化工学报 ›› 2023, Vol. 74 ›› Issue (6): 2404-2415.DOI: 10.11949/0438-1157.20230084

张媛媛1,2( ), 曲江源1, 苏欣欣3, 杨静3, 张锴1(

), 曲江源1, 苏欣欣3, 杨静3, 张锴1( )

)

收稿日期:2023-02-08

修回日期:2023-05-11

出版日期:2023-06-05

发布日期:2023-07-27

通讯作者:

张锴

作者简介:张媛媛(1985—),女,博士研究生,高级实验师,zhangyuanyuan@ncepu.edu.cn

基金资助:

Yuanyuan ZHANG1,2( ), Jiangyuan QU1, Xinxin SU3, Jing YANG3, Kai ZHANG1(

), Jiangyuan QU1, Xinxin SU3, Jing YANG3, Kai ZHANG1( )

)

Received:2023-02-08

Revised:2023-05-11

Online:2023-06-05

Published:2023-07-27

Contact:

Kai ZHANG

摘要:

采用CFD模拟方法预测了300 MW循环流化床机组SNCR脱硝过程中的还原剂液滴蒸发、烟气混合和反应特性。结果表明烟气在旋风分离器内贴壁旋转流动并形成外旋流为准自由涡和内旋流为刚性涡的双涡结构,使液滴与烟气接触约0.01 s后开始恒温蒸发,并强化了烟气与气态还原剂的混合效果。氨水为还原剂时,NH3主要分布于旋风分离器锥体上方;尿素为还原剂时,蒸发后快速分解的HNCO消耗速率高于NH3,其中NH3浓度分布与氨水为还原剂相似,相同烟气温度和氨氮摩尔比时氨水和尿素溶液对应脱硝效率分别约为79.5%和76.5%。温度对脱硝效率的影响表现为先上升后下降趋势,当温度由1023 K提高至1173 K时NH3与NO反应速率提高,脱硝效率由19.7%提高至81.0%;而当温度由1173 K进一步提高至1323 K时,NH3由于自身氧化速率显著提高而导致脱硝效率降低至17.4%。脱硝效率随氨氮摩尔比(NSR)增大而升高,但还原剂利用率的降低致使氨逃逸率增大,综合考虑本台CFB锅炉SNCR脱硝效率和氨逃逸率,NSR选取1.25~1.50可以满足NO x 排放低于50 mg/m3的超低排放标准。

中图分类号:

张媛媛, 曲江源, 苏欣欣, 杨静, 张锴. 循环流化床燃煤机组SNCR脱硝过程气液传质和反应特性[J]. 化工学报, 2023, 74(6): 2404-2415.

Yuanyuan ZHANG, Jiangyuan QU, Xinxin SU, Jing YANG, Kai ZHANG. Gas-liquid mass transfer and reaction characteristics of SNCR denitration in CFB coal-fired unit[J]. CIESC Journal, 2023, 74(6): 2404-2415.

| No. | Reaction | A | β | Ea/(J/mol) | Order |

|---|---|---|---|---|---|

| A1 | 4NH3 +4NO+O2 | 3.1×108 | 5.30 | 3.3×105 | 3 |

| A2 | 4NH3 +5O2 | 2.4×105 | 7.41 | 4.9×105 | 2 |

| U1 | NH3+NO | 4.2×108 | 5.30 | 3.5×105 | 2 |

| U2 | NH3+ O2 | 3.5×105 | 7.70 | 5.2×105 | 2 |

| U3 | HNCO+M | 2.4×1014 | 0.85 | 2.8×105 | 2 |

| U4 | NCO+NO | 1.0×1013 | 0 | -1.6×103 | 2 |

| U5 | NCO+OH | 1.0×1013 | 0 | 0 | 2 |

| U6 | N2O+OH | 2.0×1012 | 0 | 4.2×104 | 2 |

| U7 | N2O+M | 6.9×1023 | -2.50 | 2.7×105 | 2 |

| U8 | CO(NH2)2 | 1.3×104 | 0 | 6.5×104 | 1 |

| U9 | CO(NH2)2+H2O | 6.1×1010 | 0 | 8.8×104 | 2 |

表1 SNCR化学反应机理与动力学参数[7,9-10]

