CIESC Journal ›› 2025, Vol. 76 ›› Issue (5): 2026-2041.DOI: 10.11949/0438-1157.20241221

• Reviews and monographs • Previous Articles Next Articles

Bing ZHANG1( ), Jianhui LI1, Xinrong MA1, Yang CHEN1,2, Jinping LI1,2, Libo LI1,2(

), Jianhui LI1, Xinrong MA1, Yang CHEN1,2, Jinping LI1,2, Libo LI1,2( )

)

Received:2024-10-31

Revised:2024-12-16

Online:2025-06-13

Published:2025-05-25

Contact:

Libo LI

张冰1( ), 李建惠1, 马欣蓉1, 陈杨1,2, 李晋平1,2, 李立博1,2(

), 李建惠1, 马欣蓉1, 陈杨1,2, 李晋平1,2, 李立博1,2( )

)

通讯作者:

李立博

作者简介:张冰(1999—),女,硕士研究生,tyutzhangbing@163.com

基金资助:CLC Number:

Bing ZHANG, Jianhui LI, Xinrong MA, Yang CHEN, Jinping LI, Libo LI. Research progress of MOF preparation by steam-assisted method[J]. CIESC Journal, 2025, 76(5): 2026-2041.

张冰, 李建惠, 马欣蓉, 陈杨, 李晋平, 李立博. 蒸气相辅助法制备MOF基材料的研究进展[J]. 化工学报, 2025, 76(5): 2026-2041.

