CIESC Journal ›› 2025, Vol. 76 ›› Issue (7): 3125-3136.DOI: 10.11949/0438-1157.20241515

• Reviews and monographs • Next Articles

Mei ZHAO( ), Yuxin GAN, Shaolei ZHAO, Ling YANG, Tingjie WANG(

), Yuxin GAN, Shaolei ZHAO, Ling YANG, Tingjie WANG( )

)

Received:2024-12-16

Revised:2025-04-12

Online:2025-08-13

Published:2025-07-25

Contact:

Tingjie WANG

通讯作者:

王亭杰

作者简介:赵美(2000—),女,博士研究生,zhao-m22@mails.tsinghua.edu.cn

CLC Number:

Mei ZHAO, Yuxin GAN, Shaolei ZHAO, Ling YANG, Tingjie WANG. Research progress on organic modifications of silica nanoparticles and reinforcing mechanism in silicone rubber[J]. CIESC Journal, 2025, 76(7): 3125-3136.

赵美, 甘雨欣, 赵绍磊, 杨令, 王亭杰. 硅橡胶用纳米二氧化硅表面有机修饰及补强机理研究进展[J]. 化工学报, 2025, 76(7): 3125-3136.

Add to citation manager EndNote|Ris|BibTeX

| 分类方法 | 硅橡胶类型 |

|---|---|

| 单体类型 | 二甲基硅橡胶(MQ) 甲基乙烯基硅橡胶(VMQ) 甲基乙烯基苯基硅橡胶(PVMQ) 甲基乙烯基三氟丙基硅橡胶(FVMQ) |

| 硫化类型 | 高温硫化硅橡胶(HTV) 单组分室温硫化硅橡胶(RTV1) 双组分室温硫化硅橡胶(RTV2) 液体硅橡胶(LSR) |

| 硫化机理 | 缩合型硅橡胶 加成型硅橡胶 |

| 应用领域 | 耐高温型硅橡胶 低压缩永久变形型硅橡胶 耐溶剂型硅橡胶 阻燃型硅橡胶 导电型硅橡胶 |

Table 1 Classification of silicone rubber

| 分类方法 | 硅橡胶类型 |

|---|---|

| 单体类型 | 二甲基硅橡胶(MQ) 甲基乙烯基硅橡胶(VMQ) 甲基乙烯基苯基硅橡胶(PVMQ) 甲基乙烯基三氟丙基硅橡胶(FVMQ) |

| 硫化类型 | 高温硫化硅橡胶(HTV) 单组分室温硫化硅橡胶(RTV1) 双组分室温硫化硅橡胶(RTV2) 液体硅橡胶(LSR) |

| 硫化机理 | 缩合型硅橡胶 加成型硅橡胶 |

| 应用领域 | 耐高温型硅橡胶 低压缩永久变形型硅橡胶 耐溶剂型硅橡胶 阻燃型硅橡胶 导电型硅橡胶 |

| 修饰剂 | 结构式 | 应用硅橡胶与研究目标 | 主要反应条件 |

|---|---|---|---|

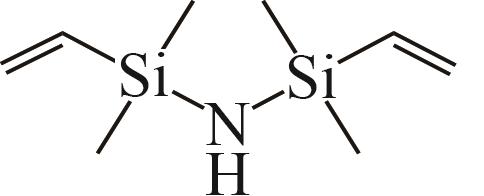

| 六甲基二硅氮烷(HMDS)(CAS: 999-97-3) |  | 室温硫化硅橡胶;降低黏度 甲基乙烯基硅橡胶;优化电气性能、提升力学性能、提高介电常数 甲基乙烯基苯基硅橡胶;提升力学性能 | 干法、100℃、2 h[ 乙醇、70℃、5 h[ 乙醇、25℃、24 h、超临界干燥[ 乙醇、原位改性、60℃、4 h[ 醇水溶液、25℃、2 h[ |