Table 1 Simplified mechanism and kinetic parameters of chemical reactions for SNCR process[7,9-10]

| No. | Reaction | A | β | Ea/(J/mol) | Order |

|---|---|---|---|---|---|

| A1 | 4NH3 +4NO+O2 | 3.1×108 | 5.30 | 3.3×105 | 3 |

| A2 | 4NH3 +5O2 | 2.4×105 | 7.41 | 4.9×105 | 2 |

| U1 | NH3+NO | 4.2×108 | 5.30 | 3.5×105 | 2 |

| U2 | NH3+ O2 | 3.5×105 | 7.70 | 5.2×105 | 2 |

| U3 | HNCO+M | 2.4×1014 | 0.85 | 2.8×105 | 2 |

| U4 | NCO+NO | 1.0×1013 | 0 | -1.6×103 | 2 |

| U5 | NCO+OH | 1.0×1013 | 0 | 0 | 2 |

| U6 | N2O+OH | 2.0×1012 | 0 | 4.2×104 | 2 |

| U7 | N2O+M | 6.9×1023 | -2.50 | 2.7×105 | 2 |

| U8 | CO(NH2)2 | 1.3×104 | 0 | 6.5×104 | 1 |

| U9 | CO(NH2)2+H2O | 6.1×1010 | 0 | 8.8×104 | 2 |

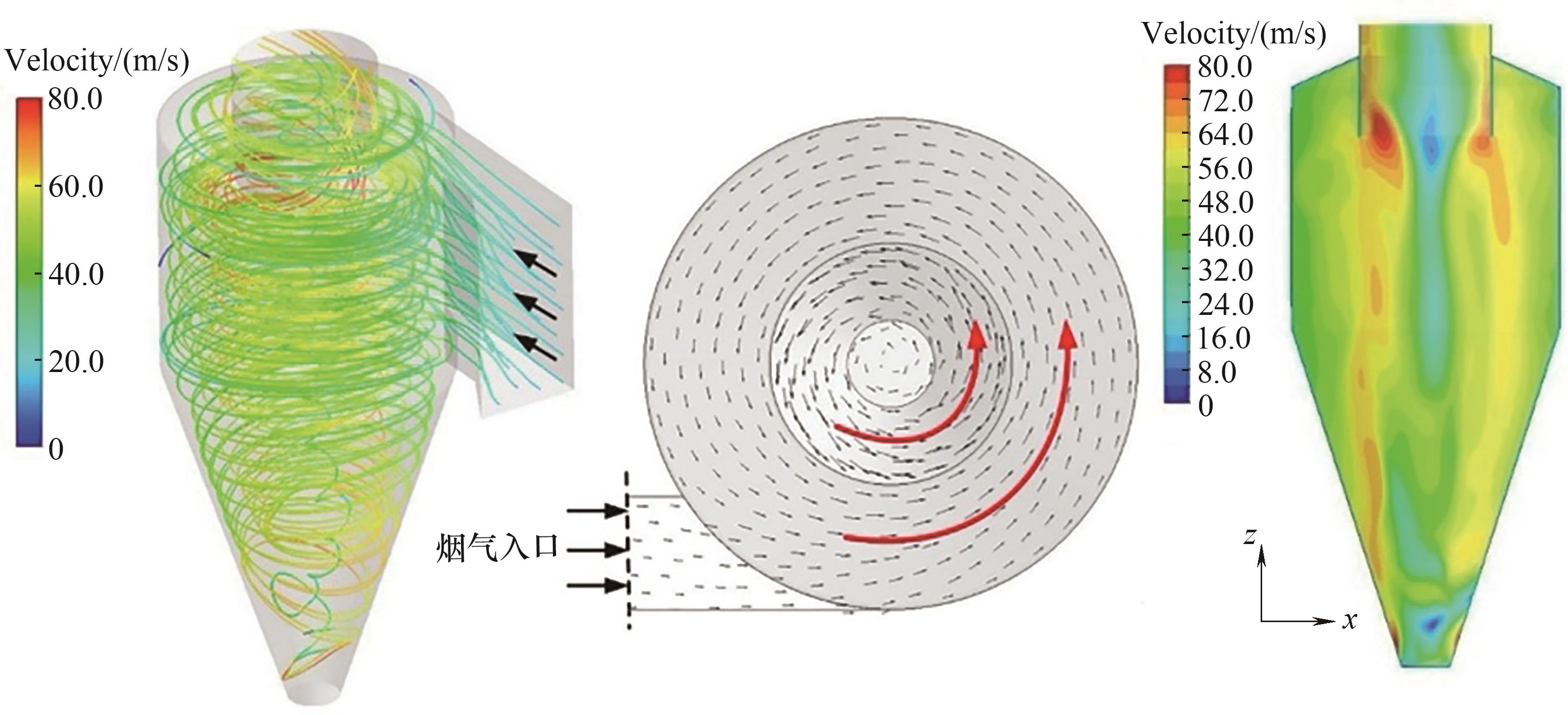

图4 旋风分离器内烟气流线、xy截面矢量图和zx截面速度分布

Fig.4 Streamline for flue gas in cyclone separator, vector field in xy cross section and velocity magnitude in zx cross section

| 1 | 岳光溪, 周大力, 田文龙, 等. 中国煤炭清洁燃烧技术路线图的初步探讨[J]. 中国工程科学, 2018, 20(3): 74-79. |

| Yue G X, Zhou D L, Tian W L, et al. Preliminary discussion on the technology roadmap of clean coal combustion in China[J]. Strategic Study of CAE, 2018, 20(3): 74-79. | |

| 2 | 国家发展与改革委员会, 环境保护部, 国家能源局. 关于印发《煤电节能减排升级与改造行动计划(2014—2020年)》的通知(发改能源[2014]2093号) [Z]. 国家发展与改革委员会, 2014. |

| National Development and Reform Commission, Ministry of Ecology and Environment of the People's Republic of China, National Energy Administration. Notification of action plan of upgrading and renovating in energy saving and emission reduction for coal fired power plant (2014—2020) ([2014] 2093) [Z]. National Development and Reform Commission, 2014. | |

| 3 | 中华人民共和国生态环境部科技标准司. 燃煤电厂超低排放烟气治理工程技术规范: [S]. 北京: 中国环境科学出版社, 2018. |

| Department of Science and Technology Standards, Ministry of Ecology and Environment of the People's Republic of China. Technical specifications for flue gas ultra-low emission engineering of coal-fired power plant: [S]. Beijing: China Environmental Science Press, 2018. | |

