化工学报 ›› 2024, Vol. 75 ›› Issue (11): 4320-4332.DOI: 10.11949/0438-1157.20240585

王茂先1( ), 孙启典1, 付哲1, 华放1, 纪晔2, 程易1(

), 孙启典1, 付哲1, 华放1, 纪晔2, 程易1( )

)

收稿日期:2024-05-30

修回日期:2024-07-12

出版日期:2024-11-25

发布日期:2024-12-26

通讯作者:

程易

作者简介:王茂先(2001—),男,博士研究生,wangmx23@mails.tsinghua.edu.cn

基金资助:

Maoxian WANG1( ), Qidian SUN1, Zhe FU1, Fang HUA1, Ye JI2, Yi CHENG1(

), Qidian SUN1, Zhe FU1, Fang HUA1, Ye JI2, Yi CHENG1( )

)

Received:2024-05-30

Revised:2024-07-12

Online:2024-11-25

Published:2024-12-26

Contact:

Yi CHENG

摘要:

随着全球塑料产量的增加,废弃塑料处理问题日益严重,热解技术作为一种将废弃塑料转化为高附加值产品的方法,引起了广泛关注。通过分子水平动力学模型与机器学习相结合的方法,研究了聚乙烯(PE)的热解过程。首先,利用分子水平动力学模型针对不同分子量分布的PE原料,生成大规模热解数据集。然后,基于大规模数据集构建了9种机器学习模型,评估其预测能力及特征重要性,分析影响热解产物收率的关键因素。结果表明,反应时间和热解温度是主要影响因素,KNN模型在气、液相产物预测中表现最佳。通过优化机器学习模型和扩大数据集,可以显著提升热解过程的预测准确性和效率,为废弃塑料资源化提供了新的思路和方法。

中图分类号:

王茂先, 孙启典, 付哲, 华放, 纪晔, 程易. 分子水平动力学模型和机器学习方法相结合研究废弃塑料热解[J]. 化工学报, 2024, 75(11): 4320-4332.

Maoxian WANG, Qidian SUN, Zhe FU, Fang HUA, Ye JI, Yi CHENG. Understanding pyrolysis process of polyethylene by combined method of molecular-level kinetic model with machine learning[J]. CIESC Journal, 2024, 75(11): 4320-4332.