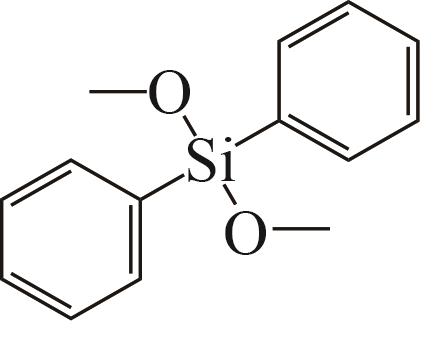

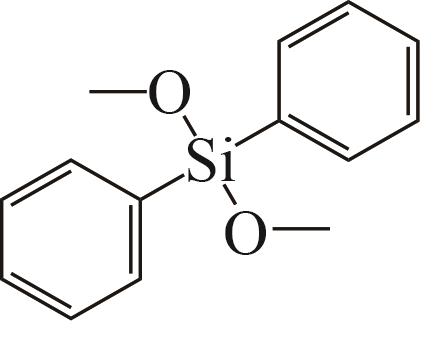

| 二苯基二甲氧基硅烷(DDS)(CAS: 6843-66-9) |  | 硅橡胶;提高热稳定性 | 水、酸性(定量盐酸)、60℃、2 h[ |

| 硬脂酸(SA)(CAS: 57-11-4) |  | 单组分室温硫化硅橡胶;优化力学、电气性能 | 乙酸乙酯、25℃、1 h[ |

| 十六烷基三甲氧基硅烷(HDTMS)(CAS: 16415-12-6) |  | 甲基乙烯基硅橡胶;优化力学性能 | 甲苯、110℃、6 h[ |

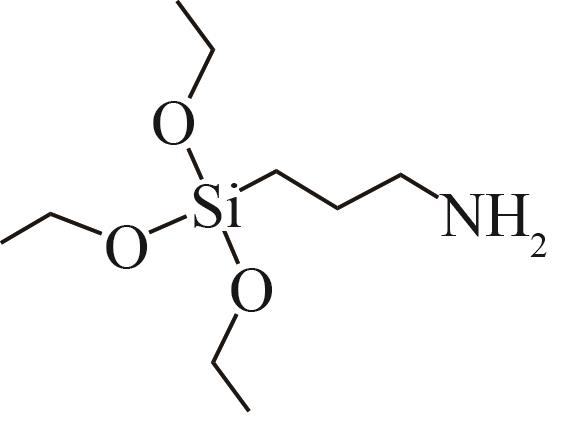

3-氨丙基三乙氧基硅烷(APTES)(CAS: 919-30-2) γ-缩水甘油醚氧丙基三甲氧基硅烷(KH560)(CAS: 2530- 83-8) |

| 室温硫化硅橡胶;提升热性能、电性能、力学性能 | Step 1(APTES):醇水溶液、100℃、15 min; Step 2(KH560):甲苯、80℃、 4 h、N2[ |

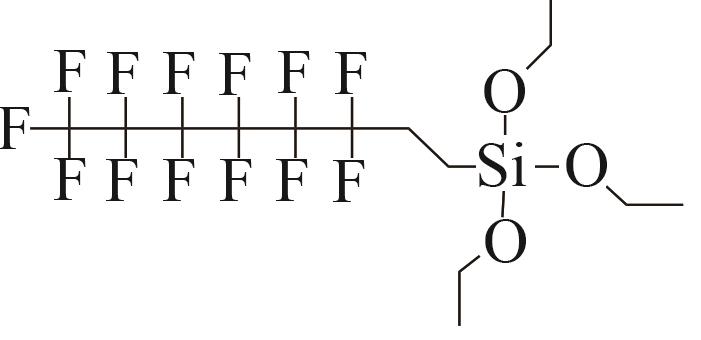

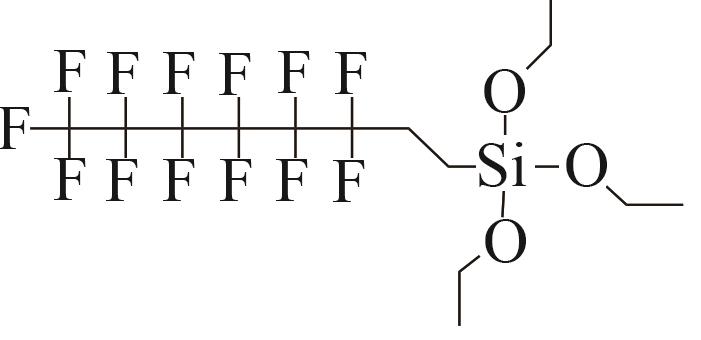

| 十三氟辛基三乙氧基硅烷(PFTS)(CAS: 51851-37-7) |  | 甲基乙烯基硅橡胶;提升低温抗性 | 醇水溶液、pH=3、70℃、4 h[ |

| 四苯基苯三乙氧基硅烷(TPHHS) |  | 高温硫化硅橡胶;提升耐辐射性、力学性能 | 甲苯、25℃、12 h[ |

Table 2 Modification examples of modifiers containing dispersible groups

| 修饰剂 | 结构式 | 应用硅橡胶与研究目标 | 主要反应条件 |

|---|---|---|---|

| 六甲基二硅氮烷(HMDS)(CAS: 999-97-3) |  | 室温硫化硅橡胶;降低黏度 甲基乙烯基硅橡胶;优化电气性能、提升力学性能、提高介电常数 甲基乙烯基苯基硅橡胶;提升力学性能 | 干法、100℃、2 h[ 乙醇、70℃、5 h[ 乙醇、25℃、24 h、超临界干燥[ 乙醇、原位改性、60℃、4 h[ 醇水溶液、25℃、2 h[ |

| 二苯基二甲氧基硅烷(DDS)(CAS: 6843-66-9) |  | 硅橡胶;提高热稳定性 | 水、酸性(定量盐酸)、60℃、2 h[ |

| 硬脂酸(SA)(CAS: 57-11-4) |  | 单组分室温硫化硅橡胶;优化力学、电气性能 | 乙酸乙酯、25℃、1 h[ |

| 十六烷基三甲氧基硅烷(HDTMS)(CAS: 16415-12-6) |  | 甲基乙烯基硅橡胶;优化力学性能 | 甲苯、110℃、6 h[ |

3-氨丙基三乙氧基硅烷(APTES)(CAS: 919-30-2) γ-缩水甘油醚氧丙基三甲氧基硅烷(KH560)(CAS: 2530- 83-8) |

| 室温硫化硅橡胶;提升热性能、电性能、力学性能 | Step 1(APTES):醇水溶液、100℃、15 min; Step 2(KH560):甲苯、80℃、 4 h、N2[ |