| 4 | Locci C, Vervisch L, Farcy B, et al. Selective non-catalytic reduction (SNCR) of nitrogen oxide emissions: a perspective from numerical modeling[J]. Flow Turbulence and Combustion, 2018, 100: 301-340. |

| 5 | Świeboda T, Krzyżyńska R, Bryszewska-Mazurek A, et al. Advanced approach to modeling of pulverized coal boilers for SNCR process optimization—review and recommendations[J]. International Journal of Thermofluids, 2020, 7/8: 100051. |

| 6 | 付世龙, 宋蔷, 仲蕾, 等. 粉体对分解炉内SNCR反应影响的研究[J]. 燃料化学学报, 2013, 41(5): 636-640. |

| Fu S L, Song Q, Zhong L, et al. Influence of calcium-based particles on the selective non-catalytic reduction process in a pre-calciner[J]. Journal of Fuel Chemistry and Technology, 2013, 41(5): 636-640. | |

| 7 | Rota R, Antos D, Zanoelo É F, et al. Experimental and modeling analysis of the NO x OUT process[J]. Chemical Engineering Science, 2002, 57(1): 27-38. |

| 8 | Farcy B, Abou-Taouk A, Vervisch L, et al. Two approaches of chemistry downsizing for simulating selective non catalytic reduction DeNO x process[J]. Fuel, 2014, 118: 291-299. |

| 9 | Farcy B, Vervisch L, Domingo P. Large eddy simulation of selective non-catalytic reduction (SNCR): a downsizing procedure for simulating nitric-oxide reduction units[J]. Chemical Engineering Science, 2016, 139: 285-303. |

| 10 | Brouwer J, Heap M P, Pershing D W, et al. A model for prediction of selective noncatalytic reduction of nitrogen oxides by ammonia, urea, and cyanuric acid with mixing limitations in the presence of CO[J]. Symposium (International) on Combustion, 1996, 26(2): 2117-2124. |

| 11 | Li J J, Yang H R, Wu Y X, et al. Effects of the updated national emission regulation in China on circulating fluidized bed boilers and the solutions to meet them[J]. Environmental Science & Technology, 2013, 47(12): 6681-6687. |

