化工学报 ›› 2025, Vol. 76 ›› Issue (10): 5203-5212.DOI: 10.11949/0438-1157.20250235

孟凡鹏1( ), 远双杰1, 周帆2, 孙玉绣2(

), 远双杰1, 周帆2, 孙玉绣2( ), 乔志华2(

), 乔志华2( )

)

收稿日期:2025-03-10

修回日期:2025-04-21

出版日期:2025-10-25

发布日期:2025-11-25

通讯作者:

孙玉绣,乔志华

作者简介:孟凡鹏(1986—),男,硕士,高级工程师,mengfanpeng@cppe.com.cn

基金资助:

Fanpeng MENG1( ), Shuangjie YUAN1, Fan ZHOU2, Yuxiu SUN2(

), Shuangjie YUAN1, Fan ZHOU2, Yuxiu SUN2( ), Zhihua QIAO2(

), Zhihua QIAO2( )

)

Received:2025-03-10

Revised:2025-04-21

Online:2025-10-25

Published:2025-11-25

Contact:

Yuxiu SUN, Zhihua QIAO

摘要:

二氧化碳的直接空气捕获是抑制全球变暖的一个必要组成部分,开发高效、低浓度CO2分离技术成为近年来研究的焦点。本研究采用聚合物-MOF复合的含氟1F-PUiO-66作为填料材料,并与对应的cPIM-1聚合物基质共混构建出负载量高达50%(质量)且对CO2具有高亲和力的混合基质膜,实现低浓度CO2的高效分离。所制备的50%(质量) 1F-PUiO-66/cPIM-1膜在1%(体积)低CO2浓度进气条件下,CO2渗透通量高达6428.3 Barrer,CO2/N2选择性提高至69.13,相较于cPIM-1纯膜分别提升1167.3%和81.2%,大幅度超越了2019年Robeson上限。本研究的聚合物-MOF复合填料材料在低CO2浓度进气条件下显著的CO2/N2分离潜力,可为工业实际气体分离提供参考。

中图分类号:

孟凡鹏, 远双杰, 周帆, 孙玉绣, 乔志华. 用于低浓度CO2捕集的高性能聚合物-MOF基混合基质膜构建[J]. 化工学报, 2025, 76(10): 5203-5212.

Fanpeng MENG, Shuangjie YUAN, Fan ZHOU, Yuxiu SUN, Zhihua QIAO. Construction of high-performance polymer-MOF based mixed matrix membrane for low concentration CO2 capture[J]. CIESC Journal, 2025, 76(10): 5203-5212.

