1621-1628. |

| 13 | Garstecki P, Fuerstman M J, Stone H A, et al. Formation of droplets and bubbles in a microfluidic T-junction-scaling and mechanism of break-up[J]. Lab on a Chip, 2006, 6(3): 437-446. |

| 14 | Zhang C, Fu T T, Zhu C Y, et al. Dynamics of bubble formation in highly viscous liquids in a flow-focusing device[J]. Chemical Engineering Science, 2017, 172: 278-285. |

| 15 | Wang K, Xie L S, Lu Y C, et al. Generating microbubbles in a co-flowing microfluidic device[J]. Chemical Engineering Science, 2013, 100: 486-495. |

| 16 | 崔永晋, 李严凯, 王凯, 等. 微分散设备数量放大方式研究进展[J]. 化工学报, 2020, 71(10): 4350-4364. |

| Cui Y J, Li Y K, Wang K, et al. Recent advances of numbering-up technology of micro-dispersion devices[J]. CIESC Journal, 2020, 71(10): 4350-4364. | |

| 17 | Chung P M Y, Kawaji M. The effect of channel diameter on adiabatic two-phase flow characteristics in microchannels[J]. International Journal of Multiphase Flow, 2004, 30(7/8): 735-761. |

| 18 | Choi C W, Yu D I, Kim M H. Adiabatic two-phase flow in rectangular microchannels with different aspect ratios (part Ⅱ): Bubble behaviors and pressure drop in single bubble[J]. International Journal of Heat and Mass Transfer, 2010, 53(23/24): 5242-5249. |

| 19 | Tan J, Li S W, Wang K, et al. Gas-liquid flow in T-junction microfluidic devices with a new perpendicular rupturing flow route[J]. Chemical Engineering Journal, 2009, 146(3): 428-433. |

| 20 | Sheng L, Chen Y C, Deng J, et al. High-frequency formation of bubble with short length in a capillary embedded step T-junction microdevice[J]. AIChE Journal, 2021, 67(11): e17376. |

| 21 | Mi S, Weldetsadik N T, Hayat Z, et al. Effects of the gas feed on bubble formation in a microfluidic T-junction: constant-pressure versus constant-flow-rate injection[J]. Industrial & Engineering Chemistry Research, 2019, 58(23): 10092-10105. |

| 22 | Wang H, Jiang S K, Zhu C Y, et al. Bubble formation in T-junctions within parallelized microchannels: effect of viscoelasticity[J]. Chemical Engineering Journal, 2021, 426: 131783. |

| 23 | 陈宇超, 崔永晋, 王凯, 等. 阶梯式T型微通道内液滴、气泡分散规律[J]. 化工学报, 2020, 71(1): 265-273. |

| Chen Y C, Cui Y J, Wang K, et al. Droplet and bubble dispersion instep T-junction microchannel[J]. CIESC Journal, 2020, 71(1): 265-273. | |

| 24 | Pasha M, Liu S E, Zhang J, et al. Recent advancements on hydrodynamics and mass transfer characteristics for CO2 absorption in microreactors[J]. Industrial & Engineering Chemistry Research, 2022, 61(34): 12249-12268. |

| 25 | Guo R W, Fu T T, Zhu C Y, et al. Hydrodynamics and mass transfer of gas-liquid flow in a tree-shaped parallel microchannel with T-type bifurcations[J]. Chemical Engineering Journal, 2019, 373: 1203-1211. |

| 26 | Fukano T, Kariyasaki A. Characteristics of gas-liquid two-phase flow in a capillary tube[J]. Nuclear Engineering and Design, 1993, 141(1/2): 59-68. |

| 27 | Mishima K, Hibiki T. Some characteristics of air-water two-phase flow in small diameter vertical tubes[J]. International Journal of Multiphase Flow, 1996, 22(4): 703-712. |

| 28 | Liu H, Vandu C O, Krishna R. Hydrodynamics of Taylor flow in vertical capillaries: flow regimes, bubble rise velocity, liquid slug length, and pressure drop[J]. Industrial & Engineering Chemistry Research, 2005, 44(14): 4884-4897. |

