化工学报 ›› 2023, Vol. 74 ›› Issue (4): 1489-1498.DOI: 10.11949/0438-1157.20221185

王晓萱1( ), 胡晓红1,2(

), 胡晓红1,2( ), 陆雨楠3,4, 王士勇3,4, 凡凤仙1,2

), 陆雨楠3,4, 王士勇3,4, 凡凤仙1,2

收稿日期:2022-08-30

修回日期:2023-02-28

出版日期:2023-04-05

发布日期:2023-06-02

通讯作者:

胡晓红

作者简介:王晓萱(1998—),女,硕士研究生,wangxx930999@163.com

基金资助:

Xiaoxuan WANG1( ), Xiaohong HU1,2(

), Xiaohong HU1,2( ), Yunan LU3,4, Shiyong WANG3,4, Fengxian FAN1,2

), Yunan LU3,4, Shiyong WANG3,4, Fengxian FAN1,2

Received:2022-08-30

Revised:2023-02-28

Online:2023-04-05

Published:2023-06-02

Contact:

Xiaohong HU

摘要:

基于计算流体力学方法对旋转膜过滤器内部层流与湍流场进行研究,利用多孔介质模型描述滤膜的渗透性对流动的影响,开展验证实验,确定滤膜阻力修正系数,并验证模型的可靠性。在此基础上,对过滤器内部流体的速度和压力分布进行数值分析,并探究滤膜转速对滤膜表面跨膜压力和剪切应力的影响。结果表明,滤膜表面流体无量纲角速度沿径向呈现中间区域基本保持不变,旋转轴附近有所降低,滤膜边缘附近略有升高的趋势;流动状态对滤膜上、下方间隙流体无黏核心区的无量纲角速度有重要影响。研究还发现,跨膜压力沿径向趋于下降,同种流动状态下,跨膜压力随滤膜转速的增大而减小;同一滤膜转速下,剪切应力沿径向线性增大,提高滤膜转速,剪切应力显著增加。

中图分类号:

王晓萱, 胡晓红, 陆雨楠, 王士勇, 凡凤仙. 旋转膜过滤器内部流动特性数值模拟[J]. 化工学报, 2023, 74(4): 1489-1498.

Xiaoxuan WANG, Xiaohong HU, Yunan LU, Shiyong WANG, Fengxian FAN. Numerical simulation of flow characteristics in a rotating membrane filter[J]. CIESC Journal, 2023, 74(4): 1489-1498.