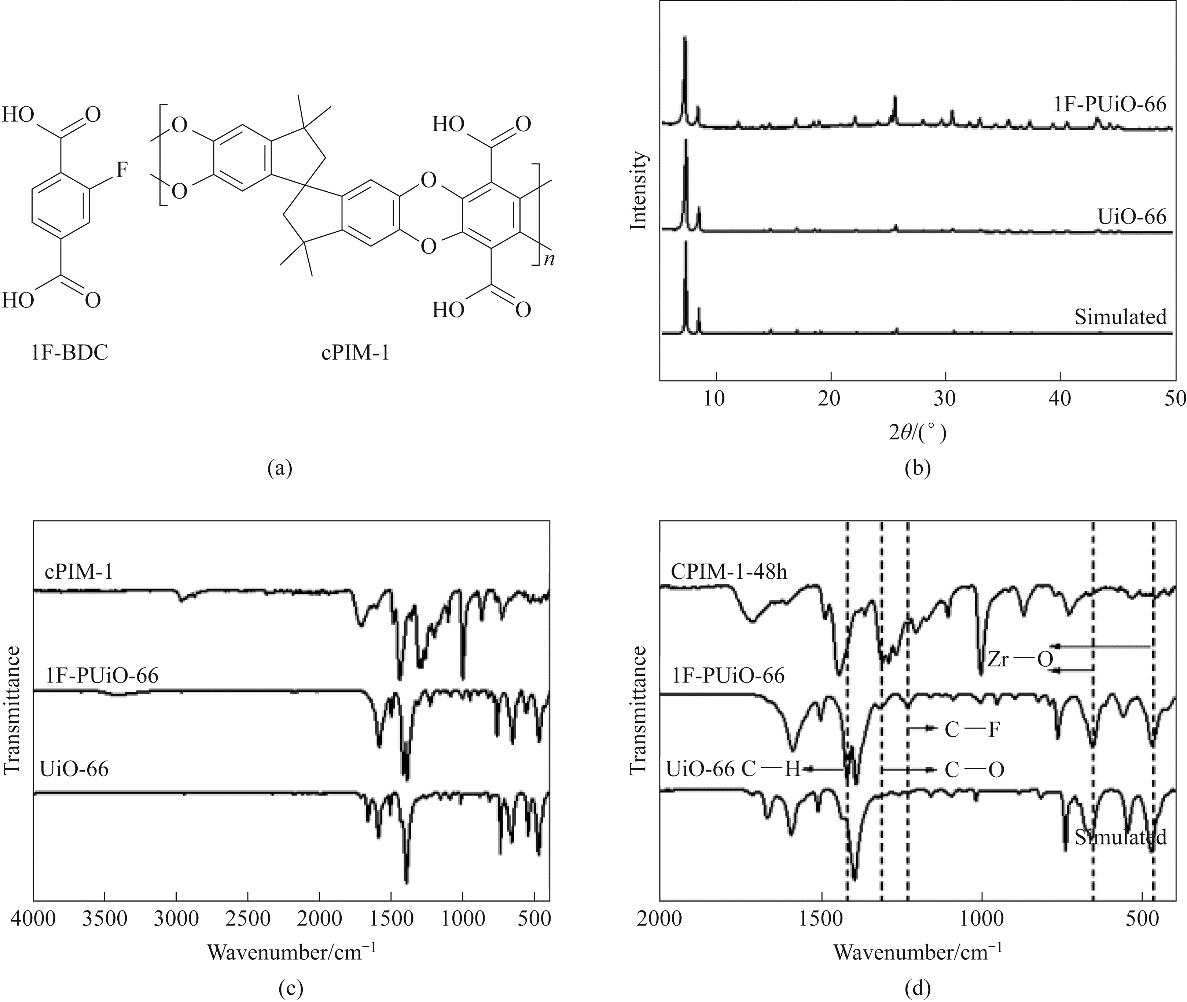

图2 (a) 1F-BDC配体及cPIM-1的结构式;(b) 1F-PUiO-66与UiO-66的PXRD谱图;cPIM-1、UiO-66和1F-PUiO-66样品的(c) FTIR光谱图及(d) 局部放大图

Fig.2 (a) Structural formulae of 1F-BDC ligand and cPIM-1; (b) PXRD spectra of UiO-66 and 1F-PUiO-66; (c) FTIR spectra of cPIM-1, UiO-66 and 1F-PUiO-66 samples and (d) localized magnification

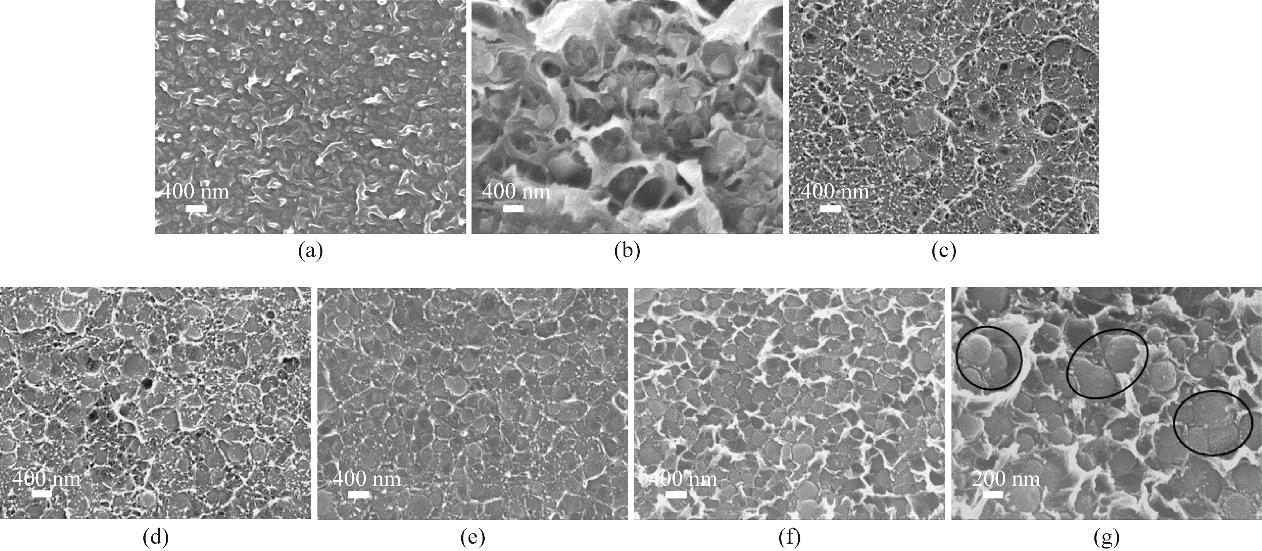

图5 cPIM-1膜(a), 20%(质量) UiO-66/cPIM-1膜(b)及负载量为10%(质量)(c)、30%(质量)(d)、50%(质量)(e)和60%(质量)(f)的1F-PUiO-66/cPIM-1膜的SEM断面图以及60%(质量)1F-PUiO-66/cPIM-1膜的局部放大图(g)

