CIESC Journal ›› 2025, Vol. 76 ›› Issue (3): 963-974.DOI: 10.11949/0438-1157.20240631

• Thermodynamics • Previous Articles Next Articles

Junbing XIAO1( ), Bo ZOU1, Jiandi REN1, Changhui LIU2(

), Bo ZOU1, Jiandi REN1, Changhui LIU2( ), Chuankun JIA1(

), Chuankun JIA1( )

)

Received:2024-06-07

Revised:2024-10-10

Online:2025-03-28

Published:2025-03-25

Contact:

Changhui LIU, Chuankun JIA

肖俊兵1( ), 邹博1, 任建地1, 刘昌会2(

), 邹博1, 任建地1, 刘昌会2( ), 贾传坤1(

), 贾传坤1( )

)

通讯作者:

刘昌会,贾传坤

作者简介:肖俊兵(1988—),男,博士,讲师,xjb1th@163.com

基金资助:CLC Number:

Junbing XIAO, Bo ZOU, Jiandi REN, Changhui LIU, Chuankun JIA. Research on heat storage performance of chloride composite molten salt based on phase diagram analysis[J]. CIESC Journal, 2025, 76(3): 963-974.

肖俊兵, 邹博, 任建地, 刘昌会, 贾传坤. 基于相图分析的氯化物复合熔盐储热性能研究[J]. 化工学报, 2025, 76(3): 963-974.