| 十三氟辛基三乙氧基硅烷(PFTS)(CAS: 51851-37-7) |  | 甲基乙烯基硅橡胶;提升低温抗性 | 醇水溶液、pH=3、70℃、4 h[ |

| 四苯基苯三乙氧基硅烷(TPHHS) |  | 高温硫化硅橡胶;提升耐辐射性、力学性能 | 甲苯、25℃、12 h[ |

| 修饰剂 | 结构式 | 应用硅橡胶与研究目标 | 主要反应条件 |

|---|---|---|---|

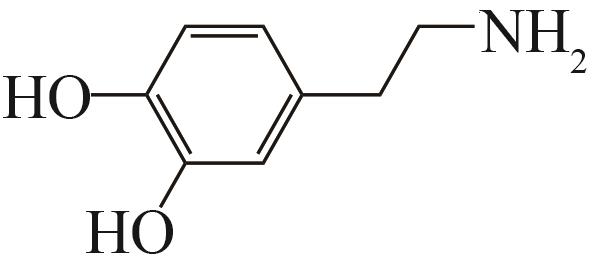

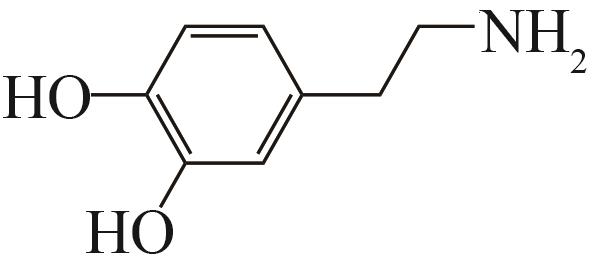

| 多巴胺(PDA)(CAS: 86389-83-5) |  | 甲基乙烯基硅橡胶;制备高导电硅橡胶 液体硅橡胶;防漏、提升力学性能 | Tris缓冲溶液、25℃、12 h[ Tris缓冲溶液、25℃、24 h[ |

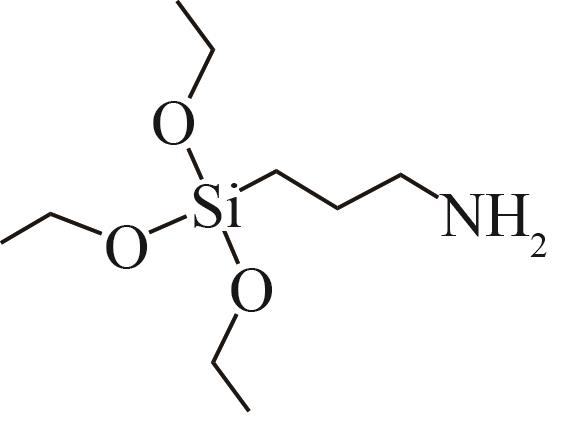

| 3-氨丙基三乙氧基硅烷(KH550)(CAS: 919-30-2) |  | 甲基硅橡胶;提升力学性能、传热性能、热稳定性 室温硫化硅橡胶;提升耐腐蚀性、力学性能 室温硫化苯基硅橡胶;优化介电常数和热导率 甲基氯丙基硅橡胶;提升热稳定性 | 醇∶水=1∶1、60℃、4 h[ 醇∶水=3∶1、70℃、3 h[ 乙醇、80℃、3 h[ 甲苯、氩气、25℃、回流2 h[ |

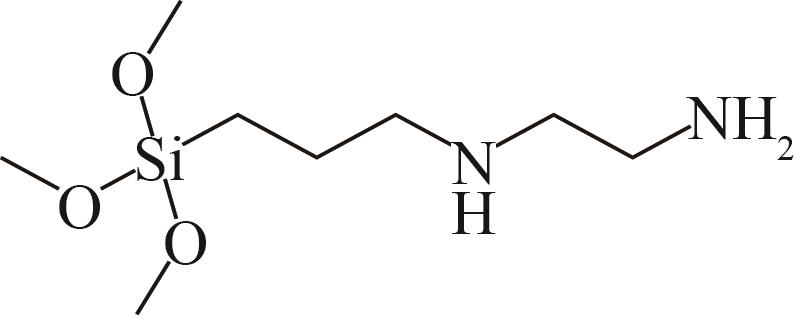

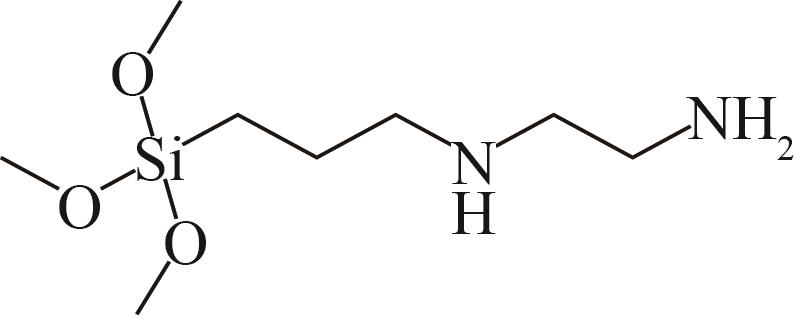

| N-(β-氨乙基)-3-氨丙基三甲氧基硅烷(KH792)(CAS: 1760-24-3) |  | 双组分室温硫化硅橡胶;提升热稳定性、 力学性能和导热性 | 水、60℃、12 h[ |

Table 3 Modification examples of modifiers containing amino functional group

| 修饰剂 | 结构式 | 应用硅橡胶与研究目标 | 主要反应条件 |

|---|---|---|---|

| 多巴胺(PDA)(CAS: 86389-83-5) |  | 甲基乙烯基硅橡胶;制备高导电硅橡胶 液体硅橡胶;防漏、提升力学性能 | Tris缓冲溶液、25℃、12 h[ Tris缓冲溶液、25℃、24 h[ |

| 3-氨丙基三乙氧基硅烷(KH550)(CAS: 919-30-2) |  | 甲基硅橡胶;提升力学性能、传热性能、热稳定性 室温硫化硅橡胶;提升耐腐蚀性、力学性能 室温硫化苯基硅橡胶;优化介电常数和热导率 甲基氯丙基硅橡胶;提升热稳定性 | 醇∶水=1∶1、60℃、4 h[ 醇∶水=3∶1、70℃、3 h[ 乙醇、80℃、3 h[ 甲苯、氩气、25℃、回流2 h[ |

| N-(β-氨乙基)-3-氨丙基三甲氧基硅烷(KH792)(CAS: 1760-24-3) |  | 双组分室温硫化硅橡胶;提升热稳定性、 力学性能和导热性 | 水、60℃、12 h[ |