Fig.5 SEM cross-sections of cPIM-1 membranes (a), 20%(mass) UiO-66/cPIM-1 membranes (b) and 1F-PUiO-66/cPIM-1 membranes with loading of 10%(mass) (c), 30%(mass) (d), 50%(mass) (e) and 60%(mass) (f), and local magnification cross-section of 60%(mass)1F-PUiO-66/cPIM-1 membrane (g)

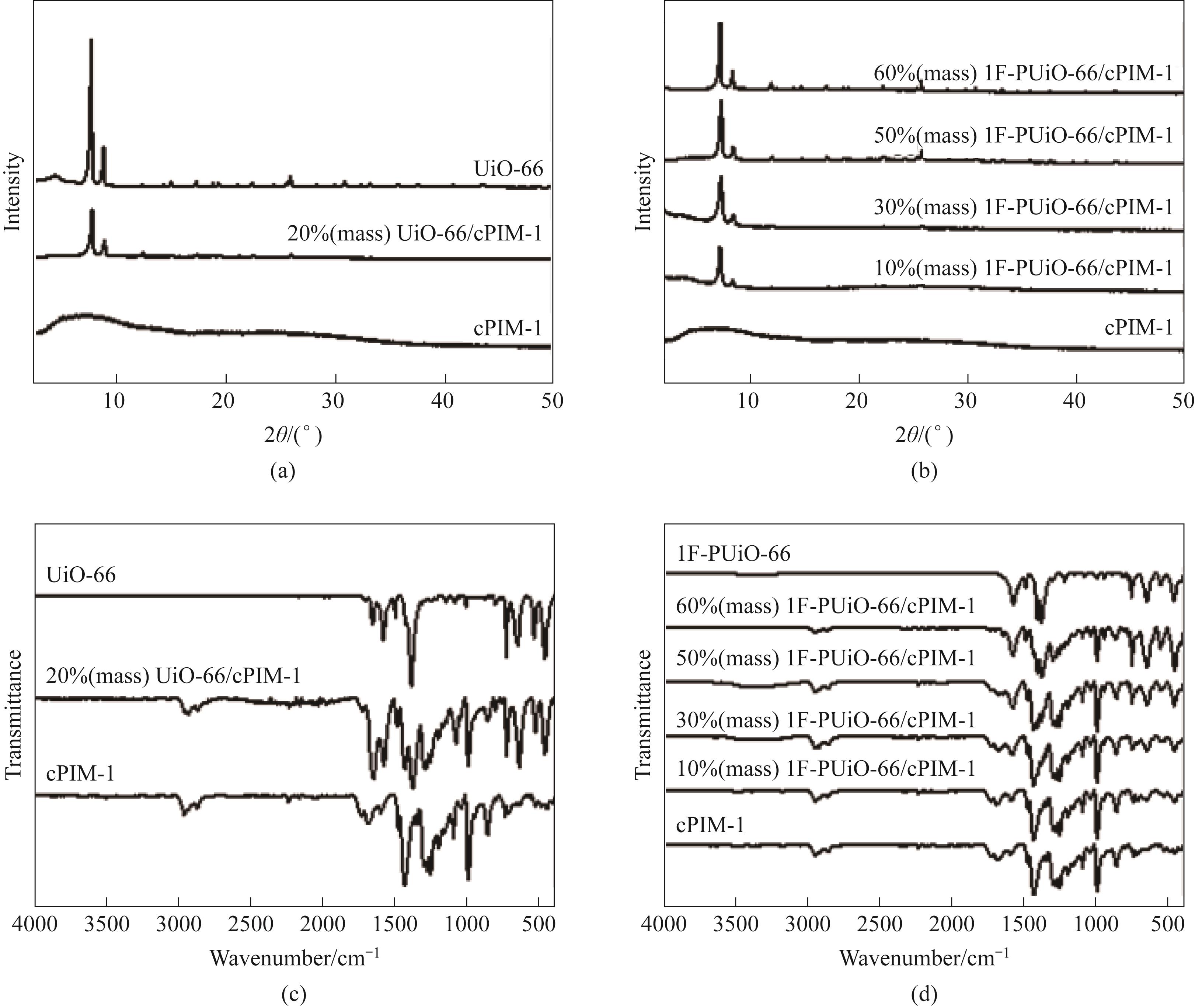

图6 不同填料负载量UiO-66/cPIM-1膜(a)和1F-PUiO-66/cPIM-1膜(b)的PXRD谱图;不同填料负载量UiO-66/cPIM-1膜(c)和1F-PUiO-66/cPIM-1膜(d)的FTIR谱图

Fig.6 PXRD patterns of UiO-66/cPIM-1 membranes (a) and 1F-PUiO-66/cPIM-1 membranes (b) with different filler loadings; FTIR spectra of UiO-66/cPIM-1 membranes (c) and 1F-PUiO-66/cPIM-1 membranes (d) with different filler loadings

