化工学报 ›› 2024, Vol. 75 ›› Issue (S1): 56-66.DOI: 10.11949/0438-1157.20240241

收稿日期:2024-03-01

修回日期:2024-06-09

出版日期:2024-12-25

发布日期:2024-12-17

通讯作者:

骆政园

作者简介:李雨霜(2000—),女,硕士研究生,liyushuang597@163.com

基金资助:

Yushuang LI( ), Xincheng WANG, Boyao WEN, Zhengyuan LUO(

), Xincheng WANG, Boyao WEN, Zhengyuan LUO( ), Bofeng BAI

), Bofeng BAI

Received:2024-03-01

Revised:2024-06-09

Online:2024-12-25

Published:2024-12-17

Contact:

Zhengyuan LUO

摘要:

了解乳状液在多孔介质中的驱油过程及其机理,是发展乳状液驱油技术应用的基础。搭建了微流体可视化实验平台,揭示了多孔介质中乳状液驱油过程的两相流动过程及其影响因素。结果表明,水和表面活性剂的驱替模式均为黏性指进,使用乳状液驱油会产生液滴堵塞效应,能有效抑制黏性指进,增强界面稳定性,提高驱替效率。分析了毛细管数、油相-驱替相黏度比和液滴-孔隙尺寸比对乳状液驱油的影响,并通过建立基于不同毛细管数与黏度比下的驱替模式分布相图,得到了多孔介质中乳状液稳定驱替和黏性指进两种驱替模式的转变界限,证明乳状液驱对比水驱提高了黏性指进出现的临界毛细管数和黏度比,有效提高了驱替稳定性和驱替效率,为利用乳状液进行实际原油开采提供了理论基础。

中图分类号:

李雨霜, 王兴成, 温伯尧, 骆政园, 白博峰. 多孔介质中乳状液驱油的两相流动过程及其影响因素[J]. 化工学报, 2024, 75(S1): 56-66.

Yushuang LI, Xincheng WANG, Boyao WEN, Zhengyuan LUO, Bofeng BAI. Two-phase flow of emulsion flooding and its influencing factors in porous media[J]. CIESC Journal, 2024, 75(S1): 56-66.

| 黏度/(mPa·s) | 界面张力/(mN/m) |

|---|---|

| 10 | 20.41 |

| 50 | 26.27 |

| 100 | 43.04 |

| 500 | 50.18 |

| 1000 | 55.61 |

表1 不同黏度二甲基硅油与纯水的界面张力

Table 1 Interfacial tension between pure water and dimethicone oil with different viscosities