| 29 | Kawahara A, Sadatomi M, Nei K, et al. Experimental study on bubble velocity, void fraction and pressure drop for gas-liquid two-phase flow in a circular microchannel[J]. International Journal of Heat and Fluid Flow, 2009, 30(5): 831-841. |

| 1 | Wang K, Li L T, Xie P, et al. Liquid-liquid microflow reaction engineering[J]. Reaction Chemistry & Engineering, 2017, 2(5): 611-627. |

| 2 | Song J, Cui Y J, Sheng L, et al. Determination of nitration kinetics of p-nitrotoluene with a homogeneously continuous microflow[J]. Chemical Engineering Science, 2022, 247: 117041. |

| 3 | Xie P, Wang K, Deng J, et al. Continuous, homogeneous and rapid synthesis of 4-bromo-3-methylanisole in a modular microreaction system[J]. Chinese Journal of Chemical Engineering, 2020, 28(8): 2092-2098. |

| 4 | Yan Z F, Tian J X, Du C C, et al. Reaction kinetics determination based on microfluidic technology[J]. Chinese Journal of Chemical Engineering, 2022, 41: 49-72. |

| 5 | Du L, Wang Y J, Wang K, et al. Growth of aragonite CaCO3 whiskers in a microreactor with calcium dodecyl benzenesulfonate as a control agent[J]. Industrial & Engineering Chemistry Research, 2015, 54(28): 7131-7140. |

| 6 | Han C L, Hu Y P, Wang K, et al. Preparation and in situ surface modification of CaCO3 nanoparticles with calcium stearate in a microreaction system[J]. Powder Technology, 2019, 356: 414-422. |

| 7 | 李严凯, 王凯, 骆广生. 液液微分散及其用于标准颗粒制备的研究进展[J]. 化工进展, 2019, 38(1): 30-44. |

| Li Y K, Wang K, Luo G S. Advances in liquid-liquid micro-dispersion and its applications in standard particle preparation[J]. Chemical Industry and Engineering Progress, 2019, 38(1): 30-44. | |

| 30 | Kawahara A, Sadatomi M, Nei K, et al. Characteristics of two-phase flows in a rectangular microchannel with a T-junction type gas-liquid mixer[J]. Heat Transfer Engineering, 2011, 32(7/8): 585-594. |

| 31 | Sheng L, Chen Y C, Wang K, et al. General rules of bubble formation in viscous liquids in a modified step T-junction microdevice[J]. Chemical Engineering Science, 2021, 239: 116621. |

| 32 | Li Y K, Wang K, Xu J H, et al. A capillary-assembled micro-device for monodispersed small bubble and droplet generation[J]. Chemical Engineering Journal, 2016, 293: 182-188. |

| 33 | Garstecki P, Whitesides G M. Flowing crystals: nonequilibrium structure of foam[J]. Physical Review Letters, 2006, 97(2): 024503. |

| 34 | Raven J P, Marmottant P. Microfluidic crystals: dynamic interplay between rearrangement waves and flow[J]. Physical Review Letters, 2009, 102(8): 084501. |

| 35 | del Giudice F, D’Avino G, Maffettone P L. Microfluidic formation of crystal-like structures[J]. Lab on a Chip, 2021, 21(11): 2069-2094. |

| 36 | Sheng L, Chen Y C, Deng J, et al. Ideality analysis and general laws of bubble swarm microflow for large-scale gas-liquid microreaction processes[J]. Chinese Journal of Chemical Engineering, 2022, 50(10): 56-65. |

| 37 | van Steijn V, Kreutzer M T, Kleijn C R. Μ-PIV study of the formation of segmented flow in microfluidic T-junctions[J]. Chemical Engineering Science, 2007, 62(24): 7505-7514. |

| 38 | Sheng L, Chang Y, Deng J, et al. Hydrodynamics and scaling laws of gas-liquid Taylor flow in viscous liquids in a microchannel[J]. Industrial & Engineering Chemistry Research, 2022, 61(28): 10275-10284. |