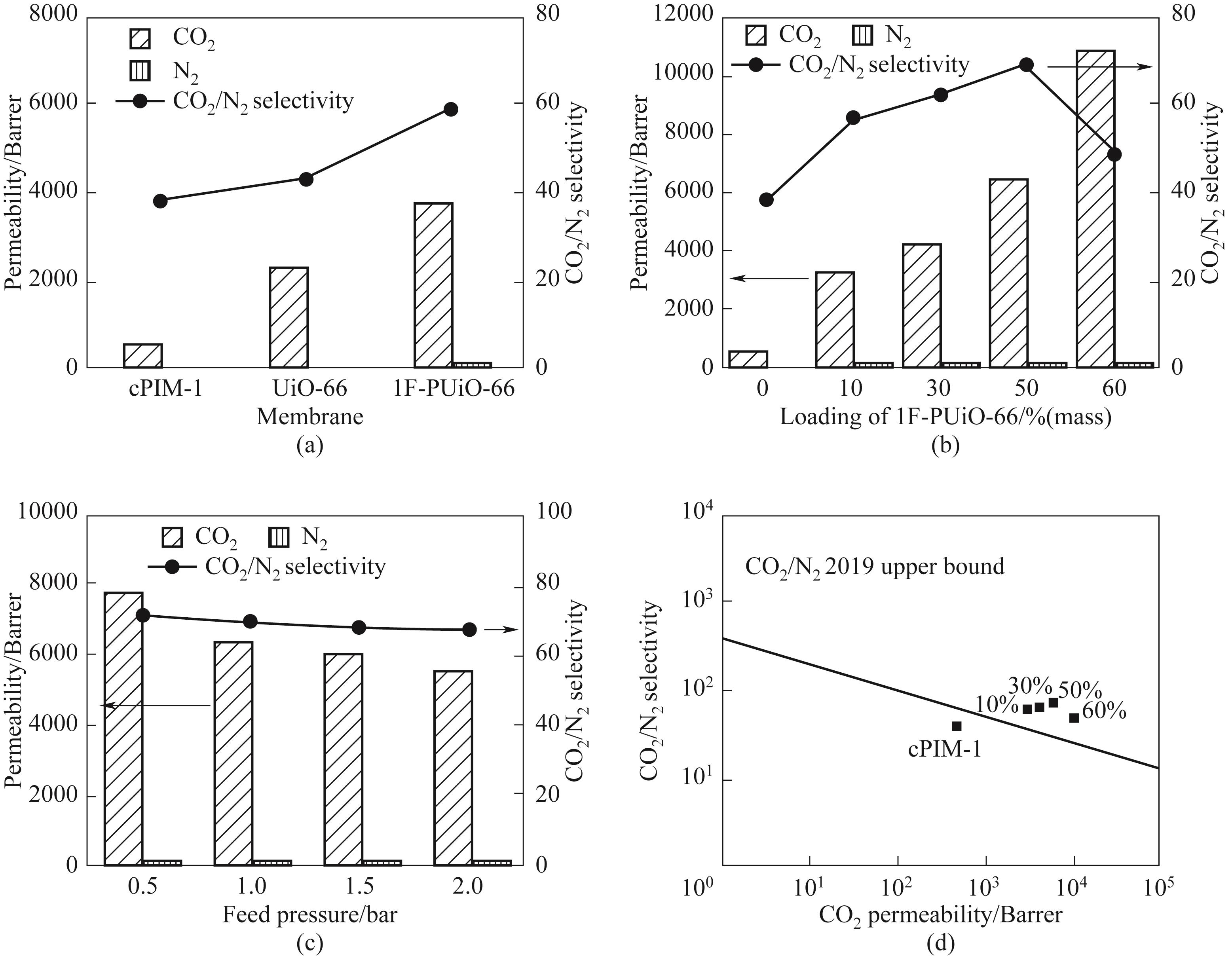

图7 (a) cPIM-1纯膜和混合基质膜的气体分离性能(混合基质膜负载量均为20%(质量));(b)不同负载量1F-PUiO-66/cPIM-1膜的二元气体分离性能;(c) 50%(质量) 1F-PUiO-66/cPIM-1膜在不同测试压力下的气体分离性能;(d) 1F-PUiO-66/cPIM-1膜的混合气体分离性能与2019年Robeson上限的对比[46](CO2/N2=1/99,体积比;25℃)