Add to citation manager EndNote|Ris|BibTeX

| 合成方法 | 优点 | 缺点 | MOF | 比表面积/ (m2/g) | 时空产率/ (kg/(m3·d)) | 文献 |

|---|---|---|---|---|---|---|

| 溶剂热合成法 | 适用范围广 | 高温高压、废液难以处理 | MOF-5 | 2900 | — | [ |

| 电化学合成法 | 合成效率高 | 能耗高、普适性差 | Cu-MOF | 1820 | — | [ |

| 微波加热法 | 效率高,反应时间短 | 微波设备成本高 | Ni-MOF-74 | 1252 | — | [ |

| Mg-MOF-74 | 1416 | — | [ | |||

| UiO-66 | 1052 | 7163 | [ | |||

| 超声波化学法 | 快速结晶 | 产品质量低 | MOF-1 | — | — | [ |

| 微通道合成技术法 | 反应速率快 | 设备加工成本高、狭窄的通道易堵塞 | MOF-808 | 1600 | 95000 | [ |

| 室温溶液合成法 | 简单、廉价、绿色 | 单体溶解度差、普适性差 | UiO-66-(COOH)2 | 890 | — | [ |

| HKUST-1 | 1749 | 1842 | [ | |||

| 机械研磨法 | 环境友好、经济高效 | 产品质量低、稳定性差 | ZIF-8 | 37 | — | [ |

Table 1 Summary of different synthesis methods of MOF

| 合成方法 | 优点 | 缺点 | MOF | 比表面积/ (m2/g) | 时空产率/ (kg/(m3·d)) | 文献 |

|---|---|---|---|---|---|---|

| 溶剂热合成法 | 适用范围广 | 高温高压、废液难以处理 | MOF-5 | 2900 | — | [ |

| 电化学合成法 | 合成效率高 | 能耗高、普适性差 | Cu-MOF | 1820 | — | [ |

| 微波加热法 | 效率高,反应时间短 | 微波设备成本高 | Ni-MOF-74 | 1252 | — | [ |

| Mg-MOF-74 | 1416 | — | [ | |||

| UiO-66 | 1052 | 7163 | [ | |||

| 超声波化学法 | 快速结晶 | 产品质量低 | MOF-1 | — | — | [ |

| 微通道合成技术法 | 反应速率快 | 设备加工成本高、狭窄的通道易堵塞 | MOF-808 | 1600 | 95000 | [ |

| 室温溶液合成法 | 简单、廉价、绿色 | 单体溶解度差、普适性差 | UiO-66-(COOH)2 | 890 | — | [ |

| HKUST-1 | 1749 | 1842 | [ | |||

| 机械研磨法 | 环境友好、经济高效 | 产品质量低、稳定性差 | ZIF-8 | 37 | — | [ |

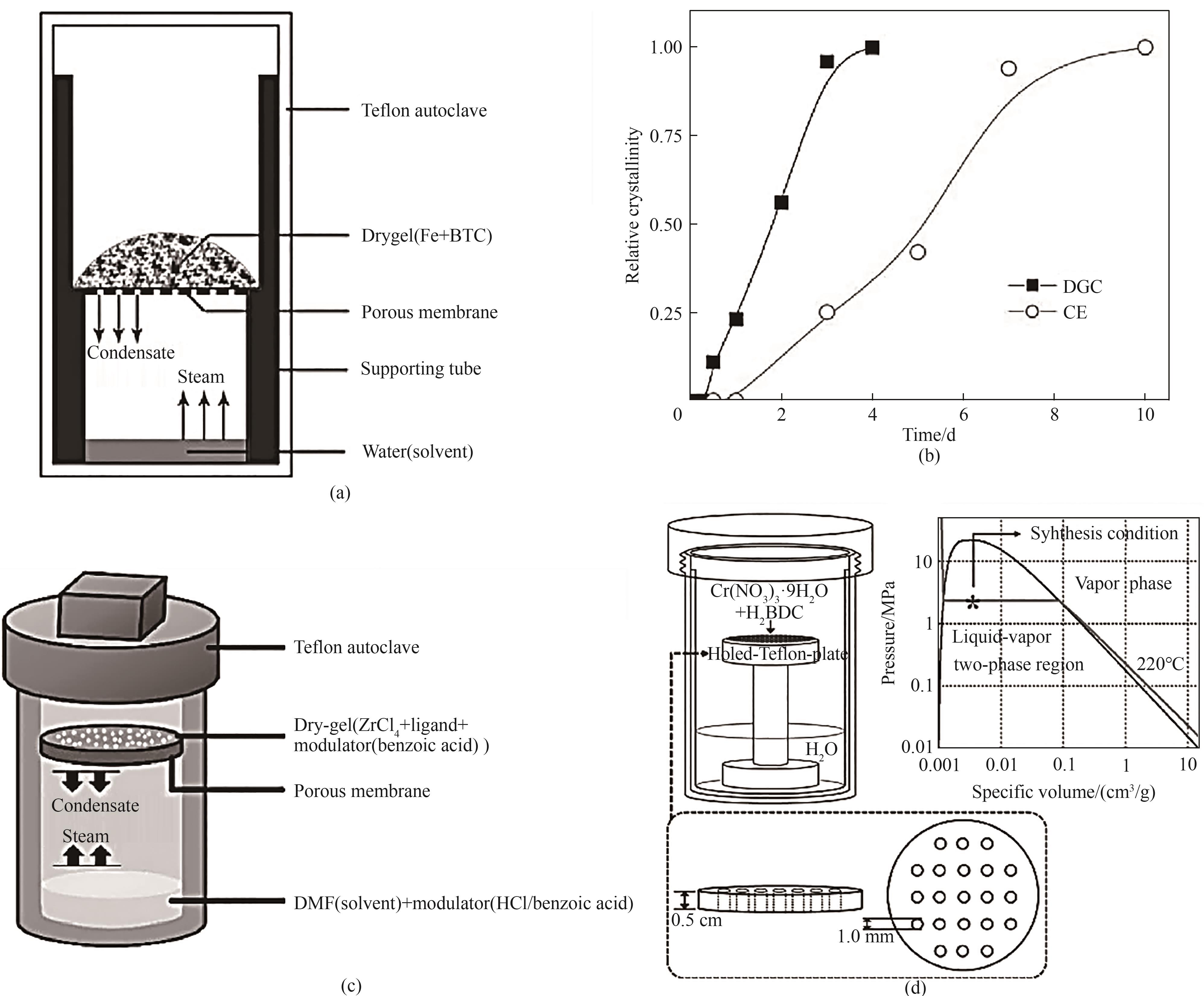

Fig.4 (a) Schematic diagram of the steam-assisted synthesis of MIL-100(Fe); (b) Relative crystallinity curves of MIL-100(Fe) by steam-assisted method and electrosynthesis[36]; (c) Schematic diagram of the device for the synthesis of UiO-type MOF by steam-assisted method[37]; (d) Reactor diagram of steam-assisted synthesis of MIL-101 (left) and holed-Teflon plate (left-bottom), P-V phase diagram of water (right)[40]

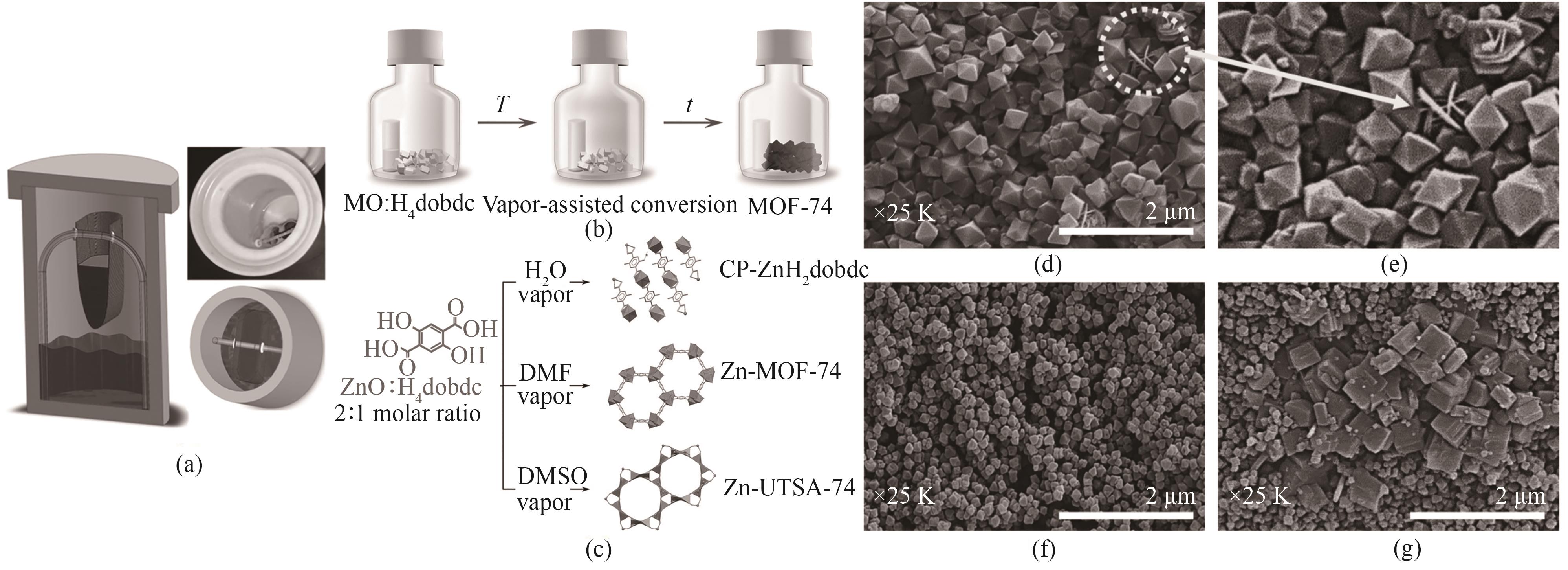

Fig.5 (a) Diagram of the internal installation of the steam-assisted synthesis MOF-74[38]; (b) Steam-assisted synthesis of MOF-74∶metal oxide (MO) and H4dobdc ligand are mixed in a ratio of 2∶1[39]; (c) Products obtained by the reaction ZnO with H4 dobdc under different steam conditions[39]; (d) SEM image of MIL-101 synthesized by solvent-thermal synthesis method; (e) The expanded images of figure (d); SEM diagram of steam-assisted synthesis MIL-101: (f) Cr/H2BDC=1/1, (g) Cr/H2BDC=1/1.2[40]