| 黏度/(mPa·s) | 界面张力/(mN/m) |

|---|---|

| 10 | 20.41 |

| 50 | 26.27 |

| 100 | 43.04 |

| 500 | 50.18 |

| 1000 | 55.61 |

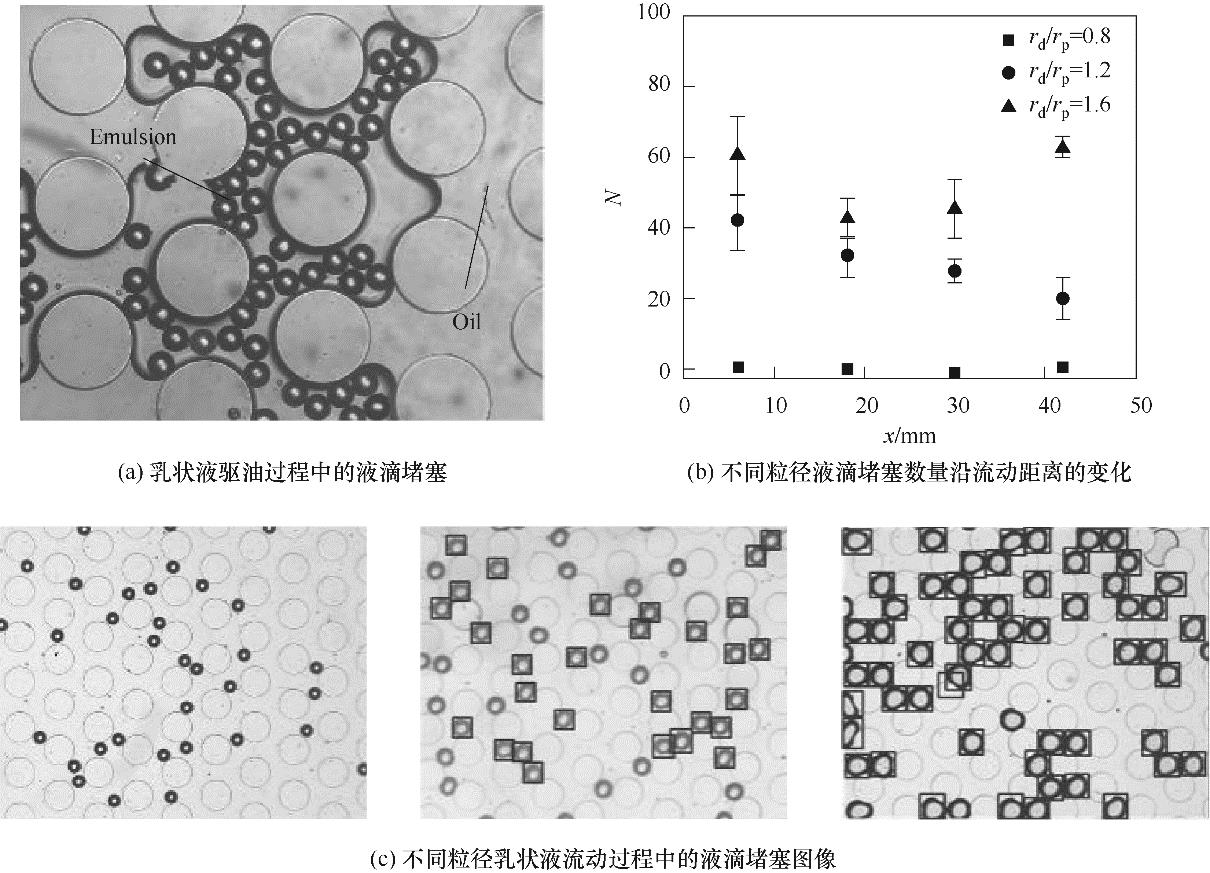

图4 乳状液驱油过程中的液滴堵塞现象及乳状液流动过程中的液滴堵塞特性

Fig.4 Droplets plugging phenomenon during emulsion flooding and droplets plugging characteristics during emulsion flow process

