化工学报 ›› 2019, Vol. 70 ›› Issue (9): 3385-3395.DOI: 10.11949/0438-1157.20190231

收稿日期:2019-03-12

修回日期:2019-06-25

出版日期:2019-09-05

发布日期:2019-09-05

通讯作者:

王浩宇

作者简介:王浩宇(1981—),女,博士,讲师,基金资助:

Haoyu WANG1( ),Yingshu LIU2,Chuanzhao ZHANG1,Xiong YANG2,Jiangwei CHEN2

),Yingshu LIU2,Chuanzhao ZHANG1,Xiong YANG2,Jiangwei CHEN2

Received:2019-03-12

Revised:2019-06-25

Online:2019-09-05

Published:2019-09-05

Contact:

Haoyu WANG

摘要:

对径向流吸附器内变压吸附(PSA)制氧的变质量流动规律进行研究,有助于准确掌握吸附过程及床层内的变量因素对制氧性能的影响。对π型向心径向流吸附器建立气固耦合的两相吸附模型,并对其PSA制氧过程进行了数值模拟研究,得到了床层内氧气浓度分布、温度分布以及产品气浓度的变化规律。结果表明:首次循环结束时床层内氧气最高摩尔分数可达66.02%,回收率29.2%。非稳定循环期间,氧气摩尔分数从66.02%升高至 97.5%,回收率从29.2%提高至38.5%。循环达到稳定后,床层内氧气摩尔分数最高可达98.6%,回收率38.9%左右,且达到稳定状态后床层内气固两相温差减小,逐渐达到热平衡。获得了吸附器内部气体与吸附剂两相间的传质、传热过程,为π型向心径向流吸附器用于PSA制氧提供技术支持。

中图分类号:

王浩宇, 刘应书, 张传钊, 杨雄, 陈江伟. π型向心径向流吸附器变质量流动特性研究[J]. 化工学报, 2019, 70(9): 3385-3395.

Haoyu WANG, Yingshu LIU, Chuanzhao ZHANG, Xiong YANG, Jiangwei CHEN. Study on variable mass flow laws in π-shaped centripetal radial flow adsorber[J]. CIESC Journal, 2019, 70(9): 3385-3395.