| 编号 | a | b | c | d | f | M | nums | numn | numr |

|---|---|---|---|---|---|---|---|---|---|

| 1 | 11 | 64 | 12.00 | 100 | 6.45×10-4 | 31024 | 1000 | 3142 | 42932 |

| 2 | 12 | 64 | 12.50 | 100 | 2.89×10-4 | 69216 | 1500 | 6342 | 87732 |

| 3 | 12.2 | 64 | 12.46 | 100 | 1.43×10-4 | 140112 | 2000 | 11998 | 166916 |

| 4 | 12.5 | 64 | 12.82 | 100 | 1.09×10-4 | 183792 | 3000 | 15998 | 222916 |

| 5 | 14.5 | 64 | 14.83 | 100 | 7.70×10-5 | 259672 | 4500 | 22998 | 320916 |

| 6 | 25 | 64 | 25.30 | 100 | 5.51×10-5 | 362992 | 6000 | 31998 | 446916 |

| 7 | 0.24 | 64 | 0.30 | 100 | 2.89×10-4 | 69202 | 200 | 5128 | 70736 |

| 8 | 5 | 64 | 5.23 | 100 | 2.89×10-4 | 69199 | 800 | 5662 | 78212 |

| 9 | 50 | 64 | 50.76 | 100 | 2.89×10-4 | 69213 | 2000 | 6840 | 94704 |

| 10 | 150 | 64 | 151.70 | 100 | 2.89×10-4 | 69223 | 3000 | 7856 | 108928 |

| 11 | 600 | 64 | 604.00 | 100 | 2.89×10-4 | 69142 | 4500 | 10000 | 138944 |

| 12 | 1600 | 64 | 1607.35 | 100 | 2.89×10-4 | 69190 | 6000 | 12598 | 175316 |

表1 PE原料分子量分布参数

Table 1 Molecular weight distribution parameters of PE raw materials

| 编号 | a | b | c | d | f | M | nums | numn | numr |

|---|---|---|---|---|---|---|---|---|---|

| 1 | 11 | 64 | 12.00 | 100 | 6.45×10-4 | 31024 | 1000 | 3142 | 42932 |

| 2 | 12 | 64 | 12.50 | 100 | 2.89×10-4 | 69216 | 1500 | 6342 | 87732 |

| 3 | 12.2 | 64 | 12.46 | 100 | 1.43×10-4 | 140112 | 2000 | 11998 | 166916 |

| 4 | 12.5 | 64 | 12.82 | 100 | 1.09×10-4 | 183792 | 3000 | 15998 | 222916 |

| 5 | 14.5 | 64 | 14.83 | 100 | 7.70×10-5 | 259672 | 4500 | 22998 | 320916 |

| 6 | 25 | 64 | 25.30 | 100 | 5.51×10-5 | 362992 | 6000 | 31998 | 446916 |