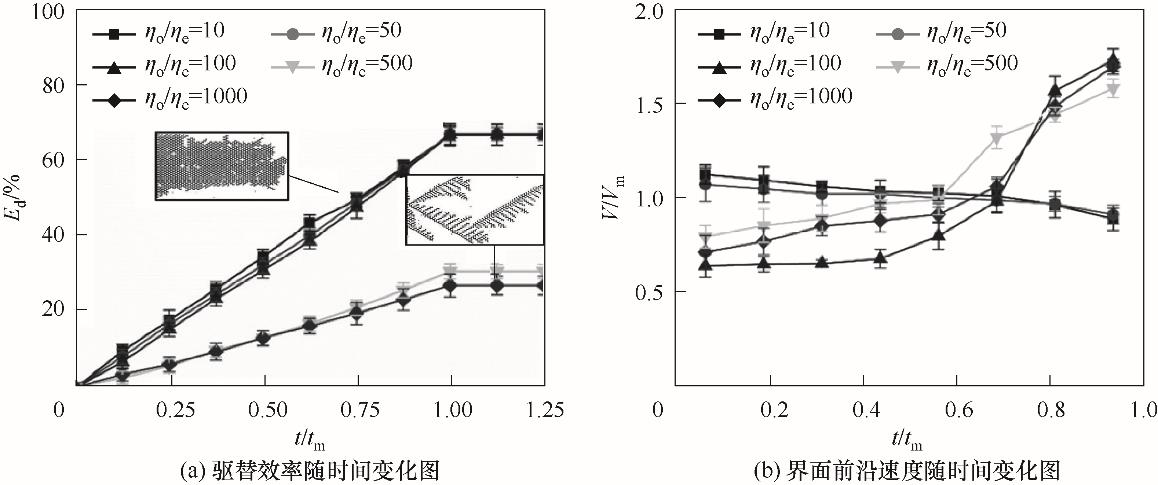

图6 不同油相-驱替相黏度比下乳状液驱油参数随时间变化图(毛细管数Ca = 1×10-5,乳状液液滴-孔隙尺寸比rd/rp = 1.2,分散相体积分数Ce = 10%)

Fig.6 Parameter variation diagram of emulsion flooding for different defense-displacing phase viscosity ratios (Ca = 1×10-5, rd/rp = 1.2, Ce = 10%)

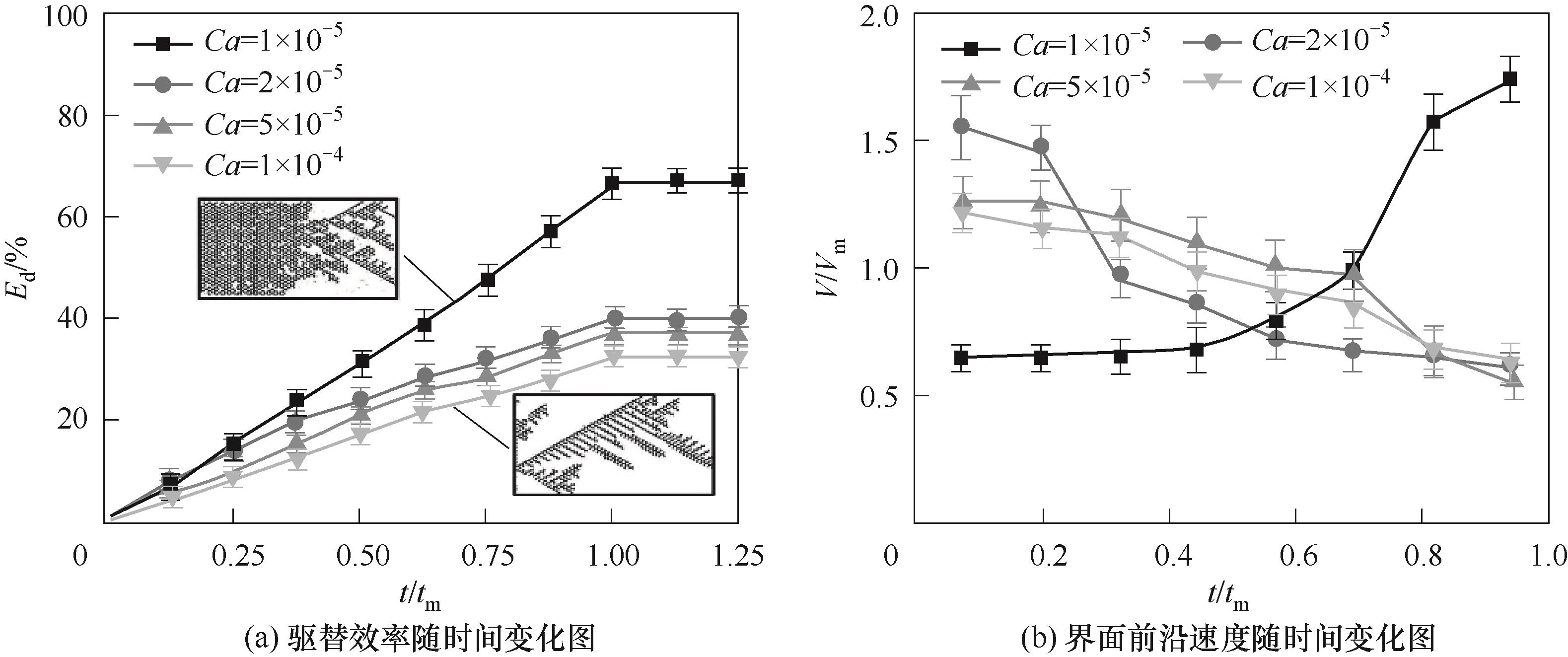

图7 不同毛细管数下乳状液驱油参数变化图(油相-驱替相黏度比ηo/ηe = 100,乳状液液滴-孔隙尺寸比rd/rp = 1.2,分散相体积分数Ce = 10%)