| 修饰剂 | 结构式 | 应用硅橡胶与研究目标 | 主要反应条件 |

|---|---|---|---|

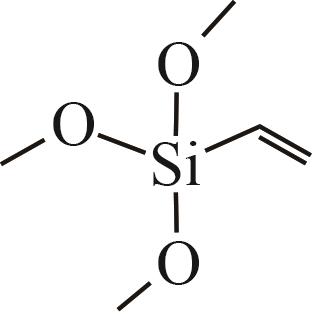

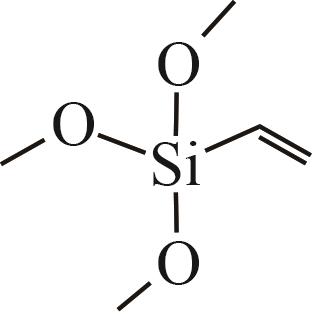

| 乙烯基三甲氧基硅烷(VTMS)(CAS: 2768-02-7) |  | 液体硅橡胶;调控液体硅橡胶与不同表面附着 二甲基硅橡胶;提升热稳定性、刚度 二甲基硅橡胶;提升橡胶膜的分离系数 | 醇水溶液30℃、24 h水解;25℃、5 min反应[ THF、邻苯二甲酸正丁酯催化、25℃、3 h[ 丙酮、50℃、3 h[ |

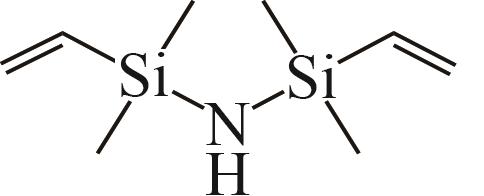

| 四甲基二乙烯基二硅氧烷(TMDVS)(CAS: 2627-95-4) |  | 二甲基乙烯基硅橡胶;提升热稳定性、电导率、力学强度 | 乙醇、氨水催化、80℃、2 h[ |

γ-甲基丙烯酰氧丙基三甲氧基 硅烷(MPS)(CAS: 2530-85-0) |  | 加成型液体硅橡胶;提升机械强度 加成型室温硫化硅橡胶;制备高疏水硅橡胶复合微球 | 醇水、25℃、5 h、氨水催化[ 乙醇∶水=6∶1、pH=4、70℃、2 h[ |

| 乙烯基三(β-甲氧基乙氧基)硅烷(A172)(CAS: 1067-53-4) |  | 室温硫化硅橡胶;提升介电常数 | 乙醇、160℃、6 h[ |

Table 4 Modification examples of modifiers containing double bond functional group

| 修饰剂 | 结构式 | 应用硅橡胶与研究目标 | 主要反应条件 |

|---|---|---|---|

| 乙烯基三甲氧基硅烷(VTMS)(CAS: 2768-02-7) |  | 液体硅橡胶;调控液体硅橡胶与不同表面附着 二甲基硅橡胶;提升热稳定性、刚度 二甲基硅橡胶;提升橡胶膜的分离系数 | 醇水溶液30℃、24 h水解;25℃、5 min反应[ THF、邻苯二甲酸正丁酯催化、25℃、3 h[ 丙酮、50℃、3 h[ |

| 四甲基二乙烯基二硅氧烷(TMDVS)(CAS: 2627-95-4) |  | 二甲基乙烯基硅橡胶;提升热稳定性、电导率、力学强度 | 乙醇、氨水催化、80℃、2 h[ |

γ-甲基丙烯酰氧丙基三甲氧基 硅烷(MPS)(CAS: 2530-85-0) |  | 加成型液体硅橡胶;提升机械强度 加成型室温硫化硅橡胶;制备高疏水硅橡胶复合微球 | 醇水、25℃、5 h、氨水催化[ 乙醇∶水=6∶1、pH=4、70℃、2 h[ |

| 乙烯基三(β-甲氧基乙氧基)硅烷(A172)(CAS: 1067-53-4) |  | 室温硫化硅橡胶;提升介电常数 | 乙醇、160℃、6 h[ |

| [1] | 康新尉, 陈乐, 陈凤, 等. SiO2/硅橡胶复合体系填料网络的形成与结构表征[J]. 西南科技大学学报, 2020, 35(2): 55-62. |

| Kang X W, Chen L, Chen F, et al. Formation and structural characterization of filler network in SiO2/silicone rubber composites system[J]. Journal of Southwest University of Science and Technology, 2020, 35(2): 55-62. | |

| [2] | Li Q G, Huang X J, Liu H, et al. Preparation and properties of room temperature vulcanized silicone rubber based on rosin-grafted polydimethylsiloxane[J]. RSC Advances, 2018, 8(26): 14684-14693. |

| [3] | Lin Y, Liu Y H, Wu K N, et al. Crystal structure dependent tensile properties of silicone rubber: influence of aluminium hydroxide[J]. Polymer Testing, 2022, 113: 107679. |

| [4] | Gu B, Pu G H, Ding B N, et al. Improved interfacial bonding strength of silicone rubber/carbon fiber modified by dopamine[J]. Polymer Composites, 2022, 43(10): 6975-6986. |

| [5] | Li D L, Dong L M, Chen Y, et al. Thermally conductive and antistatic properties of silicone rubber reinforced by the modified graphene oxide[J]. Polymers, 2022, 14(21): 4703. |

| [6] | Zhao X F, Han J R, Pu L, et al. Study on the influence of SiO2 on silicone rubber material used in cable accessories[J]. Journal of Physics: Conference Series, 2022, 2404(1): 012006. |

| [7] | 李彬, 王海燕, 张印民, 等. 硅橡胶的共混改性与应用研究进展[J]. 山东化工, 2023, 52(22): 117-120. |

| Li B, Wang H Y, Zhang Y M, et al. Research progress on blending modification and application of silicone rubber[J]. Shandong Chemical Industry, 2023, 52(22): 117-120. | |

| [8] | Han R J, Li Y L, Zhu Q S, et al. Research on the preparation and thermal stability of silicone rubber composites: a review[J]. Composites Part C: Open Access, 2022, 8: 100249. |