| 结构参数 | 数值 | 结构参数 | 数值 |

|---|---|---|---|

| 吸附器半径/mm | 110 | 中心流道宽度/mm | 12 |

| 吸附器长度/mm | 210 | 吸附剂装填层厚度/mm | 62 |

| 进气口半径/mm | 12 | 外流道宽度/mm | 30 |

| 进气口长度/mm | 40 | 气流分布孔厚度/mm | 3 |

| 出气口半径/mm | 12 | 中心流道开孔半径/mm | 2 |

| 出气口长度/mm | 60 | 外流道开孔半径/mm | 4 |

| 吸附剂装填高度/mm | 20 | 吸附剂颗粒直径/mm | 3 |

| 中心流道气流分布孔开孔率/% | 17 | 外流道气流分布孔开孔率/% | 27 |

表1 π型向心径向流吸附器的主要结构参数

Table 1 Structure parameters of π-shaped radial flow adsorber

| 结构参数 | 数值 | 结构参数 | 数值 |

|---|---|---|---|

| 吸附器半径/mm | 110 | 中心流道宽度/mm | 12 |

| 吸附器长度/mm | 210 | 吸附剂装填层厚度/mm | 62 |

| 进气口半径/mm | 12 | 外流道宽度/mm | 30 |

| 进气口长度/mm | 40 | 气流分布孔厚度/mm | 3 |

| 出气口半径/mm | 12 | 中心流道开孔半径/mm | 2 |

| 出气口长度/mm | 60 | 外流道开孔半径/mm | 4 |

| 吸附剂装填高度/mm | 20 | 吸附剂颗粒直径/mm | 3 |

| 中心流道气流分布孔开孔率/% | 17 | 外流道气流分布孔开孔率/% | 27 |

| 参数 | 数值 |

|---|---|

| 气体组分 压力/ Pa | 21%O2,79%N2 101325 |

| 气相温度/ K | 293 |

| 固相温度/ K | 293 |

| 气相氧气质量分数 | 0.233 |

| 单位质量吸附剂氧气吸附量/( mol·kg-1) | 0.0262832 |

| 单位质量吸附剂氮气吸附量/( mol·kg-1) | 0.6328067 |

表2 初始条件

Table 2 Initial conditions

| 参数 | 数值 |

|---|---|

| 气体组分 压力/ Pa | 21%O2,79%N2 101325 |

| 气相温度/ K | 293 |

| 固相温度/ K | 293 |

| 气相氧气质量分数 | 0.233 |

| 单位质量吸附剂氧气吸附量/( mol·kg-1) | 0.0262832 |

| 单位质量吸附剂氮气吸附量/( mol·kg-1) | 0.6328067 |

| 参数 | 数值 |

|---|---|

| 床层孔隙率 | 0.4 |

| 颗粒密度 | 1035 |

| 直径 | 1.6 |

| 比热容/ (J·kg-1·K-1) | 1100 |

表3 模型具体参数

Table 3 Model parameters

| 参数 | 数值 |

|---|---|