| 7 | 0.24 | 64 | 0.30 | 100 | 2.89×10-4 | 69202 | 200 | 5128 | 70736 |

| 8 | 5 | 64 | 5.23 | 100 | 2.89×10-4 | 69199 | 800 | 5662 | 78212 |

| 9 | 50 | 64 | 50.76 | 100 | 2.89×10-4 | 69213 | 2000 | 6840 | 94704 |

| 10 | 150 | 64 | 151.70 | 100 | 2.89×10-4 | 69223 | 3000 | 7856 | 108928 |

| 11 | 600 | 64 | 604.00 | 100 | 2.89×10-4 | 69142 | 4500 | 10000 | 138944 |

| 12 | 1600 | 64 | 1607.35 | 100 | 2.89×10-4 | 69190 | 6000 | 12598 | 175316 |

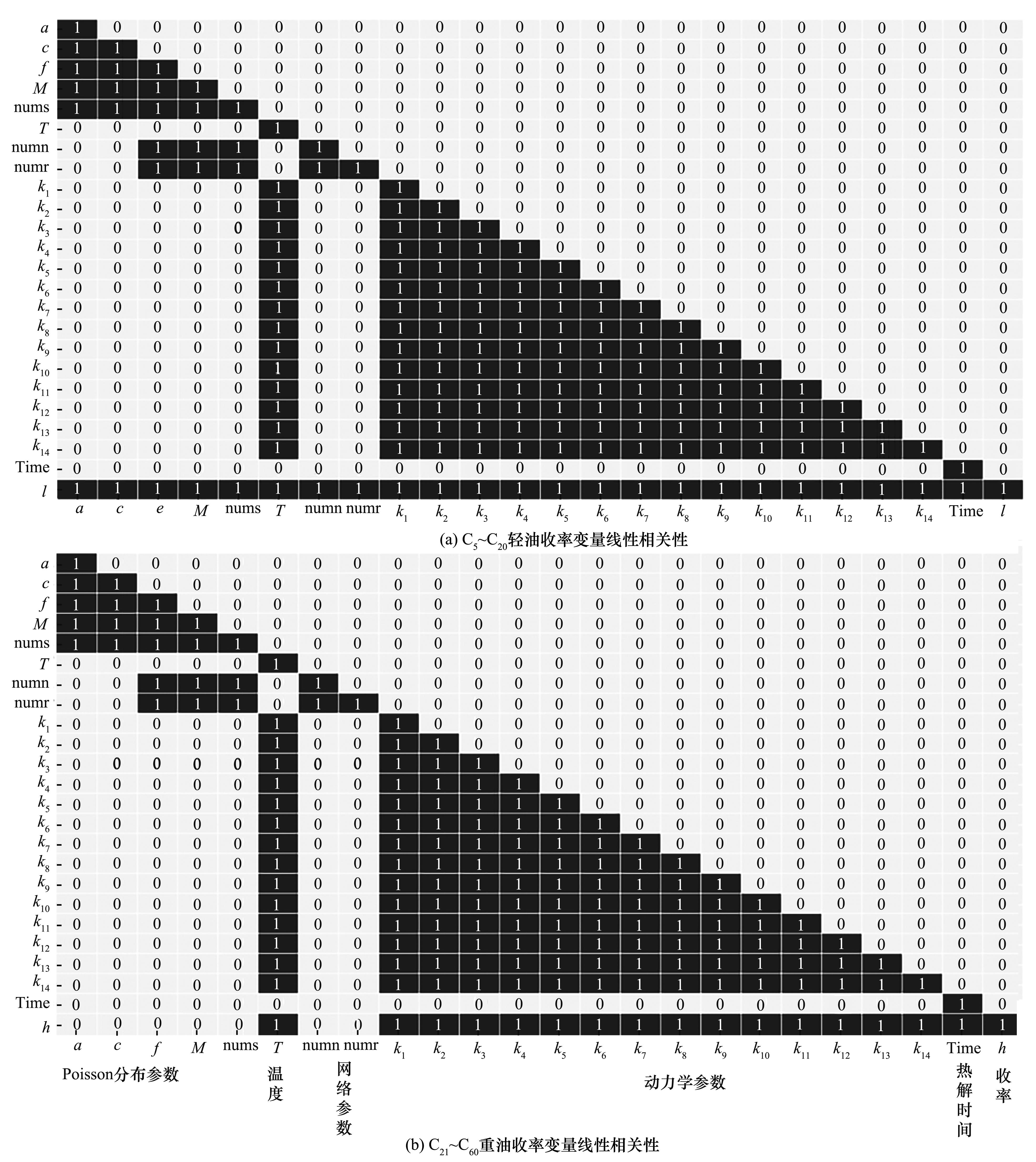

图3 PE热解Pearson相关系数显著性检验p值图(1表示p<0.05;0表示p≥0.05)

Fig.3 p-value chart of significance test of Pearson correlation coefficient of PE-biomass co-pyrolysis (1 means p<0.05, 0 means p≥0.05)

| 模型 | 训练集 | 测试集 | ||||||

|---|---|---|---|---|---|---|---|---|

| 数据量 | R2 | MAE | RMSE | 数据量 | R2 | MAE | RMSE | |

| KNN | 28800 | 1.0000 | 0.0025 | 0.0605 | 7200 | 1.0000 | 0.0012 | 0.0065 |

| RF | 28800 | 0.9997 | 0.0898 | 0.2101 | 7200 | 0.9997 | 0.0972 | 0.1918 |

| ANN | 28800 | 0.9993 | 0.1172 | 0.3426 | 7200 | 0.9995 | 0.1250 | 0.2426 |

| MLP | 28800 | 0.9975 | 0.4786 | 0.6282 | 7200 | 0.9974 | 0.4586 | 0.5458 |

| XGB | 28800 | 0.9967 | 0.3878 | 0.7228 | 7200 | 0.9930 | 0.5038 | 0.8921 |

| GBDT | 28800 | 0.9896 | 0.6642 | 1.2810 | 7200 | 0.9789 | 0.7746 | 1.5457 |

| DT | 28800 | 0.9832 | 0.6344 | 1.6254 | 7200 | 0.9775 | 0.6009 | 1.5949 |

| LGB | 28800 | 0.9846 | 0.8916 | 1.5563 | 7200 | 0.9733 | 1.0540 | 1.7362 |

| SVR | 28800 | 0.8597 | 1.3971 | 4.6972 | 7200 | 0.7283 | 1.9827 | 5.5417 |

| LR | 28800 | 0.4849 | 6.9920 | 9.0008 | 7200 | 0.3077 | 6.4794 | 8.8453 |

表2 机器学习方法轻油产物收率预测性能评估

Table 2 Performance evaluation of machine learning models for light oil product yield prediction