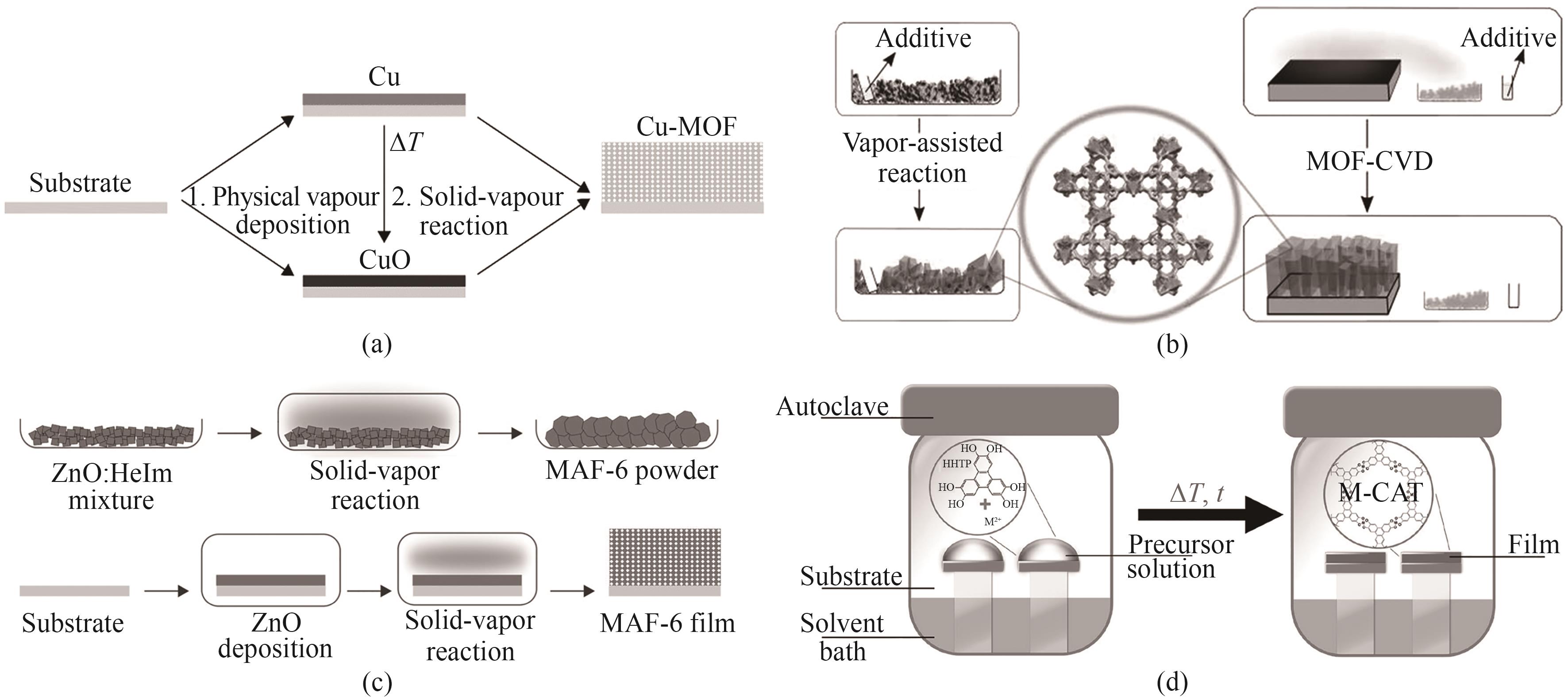

Fig.8 (a) Chemical vapor deposition Cu-based MOF film flow diagram[55]; (b) Steam-assisted synthesis of HKUST-1 powder (left) and HKUST-1 film (right)[56]; (c) Schematic diagram of preparation of large-pore MAF-6 powder (top) and thin film by steam-assisted method (bottom)[57]; (d) Flow chart of CAT-1 film device prepared by chemical vapor deposition[58]

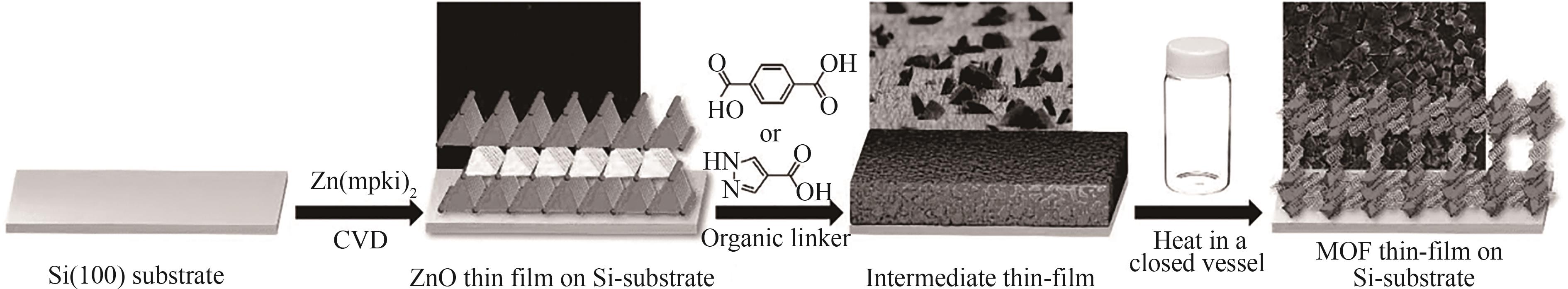

Fig.9 Schematic diagram of the preparation of ZnO thin film and conversion into MOF thin film[SEM microscopic images show the various stages of MOF formation on Si (100) substrate][59]

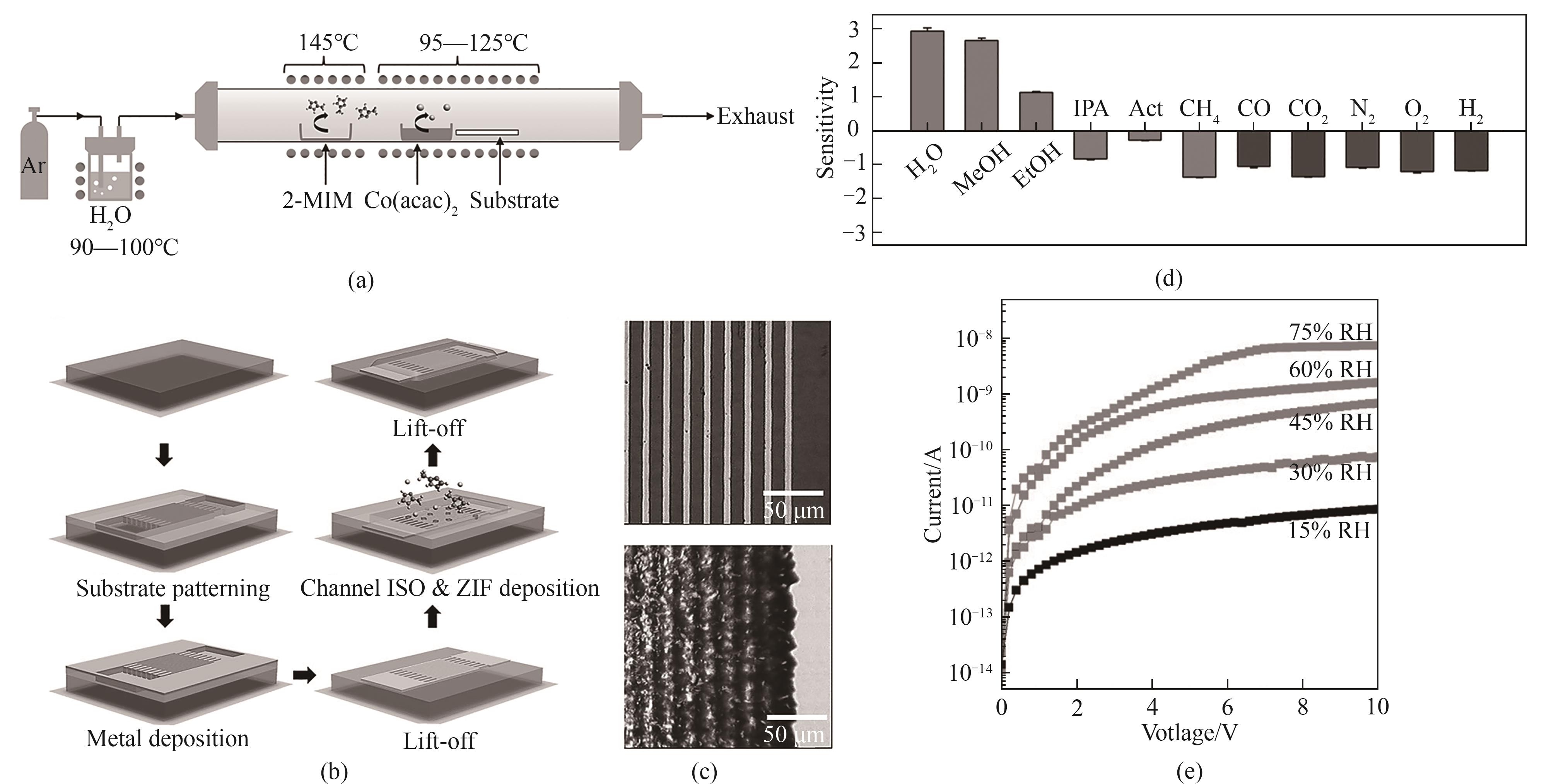

Fig.10 (a) Schematic diagram of the growth of ZIF-67 on substrate by the steam-flow assisted reaction of Co(acac)2 and 2-MIM in a CVD furnace; (b) Schematic diagram of preparation of ZIF-67 chemical resistor; (c) Optical images of ZIF-67 electrodes before and after deposition; (d) Gas sensitivity of CVD ZIF-67 chemical resistors under different environmental conditions; (e) Output characteristics of CVD ZIF-67 chemical resistor under different humidity conditions[60]