Fig.7 Parameter variation diagram of emulsion flooding for different capillary number (ηo/ηe = 100, rd/rp = 1.2, Ce = 10%)

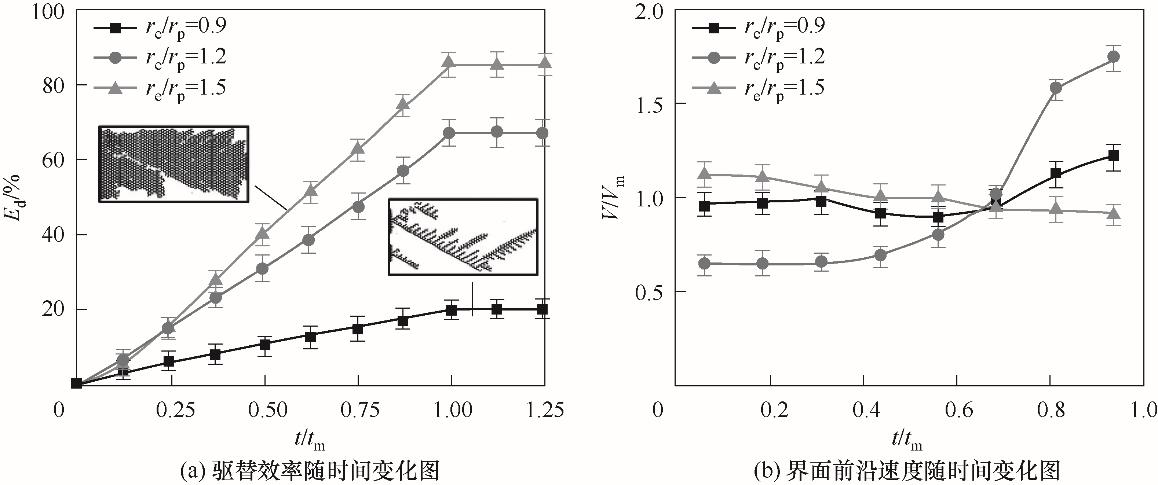

图8 不同液滴-孔隙尺寸比下乳状液驱油参数变化图(油相-驱替相黏度比ηo/ηe= 100,毛细管数Ca = 1×10-5,分散相体积分数Ce = 10%)

Fig.8 Parameter variation diagram of emulsion flooding for different droplet to pore size ratio(ηo/ηe= 100, Ca = 1×10-5, Ce = 10%)