| 模型参数 | 数值 |

|---|---|

| 筒体直径D/mm | 200 |

| 筒体高度H/mm | 80 |

| 滤膜直径dm/mm | 150 |

| 滤膜厚度δm/mm | 6 |

| 滤膜上表面与筒体顶面的间距H1/mm | 66 |

| 滤膜下表面与筒体底面的间距H2/mm | 8 |

| 滤膜平均孔径dp/μm | 2 |

| 滤膜平均孔隙率εp | 0.4 |

| 旋转轴直径ds/mm | 20 |

| 进口管道直径din/mm | 20 |

| 进口管道长度lin/mm | 30 |

| 出口管道直径dout/mm | 15 |

| 出口管道长度lout/mm | 20 |

表1 过滤器及滤膜参数取值

Table 1 Values of parameters for the filter and membrane

| 模型参数 | 数值 |

|---|---|

| 筒体直径D/mm | 200 |

| 筒体高度H/mm | 80 |

| 滤膜直径dm/mm | 150 |

| 滤膜厚度δm/mm | 6 |

| 滤膜上表面与筒体顶面的间距H1/mm | 66 |

| 滤膜下表面与筒体底面的间距H2/mm | 8 |

| 滤膜平均孔径dp/μm | 2 |

| 滤膜平均孔隙率εp | 0.4 |

| 旋转轴直径ds/mm | 20 |

| 进口管道直径din/mm | 20 |

| 进口管道长度lin/mm | 30 |

| 出口管道直径dout/mm | 15 |

| 出口管道长度lout/mm | 20 |

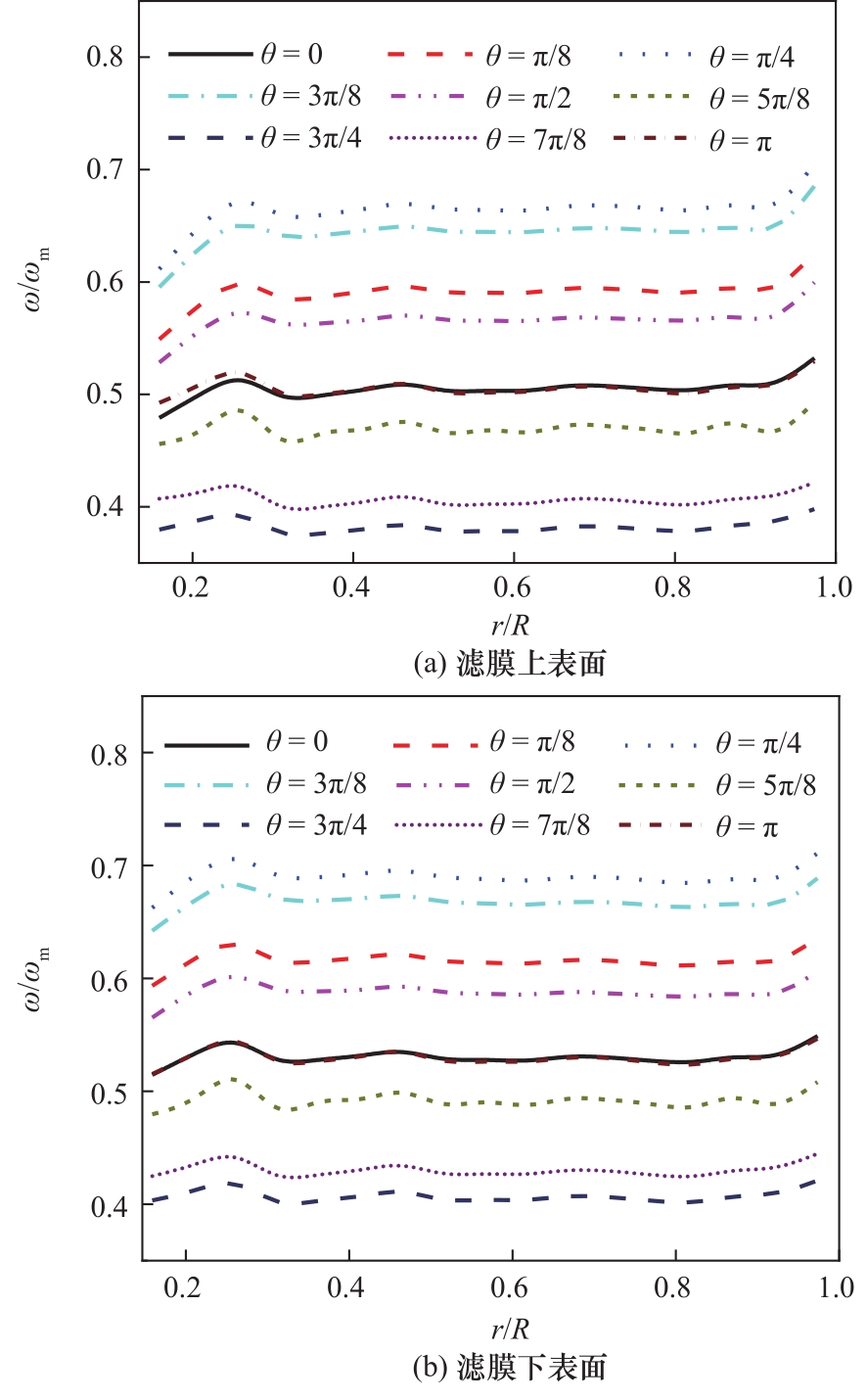

图8 滤膜表面流体无量纲角速度沿径向的变化(n = 348 r/min)

Fig.8 Variation of dimensionless angular velocity of fluid over membrane surface along radial direction (n = 348 r/min)