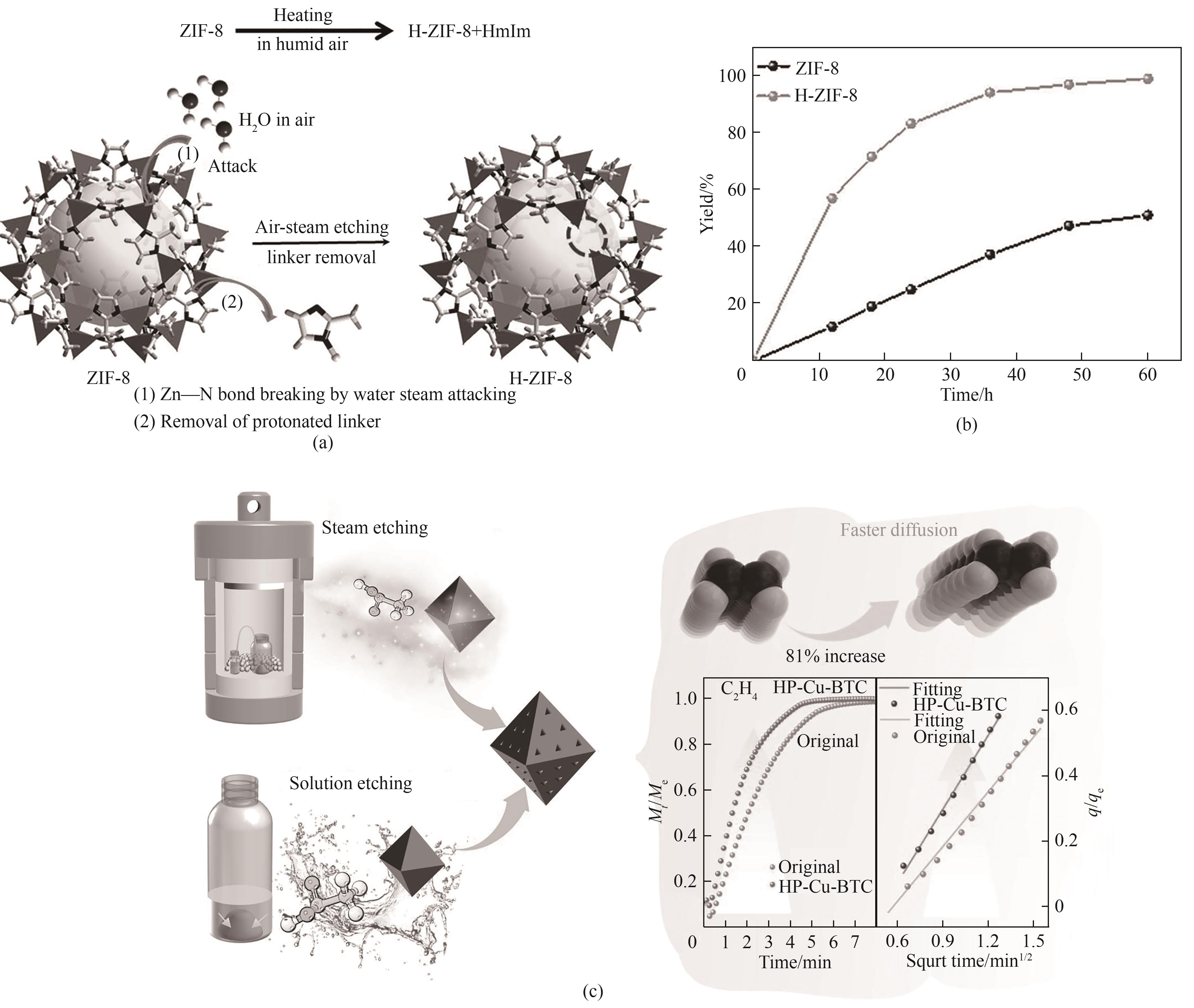

Fig.12 (a) Schematic diagram of the basic principle of the air-steam etching process for producing layered porous structures in H-ZIF-8; (b) Catalytic performance of ZIF-8 and H-ZIF-8 samples in the cycloaddition of CO2 catalyzed by epichlorohydrin[69]; (c) Method diagram of preparation of HP-Cu-BTC by steam etching and solution etching and gas separation performance diagram[70]