| [9] | Zhao X W, Zang C G, Sun Y L, et al. Borosiloxane oligomers for improving adhesion of addition-curable liquid silicone rubber with epoxy resin by surface treatment[J]. Journal of Materials Science, 2018, 53(2): 1167-1177. |

| [10] | Sanderson R T. Radical reorganization and bond energies in organic molecules[J]. The Journal of Organic Chemistry, 1982, 47(20): 3835-3839. |

| [11] | Du Y, Wu T, Xie H, et al. One-step laser etching of a bionic hierarchical structure on a silicone rubber surface with thermal and acid/alkali resistance and tunable wettability[J]. Soft Matter, 2022, 18(17): 3412-3421. |

| [12] | Peng J J, Wang G, Zhang Y. Synergistic effect of multifunctional POSS and carbon nanotubes on mechanical properties and thermal stability of silicone rubber composites[J]. Polymer Composites, 2024, 45(15): 14358-14370. |

| [13] | Guo Y Q, Qiu H, Ruan K P, et al. Flexible and insulating silicone rubber composites with sandwich structure for thermal management and electromagnetic interference shielding[J]. Composites Science and Technology, 2022, 219: 109253. |

| [14] | Govindan K, Ramabalan S, Vishvanathperumal S. Enhancement of mechanical performance and swelling resistance in silicone rubber through reinforcement with γ-methacryloxypropyltrimethoxysilane-modified halloysite nanotubes[J]. Journal of Inorganic and Organometallic Polymers and Materials, 2024, 34(5): 2242-2259. |

| [15] | Li J H. Research status and development trend of ceramifiable silicone rubber composites: a brief review[J]. Materials Research Express, 2022, 9(1): 012001. |

| [16] | Kumar V, Parvin N, Park S S, et al. Review on cutting-edge innovations in carbon nanomaterials reinforced silicone rubber composites for flexible electronics and healthcare devices[J]. ACS Applied Polymer Materials, 2024, 6(23): 14235-14259. |

| [17] | Kumar V, Alam M N, Park S S. Review of recent progress on silicone rubber composites for multifunctional sensor systems[J]. Polymers, 2024, 16(13): 1841. |

| [18] | 林森, 凤仪, 查海波, 等. 硅橡胶填充泡沫铝层合管的压缩和吸能性能[J]. 中国有色金属学报, 2007, (10): 1672-1677. |

| Lin S, Feng Y, Zha H B, et al. Compression capability and energy absorption of foam aluminum cylinder sandwich with silicone rubber[J]. The Chinese Journal of Nonferrous Metals, 2007, 17(10): 1672-1677. | |

| [19] | Shit S C, Shah P. A review on silicone rubber[J]. National Academy Science Letters, 2013, 36(4): 355-365. |

| [20] | Salon M B, Gerbaud G, Abdelmouleh M, et al. Studies of interactions between silane coupling agents and cellulose fibers with liquid and solid-state NMR[J]. Magnetic Resonance in Chemistry, 2007, 45(6): 473-483. |

| [21] | Zheng S J, Liang S, Chen Y, et al. Hyperbranched silicone MDTQ tack promoters[J]. Molecules, 2019, 24(22): 4133. |

| [22] | Gibbs G V, Hamil M M, Louisnathan S J, et al. Correlations between Si—O bond length, Si—O—Si angle and bond overlap populations calculated using extended hükel molecular orbital theory[J]. American Mineralogist, 1972, 57(11/12): 1578-1613. |

| [23] | Zhu L, Zhao S G, Zhang C, et al. Effects of chain structure on damping property and local dynamics of phenyl silicone rubber: insights from experiment and molecular simulation[J]. Polymer Testing, 2021, 93: 106885. |

| [24] | Zhu Q Q, Wang Z H, Zeng H, et al. Effects of graphene on various properties and applications of silicone rubber and silicone resin[J]. Composites Part A: Applied Science and Manufacturing, 2021, 142: 106240. |

| [25] | Shui Y, Huang L Z, Wei C S, et al. How the silica determines properties of filled silicone rubber by the formation of filler networking and bound rubber[J]. Composites Science and Technology, 2021, 215: 109024. |

| [26] | Yoon B, Kim J Y, Hong U, et al. Dynamic viscoelasticity of silica-filled styrene-butadiene rubber/polybutadiene rubber (SBR/BR) elastomer composites[J]. Composites Part B: Engineering, 2020, 187: 107865. |

| [27] | Hoshikawa Y, Kawaguchi R, Nomura K, et al. Quantitative analysis of the formation mechanism of tightly bound rubber by using carbon-coated alumina nanoparticles as a model filler[J]. Carbon, 2021, 173: 870-879. |

| [28] | Hoshikawa Y, An B G, Kashihara S, et al. Analysis of the interaction between rubber polymer and carbon black surfaces by efficient removal of physisorbed polymer from carbon-rubber composites[J]. Carbon, 2016, 99: 148-156. |

| [29] | Huang L J, Yu F M, Liu Y, et al. Understanding the reinforcement effect of fumed silica on silicone rubber: bound rubber and its entanglement network[J]. Macromolecules, 2023, 56(1): 323-334. |

| [30] | Ye N, Zheng J C, Ye X, et al. Performance enhancement of rubber composites using VOC-free interfacial silica coupling agent[J]. Composites Part B: Engineering, 2020, 202: 108301. |

| [31] | Ma Y J, Zhao H Y, Zhang X J, et al. Structure optimization of pyrolysis carbon black from waste tire and its application in natural rubber composites[J]. Applied Surface Science, 2022, 593: 153389. |

| [32] | Baeza G P, Dessi C, Costanzo S, et al. Network dynamics in nanofilled polymers[J]. Nature Communications, 2016, 7: 11368. |