| 模型 | 训练集 | 测试集 | ||||||

|---|---|---|---|---|---|---|---|---|

| 数据量 | R2 | MAE | RMSE | 数据量 | R2 | MAE | RMSE | |

| KNN | 28800 | 1.0000 | 0.0025 | 0.0605 | 7200 | 1.0000 | 0.0012 | 0.0065 |

| RF | 28800 | 0.9997 | 0.0898 | 0.2101 | 7200 | 0.9997 | 0.0972 | 0.1918 |

| ANN | 28800 | 0.9993 | 0.1172 | 0.3426 | 7200 | 0.9995 | 0.1250 | 0.2426 |

| MLP | 28800 | 0.9975 | 0.4786 | 0.6282 | 7200 | 0.9974 | 0.4586 | 0.5458 |

| XGB | 28800 | 0.9967 | 0.3878 | 0.7228 | 7200 | 0.9930 | 0.5038 | 0.8921 |

| GBDT | 28800 | 0.9896 | 0.6642 | 1.2810 | 7200 | 0.9789 | 0.7746 | 1.5457 |

| DT | 28800 | 0.9832 | 0.6344 | 1.6254 | 7200 | 0.9775 | 0.6009 | 1.5949 |

| LGB | 28800 | 0.9846 | 0.8916 | 1.5563 | 7200 | 0.9733 | 1.0540 | 1.7362 |

| SVR | 28800 | 0.8597 | 1.3971 | 4.6972 | 7200 | 0.7283 | 1.9827 | 5.5417 |

| LR | 28800 | 0.4849 | 6.9920 | 9.0008 | 7200 | 0.3077 | 6.4794 | 8.8453 |

| 16 | Westerhout R W J, Kuipers J A M, van Swaaij W P M. Experimental determination of the yield of pyrolysis products of polyethene and polypropene. Influence of reaction conditions[J]. Industrial & Engineering Chemistry Research, 1998, 37(3): 841-847. |

| 17 | Onwudili J A, Insura N, Williams P T. Composition of products from the pyrolysis of polyethylene and polystyrene in a closed batch reactor: effects of temperature and residence time[J]. Journal of Analytical and Applied Pyrolysis, 2009, 86(2): 293-303. |

| 18 | Chen D Z, Yin L J, Wang H, et al. Pyrolysis technologies for municipal solid waste: a review[J]. Waste Management, 2014, 34(12): 2466-2486. |

| 19 | Bagri R, Williams P T. Catalytic pyrolysis of polyethylene[J]. Journal of Analytical and Applied Pyrolysis, 2002, 63(1): 29-41. |

| 20 | Ratnasari D K, Nahil M A, Williams P T. Catalytic pyrolysis of waste plastics using staged catalysis for production of gasoline range hydrocarbon oils[J]. Journal of Analytical and Applied Pyrolysis, 2017, 124: 631-637. |

| 21 | Achilias D S, Roupakias C, Megalokonomos P, et al. Chemical recycling of plastic wastes made from polyethylene (LDPE and HDPE) and polypropylene (PP)[J]. Journal of Hazardous Materials, 2007, 149(3): 536-542. |

| 22 | 张雪, 白雪峰, 赵明. 废塑料热解特性研究[J]. 化学与粘合, 2015, 37(2): 107-110. |

| Zhang X, Bai X F, Zhao M. Study on pyrolysis characteristics of waste plastics[J]. Chemistry and Adhesion, 2015, 37(2): 107-110. | |

| 23 | Zhao D T, Wang X H, Miller J B, et al. The chemistry and kinetics of polyethylene pyrolysis: a process to produce fuels and chemicals[J]. ChemSusChem, 2020, 13(7): 1764-1774. |

| 24 | Li J, Yu D, Pan L J, et al. Recent advances in plastic waste pyrolysis for liquid fuel production: critical factors and machine learning applications[J]. Applied Energy, 2023, 346: 121350. |

| 25 | Prasertpong P, Onsree T, Khuenkaeo N, et al. Exposing and understanding synergistic effects in co-pyrolysis of biomass and plastic waste via machine learning[J]. Bioresource Technology, 2023, 369: 128419. |

| 26 | Belden E R, Rando M, Ferrara O G, et al. Machine learning predictions of oil yields obtained by plastic pyrolysis and application to thermodynamic analysis[J]. ACS Engineering Au, 2022, 3(2): 91-101. |

| 1 | Meijer L J J, van Emmerik T, van der Ent R, et al. More than 1000 rivers account for 80% of global riverine plastic emissions into the ocean[J]. Science Advances, 2021, 7(18): eaaz5803. |

| 2 | Nielsen T D, Hasselbalch J, Holmberg K, et al. Politics and the plastic crisis: a review throughout the plastic life cycle[J]. Wiley Interdisciplinary Reviews: Energy and Environment, 2020, 9(1): e360. |

| 3 | Bahij S, Omary S, Feugeas F, et al. Fresh and hardened properties of concrete containing different forms of plastic waste—a review[J]. Waste Management, 2020, 113: 157-175. |

| 4 | Geyer R, Jambeck J R, Law K L. Production, use, and fate of all plastics ever made[J]. Science Advances, 2017, 3(7): e1700782. |

| 5 | Groh K J, Backhaus T, Carney-Almroth B, et al. Overview of known plastic packaging-associated chemicals and their hazards[J]. Science of the Total Environment, 2019, 651: 3253-3268. |