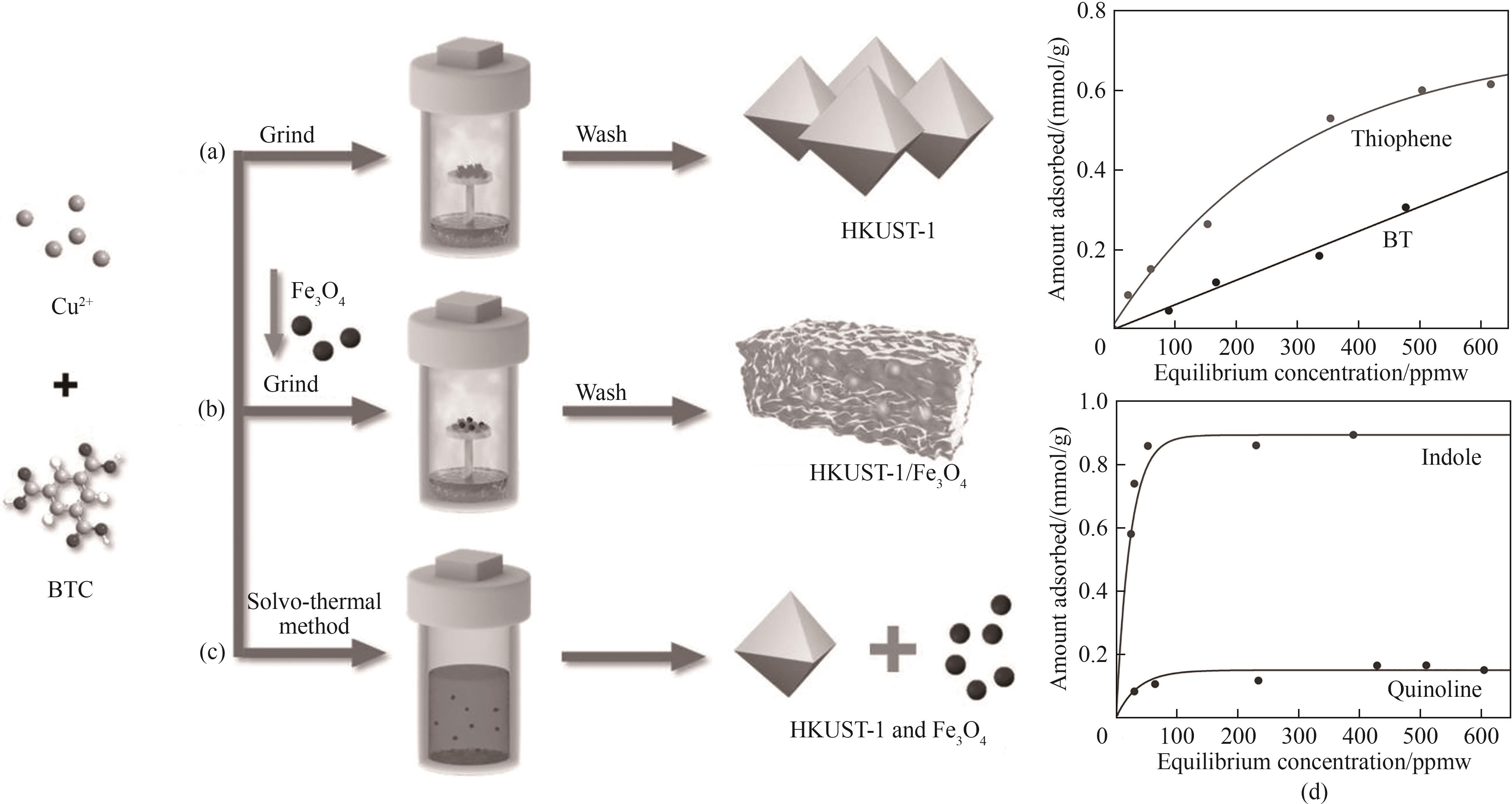

Fig.13 (a) Schematic diagram of synthesis of HKUST-1 by steam-assisted method; (b),(c) Schematic diagram of synthesis of HKUST-1/Fe3O4 composites by steam-assisted and solvothermal methods; (d) Adsorption properties of HKUST-1/Fe3O4 composites for thiophene and benzothiophene (top), indole and quinoline (bottom)[44]

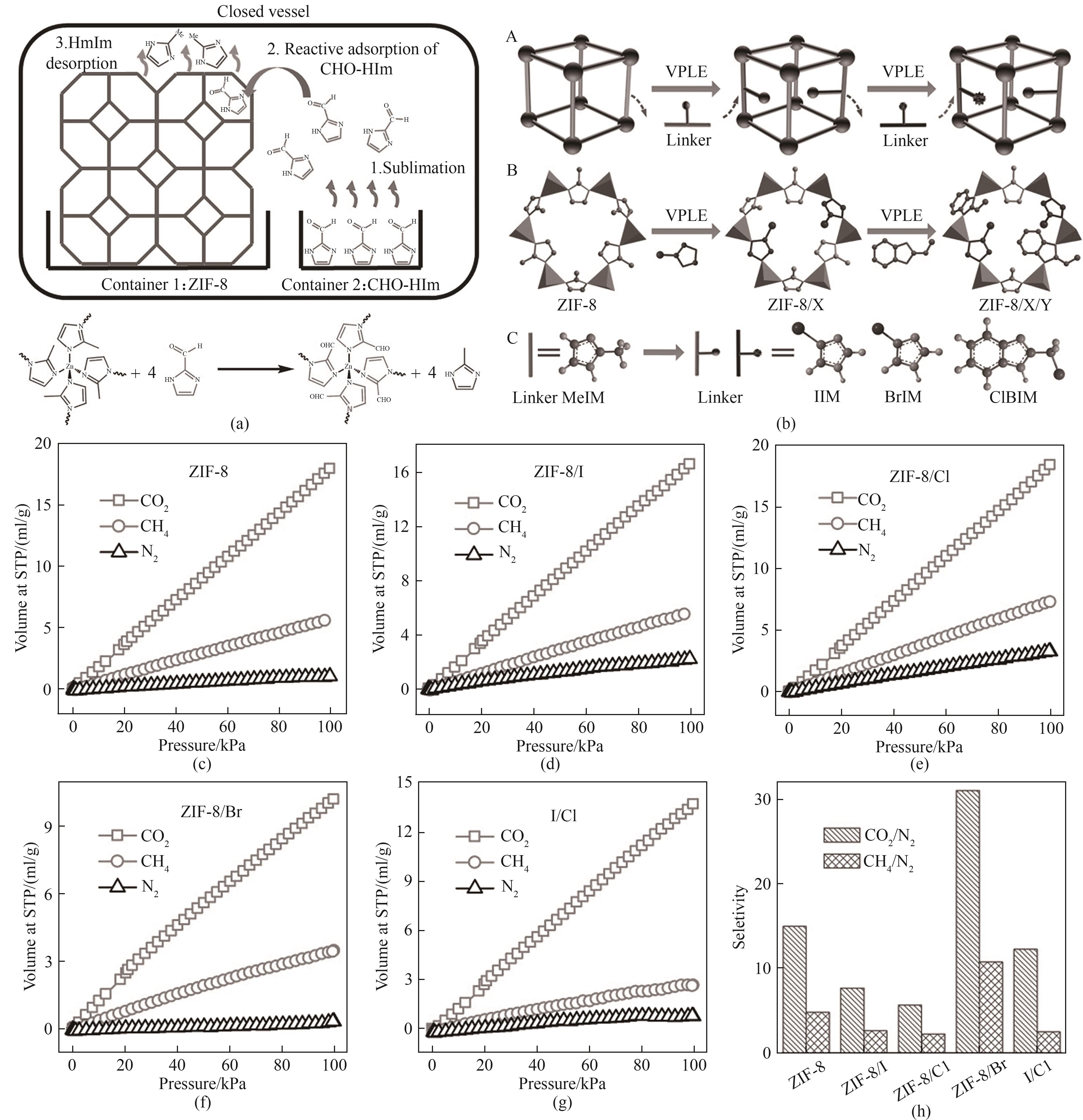

Fig.15 (a) Schematic diagram of the VPLE process[76]; (b) Schematic diagram of multi-connector VPLE strategy; (c) The adsorption isotherm of CO2, CH4 and N2 by ZIF-8; (d) Gas adsorption isotherm of ZIF-8/I; (e) Gas adsorption isotherm of ZIF-8/Cl; (f) Gas adsorption isotherm of ZIF-8/Br; (g) Gas adsorption isotherm of ZIF-8/I/Cl; (h) CO2/N2 and CH4/N2 selectivity of ZIF exchanged between ZIF-8 and the linker[77]

| 1 | Yaghi O M, Li G M, Li H L. Selective binding and removal of guests in a microporous metal-organic framework[J]. Nature, 1995, 378: 703-706. |

| 2 | Yaghi O M, O'Keeffe M, Ockwig N W, et al. Reticular synthesis and the design of new materials[J]. Nature, 2003, 423(6941): 705-714. |

| 3 | Férey G. Hybrid porous solids: past, present, future[J]. Chemical Society Reviews, 2008, 37(1): 191-214. |

| 4 | Dutta S, Walden M, Sinelshchikova A, et al. Cradle-to-gate environmental impact assessment of commercially available metal-organic frameworks manufacturing[J]. Advanced Functional Materials, 2024, 34(52): 2410751. |

| 5 | 崔希利, 邢华斌. 金属有机框架材料分离低碳烃的研究进展[J]. 化工学报, 2018, 69(6): 2339-2352. |

| Cui X L, Xing H B. Separation of light hydrocarbons with metal-organic frameworks[J]. CIESC Journal, 2018, 69(6): 2339-2352. | |

| 6 | 李建惠, 兰天昊, 陈杨, 等. MOF复合材料在气体吸附分离中的研究进展[J]. 化工学报, 2021, 72(1): 167-179. |

| Li J H, Lan T H, Chen Y, et al. Research progress of MOF-based composites for gas adsorption and separation[J]. CIESC Journal, 2021, 72(1): 167-179. | |