| [33] | Mortazavian H, Fennell C J, Blum F D. Structure of the interfacial region in adsorbed poly(vinyl acetate) on silica[J]. Macromolecules, 2016, 49(1): 298-307. |

| [34] | Warren J, Offenberger S, Toghiani H, et al. Effect of temperature on the shear-thickening behavior of fumed silica suspensions[J]. ACS Applied Materials & Interfaces, 2015, 7(33): 18650-18661. |

| [35] | Girard O, Cohen-Addad J P. Silica-siloxane mixtures: surface saturation process of particles. Kinetics[J]. Polymer, 1991, 32(5): 860-863. |

| [36] | Tian C C, Chu G Y, Feng Y X, et al. Quantitatively identify and understand the interphase of SiO2/rubber nanocomposites by using nanomechanical mapping technique of AFM[J]. Composites Science and Technology, 2019, 170: 1-6. |

| [37] | Yue Y L, Zhang H, Zhang Z, et al. Polymer–filler interaction of fumed silica filled polydimethylsiloxane investigated by bound rubber[J]. Composites Science and Technology, 2013, 86: 1-8. |

| [38] | Ansarifar A, Ibrahim N, Bennett M. Reinforcement of natural rubber with silanized precipitated silica nanofiller[J]. Rubber Chemistry and Technology, 2005, 78(5): 793-805. |

| [39] | Boonstra B B, Cochrane H, Dánnenberg E M. Reinforcement of silicone rubber by particulate silica[J]. Rubber Chemistry and Technology, 1975, 48(4): 558-576. |

| [40] | Huang L J, Yu F M, Liu Y, et al. Structural analyses of the bound rubber in silica-filled silicone rubber nanocomposites reveal mechanisms of filler-rubber interaction[J]. Composites Science and Technology, 2023, 233: 109905. |

| [41] | Huang L J, Song Z H, Song X M, et al. Performance enhancement of silicone rubber using superhydrophobic silica aerogel with robust nanonetwork structure and outstanding interfacial effect[J]. ACS Applied Materials & Interfaces, 2024, 16(17): 22580-22592. |

| [42] | Li X Y, Yang Q P, Ye Y, et al. Quantifying 3D-nanosized dispersion of SiO2 in elastomer nanocomposites by 3D-scanning transmission electron microscope (STEM)[J]. Composites Part A: Applied Science and Manufacturing, 2020, 131: 105778. |

| [43] | Genix A C, Bocharova V, Kisliuk A, et al. Enhancing the mechanical properties of glassy nanocomposites by tuning polymer molecular weight[J]. ACS Applied Materials & Interfaces, 2018, 10(39): 33601-33610. |

| [44] | Merabia S, Sotta P, Long D R. A microscopic model for the reinforcement and the nonlinear behavior of filled elastomers and thermoplastic elastomers (Payne and Mullins effects)[J]. Macromolecules, 2008, 41(21): 8252-8266. |

| [45] | Roh S, Williams A H, Bang R S, et al. Soft dendritic microparticles with unusual adhesion and structuring properties[J]. Nature Materials, 2019, 18(12): 1315-1320. |

| [46] | Duarte M, Billing J, Liu Y, et al. Uniform pores in cross-linked polymers by dispersed fumed silica templating[J]. Macromolecules, 2015, 48(13): 4382-4387. |

| [47] | Wu C, Gao Y F, Liang X D, et al. Manifestation of interactions of nano-silica in silicone rubber investigated by low-frequency dielectric spectroscopy and mechanical tests[J]. Polymers, 2019, 11(4): 717. |

| [48] | Okel T A, Waddell W H. Effect of precipitated silica physical properties on silicone rubber performance[J]. Rubber Chemistry and Technology, 1995, 68(1): 59-76. |

| [49] | Cochrane H, Lin C S. The influence of fumed silica properties on the processing, curing, and reinforcement properties of silicone rubber[J]. Rubber Chemistry and Technology, 1993, 66(1): 48-60. |

| [50] | Wang B H, Hu J N, Liu K P, et al. Reinforcement mechanism of silica surface hydroxyl: the opposite effect[J]. Applied Surface Science, 2023, 623: 157000. |

| [51] | 李露, 陈丽云, 胡盛, 等. 白炭黑处理工艺对加成型液体硅橡胶性能的影响[J]. 有机硅材料, 2020, 34(3): 39-42. |

| Li L, Chen L Y, Hu S, et al. Influence of treatment process of silica on properties of polyaddition liquid silicone rubber[J]. Silicone Material, 2020, 34(3): 39-42. | |

| [52] | Liu J, Zhang X B, Lu X Q, et al. Improving mechanical properties of silicone rubber for use as outdoor insulator sheds by manipulating matrix-filler interfacial compatibility[J]. Materials Research Express, 2019, 6(10): 105348. |

| [53] | Kopylov V M, Kostyleva E I, Kostylev I M, et al. Silica fillers for silicone rubber[J]. International Polymer Science and Technology, 2011, 38(4): 35-47. |

| [54] | Song Y Z, Yu J H, Dai D, et al. Effect of silica particles modified by in situ and ex-situ methods on the reinforcement of silicone rubber[J]. Materials & Design, 2014, 64: 687-693. |

| [55] | Peng Z W, Qin Y, Song J Q, et al. Structuring of hydroxy-terminated polydimethylsiloxane filled by fumed silica[J]. e-Polymers, 2021, 21(1): 131-139. |

| [56] | Hosseini-Far P, Razzaghi-Kashani M, Hosseini S M. Nanotribological interactions at the interface between polydimethylsiloxane and silane-modified silica[J]. Surfaces and Interfaces, 2023, 39: 102966. |

| [57] | Park J J, Lee J Y. Effect of surface-modified nano-aluminum trihydroxide on electrical properties of silicone/nano-silica nanocomposite[J]. Journal of Applied Polymer Science, 2022, 139(10): 51741. |