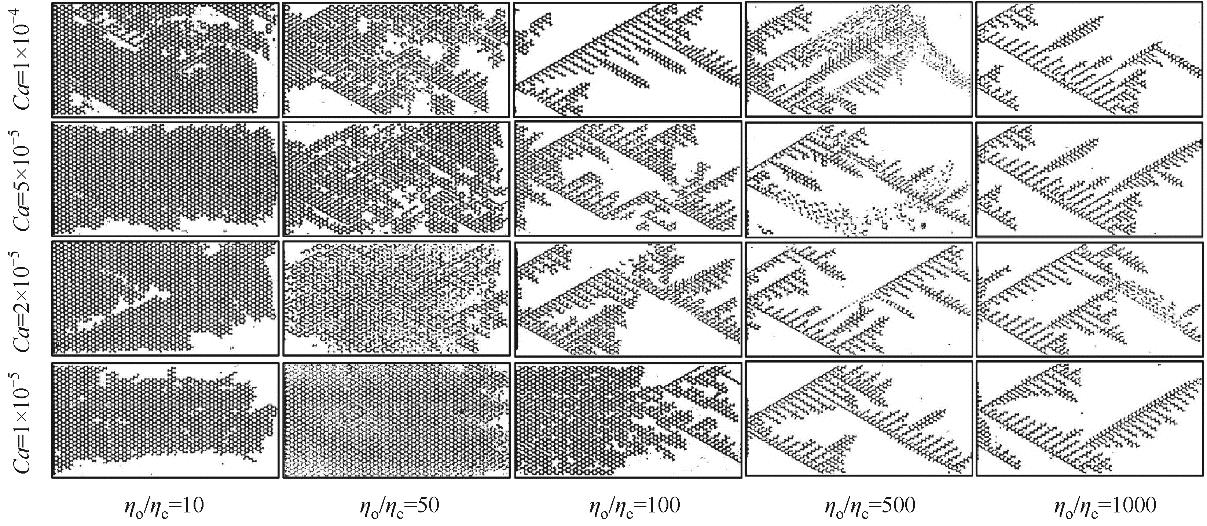

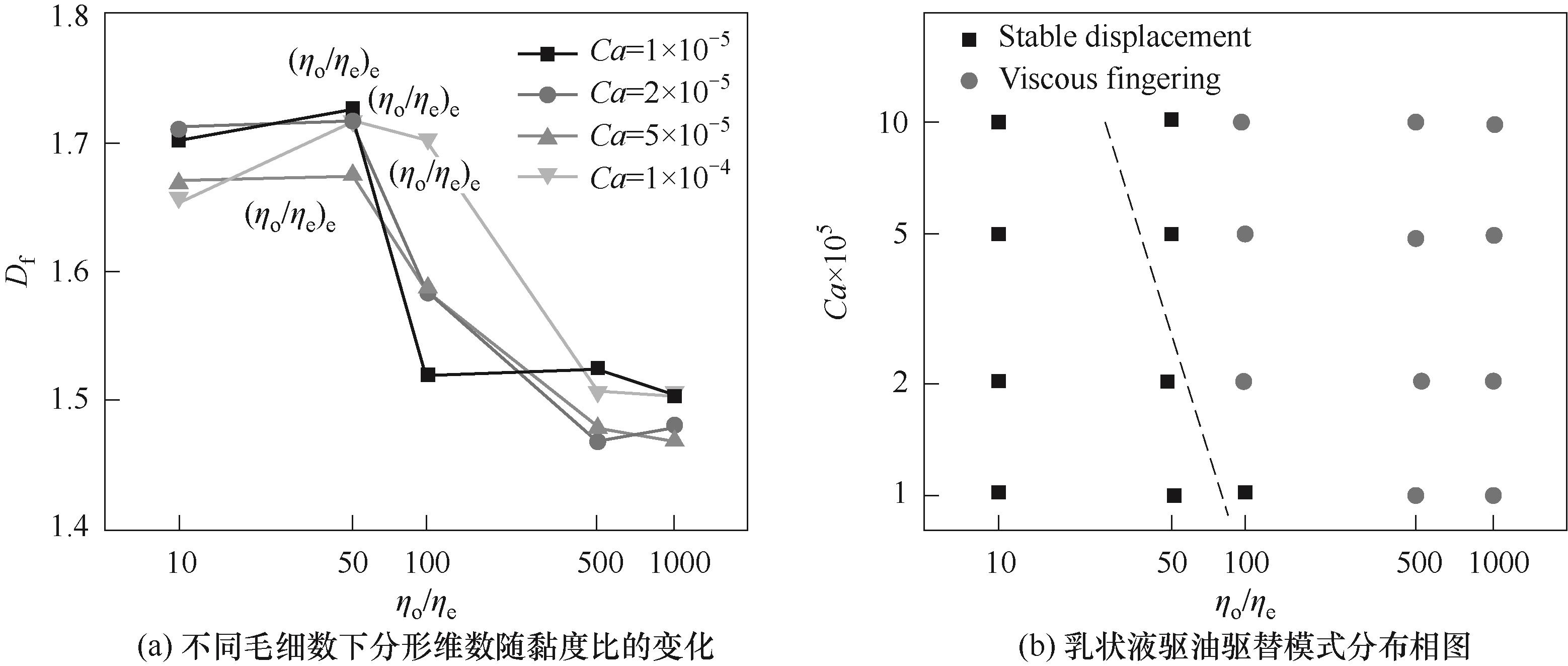

图9 不同黏度比和毛细管数条件下乳状液驱油实验对比图

Fig.9 Comparison diagram of emulsion flooding for different defense-displacing phase viscosity ratios and droplet to pore size ratio

图10 不同毛细管数和黏度比下的乳状液驱替模式变化

Fig.10 Diagram of emulsion flooding mode for different defense-displacing phase viscosity ratios and droplet to pore size ratio

| 1 | Afolabi F, Mahmood S M, Sharifigaliuk H, et al. Investigations on the enhanced oil recovery capacity of novel bio-based polymeric surfactants[J]. Journal of Molecular Liquids, 2022, 368: 120813. |

| 2 | Hosny R, Zahran A, Abotaleb A, et al. Nanotechnology impact on chemical-enhanced oil recovery: a review and bibliometric analysis of recent developments[J]. ACS Omega, 2023, 8(49): 46325-46345. |

| 3 | Ntente C, Strekla A, Iatridi Z, et al. Polymer-coated nanoparticles and Pickering emulsions as agents for enhanced oil recovery: basic studies using a porous medium model[J]. Energies, 2023, 16(24): 8043. |

| 4 | 张宇鑫. 油田三次采油驱油技术的应用[J]. 化学工程与装备, 2023(4): 84-86. |

| Zhang Y X. Application of tertiary oil recovery and oil displacement technology in oilfield[J]. Chemical Engineering & Equipment, 2023(4): 84-86. | |

| 5 | Navaie F, Esmaeilnezhad E, Choi H J. Effect of rheological properties of polymer solution on polymer flooding characteristics[J]. Polymers, 2022, 14(24): 5555. |

| 6 | 吴永超, 凡哲元, 张中华, 等. 我国石油勘探开发形势与发展前景展望[J]. 当代石油石化, 2019, 27(12): 8-13. |