Fig.7 (a) Gas separation performance of cPIM-1 pure membranes and mixed matrix membranes(mixed matrix membrane loadings were both 20%(mass)); (b) Binary gas separation performance of 1F-PUiO-66/cPIM-1 membranes with different loadings; (c) Gas separation performance of 50%(mass) 1F-PUiO-66/cPIM-1 membranes at different test pressures; (d) Mixed gas separation performance of 1F-PUiO-66/cPIM-1 membranes compared with the 2019 Robeson upper bound[46](CO2/N2=1/99,volume ratio; 25℃)

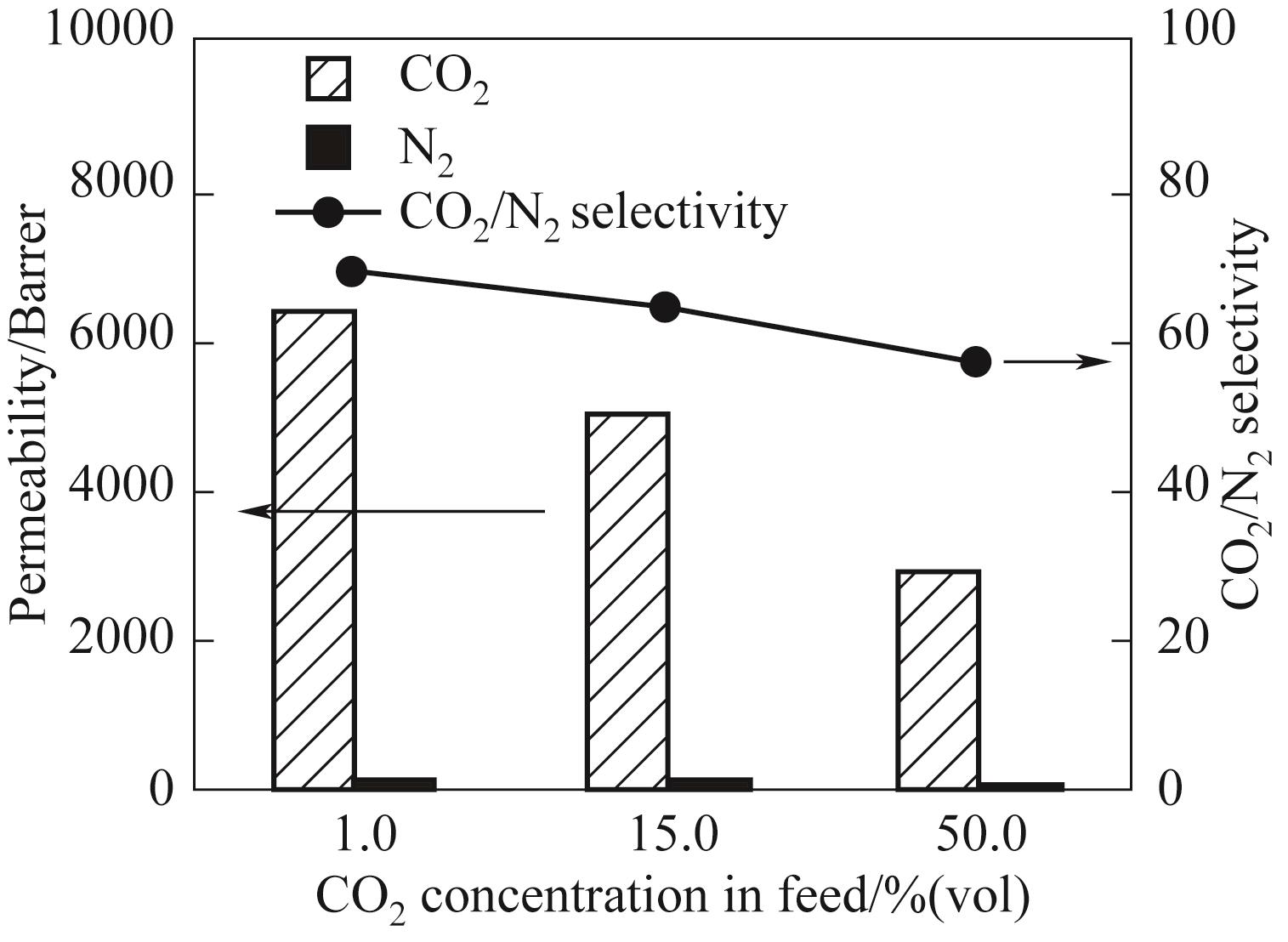

图8 1F-PUiO-66/cPIM-1膜在不同CO2浓度进气条件下的CO2/N2分离性能

Fig.8 CO2/N2 separation performance of 1F-PUiO-66/cPIM-1 membrane under different CO2 concentration feed conditions

| [1] | Bernardo P, Drioli E, Golemme G. Membrane gas separation: a review/state of the art[J]. Industrial & Engineering Chemistry Research, 2009, 48(10): 4638-4663. |

| [2] | Yampolskii Y, Freeman B. Membrane Gas Separation[M]. New Jersey: John Wiley & Sons Ltd., 2010: 29-42. |