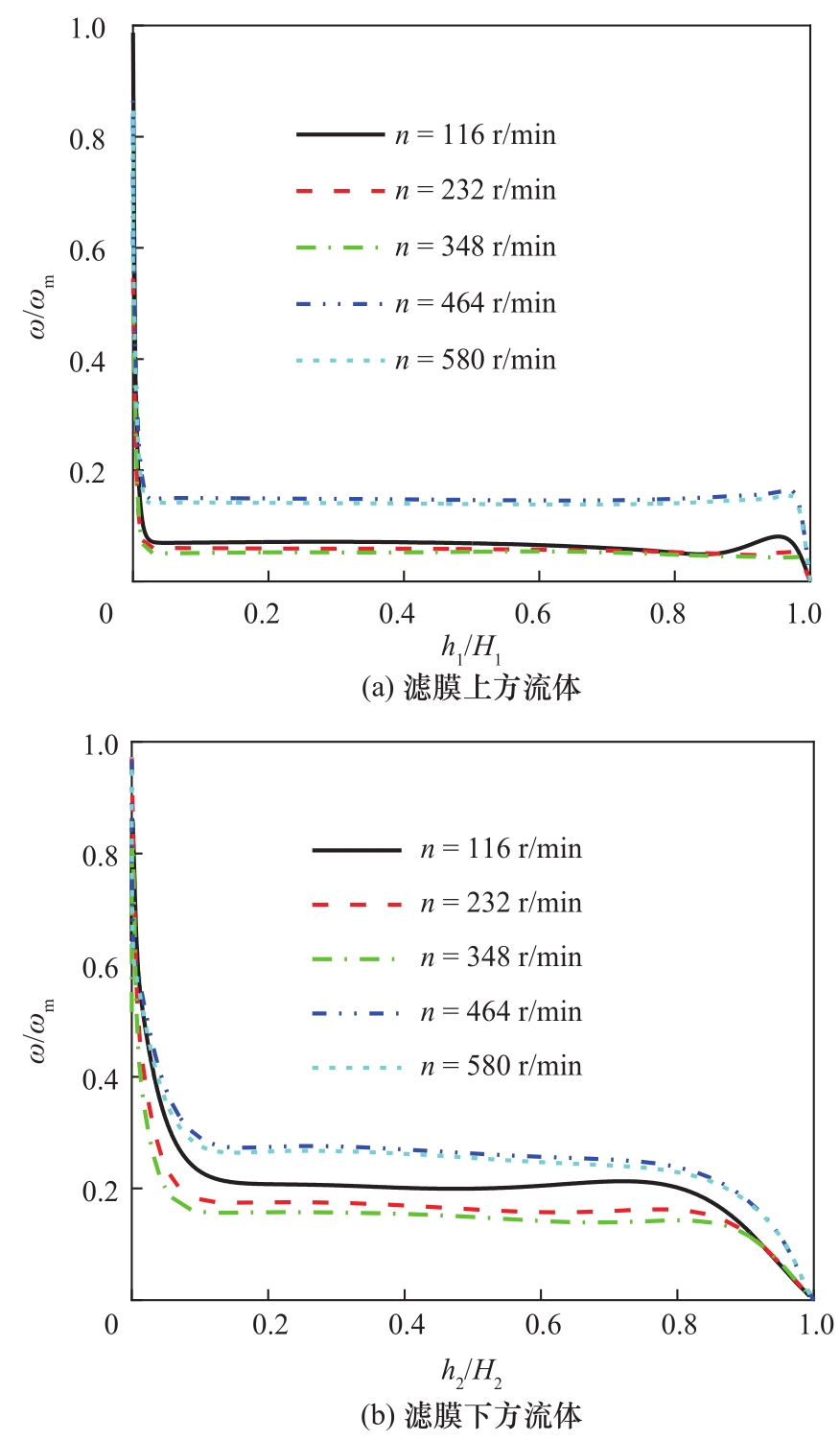

图9 不同滤膜转速下流体无量纲角速度随无量纲距离的变化(θ = 0, r/R = 0.4)