| 6 | Al-Salem S M, Lettieri P, Baeyens J. Recycling and recovery routes of plastic solid waste (PSW): a review[J]. Waste Management, 2009, 29(10): 2625-2643. |

| 7 | van Geem K M. Plastic waste recycling is gaining momentum[J]. Science, 2023, 381(6658): 607-608. |

| 8 | Rajesh Banu J, Godvin Sharmila V. A systematic review on plastic waste conversion for a circular economy: recent trends and emerging technologies[J]. Catalysis Science & Technology, 2023, 13(8): 2291-2302. |

| 9 | 胡延庆, 胡凡, 周剑池, 等. 废弃塑料回收与转化的研究进展[J]. 中国塑料, 2024, 38(4): 79-87. |

| Hu Y Q, Hu F, Zhou J C, et al. Research progress in upcycling of waste plastics[J]. China Plastics, 2024, 38(4): 79-87. | |

| 10 | Anuar Sharuddin S D, Abnisa F, Wan Daud W M A, et al. A review on pyrolysis of plastic wastes[J]. Energy Conversion and Management, 2016, 115: 308-326. |

| 11 | Maqsood T, Dai J Z, Zhang Y N, et al. Pyrolysis of plastic species: a review of resources and products[J]. Journal of Analytical and Applied Pyrolysis, 2021, 159: 105295. |

| 12 | Dave P N, Joshi A K. Plasma pyrolysis and gasification of plastics waste—a review[J]. Journal of Scientific & Industrial Research, 2010, 69(3): 177-179. |

| 13 | Solowski G, Shalaby M, Özdemir F A. Plastic and waste tire pyrolysis focused on hydrogen production—a review[J]. Hydrogen, 2022, 3(4): 531-549. |

| 14 | 孙艺蕾, 马跃, 李术元, 等. 聚烯烃塑料的热解和催化热解研究进展[J]. 化工进展, 2021, 40(5): 2784-2801. |

| Sun Y L, Ma Y, Li S Y, et al. Research progress in the pyrolysis and catalytic pyrolysis of waste polyolefin plastics[J]. Chemical Industry and Engineering Progress, 2021, 40(5): 2784-2801. | |

| 15 | Singh S, Patil T, Tekade S P, et al. Studies on individual pyrolysis and co-pyrolysis of corn cob and polyethylene: thermal degradation behavior, possible synergism, kinetics, and thermodynamic analysis[J]. Science of the Total Environment, 2021, 783: 147004. |

| 27 | Cheng Y, Ekici E, Yildiz G, et al. Applied machine learning for prediction of waste plastic pyrolysis towards valuable fuel and chemicals production[J]. Journal of Analytical and Applied Pyrolysis, 2023, 169: 105857. |

| 28 | Armenise S, Wong S, Ramírez-Velásquez J M, et al. Application of computational approach in plastic pyrolysis kinetic modelling: a review[J]. Reaction Kinetics, Mechanisms and Catalysis, 2021, 134(2): 591-614. |

| 29 | Hua F, Fu Z, Yang S Q, et al. Simulating polyethylene pyrolysis from a generalized molecular-level kinetic model[J]. Journal of Analytical and Applied Pyrolysis, 2023, 170: 105913. |

| 30 | Fu Z, Sun Q D, Hua F, et al. A molecular-level kinetic model for the primary and secondary reactions of polypropylene pyrolysis[J]. Journal of Analytical and Applied Pyrolysis, 2023, 175: 106182. |

| 31 | Quann R J, Jaffe S B. Structure-oriented lumping: describing the chemistry of complex hydrocarbon mixtures[J]. Industrial & Engineering Chemistry Research, 1992, 31(11): 2483-2497. |

| 32 | Ghosh P, Jaffe S B. Detailed composition-based model for predicting the cetane number of diesel fuels[J]. Industrial & Engineering Chemistry Research, 2006, 45(1): 346-351. |

| 33 | Ghosh P, Chawla B, Joshi P V, et al. Prediction of chromatographic retention times for aromatic hydrocarbons[J]. Energy & Fuels, 2006, 20(2): 609-619. |

| 34 | 王睿通, 刘纪昌, 仲从伟, 等. 基于结构导向集总的催化重整分子水平反应动力学模型[J]. 石油学报(石油加工), 2020, 36(1): 95-105. |