| [3] | Baker R W, Low B T. Gas separation membrane materials: a perspective[J]. Macromolecules, 2014, 47(20): 6999-7013. |

| [4] | Debost M, Klar P B, Barrier N, et al. Synthesis of discrete CHA zeolite nanocrystals without organic templates for selective CO2 capture[J]. Angewandte Chemie International Edition, 2020, 59(52): 23491-23495. |

| [5] | Cui W G, Hu T L, Bu X H. Metal-organic framework materials for the separation and purification of light hydrocarbons[J]. Advanced Materials, 2020, 32(3): 1806445. |

| [6] | Yang L F, Cui X L, Zhang Z Q, et al. An asymmetric anion-pillared metal-organic framework as a multisite adsorbent enables simultaneous removal of propyne and propadiene from propylene[J]. Angewandte Chemie International Edition, 2018, 57(40): 13145-13149. |

| [7] | Kumar S, Mondal M K. Selection of efficient absorbent for CO2 capture from gases containing low CO2 [J]. Korean Journal of Chemica Engineering, 2020, 37(2): 231-239. |

| [8] | Fine N A, Nielsen P T, Rochelle G T. Decomposition of nitrosamines in CO2 capture by aqueous piperazine or monoethanolamine[J]. Environmental Science & Technology, 2014, 48(10): 5996-6002. |

| [9] | Ding Y. Perspective on gas separation membrane materials from process economics point of view[J]. Industrial & Engineering Chemistry Research, 2020, 59(2): 556-568. |

| [10] | Gin D L, Noble R D. Designing the next generation of chemical separation membranes[J]. Science, 2011, 332(6030): 674-676. |

| [11] | Kamble A R, Patel C M, Murthy Z V P. A review on the recent advances in mixed matrix membranes for gas separation processes[J]. Renewable and Sustainable Energy Reviews, 2021, 145: 111062. |

| [12] | Cheng Y D, Wang Z H, Zhao D. Mixed matrix membranes for natural gas upgrading: current status and opportunities[J]. Industrial & Engineering Chemistry Research, 2018, 57(12): 4139-4169. |

| [13] | Zhao J H, Xie K, Liu L, et al. Enhancing plasticization-resistance of mixed-matrix membranes with exceptionally high CO2 /CH4 selectivity through incorporating ZSM-25 zeolite[J]. Journal of Membrane Science, 2019, 583: 23-30. |

| [14] | Koros W J, Zhang C. Materials for next-generation molecularly selective synthetic membranes[J]. Nature Materials, 2017, 16(3): 289-297. |

| [15] | Wang H, Zhao S, Liu Y, et al. Membrane adsorbers with ultrahigh metal-organic framework loading for high flux separations[J]. Nature Communications, 2019, 10: 4204. |

| [16] | Lu Y Z H, Zhang H C, Chan J Y, et al. Homochiral MOF-polymer mixed matrix membranes for efficient separation of chiral molecules[J]. Angewandte Chemie International Edition, 2019, 131(47): 17084-17091. |

| [17] | Rodenas T, Luz I, Prieto G, et al. Metal-organic framework nanosheets in polymer composite materials for gas separation[J]. Nature Materials, 2015, 14(1): 48-55. |

| [18] | Caro J. Quo vadis, MOF?[J]. Chemie Ingenieur Technik, 2018, 90(11): 1759-1768. |

| [19] | Bae T H, Lee J S, Qiu W L, et al. A high-performance gas-separation membrane containing submicrometer-sized metal-organic framework crystals[J]. Angewandte Chemie International Edition, 2010, 49(51): 9863-9866. |

| [20] | Wu X Y, Tian Z Z, Wang S F, et al. Mixed matrix membranes comprising polymers of intrinsic microporosity and covalent organic framework for gas separation[J]. Journal of Membrane Science, 2017, 528: 273-283. |

| [21] | Guo A, Ban Y J, Yang K, et al. Molecular sieving mixed matrix membranes embodying nano-fillers with extremely narrow pore-openings[J]. Journal of Membrane Science, 2020, 601: 117880. |

| [22] | Zou C C, Li Q Q, Hua Y Y, et al. Mechanical synthesis of COF nanosheet cluster and its mixed matrix membrane for efficient CO2 removal[J]. ACS Applied Materials & Interfaces, 2017, 9(34): 29093-29100. |

| [23] | Qian Q H, Asinger P A, Lee M J, et al. MOF-based membranes for gas separations[J]. Chemical Reviews, 2020, 120(16): 8161-8266. |

| [24] | Ma X J, Chai Y T, Li P, et al. Metal-organic framework films and their potential applications in environmental pollution control[J]. Accounts of Chemical Research, 2019 52(5): 1461-1470. |