| 7 | Zhang L, Yu B, Wang M, et al. Ethane triggered gate-opening in a flexible-robust metal-organic framework for ultra-high purity ethylene purification[J]. Angewandte Chemie International Edition, 2025, 64(7): e202418853. |

| 8 | Feng Y, Yan W, Kang Z X, et al. Thermal treatment optimization of porous MOF glass and polymer for improving gas permeability and selectivity of mixed matrix membranes[J]. Chemical Engineering Journal, 2023, 465: 142873. |

| 9 | Gao Z Z, Li B J, Li Z, et al. Free-standing metal-organic framework membranes made by solvent-free space-confined conversion for efficient H2/CO2 separation[J]. ACS Applied Materials & Interfaces, 2023, 15(15): 19241-19249. |

| 10 | Vikal A, Maurya R, Patel P, et al. Exploring metal-organic frameworks (MOFs) in drug delivery: a concise overview of synthesis approaches, versatile applications, and current challenges[J]. Applied Materials Today, 2024, 41: 102443. |

| 11 | Hou Q Q, Zhou S, Wei Y Y, et al. Balancing the grain boundary structure and the framework flexibility through bimetallic metal-organic framework (MOF) membranes for gas separation[J]. Journal of the American Chemical Society, 2020, 142(21): 9582-9586. |

| 12 | Lan T H, Li L B, Chen Y, et al. Opportunities and critical factors of porous metal-organic frameworks for industrial light olefins separation[J]. Materials Chemistry Frontiers, 2020, 4(7): 1954-1984. |

| 13 | Yang M X, Xiao L F, Chen W T, et al. Recent advances on metal-organic framework-based electrochemical sensors for determination of organic small molecules[J]. Talanta, 2024, 280: 126744. |

| 14 | Zhang Y, Yu X H, Hou Y W, et al. Current research status of MOF materials for catalysis applications[J]. Molecular Catalysis, 2024, 555: 113851. |

| 15 | Li H, Li L B, Lin R B, et al. Porous metal-organic frameworks for gas storage and separation: status and challenges[J]. EnergyChem, 2019, 1(1): 100006. |

| 16 | Felix Sahayaraj A, Joy Prabu H, Maniraj J, et al. Metal-organic frameworks (MOFs): the next generation of materials for catalysis, gas storage, and separation[J]. Journal of Inorganic and Organometallic Polymers and Materials, 2023, 33(7): 1757-1781. |

| 17 | Shi L, Zhong Y L, Cao H H, et al. A hetero-supermolecular-building-block strategy for the assembly of porous (3,12,24)-connected uru metal-organic frameworks[J]. Nature Synthesis, 2024, 3(12): 1560-1566. |

| 18 | Li H L, Eddaoudi M, O’Keeffe M, et al. Design and synthesis of an exceptionally stable and highly porous metal-organic framework[J]. Nature, 1999, 402: 276-279. |

| 19 | Han J L, He X D, Liu J, et al. Determining factors in the growth of MOF single crystals unveiled by in situ interface imaging[J]. Chem, 2022, 8(6): 1637-1657. |

| 20 | Li H, Qin Z, Yang X F, et al. Growth pattern control and nanoarchitecture engineering of metal-organic framework single crystals by confined space synthesis[J]. ACS Central Science, 2022, 8(6): 718-728. |

| 21 | Zhang P, Kang X C, Tao L M, et al. A new route for the rapid synthesis of metal-organic frameworks at room temperature[J]. CCS Chemistry, 2023, 5(6): 1462-1469. |

| 22 | Chen Z J, Wang X J, Noh H, et al. Scalable, room temperature, and water-based synthesis of functionalized zirconium-based metal-organic frameworks for toxic chemical removal[J]. CrystEngComm, 2019, 21(14): 2409-2415. |

| 23 | Mueller U, Schubert M, Teich F, et al. Metal-organic frameworks—prospective industrial applications[J]. Journal of Materials Chemistry, 2006, 16(7): 626-636. |

| 24 | Wu X F, Bao Z B, Yuan B, et al. Microwave synthesis and characterization of MOF-74 (M=Ni, Mg) for gas separation[J]. Microporous and Mesoporous Materials, 2013, 180: 114-122. |

| 25 | Ogura Y, Taniya K, Horie T, et al. Process intensification of synthesis of metal organic framework particles assisted by ultrasound irradiation[J]. Ultrasonics Sonochemistry, 2023, 96: 106443. |

| 26 | Qiu L G, Li Z Q, Wu Y, et al. Facile synthesis of nanocrystals of a microporous metal-organic framework by an ultrasonic method and selective sensing of organoamines[J]. Chemical Communications, 2008(31): 3642-3644. |

| 27 | Bagi S, Yuan S, Rojas-Buzo S, et al. A continuous flow chemistry approach for the ultrafast and low-cost synthesis of MOF-808[J]. Green Chemistry, 2021, 23(24): 9982-9991. |

| 28 | Katsenis A D, Puškarić A, Štrukil V, et al. In situ X-ray diffraction monitoring of a mechanochemical reaction reveals a unique topology metal-organic framework[J]. Nature Communications, 2015, 6: 6662. |

| 29 | Wang C, Zhang F F, Yang J F, et al. Rapid and HF-free synthesis of MIL-100(Cr) via steam-assisted method[J]. Materials Letters, 2019, 252: 286-288. |

| 30 | Taddei M, Casati N, Steitz D A, et al. In situ high-resolution powder X-ray diffraction study of UiO-66 under synthesis conditions in a continuous-flow microwave reactor[J]. CrystEngComm, 2017, 19(23): 3206-3214. |

| 31 | Majano G, Pérez-Ramírez J. Scalable room-temperature conversion of copper(Ⅱ) hydroxide into HKUST-1 (Cu3(btc)2)[J]. Advanced Materials, 2013, 25(7): 1052-1057. |

| 32 | Xu W Y, Dong J X, Li J P, et al. A novel method for the preparation of zeolite ZSM-5[J]. Journal of the Chemical Society, Chemical Communications, 1990(10): 755-756. |

| 33 | Shi Q, Chen Z F, Song Z W, et al. Synthesis of ZIF-8 and ZIF-67 by steam-assisted conversion and an investigation of their tribological behaviors[J]. Angewandte Chemie International Edition, 2011, 50(3): 672-675. |

| 34 | Horcajada P, Surblé S, Serre C, et al. Synthesis and catalytic properties of MIL-100(Fe), an iron(Ⅲ) carboxylate with large pores[J]. Chemical Communications, 2007(27): 2820-2822. |

| 35 | Seo Y K, Yoon J W, Lee J S, et al. Large scale fluorine-free synthesis of hierarchically porous iron(Ⅲ) trimesate MIL-100(Fe) with a zeolite MTN topology[J]. Microporous and Mesoporous Materials, 2012, 157: 137-145. |

| 36 | Ahmed I, Jeon J, Khan N A, et al. Synthesis of a metal-organic framework, iron-benezenetricarboxylate, from dry gels in the absence of acid and salt[J]. Crystal Growth & Design, 2012, 12(12): 5878-5881. |

| 37 | Gökpinar S, Diment T, Janiak C. Environmentally benign dry-gel conversions of Zr-based UiO metal-organic frameworks with high yield and the possibility of solvent re-use[J]. Dalton Transactions, 2017, 46(30): 9895-9900. |