Fig.9 Dependence of dimensionless angular velocity of fluid on dimensionless distance at different rotational speeds of membrane(θ = 0, r/R = 0.4)

| 1 | Boiocchi R, Behera C R, Sherratt A, et al. Dynamic model validation and advanced polymer control for rotating belt filtration as primary treatment of domestic wastewaters[J]. Chemical Engineering Science, 2020, 217: 115510. |

| 2 | Wang J W, Cahyadi A, Wu B, et al. The roles of particles in enhancing membrane filtration: a review[J]. Journal of Membrane Science, 2020, 595: 117570. |

| 3 | Chen W M, Gu Z P, Ran G, et al. Application of membrane separation technology in the treatment of leachate in China: a review[J]. Waste Management, 2021, 121: 127-140. |

| 4 | 滕达, 李铁林, 李昂, 等. 单通道陶瓷膜管低压透水性能实验分析[J]. 化工学报, 2020, 71(S1): 261-271. |

| Teng D, Li T L, Li A, et al. Experimental analysis of low pressure water permeability of single channel ceramic membrane tube[J]. CIESC Journal, 2020, 71(S1): 261-271. | |

| 5 | 王帅帅, 关顺, 陈家庆, 等. 轴盘旋转陶瓷膜动态错流过滤器处理油水乳化液的实验研究[J]. 膜科学与技术, 2022, 42(3): 113-121. |

| Wang S S, Guan S, Chen J Q, et al. Experimental research on treatment of oil-water emulsion by rotary ceramic membrane dynamic cross-flow filter[J]. Membrane Science and Technology, 2022, 42(3): 113-121. | |

| 6 | Jaffrin M Y. Dynamic shear-enhanced membrane filtration: a review of rotating disks, rotating membranes and vibrating systems[J]. Journal of Membrane Science, 2008, 324(1/2): 7-25. |

| 7 | 吕斯濠, 秦琦, 张杰琳, 等. 旋转剪切强化膜过滤技术研究进展[J]. 化工进展, 2012, 31(11): 2373-2383. |

| Lyu S H, Qin Q, Zhang J L, et al. Progress in rotary shear-enhanced membrane filtration process[J]. Chemical Industry and Engineering Progress, 2012, 31(11): 2373-2383. | |

| 8 | 蔡钊, 耿安朝, 廖德祥. 旋转错流式膜分离过程的CFD流体动力学研究[J]. 膜科学与技术, 2017, 37(4): 107-113, 121. |

| Cai Z, Geng A C, Liao D X. The study in CFD simulation of the rotating disk filtration process[J]. Membrane Science and Technology, 2017, 37(4): 107-113, 121. | |

| 9 | 徐舟. 旋转圆盘动态膜过滤系统的计算流体力学研究[D]. 大连: 大连理工大学, 2009. |

| Xu Z. CFD simulation of dynamic filtration system with rotating disks[D]. Dalian: Dalian University of Technology, 2009. | |

| 10 | Bouzerar R, Jaffrin M Y, Ding L H, et al. Influence of geometry and angular velocity on performance of a rotating disk filter[J]. AIChE Journal, 2000, 46(2): 257-265. |

| 11 | Mellal M, Jaffrin M Y, Ding L H, et al. Separation of oligoglucuronans of low degrees of polymerization by using a high shear rotating disk filtration module[J]. Separation and Purification Technology, 2008, 60(1): 22-29. |

| 12 | Hwang K J, Wang S Y, Iritani E, et al. Fine particle removal from seawater by using cross-flow and rotating-disk dynamic filtration[J]. Journal of the Taiwan Institute of Chemical Engineers, 2016, 62: 45-53. |

| 13 | Ding L H, Akoum O, Abraham A, et al. High shear skim milk ultrafiltration using rotating disk filtration systems[J]. AIChE Journal, 2003, 49(9): 2433-2441. |

| 14 | 杜钟雨, 吴俊飞, 赵文捷. 圆盘错流过滤黑液截留木质素数值模拟研究[J]. 化工机械, 2021, 48(2): 256-262. |

| Du Z Y, Wu J F, Zhao W J. Numerical simulation of intercepting lignin from black liquor through disk cross-flow filtration[J]. Chemical Engineering & Machinery, 2021, 48(2): 256-262. | |