| 床层孔隙率 | 0.4 |

| 颗粒密度 | 1035 |

| 直径 | 1.6 |

| 比热容/ (J·kg-1·K-1) | 1100 |

| 项目 | 升压 | 吸附 | 降压 | 反吹 |

|---|---|---|---|---|

| 循环过程 示意图 | | | | |

| 时间/s | 7 | 5 | 3 | 5 |

表4 循环顺序

Table 4 Cyclic sequence

| 项目 | 升压 | 吸附 | 降压 | 反吹 |

|---|---|---|---|---|

| 循环过程 示意图 | | | | |

| 时间/s | 7 | 5 | 3 | 5 |

| 入口 | 出口 | 床壁 | 轴线 |

|---|---|---|---|

| 质量入口q in(p) | 壁 | 壁 | 对称轴 |

| 质量入口q in(p) | 压力出口(大气压) | 壁 | 对称轴 |

| 压力出口(大气压) | 壁 | 壁 | 对称轴 |

| 压力出口(大气压) | 质量入口 | 壁 | 对称轴 |

表5 吸附器1边界条件设置

Table 5 Boundary condition setting of absorber 1

| 入口 | 出口 | 床壁 | 轴线 |

|---|---|---|---|

| 质量入口q in(p) | 壁 | 壁 | 对称轴 |

| 质量入口q in(p) | 压力出口(大气压) | 壁 | 对称轴 |

| 压力出口(大气压) | 壁 | 壁 | 对称轴 |

| 压力出口(大气压) | 质量入口 | 壁 | 对称轴 |

| 吸附质 | k 1/(mol·kg-1·Pa-1) | k 2/K | k 3/Pa-1 | k 4/K | ΔH/(kJ·mol-1) |

|---|---|---|---|---|---|

| O2 | 7.87×10-9 | 1541.211 | 6.79×10-10 | 1968.24 | 12 |

| N2 | 9.86×10-9 | 2010.908 | 1.67×10-9 | 2250 | 18 |

表6 吸附等温线参数

Table 6 Adsorption isotherm parameters

| 吸附质 | k 1/(mol·kg-1·Pa-1) | k 2/K | k 3/Pa-1 | k 4/K | ΔH/(kJ·mol-1) |

|---|---|---|---|---|---|

| O2 | 7.87×10-9 | 1541.211 | 6.79×10-10 | 1968.24 | 12 |

| N2 | 9.86×10-9 | 2010.908 | 1.67×10-9 | 2250 | 18 |

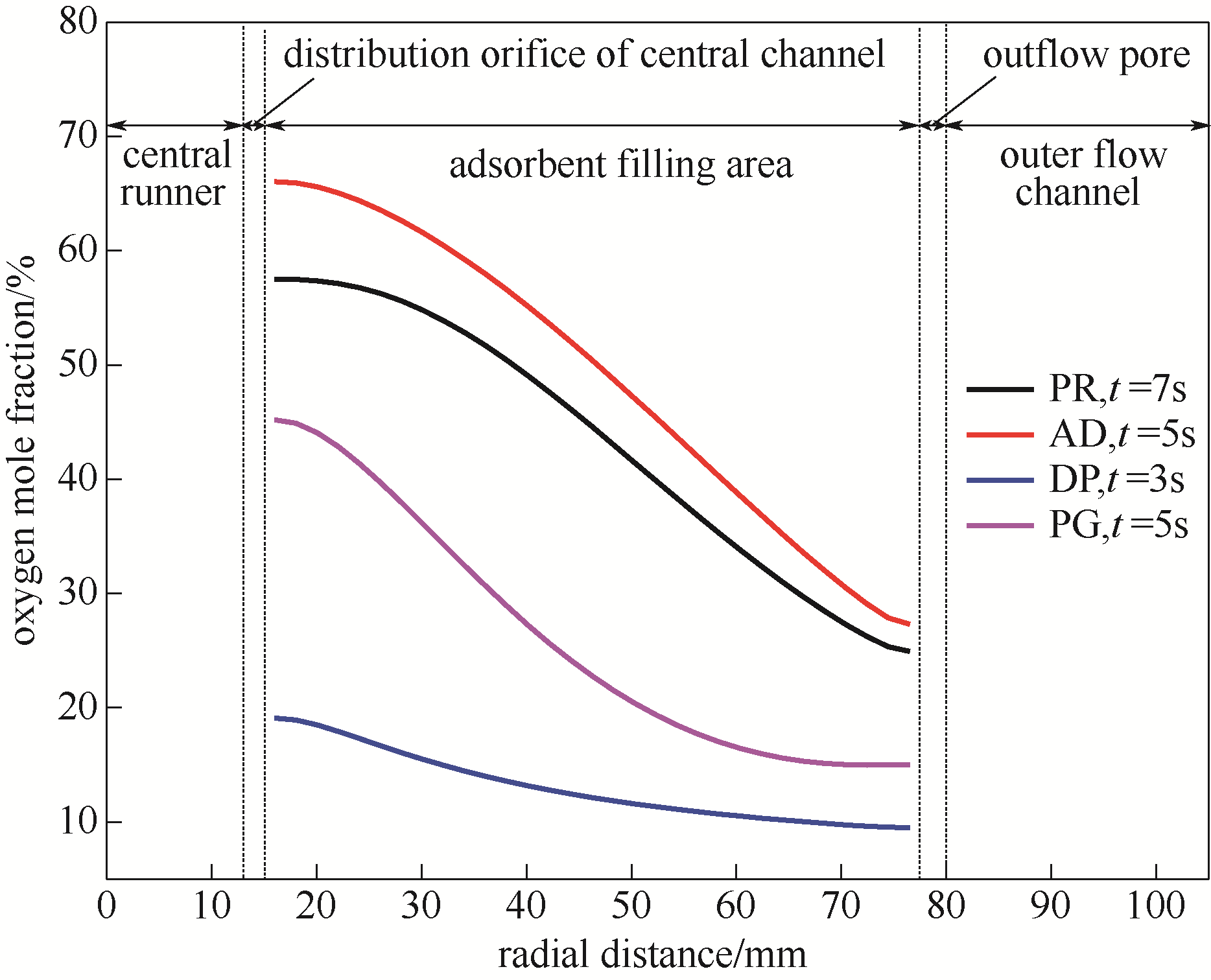

图4 首次循环结束时刻π型吸附器1中各阶段结束时刻氧气摩尔分数在L位置沿径向变化规律

Fig.4 Distribution of O2 concentration along L position at the end of each step for the first PSA process in π-RFA 1