| [58] | Zhu Q Q, Liao W Q, Sun C, et al. Highly stretchable, conductive, and wide-operating temperature ionogel based wearable triboelectric nanogenerator[J]. Nano Research, 2023, 16(9): 11638-11645. |

| [59] | Sohrabi-Kashani L, Zolriasatein A, Yekta B E. Synthesis of silica nanoparticles from water glass for preparing hydrophobic RTV1 silicone rubber-SiO2 nanocomposite[J]. Bulletin of Materials Science, 2022, 45(3): 163. |

| [60] | Huang X, Fang X L, Lu Z, et al. Reinforcement of polysiloxane with superhydrophobic nanosilica[J]. Journal of Materials Science, 2009, 44(17): 4522-4530. |

| [61] | Zhou R, Ma H H, Zhou Z F, et al. Preparation of SiO2 particles with silicone-methoxy groups on surface and its co-curing hydroxyl silicone oil[J]. Materials Research Express, 2020, 7(6): 065309. |

| [62] | Ma Y C, Fu Y, Xing L, et al. Bi-functionalized SiO2 nanoparticles induced cooperation of fluorine-silicone heterogeneous rubbers with designable low-temperature resistance[J]. Polymers for Advanced Technologies, 2024, 35(8): e6544. |

| [63] | Diao S, Zhang S Y, Yang Z Z, et al. Effect of tetraphenylphenyl-modified fumed silica on silicone rubber radiation resistance[J]. Journal of Applied Polymer Science, 2011, 120(4): 2440-2447. |

| [64] | Guo G Z, Zhang J N, Chen X, et al. Molecular-dynamics study on the thermodynamic properties of nano-SiO2 particle-doped silicone rubber composites[J]. Computational Materials Science, 2022, 212: 111571. |

| [65] | Guo Y L, Yang W B, Jiang Z N, et al. Silicone rubber/paraffin@silicon dioxide form-stable phase change materials with thermal energy storage and enhanced mechanical property[J]. Solar Energy Materials and Solar Cells, 2019, 196: 16-24. |

| [66] | Zheng W, Tang C, Xie J F, et al. Micro-scale effects of nano-SiO2 modification with silane coupling agents on the cellulose/nano-SiO2 interface[J]. Nanotechnology, 2019, 30(44): 445701. |

| [67] | Hao M Z, Zhao W, Li R Y, et al. Surface modification of as-prepared silver-coated silica microspheres through mussel-inspired functionalization and its application properties in silicone rubber[J]. Industrial & Engineering Chemistry Research, 2018, 57(22): 7486-7494. |

| [68] | Deng H, Yang Y M, Tang X H, et al. Phase-change composites composed of silicone rubber and Pa@SiO2@PDA double-shelled microcapsules with low leakage rate and improved mechanical strength[J]. ACS Applied Materials & Interfaces, 2021, 13(33): 39394-39403. |

| [69] | Zhu G Z, Tian Y L, Tan J R, et al. Fabrication of core–shell liquid metal@silica nanoparticles for enhanced mechanical, dielectric and thermal properties of silicone rubber[J]. CrystEngComm, 2023, 25(22): 3299-3307. |

| [70] | Sun J Y, Li W, Li N, et al. Effect of surface modified nano-SiO2 particles on properties of TO@CA/SR self-healing anti-corrosion composite coating[J]. Progress in Organic Coatings, 2022, 164: 106689. |

| [71] | Yang H, Gao Q, Xie Y T, et al. Effect of SiO2 and TiO2 nanoparticle on the properties of phenyl silicone rubber[J]. Journal of Applied Polymer Science, 2015, 132(46): 42806. |

| [72] | Dong F Y, Ma D P, Feng S Y. Aminopropyl-modified silica as cross-linkers of polysiloxane containing γ-chloropropyl groups for preparing heat-curable silicone rubber[J]. Polymer Testing, 2016, 52: 124-132. |

| [73] | Yang B, Zhang S H, Zou Y F, et al. Improving the thermal conductivity and mechanical properties of two-component room temperature vulcanized silicone rubber by filling with hydrophobically modified SiO2-graphene nanohybrids[J]. Chinese Journal of Polymer Science, 2019, 37(2): 189-196. |

| [74] | Feng L L, Li S S, Feng S Y. Preparation and characterization of silicone rubber with high modulus via tension spring-type crosslinking[J]. RSC Advances, 2017, 7(22): 13130-13137. |

| [75] | Javadi S, Razzaghi-Kashani M. Effects of filler modification and structuring on dielectric enhancement of silicone rubber composites[C]//Electroactive Polymer Actuators and Devices (EAPAD). SPIE, 2013: 421-428. |

| [76] | Zhou H L, Su Y, Chen X R, et al. Modification of silicalite-1 by vinyltrimethoxysilane (VTMS) and preparation of silicalite-1 filled polydimethylsiloxane (PDMS) hybrid pervaporation membranes[J]. Separation and Purification Technology, 2010, 75(3): 286-294. |

| [77] | Zhang Y L, Liu W, Zhou Q, et al. Effects of vinyl functionalized silica particles on thermal and mechanical properties of liquid silicone rubber nanocomposites[J]. Polymers, 2023, 15(5): 1224. |

| [78] | Wang F, Li Y N, Wang D. Adhesion enhancement for liquid silicone rubber and different surface by organosilane and Pt catalyst at room temperature[J]. Bulletin of Materials Science, 2013, 36(6): 1013-1017. |

| [79] | Silva V P, Gonçalves M C, Yoshida I V P. Biogenic silica short fibers as alternative reinforcing fillers of silicone rubbers[J]. Journal of Applied Polymer Science, 2006, 101(1): 290-299. |