| 15 | Xie X, Dietrich N, Fillaudeau L, et al. Local hydrodynamics investigation within a dynamic filtration unit under laminar flow[J]. Chemical Engineering Research and Design, 2018, 132: 954-965. |

| 16 | Hwang K J, Wu S E. Disk structure on the performance of a rotating-disk dynamic filter: a case study on microalgae microfiltration[J]. Chemical Engineering Research and Design, 2015, 94: 44-51. |

| 17 | Ding L H, Jaffrin M Y, Mellal M, et al. Investigation of performances of a multishaft disk (MSD) system with overlapping ceramic membranes in microfiltration of mineral suspensions[J]. Journal of Membrane Science, 2006, 276(1/2): 232-240. |

| 18 | He G H, Ding L H, Paullier P, et al. Experimental study of a dynamic filtration system with overlapping ceramic membranes and non-permeating disks rotating at independent speeds[J]. Journal of Membrane Science, 2007, 300(1/2): 63-70. |

| 19 | Espina V S, Jaffrin M Y, Ding L H. Comparison of rotating ceramic membranes and polymeric membranes in fractionation of milk proteins by microfiltration[J]. Desalination, 2009, 245(1/2/3): 714-722. |

| 20 | Bendick J, Reed B, Morrow P, et al. Using a high shear rotary membrane system to treat shipboard wastewaters: experimental disc diameter, rotation and flux relationships[J]. Journal of Membrane Science, 2014, 462: 178-184. |

| 21 | Meyer P, Mayer A, Kulozik U. High concentration of skim milk proteins by ultrafiltration: characterisation of a dynamic membrane system with a rotating membrane in comparison with a spiral wound membrane[J]. International Dairy Journal, 2015, 51: 75-83. |

| 22 | Schäfer J, Bast R, Atamer Z, et al. Concentration of skim milk by means of dynamic filtration using overlapping rotating ceramic membrane disks[J]. International Dairy Journal, 2018, 78: 11-19. |

| 23 | Marke H S, Breil M P, Hansen E B, et al. Investigation of the velocity factor in a rotational dynamic microfiltration system[J]. Separation and Purification Technology, 2019, 220: 69-77. |

| 24 | Pinilla A, Berrio J C, Guerrero E, et al. CFD modelling of the hydrodynamics in a filtration unit with rotating membranes[J]. Journal of Water Process Engineering, 2020, 36: 101368. |

| 25 | Marke H S, Breil M P, Hansen E B, et al. Cake resistance in rotational dynamic filtration: determination and modeling[J]. Separation and Purification Technology, 2020, 250: 117100. |

| 26 | Goldnik D, Lösch P, Ripperger S, et al. Diafiltration of highly concentrated suspensions with fine particles by dynamic disk filtration[J]. Chemical Engineering & Technology, 2021, 44(12): 2191-2198. |

| 27 | Versteeg H K, Malalasekera W. An Introduction to Computational Fluid Dynamics: The Finite Volume Method[M]. 2nd ed. Harlow: Prentice Hall, 1995. |

| 28 | Orszag S A, Yakhot V, Flannery W S, et al. Renormalization group modeling and turbulence simulations[C]//Proceedings of the International Conference on Near-Wall Turbulent Flows. Amsterdam: Elsevier Science Publishers, 1993: 1031-1046. |

| 29 | 金业豪, 冯孝权, 朱军勇, 等. 有机溶剂纳滤传递模型及最新膜材料研究进展[J]. 化工进展, 2021, 40(11): 6181-6194. |

| Jin Y H, Feng X Q, Zhu J Y, et al. Research progress in transfer models and membrane materials for organic solvent nanofiltration[J]. Chemical Industry and Engineering Progress, 2021, 40(11): 6181-6194. | |

| 30 | 熊长川, 李卫星, 刘业飞, 等. 柱式膜组件结构的CFD优化设计[J]. 化工学报, 2017, 68(11): 4341-4350. |

| Xiong C C, Li W X, Liu Y F, et al. Optimization membrane module structure of column type by CFD[J]. CIESC Journal, 2017, 68(11): 4341-4350. | |