| Wang R T, Liu J C, Zhong C W, et al. Reaction kinetic model for catalytic reforming based on structure oriented lumping[J]. Acta Petrolei Sinica (Petroleum Processing Section), 2020, 36(1): 95-105. | |

| 35 | Hua F, Fu Z, Cheng Y. A simplified and effective molecular-level kinetic model for plastic pyrolysis [J]. Chemical Engineering Science, 2022, 264: 118146. |

| 36 | Dubdub I, Al-Yaari M. Pyrolysis of low density polyethylene: kinetic study using TGA data and ANN prediction[J]. Polymers, 2020, 12(4): 891. |

| [1] | 董新宇, 边龙飞, 杨怡怡, 张宇轩, 刘璐, 王腾. 冷却条件下倾斜上升管S-CO2流动与传热特性研究[J]. 化工学报, 2024, 75(S1): 195-205. |

| [2] | 郭骐瑞, 任丽媛, 陈康, 黄翔宇, 马卫华, 肖乐勤, 周伟良. 用于HTPB推进剂浆料的静态混合管数值模拟[J]. 化工学报, 2024, 75(S1): 206-216. |

| [3] | 李匡奚, 于佩潜, 王江云, 魏浩然, 郑志刚, 冯留海. 微气泡旋流气浮装置内流动分析与结构优化[J]. 化工学报, 2024, 75(S1): 223-234. |

| [4] | 赵昂然, 韩永强, 王志鹏, 李鹏飞, 许亚伟, 佟会玲. 常温条件下赤泥同时脱硫脱硝实验研究[J]. 化工学报, 2024, 75(S1): 276-282. |

| [5] | 徐英宇, 杨国强, 彭璟, 孙海宁, 张志炳. 微界面高级氧化处理煤化工废水的研究[J]. 化工学报, 2024, 75(S1): 283-291. |

| [6] | 王新月, 徐小虎, 张海洋, 尹春华. 维生素A醋酸酯/环糊精包合及性质研究[J]. 化工学报, 2024, 75(S1): 321-328. |

| [7] | 汪张洲, 唐天琪, 夏嘉俊, 何玉荣. 基于复合相变材料的电池热管理性能模拟[J]. 化工学报, 2024, 75(S1): 329-338. |

| [8] | 胡俭, 姜静华, 范生军, 刘建浩, 邹海江, 蔡皖龙, 王沣浩. 中深层U型地埋管换热器取热特性研究[J]. 化工学报, 2024, 75(S1): 76-84. |

| [9] | 钟屹, 周仕遇, 纠连朝, 李钰晓, 吴豪江, 周智勇. 废旧磷酸铁锂电池正极材料直接修复再生研究进展[J]. 化工学报, 2024, 75(S1): 1-13. |

| [10] | 任冠宇, 张义飞, 李新泽, 杜文静. 翼型印刷电路板式换热器流动传热特性数值研究[J]. 化工学报, 2024, 75(S1): 108-117. |

| [11] | 杨勇, 祖子轩, 李煜坤, 王东亮, 范宗良, 周怀荣. T型圆柱形微通道内CO2碱液吸收数值模拟[J]. 化工学报, 2024, 75(S1): 135-142. |

| [12] | 黄俊豪, 庞克亮, 孙方远, 刘福军, 谷致远, 韩龙, 段衍泉, 冯妍卉. 干熄炉料钟结构对焦炭布料粒径均匀度影响的模拟研究[J]. 化工学报, 2024, 75(S1): 158-169. |

| [13] | 吴学红, 韦新, 侯加文, 吕财, 刘勇, 刘鹤, 常志娟. 热解法制备碳纳米管及其在散热涂层中的应用研究[J]. 化工学报, 2024, 75(9): 3360-3368. |

| [14] | 丁湧, 李文建, 陈昭宇, 曹立辉, 刘轩铭, 任强强, 胡松, 向军. 废旧晶体硅光伏组件EVA有氧热解动力学与产物特性[J]. 化工学报, 2024, 75(9): 3310-3319. |

| [15] | 陈巨辉, 苏潼, 李丹, 陈立伟, 吕文生, 孟凡奇. 翅形扰流片作用下的微通道换热特性[J]. 化工学报, 2024, 75(9): 3122-3132. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号