Add to citation manager EndNote|Ris|BibTeX

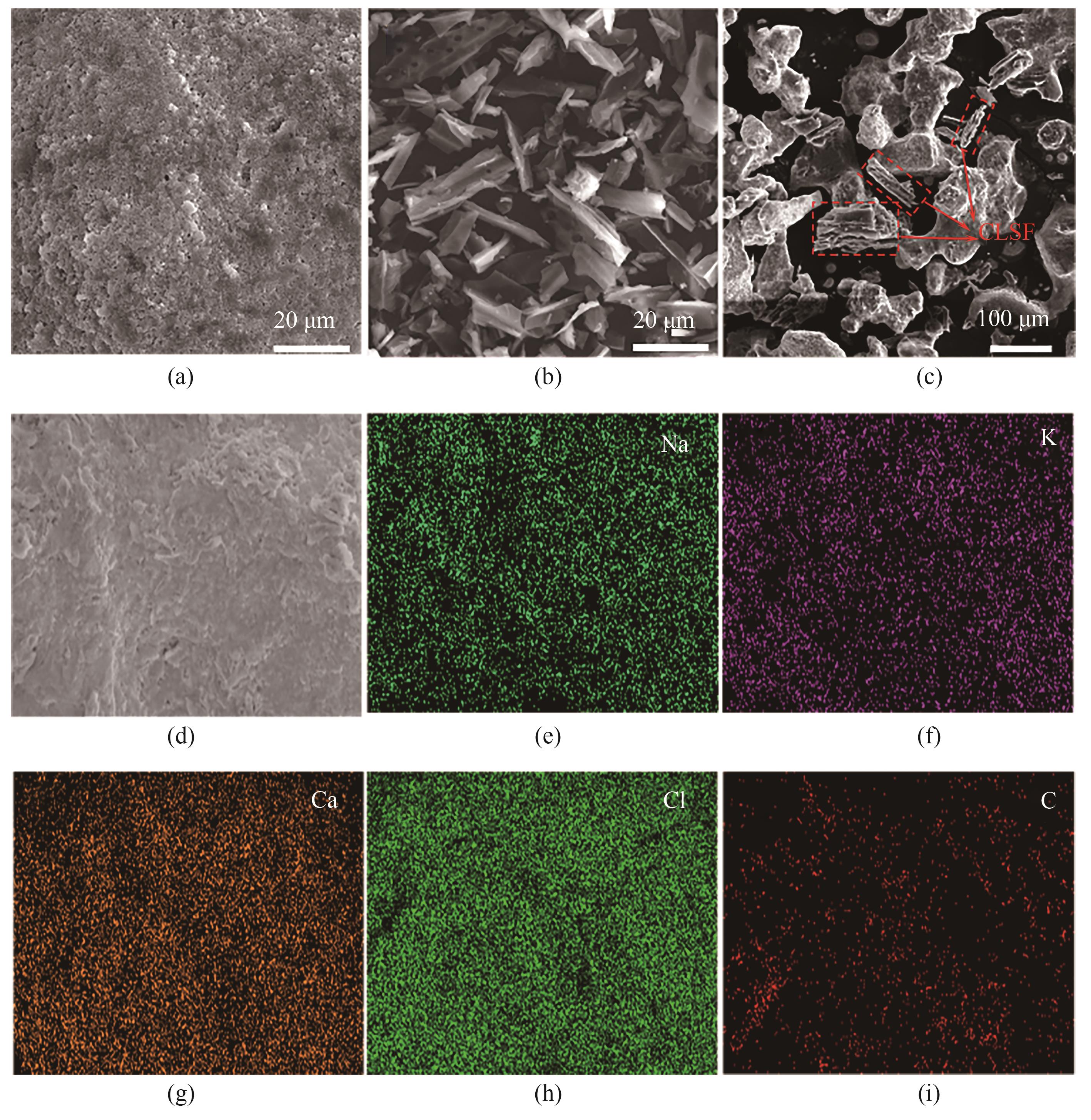

Fig.6 Microtopography images: SEM images of (a) NaCl-KCl-CaCl2 ternary molten salt, (b) CLSF, (c) NaCl-KCl-CaCl2/CLSF0.3 composite molten salt; (d)—(i) EDS energy spectra of