| 38 | Das A K, Vemuri R S, Kutnyakov I, et al. An efficient synthesis strategy for metal-organic frameworks: dry-gel synthesis of MOF-74 framework with high yield and improved performance[J]. Scientific Reports, 2016, 6: 28050. |

| 39 | Wauteraerts N, Tu M, Chanut N, et al. Vapor-assisted synthesis of the MOF-74 metal-organic framework family from zinc, cobalt, and magnesium oxides[J]. Dalton Transactions, 2023, 52(47): 17873-17880. |

| 40 | Kim J, Lee Y R, Ahn W S. Dry-gel conversion synthesis of Cr-MIL-101 aided by grinding: high surface area and high yield synthesis with minimum purification[J]. Chemical Communications, 2013, 49(69): 7647-7649. |

| 41 | Férey G, Mellot-Draznieks C, Serre C, et al. A chromium terephthalate-based solid with unusually large pore volumes and surface area[J]. Science, 2005, 309(5743): 2040-2042. |

| 42 | Latroche M, Surblé S, Serre C, et al. Hydrogen storage in the giant-pore metal-organic frameworks MIL-100 and MIL-101[J]. Angewandte Chemie International Edition, 2006, 45(48): 8227-8231. |

| 43 | Horcajada P, Serre C, Vallet-Regí M, et al. Metal-organic frameworks as efficient materials for drug delivery[J]. Angewandte Chemie International Edition, 2006, 45(36): 5974-5978. |

| 44 | Tan P, Xie X Y, Liu X Q, et al. Fabrication of magnetically responsive HKUST-1/Fe3O4 composites by dry gel conversion for deep desulfurization and denitrogenation[J]. Journal of Hazardous Materials, 2017, 321: 344-352. |

| 45 | Chen Y, Yang C Y, Wang X Q, et al. Vapor phase solvents loaded in zeolite as the sustainable medium for the preparation of Cu-BTC and ZIF-8[J]. Chemical Engineering Journal, 2017, 313: 179-186. |

| 46 | Liu Y T, Chen H, Li T, et al. Balancing the crystallinity and film formation of metal-organic framework membranes through in situ modulation for efficient gas separation[J]. Angewandte Chemie International Edition, 2023, 62(37): e202309095. |

| 47 | Wu M M, Sun Y W, Ji T T, et al. Fabrication of water-stable MOF-808 membrane for efficient salt/dye separation[J]. Journal of Membrane Science, 2023, 686: 122023. |

| 48 | Shah M, McCarthy M C, Sachdeva S, et al. Current status of metal-organic framework membranes for gas separations: promises and challenges[J]. Industrial & Engineering Chemistry Research, 2012, 51(5): 2179-2199. |

| 49 | Luo L X, Hou L X, Cui X P, et al. Self-condensation-assisted chemical vapour deposition growth of atomically two-dimensional MOF single-crystals[J]. Nature Communications, 2024, 15(1): 3618. |

| 50 | Fu M, Liu Y L, Lyu Q, et al. Sustainable vapor-phase deposition and applications of MOF films and membranes: a critical review[J]. Separation and Purification Technology, 2025, 356: 129883. |

| 51 | Choe M, Koo J Y, Park I, et al. Chemical vapor deposition of edge-on oriented 2D conductive metal-organic framework thin films[J]. Journal of the American Chemical Society, 2022, 144(37): 16726-16731. |

| 52 | Hachem K, Ansari M J, Saleh R O, et al. Methods of chemical synthesis in the synthesis of nanomaterial and nanoparticles by the chemical deposition method: a review[J]. BioNanoScience, 2022, 12(3): 1032-1057. |

| 53 | Salmi L D, Heikkilä M J, Puukilainen E, et al. Studies on atomic layer deposition of MOF-5 thin films[J]. Microporous and Mesoporous Materials, 2013, 182: 147-154. |

| 54 | Stassen I, Styles M, Grenci G, et al. Chemical vapour deposition of zeolitic imidazolate framework thin films[J]. Nature Materials, 2016, 15(3): 304-310. |

| 55 | Stassin T, Rodríguez-Hermida S, Schrode B, et al. Vapour-phase deposition of oriented copper dicarboxylate metal-organic framework thin films[J]. Chemical Communications, 2019, 55(68): 10056-10059. |

| 56 | Rodríguez-Hermida S, Kravchenko D E, Wauteraerts N, et al. Vapor-assisted powder synthesis and oriented MOF-CVD thin films of the metal-organic framework HKUST-1[J]. Inorganic Chemistry, 2022, 61(45): 17927-17931. |

| 57 | Stassin T, Stassen I, Marreiros J, et al. Solvent-free powder synthesis and MOF-CVD thin films of the large-pore metal-organic framework MAF-6[J]. Chemistry of Materials, 2020, 32(5): 1784-1793. |

| 58 | Mähringer A, Jakowetz A C, Rotter J M, et al. Oriented thin films of electroactive triphenylene catecholate-based two-dimensional metal-organic frameworks[J]. ACS Nano, 2019, 13(6): 6711-6719. |

| 59 | Medishetty R, Zhang Z J, Sadlo A, et al. Fabrication of zinc-dicarboxylate- and zinc-pyrazolate-carboxylate-framework thin films through vapour-solid deposition[J]. Dalton Transactions, 2018, 47(40): 14179-14183. |

| 60 | Huang J K, Saito N, Cai Y C, et al. Steam-assisted chemical vapor deposition of zeolitic imidazolate framework[J]. ACS Materials Letters, 2020, 2(5): 485-491. |

| 61 | Tu M, Kravchenko D E, Xia B Z, et al. Template-mediated control over polymorphism in the vapor-assisted formation of zeolitic imidazolate framework powders and films[J]. Angewandte Chemie International Edition, 2021, 60(14): 7553-7558. |

| 62 | Kim K J, Culp J T, Ohodnicki P R, et al. Synthesis of high-quality Mg-MOF-74 thin films via vapor-assisted crystallization[J]. ACS Applied Materials & Interfaces, 2021, 13(29): 35223-35231. |

| 63 | Gschwind W, McCarthy B D, Suremann N F, et al. The influence of water in the vapor-assisted conversion synthesis of UiO-67 MOF thin films[J]. European Journal of Inorganic Chemistry, 2023, 26(27): e202300216. |

| 64 | 杨东晓, 熊启钊, 王毅, 等. 多级孔MOF的制备及其吸附分离应用研究进展[J]. 化工进展, 2024, 43(4): 1882-1896. |

| Yang D X, Xiong Q Z, Wang Y, et al. Progress in the preparation of hierarchically porous MOF and applications in adsorption and separation[J]. Chemical Industry and Engineering Progress, 2024, 43(4): 1882-1896. | |

| 65 | Koo J, Hwang I C, Yu X J, et al. Hollowing out MOFs: hierarchical micro-and mesoporous MOFs with tailorable porosity via selective acid etching[J]. Chemical Science, 2017, 8(10): 6799-6803. |

| 66 | Xi D Y, Sun Q M, Xu J, et al. In situ growth-etching approach to the preparation of hierarchically macroporous zeolites with high MTO catalytic activity and selectivity[J]. Journal of Materials Chemistry A, 2014, 2(42): 17994-18004. |