| Wu Y C, Fan Z Y, Zhang Z H, et al. The situation and prospect of petroleum E & D in China[J]. Petroleum & Petrochemical Today, 2019, 27(12): 8-13. | |

| 7 | Jia J F, Xu Z D, Zhang B, et al. Microemulsion oil displacement effect of fracture reservoirs[J]. E3S Web of Conferences, 2020, 145: 02059. |

| 8 | Man Z Q, Wu W X. Research on the ratio of multicomponent emulsion flooding system[J]. Frontiers in Energy Research, 2023, 11: 1270607. |

| 9 | de Castro Dantas T N, de Oliveira A C, de Souza T T C, et al. Experimental study of the effects of acid microemulsion flooding to enhancement of oil recovery in carbonate reservoirs[J]. Journal of Petroleum Exploration and Production Technology, 2020, 10(3): 1127-1135. |

| 10 | 史胜龙, 汪庐山, 靳彦欣, 等. 乳状液体系在驱油和调剖堵水中的应用进展[J]. 油田化学, 2014, 31(1): 141-145. |

| Shi S L, Wang L S, Jin Y X, et al. Application progress and developmental tendency of emulsion system used in flooding, profile control and water plugging[J]. Oilfield Chemistry, 2014, 31(1): 141-145. | |

| 11 | Yu L, Dong M Z, Ding B X, et al. Emulsification of heavy crude oil in brine and its plugging performance in porous media[J]. Chemical Engineering Science, 2018, 178: 335-347. |

| 12 | 赵修太, 白英睿, 王增宝, 等. 乳状液体系在油田中的应用综述[J]. 中外能源, 2011, 16(11): 45-50. |

| Zhao X T, Bai Y R, Wang Z B, et al. Summary about application of emulsion system in oilfield[J]. Sino-Global Energy, 2011, 16(11): 45-50. | |