| [80] | Deng H, Yang W B, Cai T Y, et al. Phase-change composites silicone rubber/paraffin@SiO2 microcapsules with different core/shell ratio for thermal management[J]. International Journal of Energy Research, 2021, 45(12): 18033-18047. |

| [81] | Zhang X M, Chen J, Chen Y Y, et al. Studies on hydrophobic silica/silicone rubber composite microspheres with dual-size microstructures[J]. Langmuir, 2021, 37(50): 14668-14678. |

| [82] | Zheng J, Wang H, Li J. Preparation and properties of silica tubes/high-temperature vulcanized silicone rubber composites[J]. Journal of Reinforced Plastics and Composites, 2012, 31(14): 989-996. |

| [83] | Yin Y L, Chen X T, Lu J, et al. Influence of molar ratio of Si—H to Si—CH=CH2 on mechanical and optical properties of silicone rubber[J]. Journal of Elastomers & Plastics, 2016, 48(3): 206-216. |

| [84] | 欧阳舴艋, 李双双, 石琢, 等. 改性纳米SiO2/硅橡胶复合材料的制备及性能[J]. 复合材料学报, 2019, 36(7): 1700-1707. |

| Ouyang Z M, Li S S, Shi Z, et al. Preparation and properties of modified nano SiO2/silicone rubber composites[J]. Acta Materiae Compositae Sinica, 2019, 36(7): 1700-1707. |

| [1] | Shengmei ZHANG, Ming LI, Ying ZHANG, Xi YI, Yiting YANG, Yali LIU. Effects of emulsifier and reacting temperature on characteristics of phase change microcapsules [J]. CIESC Journal, 2025, 76(S1): 444-452. |

| [2] | Xin WU, Jianying GONG, Xiangyu LI, Yutao WANG, Xiaolong YANG, Zhen JIANG. Experimental study on the droplet motion on the hydrophobic surface under ultrasonic excitation [J]. CIESC Journal, 2025, 76(S1): 133-139. |

| [3] | Liang QIAO, Shang LI, Xinliang LIU, Ming WANG, Pei ZHANG, Yingfei HOU. Synthesis and molecular simulation of terpolymer viscosity reducer for heavy oil [J]. CIESC Journal, 2025, 76(7): 3686-3695. |

| [4] | Haifeng ZHANG, Jingyi YAN, Yuxue YUE, Zilong ZHANG, Bolin WANG, Xiaonian LI. Investigation of hydroxylation-induced reconstruction on WO3 surface and the modification mechanism of transformer oil [J]. CIESC Journal, 2025, 76(7): 3696-3709. |

| [5] | Junyi WANG, Zhangxun XIA, Fenning JING, Suli WANG. Study on the relaxation time distribution of electrochemical impedance spectroscopy in high temperature polymer electrolyte membrane fuel cells based on reformed hydrogen fuels [J]. CIESC Journal, 2025, 76(7): 3509-3520. |

| [6] | Tonghui LI, Tianli HUI, Tao ZHENG, Rui ZHANG, Haiyan LIU, Zhichang LIU, Chunming XU, Xianghai MENG. Synergistic palladium double active sites with hydroxide for high current density and pH-universal hydrogen evolution reaction [J]. CIESC Journal, 2025, 76(7): 3671-3685. |

| [7] | Changqiu HE, Jiameng TIAN, Yiqi CHEN, Yuchen ZHU, Xin LIU, Hai WANG, Zhentao WANG, Junfeng WANG, Zhifu ZHOU, Bin CHEN. Synergistic heat transfer enhancement characteristics due to electric field and macro-structured surface during thin film boiling [J]. CIESC Journal, 2025, 76(6): 2589-2602. |

| [8] | Naisheng GUO, Xiaobo ZHU, Shuang WANG, Ping CHEN, Zhaoyang CHU, Zhichen WANG. Research progress on high and low temperature performance and influencing factors of polyurethane modified asphalt [J]. CIESC Journal, 2025, 76(6): 2505-2523. |

| [9] | Ziyang LI, Peixin SHEN, Xiao'a ZHANG, Chengzhong WANG, Ling SHI, Junying ZHANG. Synthesis and thermal stability of α, ω-hydroxy-terminated phenyl/phenylene-containing polysiloxanes with high vinyl content [J]. CIESC Journal, 2025, 76(6): 3041-3052. |

| [10] | Yanqiu LU, Yang DI, Wenbo SHI, Congcong YIN, Yong WANG. Research progress of smart responsive membranes based on novel porous organic polymers [J]. CIESC Journal, 2025, 76(5): 2101-2118. |

| [11] | Bingbing GAO, Nuo XU, Yunxiang BAI, Chunfang ZHANG, Yongqiang YANG, Liangliang DONG. Polymeric membranes for helium separation [J]. CIESC Journal, 2025, 76(5): 2119-2135. |

| [12] | Zijuan LI, Xiaoyan TAN, Yongsheng WU, Chenyi YANG, Hong CHEN, Xiaogang BI, Jie LIU, Faquan YU. Molecular simulation study on CO2/N2 separation via 3D-contorted catalytic arene-norbornene annulation polymer membrane [J]. CIESC Journal, 2025, 76(5): 2348-2357. |

| [13] | Bing ZHANG, Jianhui LI, Xinrong MA, Yang CHEN, Jinping LI, Libo LI. Research progress of MOF preparation by steam-assisted method [J]. CIESC Journal, 2025, 76(5): 2026-2041. |

| [14] | Yaohui ZHANG, Yujie BAN, Weishen YANG. Vapor-phase synthesis and post-synthetic modification of metal-organic framework membranes [J]. CIESC Journal, 2025, 76(5): 2070-2086. |

| [15] | Runjian LIU, Gang LIN, Ling ZHANG, Dong XU, Ming LI, Luchang HAN. A coupling model of the approaching-thinning process with the effect of bubble surface deformation [J]. CIESC Journal, 2025, 76(4): 1504-1512. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||