NaCl-KCl-CaCl2/CLSF0.3 composite molten salt

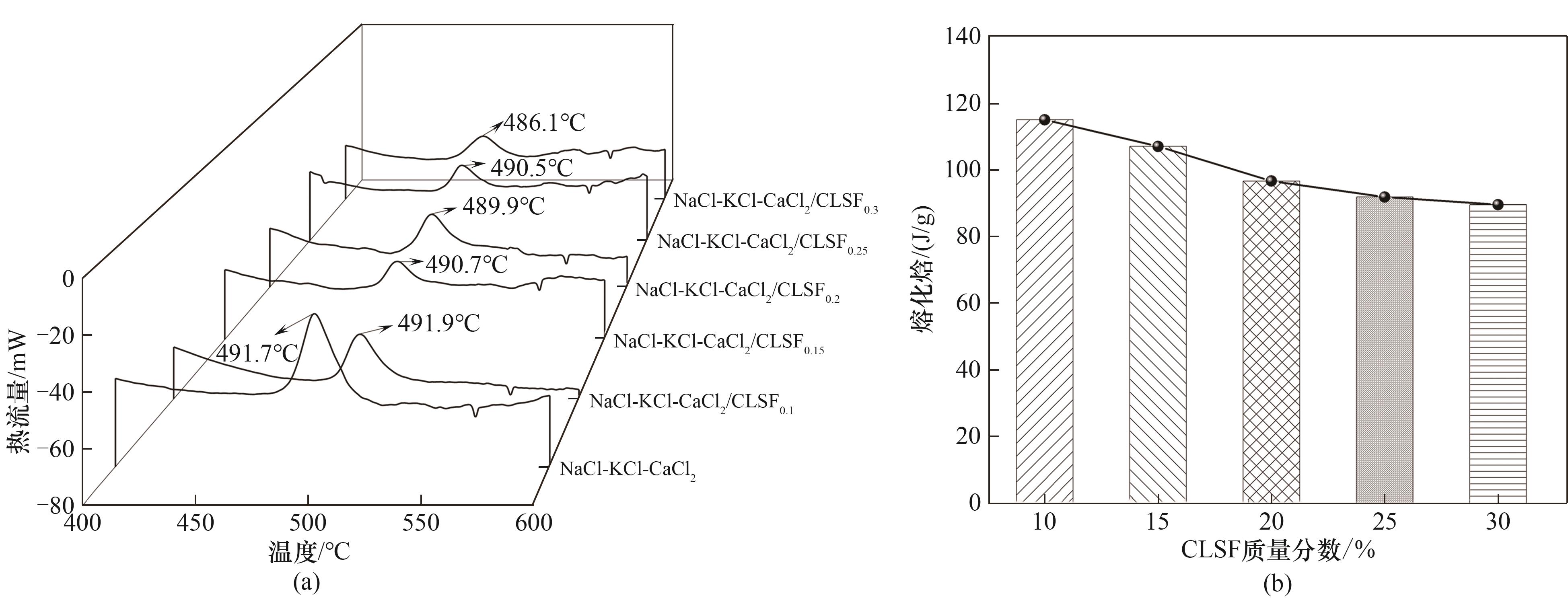

Fig.7 Result of melting enthalpy: (a) DSC curves of NaCl-KCl-CaCl2/CLSF composite molten salts; (b) variation of melting enthalpy of composite molten salts with CLSF mass fraction