| [25] | Jeong H K. Metal-organic framework membranes: unprecedented opportunities for gas separations[J]. AIChE Journal, 2021, 67(6): e17258. |

| [26] | Lee T H, Lee B K, Youn C, et al. Interface engineering in MOF/crosslinked polyimide mixed matrix membranes for enhanced propylene/propane separation performance and plasticization resistance[J]. Journal of Membrane Science, 2023, 667: 121182. |

| [27] | Lee T H, Oh J Y, Jang J K, et al. Elucidating the role of embedded metal-organic frameworks in water and ion transport properties in polymer nanocomposite membranes[J]. Chemistry of Materials, 2020, 32(23): 10165-10175. |

| [28] | Wang H L, He S F, Qin X D, et al. Interfacial engineering in metal-organic framework-based mixed matrix membranes using covalently grafted polyimide brushes[J]. Journal of the American Chemical Society, 2018, 140(49): 17203-17210. |

| [29] | Zhu B, He S S, Yang Y, et al. Boosting membrane carbon capture via multifaceted polyphenol-mediated soldering[J]. Nature Communications, 2023, 14: 1697. |

| [30] | Tien-Binh N, Rodrigue D, Kaliaguine S. In-situ cross interface linking of PIM-1 polymer and UiO-66-NH2 for outstanding gas separation and physical aging control[J]. Journal of Membrane Science, 2018, 548: 429-438. |

| [31] | Cheng Y D, Joarder B, Datta S J, et al. Mixed matrix membranes with surface functionalized metal-organic framework sieves for efficient propylene/propane separation[J]. Advanced Materials, 2023, 35(25): 2300296. |

| [32] | Wu C H, Zhang K X, Wang H L, et al. Enhancing the gas separation selectivity of mixed-matrix membranes using a dual-interfacial engineering approach[J]. Journal of the American Chemical Society, 2020, 142(43): 18503-18512. |

| [33] | Japip S, Xiao Y C, Chung T S. Particle-size effects on gas transport properties of 6FDA-durene/ZIF-71 mixed matrix membranes[J]. Industrial & Engineering Chemistry Research, 2016, 55(35): 9507-9517. |

| [34] | Li H, Tuo L H, Yang K, et al. Simultaneous enhancement of mechanical properties and CO2 selectivity of ZIF-8 mixed matrix membranes: interfacial toughening effect of ionic liquid[J]. Journal of Membrane Science, 2016, 511: 130-142. |

| [35] | Zhang Z J, Nguyen H T H, Miller S A, et al. polyMOFs: a class of interconvertible polymer-metal-organic-framework hybrid materials[J]. Angewandte Chemie International Edition, 2015, 54(21): 6152-6157. |

| [36] | Zhang Z J, Nguyen H T H, Miller S A, et al. Polymer-metal-organic frameworks (polyMOFs) as water tolerant materials for selective carbon dioxide separations[J]. Journal of the American Chemical Society, 2016, 138(3): 920-925. |

| [37] | Qin Z X, Sun Y X, Zhang Z Q, et al. Synergistic effect of molecular sieving and adsorption inhibition in MOF-based mixed matrix membranes for efficient O2/N2 separation[J]. Chemical Engineering Journal, 2024, 497: 154615. |

| [38] | Rodriguez K M, Wu A X, Qian Q H, et al. Facile and time-efficient carboxylic acid functionalization of PIM-1: effect on molecular packing and gas separation performance[J]. Macromolecules, 2020, 53(15): 6220-6234. |

| [39] | Lee T H, Lee B K, Yoo S Y, et al. PolyMOF nanoparticles constructed from intrinsically microporous polymer ligand towards scalable composite membranes for CO2 separation[J]. Nature Communications, 2023, 14: 8330. |

| [40] | Sun Y X, Geng C X, Zhang Z Q, et al. Two-dimensional basic cobalt carbonate supported ZIF-67 composites towards mixed matrix membranes for efficient CO2/N2 separation[J]. Journal of Membrane Science, 2022, 661: 120928. |

| [41] | Sun Y X, Qin Z X, Geng C X, et al. Enhancing CO2/N2 separation performances by turning membrane affinity for CO2 [J]. Separation and Purification Technology, 2024, 337: 126377. |

| [42] | Wang Z B, Sun Y X, Qin Z X, et al. Construction of MOF-based mixed matrix membranes with multiple fluorine sites for low concentration CO2 separation under humid conditions[J]. Separation and Purification Technology, 2025, 369: 133149. |

| [43] | Shieh F K, Wang S C, Leo S Y, et al. Water-based synthesis of zeolitic imidazolate framework-90 (ZIF-90) with a controllable particle size[J]. Chemistry-A European Journal, 2013, 19(34): 11139-11142. |

| [44] | Chen Z, Zhang P, Wu H, et al. Incorporating amino acids functionalized graphene oxide nanosheets into Pebax membranes for CO2 separation[J]. Separation and Purification Technology, 2022, 288: 120682. |