| 31 | 方璨, 钱付平, 叶蒙蒙, 等. 无纺针刺毡滤料褶式滤袋的阻力特性分析[J]. 过程工程学报, 2020, 20(3): 285-293. |

| Fang C, Qian F P, Ye M M, et al. Analysis of resistance characteristic of non-woven fiber needle felting mat pleated filter bag[J]. The Chinese Journal of Process Engineering, 2020, 20(3): 285-293. |

| [1] | 叶展羽, 山訸, 徐震原. 用于太阳能蒸发的折纸式蒸发器性能仿真[J]. 化工学报, 2023, 74(S1): 132-140. |

| [2] | 邵苛苛, 宋孟杰, 江正勇, 张旋, 张龙, 高润淼, 甄泽康. 水平方向上冰中受陷气泡形成和分布实验研究[J]. 化工学报, 2023, 74(S1): 161-164. |

| [3] | 张义飞, 刘舫辰, 张双星, 杜文静. 超临界二氧化碳用印刷电路板式换热器性能分析[J]. 化工学报, 2023, 74(S1): 183-190. |

| [4] | 王志国, 薛孟, 董芋双, 张田震, 秦晓凯, 韩强. 基于裂隙粗糙性表征方法的地热岩体热流耦合数值模拟与分析[J]. 化工学报, 2023, 74(S1): 223-234. |

| [5] | 吴延鹏, 李晓宇, 钟乔洋. 静电纺丝纳米纤维双疏膜油性细颗粒物过滤性能实验分析[J]. 化工学报, 2023, 74(S1): 259-264. |

| [6] | 宋嘉豪, 王文. 斯特林发动机与高温热管耦合运行特性研究[J]. 化工学报, 2023, 74(S1): 287-294. |

| [7] | 张思雨, 殷勇高, 贾鹏琦, 叶威. 双U型地埋管群跨季节蓄热特性研究[J]. 化工学报, 2023, 74(S1): 295-301. |

| [8] | 李艺彤, 郭航, 陈浩, 叶芳. 催化剂非均匀分布的质子交换膜燃料电池操作条件研究[J]. 化工学报, 2023, 74(9): 3831-3840. |

| [9] | 胡建波, 刘洪超, 胡齐, 黄美英, 宋先雨, 赵双良. 有机笼跨细胞膜易位行为的分子动力学模拟研究[J]. 化工学报, 2023, 74(9): 3756-3765. |

| [10] | 齐聪, 丁子, 余杰, 汤茂清, 梁林. 基于选择吸收纳米薄膜的太阳能温差发电特性研究[J]. 化工学报, 2023, 74(9): 3921-3930. |

| [11] | 何松, 刘乔迈, 谢广烁, 王斯民, 肖娟. 高浓度水煤浆管道气膜减阻两相流模拟及代理辅助优化[J]. 化工学报, 2023, 74(9): 3766-3774. |

| [12] | 邢雷, 苗春雨, 蒋明虎, 赵立新, 李新亚. 井下微型气液旋流分离器优化设计与性能分析[J]. 化工学报, 2023, 74(8): 3394-3406. |

| [13] | 韩晨, 司徒友珉, 朱斌, 许建良, 郭晓镭, 刘海峰. 协同处理废液的多喷嘴粉煤气化炉内反应流动研究[J]. 化工学报, 2023, 74(8): 3266-3278. |

| [14] | 胡亚丽, 胡军勇, 马素霞, 孙禹坤, 谭学诣, 黄佳欣, 杨奉源. 逆电渗析热机新型工质开发及电化学特性研究[J]. 化工学报, 2023, 74(8): 3513-3521. |

| [15] | 张佳怡, 何佳莉, 谢江鹏, 王健, 赵鹬, 张栋强. 渗透汽化技术用于锂电池生产中N-甲基吡咯烷酮回收的研究进展[J]. 化工学报, 2023, 74(8): 3203-3215. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号