| 13 | 王凤琴, 曲志浩, 孔令荣. 利用微观模型研究乳状液驱油机理[J]. 石油勘探与开发, 2006, 33(2): 221-224. |

| Wang F Q, Qu Z H, Kong L R. Experimental study on the mechanism of emulsion flooding with micromodels[J]. Petroleum Exploration and Development, 2006, 33(2): 221-224. | |

| 14 | Zhou Y Z, Yin D Y, Chen W L, et al. A comprehensive review of emulsion and its field application for enhanced oil recovery[J]. Energy Science & Engineering, 2019, 7(4): 1046-1058. |

| 15 | Romero M I, Carvalho M S, Alvarado V. Experiments and network model of flow of oil-water emulsion in porous media[J]. Physical Review E, 2011, 84(4): 046305. |

| 16 | Foroozesh J, Kumar S. Nanoparticles behaviors in porous media: application to enhanced oil recovery[J]. Journal of Molecular Liquids, 2020, 316: 113876. |

| 17 | She Y, Mahardika M A, Hu Y X, et al. Three-dimensional visualization of the alkaline flooding process with in situ emulsification for oil recovery in porous media[J]. Journal of Petroleum Science and Engineering, 2021, 202: 108519. |

| 18 | Yu L, Ding B X, Dong M Z, et al. Plugging ability of oil-in-water emulsions in porous media: experimental and modeling study[J]. Industrial & Engineering Chemistry Research, 2018, 57(43): 14795-14808. |

| 19 | Chen Z, Dong M Z, Husein M, et al. Effects of oil viscosity on the plugging performance of oil-in-water emulsion in porous media[J]. Industrial & Engineering Chemistry Research, 2018, 57(21): 7301-7309. |

| 20 | Zinchenko A Z, Davis R H. Emulsion flow through a packed bed with multiple drop breakup[J]. Journal of Fluid Mechanics, 2013, 725: 611-663. |

| 21 | Mandal A, Samanta A, Bera A, et al. Characterization of oil-water emulsion and its use in enhanced oil recovery[J]. Industrial & Engineering Chemistry Research, 2010, 49(24): 12756-12761. |

| 22 | Zhou Y Z, Yin D Y, Cao R, et al. The mechanism for pore-throat scale emulsion displacing residual oil after water flooding[J]. Journal of Petroleum Science and Engineering, 2018, 163: 519-525. |

| 23 | Liu Z Y, Li Y Q, Luan H X, et al. Pore scale and macroscopic visual displacement of oil-in-water emulsions for enhanced oil recovery[J]. Chemical Engineering Science, 2019, 197: 404-414. |

| 24 | Xu K, Zhu P X, Colon T, et al. A microfluidic investigation of the synergistic effect of nanoparticles and surfactants in macro-emulsion-based enhanced oil recovery[J]. SPE Journal, 2017, 22(2): 459-469. |

| 25 | Demikhova I I, Likhanova N V, Perez J R H, et al. Emulsion flooding for enhanced oil recovery: filtration model and numerical simulation[J]. Journal of Petroleum Science and Engineering, 2016, 143: 235-244. |

| 26 | Sun Z, Pu W, Zhao R, et al. Study on the mechanism of W/O emulsion flooding to enhance oil recovery for heavy oil reservoir[J]. Journal of Petroleum Science and Engineering, 2022, 209: 109899. |

| 27 | Pei H H, Zhang G C, Ge J J, et al. Study of polymer-enhanced emulsion flooding to improve viscous oil recovery in waterflooded heavy oil reservoirs[J]. Colloids and Surfaces A: Physicochemical and Engineering Aspects, 2017, 529: 409-416. |

| 28 | Xu K, Liang T, Zhu P, et al. A 2.5-D glass micromodel for investigation of multi-phase flow in porous media[J]. Lab Chip, 2017, 17(4): 640-646. |

| 29 | Azizov I, Dudek M, Øye G. Studying droplet retention in porous media by novel microfluidic methods[J]. Chemical Engineering Science, 2022, 248: 117152. |