| 12 | Yan J, Lu X F, Zhang C F, et al. An experimental study on the characteristics of NO x distributions at the SNCR inlets of a large-scale CFB boiler[J]. Energies, 2021, 14: 1267. |

| 13 | Ke X W, Zhu S H, Huang Z, et al. Issues in deep peak regulation for circulating fluidized bed combustion: variation of NO x emissions with boiler load[J]. Environmental Pollution, 2023, 318: 120912. |

| 14 | Svith C S, Lin W G, Dam-Johansen K, et al. An experimental and modelling study of the selective non-catalytic reduction (SNCR) of NO x and NH3 in a cyclone reactor[J]. Chemical Engineering Research and Design, 2022, 183: 331-344. |

| 15 | Bo L, Maria K, Kim D J, et al. Influence of additives on selective noncatalytic reduction of NO with NH3 in circulating fluidized bed boilers[J]. Industrial & Engineering Chemistry Research, 1991, 30(11): 2396-2404. |

| 16 | Østberg M, Dam-Johansen K. Empirical modeling of the selective non-catalytic reduction of NO: comparison with large-scale experiments and detailed kinetic modeling[J]. Chemical Engineering Science, 1994, 49(12): 1897-1904. |

| 17 | Zhao Y J, Feng J X, Chen Y M, et al. Thermal process and NO emission reduction characteristics of a new-type coke oven regenerator coupled with SNCR process[J]. Fuel, 2021, 305: 121510. |

| 18 | Kang Z Z, Yuan Q X, Zhao L Z, et al. Study of the performance, simplification and characteristics of SNCR de-NO x in large-scale cyclone separator[J]. Applied Thermal Engineering, 2017, 123: 635-645. |

| 19 | Morteza M S, Hesameddin F, Bai X S. Numerical study of the combustion and application of SNCR for NO x reduction in a lab-scale biomass boiler[J]. Fuel, 2021, 293: 120154. |

| 20 | Duo W, Dam-Johansen K, Østergaard K. Kinetics of the gas-phase reaction between nitric oxide, ammonia and oxygen[J]. The Canadian Journal of Chemical Engineering, 1992, 70: 1014-1020. |

| 21 | Liang L, Hui S E, Pan S, et al. Influence of mixing, oxygen and residence time on the SNCR process[J]. Fuel, 2014, 120: 38-45. |

| 22 | 韩奎华, 路春美, 王永征, 等. 选择性非催化还原脱硝特性试验研究[J]. 中国电机工程学报, 2008, 28(14): 80-85. |

| Han K H, Lu C M, Wang Y Z, et al. Experimental study on de-NO x characteristics of selective non-catalytic reduction[J]. Proceedings of the CSEE, 2008, 28(14): 80-85. | |

| 23 | Baleta J, Mikulčić H, Vujanović M, et al. Numerical simulation of urea based selective non-catalytic reduction deNO x process for industrial applications[J]. Energy Conversion and Management, 2016, 125: 59-69. |

| 24 | 杨栩聪, 廖艳芬, 林涛, 等. 350 t/d垃圾焚烧炉污泥掺混燃烧与SNCR脱硝特性的数值模拟[J]. 中国电机工程学报, 2020, 40(21): 6964-6973. |

| Yang X C, Liao Y F, Lin T, et al. Numerical study of 350 t/d MSW incinerator on sludge blending combustion and SNCR denitration characteristics[J]. Proceedings of the CSEE, 2020, 40(21): 6964-6973. | |

| 25 | 王华山, 陈庆杰, 于秀春, 等. 小型循环流化床锅炉的选择性非催化还原脱硝工艺改造[J]. 科学技术与工程, 2018, 18(16): 318-322. |

| Wang H S, Chen Q J, Yu X C, et al. Retrofit of selective non-catalytic reduction denitrification process of small-scale circulating fluid bed boiler[J]. Science Technology and Engineering, 2018, 18(16): 318-322. | |

| 26 | 李穹, 吴玉新, 杨海瑞, 等. SNCR脱硝特性的模拟及优化[J]. 化工学报, 2013, 64(5): 1789-1796. |

| Li Q, Wu Y X, Yang H R, et al. Simulation and optimization of SNCR process[J]. CIESC Journal, 2013, 64(5): 1789-1796. | |

| 27 | Crowe C T, Sharma M P, Stock D E. The particle-source-in cell (PSI-CELL) model for gas-droplet flow[J]. Journal of Fluids Engineering,1977, 99 (2): 325-332. |