| 样品 | 熔点/℃ | 熔化焓测量值/(J/g) | 熔化焓计算值/(J/g) | 偏差/% |

|---|---|---|---|---|

| NaCl-KCl-CaCl2 | 491.7 | 132.5 | 132.5 | — |

| NaCl-KCl-CaCl2/CLSF0.1 | 491.9 | 115.0 | 119.3 | 3.6 |

| NaCl-KCl-CaCl2/CLSF0.15 | 490.7 | 107.0 | 112.6 | 5.0 |

| NaCl-KCl-CaCl2/CLSF0.2 | 489.9 | 96.6 | 106 | 8.9 |

| NaCl-KCl-CaCl2/CLSF0.25 | 490.5 | 91.8 | 99.4 | 7.6 |

| NaCl-KCl-CaCl2/CLSF0.3 | 486.1 | 89.5 | 92.8 | 3.4 |

Table 1 Melting point and melting enthalpy of pure salts and composites

| 样品 | 熔点/℃ | 熔化焓测量值/(J/g) | 熔化焓计算值/(J/g) | 偏差/% |

|---|---|---|---|---|

| NaCl-KCl-CaCl2 | 491.7 | 132.5 | 132.5 | — |

| NaCl-KCl-CaCl2/CLSF0.1 | 491.9 | 115.0 | 119.3 | 3.6 |

| NaCl-KCl-CaCl2/CLSF0.15 | 490.7 | 107.0 | 112.6 | 5.0 |

| NaCl-KCl-CaCl2/CLSF0.2 | 489.9 | 96.6 | 106 | 8.9 |

| NaCl-KCl-CaCl2/CLSF0.25 | 490.5 | 91.8 | 99.4 | 7.6 |

| NaCl-KCl-CaCl2/CLSF0.3 | 486.1 | 89.5 | 92.8 | 3.4 |

| 样品组成 | 分解温度/℃ | 质量损失/% |

|---|---|---|

| NaCl-KCl-CaCl2 | 747.50 | 1.0 |

| NaCl-KCl-CaCl2/CLSF0.1 | 745.23 | 1.6 |

| NaCl-KCl-CaCl2/CLSF0.15 | 742.37 | 1.2 |

| NaCl-KCl-CaCl2/CLSF0.2 | 748.41 | 1.4 |

| NaCl-KCl-CaCl2/CLSF0.25 | 742.49 | 1.8 |

| NaCl-KCl-CaCl2/CLSF0.3 | 746.89 | 2.1 |

Table 2 TGA results of NaCl-KCl-CaCl2/CLSF composites

| 样品组成 | 分解温度/℃ | 质量损失/% |

|---|---|---|

| NaCl-KCl-CaCl2 | 747.50 | 1.0 |

| NaCl-KCl-CaCl2/CLSF0.1 | 745.23 | 1.6 |

| NaCl-KCl-CaCl2/CLSF0.15 | 742.37 | 1.2 |

| NaCl-KCl-CaCl2/CLSF0.2 | 748.41 | 1.4 |

| NaCl-KCl-CaCl2/CLSF0.25 | 742.49 | 1.8 |

| NaCl-KCl-CaCl2/CLSF0.3 | 746.89 | 2.1 |

| 复合材料 | 添加剂质量分数/% | 热导率/(W/(m·K)) | 热导率增加分数/% | 文献 |

|---|---|---|---|---|

| NaCl-KCl-MgCl2/Al2O3 | 0.7 | — | 62.59 | [ |

| NaNO3-NaNO2-KNO2-LiNO3/MgO | 40 | 0.41 | — | [ |

| NaCl-KCl-MgCl2/CuO | 0.2 | 0.340 | 15.85 | [ |

| 0.7 | 0.385 | 31.40 | ||

| 2 | 0.409 | 39.55 | ||

| NaCl-KCl-LiCl/CuO | 1 | 0.483 | 3.20 | [ |

| 3 | 0.529 | 13.03 | ||

| 5 | 0.571 | 22.01 | ||

| NaNO3-KNO3/MgO | 0.125 | 0.851 | 9.24 | [ |

| 0.25 | 0.883 | 13.36 | ||

| 0.5 | 0.853 | 9.57 | ||

| 1 | 0.858 | 10.19 | ||

| 2 | 0.872 | 11.99 | ||

| NaNO3/SiC | 20 | 1.16 | 50 | [ |

| LiNO3-NaNO3-KNO3-Ca(NO3)2/CaSiO3 | 20 | 1.177 | — | [ |

| NaCl-Na2CO3-Na2SO4/graphene nanoplatelets | 0.2 | 1.21 | 11.53 | [ |

| 0.5 | 1.13 | 3.69 | ||

| 1 | 1.38 | 27.02 | ||

| 2 | 1.44 | 32.02 | ||

| NaNO3-KNO3/EG | 20 | — | 71.31 | [ |

| lauric acid/modified BN | 21.8 | 0.563 | 124.30 | [ |

| diglycidyl ether of bisphenol A/BN | 20 | 0.61 | — | [ |

| polyimide/BN | 30 | 0.696 | — | [ |

| poly (tetradecyl acrylate)/BN | 5 | 0.33 | 13.7 | [ |

| 10 | 0.41 | 41.4 | ||

| 15 | 0.46 | 58.6 | ||

| 20 | 0.62 | 113.8 | ||

| NaCl-KCl-CaCl2/CLSF | 10 | 0.3611 | 2.73 | 本文 |

| 15 | 0.3937 | 12.01 | ||

| 20 | 0.4207 | 19.69 | ||

| 25 | 0.4603 | 30.95 | ||

| 30 | 0.5625 | 60.03 |

Table 3 Effect of different types of additives on thermal conductivity of composite materials