| 30 | Guillen V R, Carvalho M S, Alvarado V. Pore scale and macroscopic displacement mechanisms in emulsion flooding[J]. Transport in Porous Media, 2012, 94(1): 197-206. |

| 31 | Chen Y F, Fang S, Wu D S, et al. Visualizing and quantifying the crossover from capillary fingering to viscous fingering in a rough fracture[J]. Water Resources Research, 2017, 53(9): 7756-7772. |

| [1] | 杨勇, 祖子轩, 李煜坤, 王东亮, 范宗良, 周怀荣. T型圆柱形微通道内CO2碱液吸收数值模拟[J]. 化工学报, 2024, 75(S1): 135-142. |

| [2] | 赵振刚, 周梦瑶, 金典, 张大骋. 基于泡沫碳扩散层的直接甲醇燃料电池改性研究[J]. 化工学报, 2024, 75(S1): 259-266. |

| [3] | 徐英宇, 杨国强, 彭璟, 孙海宁, 张志炳. 微界面高级氧化处理煤化工废水的研究[J]. 化工学报, 2024, 75(S1): 283-291. |

| [4] | 刘律, 刘洁茹, 范亮亮, 赵亮. 基于层流效应的被动式颗粒分离微流控方法研究[J]. 化工学报, 2024, 75(S1): 67-75. |

| [5] | 杜得辉, 冯威, 张江辉, 项燕龙, 乔高攀, 李蔚. 微型翅片疏水复合强化管管内流动沸腾换热预测模型[J]. 化工学报, 2024, 75(S1): 95-107. |

| [6] | 祝赫, 张仪, 齐娜娜, 张锴. 欧拉-欧拉双流体模型中颗粒黏性对液固散式流态化的影响[J]. 化工学报, 2024, 75(9): 3103-3112. |

| [7] | 唐昊, 胡定华, 李强, 张轩畅, 韩俊杰. 抗加速度双切线弧流道内气泡动力学行为数值与可视化研究[J]. 化工学报, 2024, 75(9): 3074-3082. |

| [8] | 陈巨辉, 苏潼, 李丹, 陈立伟, 吕文生, 孟凡奇. 翅形扰流片作用下的微通道换热特性[J]. 化工学报, 2024, 75(9): 3122-3132. |

| [9] | 陈超伟, 柳洋, 杜文静, 李金波, 史大阔, 辛公明. 局部热点下微肋通道流动传热特性[J]. 化工学报, 2024, 75(9): 3113-3121. |

| [10] | 王皓宇, 杨杨, 荆文婕, 杨斌, 唐雨, 刘毅. 不同旋流器作用下气液螺旋环状流动特性研究[J]. 化工学报, 2024, 75(8): 2744-2755. |

| [11] | 赵亮, 李雨桥, 张德, 沈胜强. 螺旋喷嘴内外流场特性的实验研究[J]. 化工学报, 2024, 75(8): 2777-2786. |

| [12] | 罗正航, 李敬宇, 陈伟雄, 种道彤, 严俊杰. 摇摆运动下低流率蒸汽冷凝换热特性和气泡受力数值模拟[J]. 化工学报, 2024, 75(8): 2800-2811. |

| [13] | 曲玖哲, 杨鹏, 杨绪飞, 张伟, 宇波, 孙东亮, 王晓东. 硅基微柱簇阵列微通道流动沸腾实验研究[J]. 化工学报, 2024, 75(8): 2840-2851. |

| [14] | 李彦熹, 王晔春, 谢向东, 王进芝, 王江, 周煜, 潘盈秀, 丁文涛, 郭烈锦. 蜗壳式多通道气液旋流分离器结构优化及分离特性研究[J]. 化工学报, 2024, 75(8): 2875-2885. |

| [15] | 杨明军, 巩广军, 郑嘉男, 宋永臣. 泥质低渗水合物降压开采特性与模型研究[J]. 化工学报, 2024, 75(8): 2909-2916. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号