| 39 | Hatch A C, Fisher J S, Pentoney S L, et al. Tunable 3D droplet self-assembly for ultra-high-density digital micro-reactor arrays[J]. Lab on a Chip, 2011, 11(15): 2509-2517. |

| 40 | Elvira K S, Solvas X C i, Wootton R C R, et al. The past, present and potential for microfluidic reactor technology in chemical synthesis[J]. Nature Chemistry, 2013, 5(11): 905-915. |

| [1] | 肖明堃, 杨光, 黄永华, 吴静怡. 浸没孔液氧气泡动力学数值研究[J]. 化工学报, 2023, 74(S1): 87-95. |

| [2] | 邵苛苛, 宋孟杰, 江正勇, 张旋, 张龙, 高润淼, 甄泽康. 水平方向上冰中受陷气泡形成和分布实验研究[J]. 化工学报, 2023, 74(S1): 161-164. |

| [3] | 江河, 袁俊飞, 王林, 邢谷雨. 均流腔结构对微细通道内相变流动特性影响的实验研究[J]. 化工学报, 2023, 74(S1): 235-244. |

| [4] | 袁佳琦, 刘政, 黄锐, 张乐福, 贺登辉. 泡状入流条件下旋流泵能量转换特性研究[J]. 化工学报, 2023, 74(9): 3807-3820. |

| [5] | 刘文竹, 云和明, 王宝雪, 胡明哲, 仲崇龙. 基于场协同和 耗散的微通道拓扑优化研究[J]. 化工学报, 2023, 74(8): 3329-3341. 耗散的微通道拓扑优化研究[J]. 化工学报, 2023, 74(8): 3329-3341. |

| [6] | 岳林静, 廖艺涵, 薛源, 李雪洁, 李玉星, 刘翠伟. 凹坑缺陷对厚孔板喉部空化流动特性影响研究[J]. 化工学报, 2023, 74(8): 3292-3308. |

| [7] | 邢雷, 苗春雨, 蒋明虎, 赵立新, 李新亚. 井下微型气液旋流分离器优化设计与性能分析[J]. 化工学报, 2023, 74(8): 3394-3406. |

| [8] | 高燕, 伍鹏, 尚超, 胡泽君, 陈晓东. 基于双流体喷嘴的磁性琼脂糖微球的制备及其蛋白吸附性能探究[J]. 化工学报, 2023, 74(8): 3457-3471. |

| [9] | 王海, 林宏, 王晨, 许浩洁, 左磊, 王军锋. 高压静电场强化多孔介质表面沸腾传热特性研究[J]. 化工学报, 2023, 74(7): 2869-2879. |

| [10] | 高金明, 郭玉娇, 鄂承林, 卢春喜. 一种封闭罩内顺流多旋臂气液分离器的分离特性研究[J]. 化工学报, 2023, 74(7): 2957-2966. |

| [11] | 刘起超, 周云龙, 陈聪. 起伏振动垂直上升管气液两相流截面含气率分析与计算[J]. 化工学报, 2023, 74(6): 2391-2403. |

| [12] | 江锦波, 彭新, 许文烜, 门日秀, 刘畅, 彭旭东. 泵出型螺旋槽油气密封泄漏特性及参数影响研究[J]. 化工学报, 2023, 74(6): 2538-2554. |

| [13] | 董鑫, 单永瑞, 刘易诺, 冯颖, 张建伟. 非牛顿流体气泡羽流涡特性数值模拟研究[J]. 化工学报, 2023, 74(5): 1950-1964. |

| [14] | 周必茂, 许世森, 王肖肖, 刘刚, 李小宇, 任永强, 谭厚章. 烧嘴偏转角度对气化炉渣层分布特性的影响[J]. 化工学报, 2023, 74(5): 1939-1949. |

| [15] | 王泽栋, 石至平, 刘丽艳. 考虑气泡非均匀耗散的矩形反应器声流场数值模拟及结构优化[J]. 化工学报, 2023, 74(5): 1965-1973. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号