| 复合材料 | 添加剂质量分数/% | 热导率/(W/(m·K)) | 热导率增加分数/% | 文献 |

|---|---|---|---|---|

| NaCl-KCl-MgCl2/Al2O3 | 0.7 | — | 62.59 | [ |

| NaNO3-NaNO2-KNO2-LiNO3/MgO | 40 | 0.41 | — | [ |

| NaCl-KCl-MgCl2/CuO | 0.2 | 0.340 | 15.85 | [ |

| 0.7 | 0.385 | 31.40 | ||

| 2 | 0.409 | 39.55 | ||

| NaCl-KCl-LiCl/CuO | 1 | 0.483 | 3.20 | [ |

| 3 | 0.529 | 13.03 | ||

| 5 | 0.571 | 22.01 | ||

| NaNO3-KNO3/MgO | 0.125 | 0.851 | 9.24 | [ |

| 0.25 | 0.883 | 13.36 | ||

| 0.5 | 0.853 | 9.57 | ||

| 1 | 0.858 | 10.19 | ||

| 2 | 0.872 | 11.99 | ||

| NaNO3/SiC | 20 | 1.16 | 50 | [ |

| LiNO3-NaNO3-KNO3-Ca(NO3)2/CaSiO3 | 20 | 1.177 | — | [ |

| NaCl-Na2CO3-Na2SO4/graphene nanoplatelets | 0.2 | 1.21 | 11.53 | [ |

| 0.5 | 1.13 | 3.69 | ||

| 1 | 1.38 | 27.02 | ||

| 2 | 1.44 | 32.02 | ||

| NaNO3-KNO3/EG | 20 | — | 71.31 | [ |

| lauric acid/modified BN | 21.8 | 0.563 | 124.30 | [ |

| diglycidyl ether of bisphenol A/BN | 20 | 0.61 | — | [ |

| polyimide/BN | 30 | 0.696 | — | [ |

| poly (tetradecyl acrylate)/BN | 5 | 0.33 | 13.7 | [ |

| 10 | 0.41 | 41.4 | ||

| 15 | 0.46 | 58.6 | ||

| 20 | 0.62 | 113.8 | ||

| NaCl-KCl-CaCl2/CLSF | 10 | 0.3611 | 2.73 | 本文 |

| 15 | 0.3937 | 12.01 | ||

| 20 | 0.4207 | 19.69 | ||

| 25 | 0.4603 | 30.95 | ||

| 30 | 0.5625 | 60.03 |

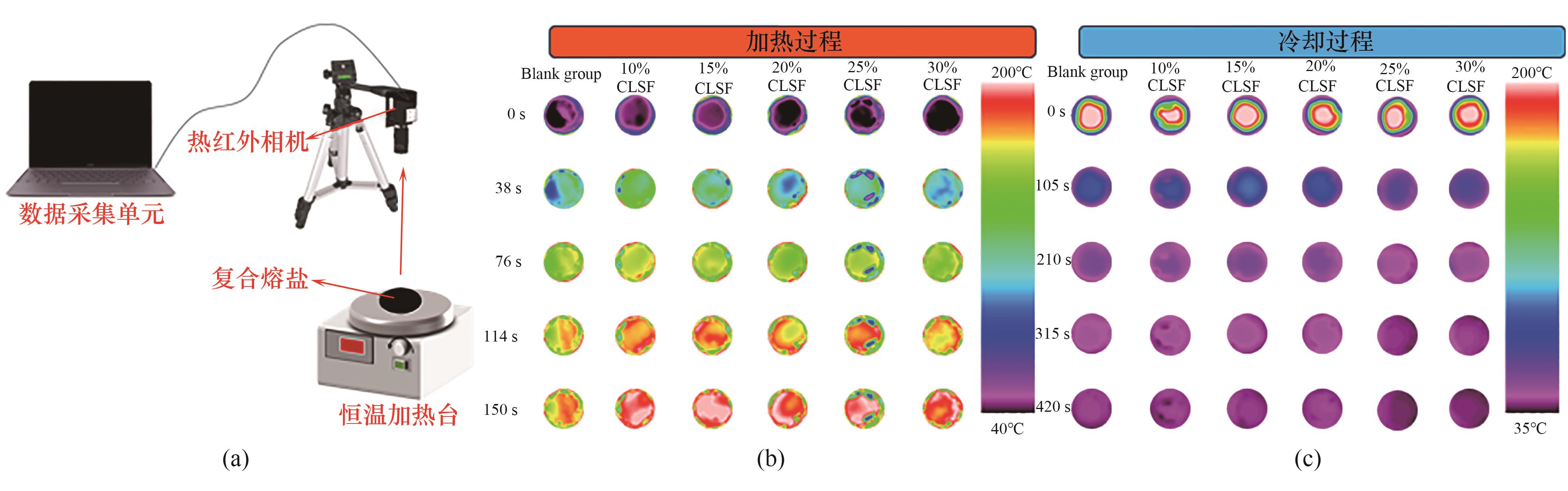

Fig.10 Transient thermal response performance analysis: (a) schematic diagram of the thermal response performance measurement platform; infrared thermograms of the sample during (b) heating and (c) cooling processes

| 1 | Lewis N S. Research opportunities to advance solar energy utilization[J]. Science, 2016, 351(6271): aad1920. |

| 2 | 郭学伯, 范良迟, 许浈婧, 等. 助力节能降碳的相变储热材料研究和应用进展[J]. 发电技术, 2023, 44(2): 201-212. |

| Guo X B, Fan L C, Xu Z J, et al. Research and application progress of phase change thermal energy storage materials for energy saving and carbon reduction[J]. Power Generation Technology, 2023, 44(2): 201-212. | |

| 3 | Skrbek K, Bartůněk V, Sedmidubský D. Molten salt-based nanocomposites for thermal energy storage: materials, preparation techniques and properties[J]. Renewable and Sustainable Energy Reviews, 2022, 164: 112548. |

| 4 | Xiao X, Jia H W, Wen D S, et al. Thermal performance analysis of a solar energy storage unit encapsulated with HITEC salt/copper foam/nanoparticles composite[J]. Energy, 2020, 192: 116593. |

| 5 | Ding W J, Bauer T. Progress in research and development of molten chloride salt technology for next generation concentrated solar power plants[J]. Engineering, 2021, 7(3): 334-347. |

| 6 | 魏小兰, 谢佩, 张雪钏, 等. 氯化物熔盐材料的制备及其热物理性质研究[J]. 化工学报, 2020, 71(5): 2423-2431. |

| Wei X L, Xie P, Zhang X C, et al. Research on preparation and thermodynamic properties of chloride molten salt materials[J]. CIESC Journal, 2020, 71(5): 2423-2431. | |