| [45] | Qu K, Xu J P, Dai L H, et al. Electrostatic-induced crystal-rearrangement of porous organic cage membrane for CO2 capture[J]. Angewandte Chemie International Edition, 2022, 61(31): e202205481. |

| [46] | Comesaña-Gándara B, Chen J, Bezzu C G, et al. Redefining the Robeson upper bounds for CO2/CH4 and CO2/N2 separations using a series of ultrapermeable benzotriptycene-based polymers of intrinsic microporosity[J]. Energy & Environmental Science, 2019, 12(9): 2733-2740. |

| [47] | Chew T L, Yeong Y F, Ho C D, et al. Ion-exchanged silicoaluminophosphate-34 membrane for efficient CO2/N2 separation with low CO2 concentration in the gas mixture[J]. Industrial & Engineering Chemistry Research, 2019, 58(2): 729-735. |

| [1] | 顾栋, 皮行健, 张叠, 张瑛. 不同粒径CAU-1/PI混合基质膜的构建与H2/CO2分离性能研究[J]. 化工学报, 2025, 76(5): 2410-2418. |

| [2] | 赵浩帆, 任豪杰, 刘宗凯, 董冠英, 张亚涛. MOFs玻璃膜在气体分离领域的研究进展[J]. 化工学报, 2025, 76(5): 2042-2054. |

| [3] | 陶春珲, 李印辉, 傅钰, 段然, 赵泽一, 唐羽丰, 张罡, 马和平. 不同吸附剂对低浓度Kr气的选择性吸附与纯化[J]. 化工学报, 2025, 76(5): 2358-2366. |

| [4] | 刘鑫, 郑皓仁, 陈强, 丁静怡, 黄康, 徐至. 全钒液流电池用纤维素纳米晶掺杂混合基质膜[J]. 化工学报, 2025, 76(5): 2294-2303. |

| [5] | 张瑞航, 曹潘, 杨锋, 李昆, 肖朋, 邓春, 刘蓓, 孙长宇, 陈光进. ZIF-8纳米流体天然气乙烷回收工艺的产品纯度关键影响因素分析[J]. 化工学报, 2023, 74(8): 3386-3393. |

| [6] | 裴仁花, 王永洪, 张新儒, 李晋平. 碳纳米管/环糊精金属有机骨架协同强化混合基质膜的CO2分离[J]. 化工学报, 2022, 73(9): 3904-3914. |

| [7] | 席国君, 刘子涵, 雷广平. FeTPPs-CuBTC协同强化低浓度煤层气吸附分离[J]. 化工学报, 2022, 73(9): 3940-3949. |

| [8] | 刘学安, 汤丽怡, 覃健, 唐大江, 童张法, 曲慧颖. 热解Ni/Co-ZIF-8制备碳纳米管桥连多孔碳及其在超级电容器中的应用[J]. 化工学报, 2022, 73(7): 3287-3297. |

| [9] | 王立维, 王娟娟, 王永洪, 张新儒, 李晋平. 聚乙烯胺/Cu3(BTC)2-MMT-NH2混合基质膜的制备及气体传递性能[J]. 化工学报, 2022, 73(7): 3068-3077. |

| [10] | 于喆淼, 王志, 生梦龙, 邢广宇, 王纪孝. 界面聚合法制备用于脱氮提纯CH4的N2优先渗透ZIF-90/聚酰胺混合基质膜[J]. 化工学报, 2022, 73(7): 3273-3286. |

| [11] | 毛恒, 王月, 王森, 刘伟民, 吕静, 陈甫雪, 赵之平. APTES改性ZIF-L/PEBA混合基质膜强化渗透汽化分离苯酚研究[J]. 化工学报, 2022, 73(3): 1389-1402. |

| [12] | 王洒, 温怡静, 郭丹煜, 周欣, 李忠. 锆基MOF次级结构单元调控及轻烃吸附分离性能增强[J]. 化工学报, 2022, 73(2): 730-738. |

| [13] | 靳卓, 王永洪, 张新儒, 白雪, 李晋平. Pebax/a-MoS2/MIP-202混合基质膜的制备及CO2分离性能[J]. 化工学报, 2022, 73(10): 4527-4538. |

| [14] | 耿晨旭, 孙玉绣, 黄宏亮, 郭翔宇, 乔志华, 仲崇立. 机械化学法合成小尺寸MOF填料助力高性能CO2分离[J]. 化工学报, 2021, 72(9): 4750-4758. |

| [15] | 王绍宇, 马翰泽, 吴洪, 梁旭, 王洪建, 朱姿亭, 姜忠义. 有机框架膜在气体分离中的研究进展[J]. 化工学报, 2021, 72(7): 3488-3510. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号