| 67 | McNamara N D, Hicks J C. Chelating agent-free, vapor-assisted crystallization method to synthesize hierarchical microporous/mesoporous MIL-125 (Ti)[J]. ACS Applied Materials & Interfaces, 2015, 7(9): 5338-5346. |

| 68 | Hou C C, Wang Y, Zou L L, et al. A gas-steamed MOF route to P-doped open carbon cages with enhanced Zn-ion energy storage capability and ultrastability[J]. Advanced Materials, 2021, 33(31): e2101698. |

| 69 | Huang H L, Sun Y X, Jia X M, et al. Air-steam etched construction of hierarchically porous metal-organic frameworks[J]. Chinese Journal of Chemistry, 2021, 39(6): 1538-1544. |

| 70 | Chen Y, Dai Y H, Xiong Q Z, et al. Synthesis of hierarchically porous Cu-BTC through phase-controlled etching[J]. Chemical Engineering Science, 2024, 297: 120293. |

| 71 | 代艳辉, 熊启钊, 房强, 等. 原位蒸汽辅助法用于一步制备多级孔Cu-BTC[J]. 化工学报, 2024, 75(9): 3329-3337. |

| Dai Y H, Xiong Q Z, Fang Q, et al. In situ steam-assisted method for one-step synthesis of hierarchically porous Cu-BTC[J]. CIESC Journal, 2024, 75(9): 3329-3337. | |

| 72 | Cohen S M. Postsynthetic methods for the functionalization of metal-organic frameworks[J]. Chemical Reviews, 2012, 112(2): 970-1000. |

| 73 | Liu L J, Li L, Ziebel M E, et al. Metal-diamidobenzoquinone frameworks via post-synthetic linker exchange[J]. Journal of the American Chemical Society, 2020, 142(10): 4705-4713. |

| 74 | Su P C, Tu M, Ameloot R, et al. Vapor-phase processing of metal-organic frameworks[J]. Accounts of Chemical Research, 2022, 55(2): 186-196. |

| 75 | Park K S, Ni Z, Côté A P, et al. Exceptional chemical and thermal stability of zeolitic imidazolate frameworks[J]. Proceedings of the National Academy of Sciences of the United States of America, 2006, 103(27): 10186-10191. |

| 76 | Marreiros J, Van Dommelen L, Fleury G, et al. Vapor-phase linker exchange of the metal-organic framework ZIF-8: a solvent-free approach to post-synthetic modification[J]. Angewandte Chemie International Edition, 2019, 58(51): 18471-18475. |

| 77 | Wu W F, Su J Y, Jia M M, et al. Vapor-phase linker exchange of metal-organic frameworks[J]. Science Advances, 2020, 6(18): eaax7270. |

| 78 | Kim I S, Ahn S, Vermeulen N A, et al. The synthesis science of targeted vapor-phase metal-organic framework postmodification[J]. Journal of the American Chemical Society, 2020, 142(1): 242-250. |

| 79 | De S, Quan G C, Gikonyo B, et al. Vapor-phase infiltration inside a microporous porphyrinic metal-organic framework for postsynthesis modification[J]. Inorganic Chemistry, 2020, 59(14): 10129-10137. |

| [1] | Haofan ZHAO, Haojie REN, Zongkai LIU, Guanying DONG, Yatao ZHANG. Research progress of MOFs glass membranes in gas separation applications [J]. CIESC Journal, 2025, 76(5): 2042-2054. |

| [2] | Dandong NING, Jianhui LI, Yang CHEN, Jinping LI, Libo LI. Study on flocculation techniques in the large-scale production of MIL-101(Cr) [J]. CIESC Journal, 2025, 76(5): 2327-2336. |

| [3] | Yaohui ZHANG, Yujie BAN, Weishen YANG. Vapor-phase synthesis and post-synthetic modification of metal-organic framework membranes [J]. CIESC Journal, 2025, 76(5): 2070-2086. |

| [4] | Junde ZHAO, Aiguo ZHOU, Yanlin CHEN, Jiale ZHENG, Tianshu GE. Current status of energy consumption of adsorption CO2 direct air capture [J]. CIESC Journal, 2025, 76(4): 1375-1390. |

| [5] | Wen CHAN, Wan YU, Gang WANG, Huashan SU, Fenxia HUANG, Tao HU. Thermodynamic and economic analyses and dual-objective optimization of Allam cycle with improved regenerator layout [J]. CIESC Journal, 2025, 76(4): 1680-1692. |

| [6] | Yihao JIN, Junxin LUO, Zhangmao HU, Wei WANG, Qian YIN. Experimental investigation on hydrophilic functionalized MgSO4/expanded vermiculite composites for water adsorption and heat storage [J]. CIESC Journal, 2025, 76(4): 1852-1862. |

| [7] | Haiqian ZHAO, Fang CHEN, Tao CHEN, Jianwei GUO, Wenjing LIN, Chufen YANG. Folate-modified pH-responsive copolymer mixed micelles for anticancer drug delivery [J]. CIESC Journal, 2025, 76(4): 1702-1710. |

| [8] | Zhenglei HE, Dingding HU. Multi-objective optimization of papermaking wastewater based on multi-agent reinforcement learning [J]. CIESC Journal, 2025, 76(4): 1617-1634. |

| [9] | Jingrun LI, Siyu YANG, Qinghui LIU, An PAN, Jiayue WANG, Xiaogui FU, Hao YU. Analysis of multiple operating strategies for large-scale wind power coupled with thermal power for hydrogen production under various scenarios [J]. CIESC Journal, 2025, 76(3): 1191-1206. |

| [10] | Yanjiao XU, Linjin LOU, Zhuoqin FAN, Haomiao ZHANG, Jingdai WANG, Yongrong YANG. Research progress on modification technology of methylaluminoxane [J]. CIESC Journal, 2025, 76(2): 454-465. |

| [11] | Xin YING, Miao DU, Pengju PAN, Guorong SHAN. Synthesis, structure and properties of high refrective index polythiourethane [J]. CIESC Journal, 2025, 76(2): 858-867. |

| [12] | Fei CHANG, Renbo SHI, Shihua LIU, Wenqian GAO, Yifei WANG, Bin ZHENG, Yixuan JIAO, Xingying LAN, Chunming XU, Yehua HAN. Product life cycle carbon footprint evaluation for petrochemical industry [J]. CIESC Journal, 2025, 76(2): 419-437. |

| [13] | Mengfan YIN, Qian WANG, Tao ZHENG, Kui JI, Shaogui WANG, Hui GUO, Zhiqiang LIN, Rui ZHANG, Hui SUN, Haiyan LIU, Zhichang LIU, Chunming XU, Xianghai MENG, Yueping WANG. Process design of 10000 t industrial demonstration of hydrogen production from renewable energy electrolytic water - low temperature and low pressure ammonia synthesis [J]. CIESC Journal, 2025, 76(2): 825-834. |

| [14] | Shiping SONG, Xiaoling TANG, Renchao ZHENG. Molecular modification of glutathione bifunctional synthase and its application [J]. CIESC Journal, 2024, 75(S1): 251-258. |

| [15] | Yanhui DAI, Qizhao XIONG, Qiang FANG, Dongxiao YANG, Yi WANG, Yang CHEN, Jinping LI, Libo LI. In situ steam-assisted method for one-step synthesis of hierarchically porous Cu-BTC [J]. CIESC Journal, 2024, 75(9): 3329-3337. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||