| 7 | Wu S, Peng H, Xie L D. Design and investigation of the novel ZnCl2 based ternary chloride salts with low-temperature for sensible energy storage[J]. Applied Thermal Engineering, 2020, 171: 114917. |

| 8 | 涂易, 王文磊, 王军涛, 等. 高温熔盐储能材料的模型计算方法研究[J]. 材料导报, 2014, 28(6): 136-140, 148. |

| Tu Y, Wang W L, Wang J T, et al. Study on model calculation methods of high temperature fused salt energy storage material[J]. Materials Review, 2014, 28(6): 136-140, 148. | |

| 9 | Xu X K, Dehghani G, Ning J X, et al. Basic properties of eutectic chloride salts NaCl-KCl-ZnCl2 and NaCl-KCl-MgCl2 as HTFs and thermal storage media measured using simultaneous DSC-TGA[J]. Solar Energy, 2018, 162: 431-441. |

| 10 | Bauer T, Odenthal C, Bonk A. Molten salt storage for power generation[J]. Chemie Ingenieur Technik, 2021, 93(4): 534-546. |

| 11 | Han D M, Lougou B G, Shuai Y, et al. Study of thermophysical properties of chloride salts doped with CuO nanoparticles for solar thermal energy storage[J]. Solar Energy Materials and Solar Cells, 2022, 234: 111432. |

| 12 | Wang Q, Wu C L, Sun S P, et al. Comprehensive performance of composite phase change materials based on ternary eutectic chloride with CuO nanoparticles for thermal energy storage systems[J]. Solar Energy, 2023, 250: 324-334. |

| 13 | Liu J W, Wang Q H, Ling Z Y, et al. A novel process for preparing molten salt/expanded graphite composite phase change blocks with good uniformity and small volume expansion[J]. Solar Energy Materials and Solar Cells, 2017, 169: 280-286. |

| 14 | Tian H Q, Wang W L, Ding J, et al. Thermal conductivities and characteristics of ternary eutectic chloride/expanded graphite thermal energy storage composites[J]. Applied Energy, 2015, 148: 87-92. |

| 15 | Xiao J B, Zou B, Liu C H, et al. Carbonized loofah sponge fragments enhanced phase change thermal energy storage: preparation and thermophysical property analysis[J]. Applied Thermal Engineering, 2024, 242: 122505. |

| 16 | Xiao J B, Zou B, Zhong F F, et al. Phase change energy storage using boron nitride/carbonized loofah sponge[J]. Applied Thermal Engineering, 2024, 257: 124182. |

| 17 | Su H X, Guo X, Chen G L, et al. A novel honeycomb-like porous carbon from loofah sponge for form-stable phase change materials with high encapsulation capacity and reliability[J]. Materials Letters, 2022, 308: 131118. |

| 18 | Song J Y, He H F, Wang Y B, et al. Shape-stabilized phase change composites supported by biomass loofah sponge-derived microtubular carbon scaffold toward thermal energy storage and electric-to-thermal conversion[J]. Journal of Energy Storage, 2022, 56: 105891. |

| 19 | Tian H Q, Wang W L, Ding J, et al. Thermal performance and economic evaluation of NaCl-CaCl2 eutectic salt for high-temperature thermal energy storage[J]. Energy, 2021, 227: 120412. |

| 20 | Yin H Q, Wang Z R, Lai X, et al. Optimum design and key thermal property of NaCl-KCl-CaCl2 eutectic salt for ultra-high-temperature thermal energy storage[J]. Solar Energy Materials and Solar Cells, 2022, 236: 111541. |

| 21 | Sang L X, Lv X Y, Wu Y T. NaNO3-KNO3-KCl/K2CO3 with the elevated working temperature for CSP application: phase diagram calculation and machine learning[J]. Solar Energy, 2023, 252: 322-329. |

| 22 | Ren N, Wu Y T, Ma C F, et al. Preparation and thermal properties of quaternary mixed nitrate with low melting point[J]. Solar Energy Materials and Solar Cells, 2014, 127: 6-13. |

| 23 | Mohan G, Venkataraman M, Gomez-Vidal J, et al. Assessment of a novel ternary eutectic chloride salt for next generation high-temperature sensible heat storage[J]. Energy Conversion and Management, 2018, 167: 156-164. |

| 24 | Li J Q, Qin Y, Shen J, et al. Evolution of carbon nanostructures during coal graphitization: insights from X-ray diffraction and high-resolution transmission electron microscopy[J]. Energy, 2024, 290: 130316. |