| 28 | Nelson P A, Galloway T R. Particle-to-fluid heat and mass transfer in dense systems of fine particles[J]. Chemical Engineering Science, 1975, 30(1): 1-6. |

| 29 | Sazhin S S. Advanced models of fuel droplet heating and evaporation[J]. Progress in Energy and Combustion Science, 2006, 32(2): 162-214. |

| 30 | 胡瓅元, 时铭显. 蜗壳式旋风分离器全空间三维时均流场的结构[J]. 化工学报, 2003, 54(4): 549-556. |

| Hu L Y, Shi M X. Three-dimensional time-averaged flow structure in cyclone separator with volute inlet[J]. Journal of Chemical Industry and Engineering (China), 2003, 54(4): 549-556. | |

| 31 | Elsayed K, Lacor C. The effect of cyclone vortex finder dimensions on the flow pattern and performance using LES[J]. Computers & Fluids, 2013, 71 (2): 224-239. |

| [1] | 宋嘉豪, 王文. 斯特林发动机与高温热管耦合运行特性研究[J]. 化工学报, 2023, 74(S1): 287-294. |

| [2] | 张思雨, 殷勇高, 贾鹏琦, 叶威. 双U型地埋管群跨季节蓄热特性研究[J]. 化工学报, 2023, 74(S1): 295-301. |

| [3] | 晁京伟, 许嘉兴, 李廷贤. 基于无管束蒸发换热强化策略的吸附热池的供热性能研究[J]. 化工学报, 2023, 74(S1): 302-310. |

| [4] | 张化福, 童莉葛, 张振涛, 杨俊玲, 王立, 张俊浩. 机械蒸汽压缩蒸发技术研究现状与发展趋势[J]. 化工学报, 2023, 74(S1): 8-24. |

| [5] | 吴馨, 龚建英, 靳龙, 王宇涛, 黄睿宁. 超声波激励下铝板表面液滴群输运特性的研究[J]. 化工学报, 2023, 74(S1): 104-112. |

| [6] | 叶展羽, 山訸, 徐震原. 用于太阳能蒸发的折纸式蒸发器性能仿真[J]. 化工学报, 2023, 74(S1): 132-140. |

| [7] | 毕丽森, 刘斌, 胡恒祥, 曾涛, 李卓睿, 宋健飞, 吴翰铭. 粗糙界面上纳米液滴蒸发模式的分子动力学研究[J]. 化工学报, 2023, 74(S1): 172-178. |

| [8] | 张义飞, 刘舫辰, 张双星, 杜文静. 超临界二氧化碳用印刷电路板式换热器性能分析[J]. 化工学报, 2023, 74(S1): 183-190. |

| [9] | 陈爱强, 代艳奇, 刘悦, 刘斌, 吴翰铭. 基板温度对HFE7100液滴蒸发过程的影响研究[J]. 化工学报, 2023, 74(S1): 191-197. |

| [10] | 王志国, 薛孟, 董芋双, 张田震, 秦晓凯, 韩强. 基于裂隙粗糙性表征方法的地热岩体热流耦合数值模拟与分析[J]. 化工学报, 2023, 74(S1): 223-234. |

| [11] | 何松, 刘乔迈, 谢广烁, 王斯民, 肖娟. 高浓度水煤浆管道气膜减阻两相流模拟及代理辅助优化[J]. 化工学报, 2023, 74(9): 3766-3774. |

| [12] | 邢雷, 苗春雨, 蒋明虎, 赵立新, 李新亚. 井下微型气液旋流分离器优化设计与性能分析[J]. 化工学报, 2023, 74(8): 3394-3406. |

| [13] | 程小松, 殷勇高, 车春文. 不同工质在溶液除湿真空再生系统中的性能对比[J]. 化工学报, 2023, 74(8): 3494-3501. |

| [14] | 刘文竹, 云和明, 王宝雪, 胡明哲, 仲崇龙. 基于场协同和 耗散的微通道拓扑优化研究[J]. 化工学报, 2023, 74(8): 3329-3341. 耗散的微通道拓扑优化研究[J]. 化工学报, 2023, 74(8): 3329-3341. |

| [15] | 洪瑞, 袁宝强, 杜文静. 垂直上升管内超临界二氧化碳传热恶化机理分析[J]. 化工学报, 2023, 74(8): 3309-3319. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号