| 25 | Yan C, Liang J F, Zhong X B, et al. BN white graphene well-dispersed solar salt nanofluids with significant improved thermal properties for concentrated solar power plants[J]. Solar Energy Materials and Solar Cells, 2022, 245: 111875. |

| 26 | Kang Z Y, Huang S H, Liu X Y, et al. A novel high temperature eutectic salt and its composite with enhanced high conductivity[J]. Journal of Energy Storage, 2023, 59: 106409. |

| 27 | Zhang T Y, Wang T Y, Wang K C, et al. Development and characterization of NaCl-KCl/Kaolin composites for thermal energy storage[J]. Solar Energy, 2021, 227: 468-476. |

| 28 | Han D M, Guene Lougou B, Xu Y T, et al. Thermal properties characterization of chloride salts/nanoparticles composite phase change material for high-temperature thermal energy storage[J]. Applied Energy, 2020, 264: 114674. |

| 29 | 许荣玉, 陆海涛, 郭荷渡, 等. 低熔点四元硝酸盐基定型复合相变材料的制备与研究[J]. 储能科学与技术, 2024, 13(5): 1451-1459. |

| Xu R Y, Lu H T, Guo H D, et al. Form-stable quaternary nitrate salt-based composite phase change material with low melting temperature for low-mediumtemperature thermal energy storage[J]. Energy Storage Science and Technology, 2024, 13(5): 1451-1459. | |

| 30 | Saranprabhu M K, Rajan K S. Magnesium oxide nanoparticles dispersed solar salt with improved solid phase thermal conductivity and specific heat for latent heat thermal energy storage[J]. Renewable Energy, 2019, 141: 451-459. |

| 31 | Jiang F, Ling X, Zhang L L, et al. Improved thermal conductivity of form-stable NaNO3: using the skeleton of porous ceramic modified by SiC[J]. Solar Energy Materials and Solar Cells, 2021, 231: 111310. |

| 32 | Jiang Z, Leng G H, Ye F, et al. Form-stable LiNO3-NaNO3-KNO3-Ca(NO3)2/calcium silicate composite phase change material (PCM) for mid-low temperature thermal energy storage[J]. Energy Conversion and Management, 2015, 106: 165-172. |

| 33 | Liu X Y, Kang Z Y, Zhao J H, et al. Preparation and thermal property characterization of NaCl-Na2CO3-Na2SO4 eutectic salt mixed with carbon nanomaterials for heat storage[J]. Solar Energy Materials and Solar Cells, 2023, 251: 112173. |

| 34 | Yu Q, Lu Y W, Zhang C C, et al. Preparation and thermal properties of novel eutectic salt/nano-SiO2/expanded graphite composite for thermal energy storage[J]. Solar Energy Materials and Solar Cells, 2020, 215: 110590. |

| 35 | Wang X, Cheng Q J, Wu M M, et al. Thermal properties optimization of lauric acid as phase change material with modified boron nitride nanosheets-sodium sulfate for thermal energy storage[J]. Journal of Energy Storage, 2023, 61: 106781. |

| 36 | Isarn I, Massagués L, Ramis X, et al. New BN-epoxy composites obtained by thermal latent cationic curing with enhanced thermal conductivity[J]. Composites Part A: Applied Science and Manufacturing, 2017, 103: 35-47. |

| 37 | Gu J W, Lv Z Y, Wu Y L, et al. Dielectric thermally conductive boron nitride/polyimide composites with outstanding thermal stabilities via in situ polymerization-electrospinning-hot press method[J]. Composites Part A: Applied Science and Manufacturing, 2017, 94: 209-216. |

| 38 | Li S Q, Wang H X, Mao H Q, et al. Enhanced thermal management performance of comb-like polymer/boron nitride composite phase change materials for the thermoregulated fabric application[J]. Journal of Energy Storage, 2021, 40: 102826. |

| [1] | Junbing XIAO, Xiangyu ZHONG, Jiandi REN, Fangfang ZHONG, Changhui LIU, Chuankun JIA. Research on the heat storage properties of stearic acid phase change materials enhanced by bio-carbon materials [J]. CIESC Journal, 2025, 76(3): 1312-1322. |

| [2] | Yanbei LIU, Ruoming WANG, Juan LIU, Taimoor Raza, Yuzheng LU, Rizwan Raza, Bin ZHU, Songbo LI, Shengli AN, Sining YUN. Preparation of CeO2@La0.6Sr0.4Co0.2Fe0.8O3-δ electrolyte and its property in semiconductor ionic fuel cells performance [J]. CIESC Journal, 2025, 76(3): 1353-1362. |

| [3] | Xiankai ZHANG, Boyu WANG, Yali GUO, Shengqiang SHEN. Calculation and analysis of thermal performance of horizontal circular tube falling film evaporative condenser [J]. CIESC Journal, 2025, 76(3): 995-1005. |

| [4] | Yuanhua LI, Siqi LING, Kejun FENG, Ying FENG, Yuching KUO, Shihhuan HSIEH. Construction and catalytic application of immobilized lipase microreactors based on cMOFs for the synthesis of mandelic acid [J]. CIESC Journal, 2025, 76(3): 1170-1179. |

| [5] | Yiming ZHANG, Peng YANG, Xianbing JI, Jixing REN, Lei ZHANG, Zheng MIAO. Thermal performance of multi-loop flat loop heat pipes [J]. CIESC Journal, 2025, 76(3): 1018-1028. |

| [6] | Lyusheng ZHANG, Zhihong WANG, Qing LIU, Xuewen LI, Renmin TAN. Research progress in carbon dioxide capture using liquid-liquid phase change absorbents [J]. CIESC Journal, 2025, 76(3): 933-950. |

| [7] | Bo GAO, Jiaqi WANG, Zhiliang LIU, Xuanlie ZHAO, Kun GE. Modeling and thermodynamic and economic analysis of offshore wind power-based hydrogen production systems [J]. CIESC Journal, 2025, 76(3): 1207-1220. |

| [8] | Wenbao LI, Jinpeng HU, Miao DU, Pengju PAN, Guorong SHAN. High strength and toughness P(SBMA-co-AAc)/SiO2 composite hydrogel marine antifouling and drag-reducing coating [J]. CIESC Journal, 2025, 76(2): 787-796. |

| [9] | Mengfan YIN, Qian WANG, Tao ZHENG, Kui JI, Shaogui WANG, Hui GUO, Zhiqiang LIN, Rui ZHANG, Hui SUN, Haiyan LIU, Zhichang LIU, Chunming XU, Xianghai MENG, Yueping WANG. Process design of 10000 t industrial demonstration of hydrogen production from renewable energy electrolytic water - low temperature and low pressure ammonia synthesis [J]. CIESC Journal, 2025, 76(2): 825-834. |

| [10] | Qiwo HAN, Yongfeng LIU, Pucheng PEI, Lu ZHANG, Shengzhuo YAO. Analysis of influence of operating temperature on water distribution, proton transport and performance of PEMFC [J]. CIESC Journal, 2025, 76(1): 374-384. |

| [11] | Su TANG, Zi'ao ZHENG, Hanze WEI, Xiaoling XU, Xiaoqiang ZHAI. Preparation and thermal conductivity reinforcement of PMMA/PEG600/CNT composite shaped phase change materials [J]. CIESC Journal, 2024, 75(S1): 309-320. |

| [12] | Zhangzhou WANG, Tianqi TANG, Jiajun XIA, Yurong HE. Battery thermal management performance simulation based on composite phase change material [J]. CIESC Journal, 2024, 75(S1): 329-338. |

| [13] | Siyu QIN, Yijia LIU, Jiacheng YANG, Wei TONG, Liwen JIN, Xiangzhao MENG. Characteristics of gas-liquid two-phase heat transfer in a confined vapor chamber [J]. CIESC Journal, 2024, 75(S1): 47-55. |

| [14] | Jian HU, Jinghua JIANG, Shengjun FAN, Jianhao LIU, Haijiang ZOU, Wanlong CAI, Fenghao WANG. Research on heat extraction performance of deep U-type borehole heat exchanger [J]. CIESC Journal, 2024, 75(S1): 76-84. |

| [15] | Dehui DU, Wei FENG, Jianghui ZHANG, Yanlong XIANG, Gaopan QIAO, Wei LI. Prediction model of flow boiling heat transfer in microfinned hydrophobic composite enhanced tube [J]. CIESC Journal, 2024, 75(S1): 95-107. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||