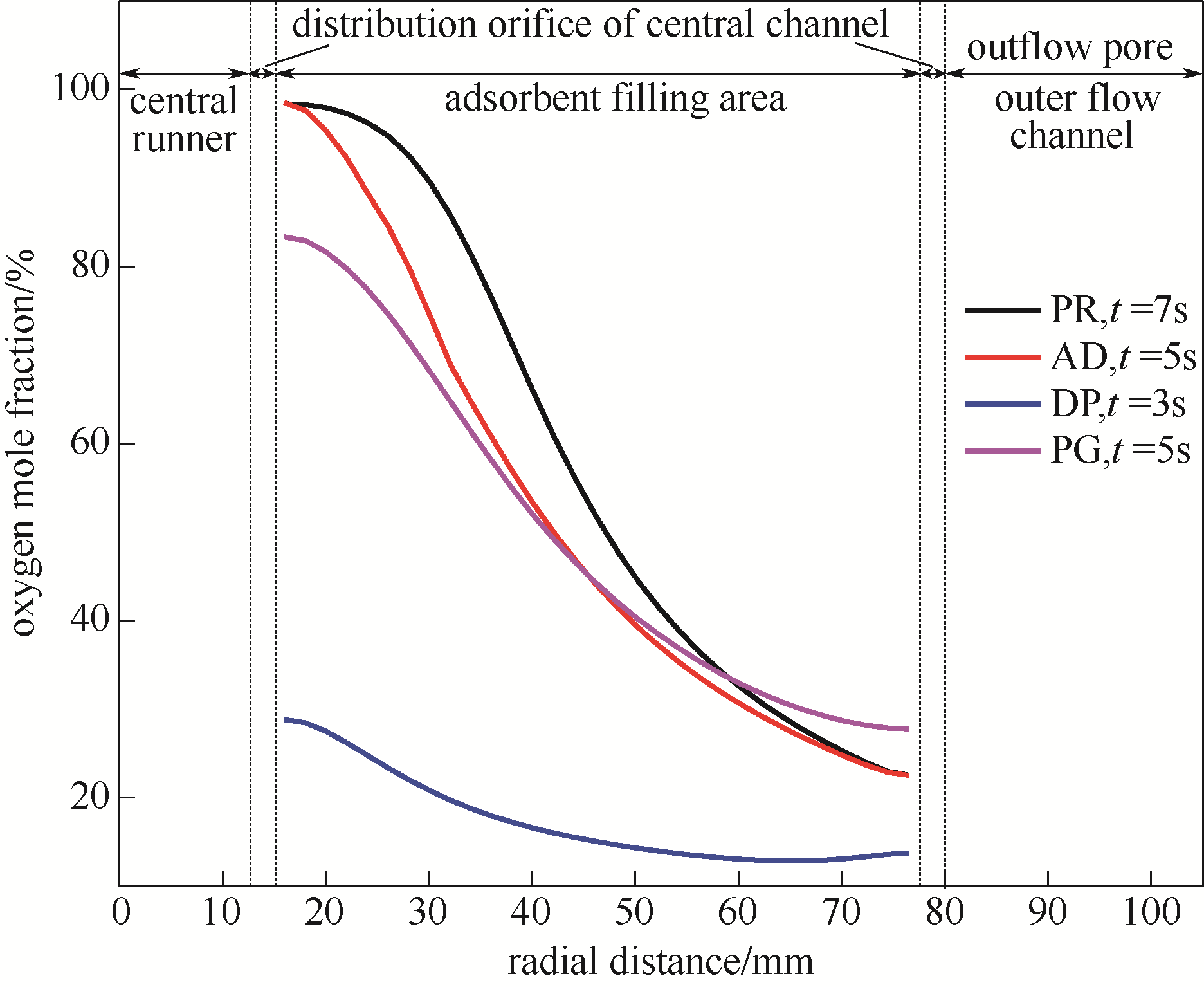

图9 循环稳定状态四步结束时刻床1中各阶段结束时刻氧气摩尔分数沿径向变化

Fig.9 Distribution of O2 concentration along L position at the end of each step after PSA process stabilized in π-RFA 1

| 1 | 王啸 . 非等温变压吸附空分制氧过程的计算和优化[D]. 南京: 南京工业大学, 2003. |

| Wang X . Computation and optimization of non-isothermal pressure swing adsorption process of air separation for oxygen[D]. Nanjing: Nanjing University of Technology, 2003. | |

| 2 | 侯梅芳, 崔杏雨, 李瑞丰 . 沸石分子筛在气体吸附分离方面的应用研究[J]. 太原理工大学学报, 2001, 32(2): 135-139. |

| Hou M F , Cui X Y , Li R F . Application of zeolite molecular sieves adsorbents in gas separation [J]. Journal of Taiyuan University of Technology, 2001, 32(2): 135-139. | |

| 3 | 李杰, 周理 . 变压吸附空分制氧的技术进展[J]. 化学工业与工程, 2004, 21(3): 201-205. |

| Li J , Zhou L . Progress in oxygen separation from air by pressure swing adsorption[J]. Chemical Industry and Engineering, 2004, 21(3): 201-205. | |

| 4 | Dai Z S , Yu M , Rui D Z , et al . Investigation on a vertical radial flow adsorber designed by a novel parallel connection method[J]. Chinese Journal of Chemical Engineering, 2018, 26(3): 484-493. |

| 5 | Tian Q Q , He G G , Wang Z P , et al . A novel radial adsorber with parallel layered beds for prepurification of large-scale air separation units[J]. Industrial & Engineering Chemistry Research, 2015, 54(30): 7502-7515. |

| 6 | Zheng T , Du Z L , Cao H Z , et al . Development of a novel mobile industrial-scale fluidized adsorption process for emergency treatment of water polluted by aniline: CFD simulation and experiments[J]. Advanced Powder Technology, 2016, 27(4): 1576-1587. |

| 7 | Li R J , Zhu Z B . Investigations on hydrodynamics of multilayer Π-type radial flow reactors[J]. Asia-Pacific Journal of Chemical Engineering, 2012, 7(4): 517-527. |

| 8 | Chiang A S T , Hong M C . Radial flow rapid pressure swing adsorption[J]. Adsorption, 1995, 1(2): 153-164. |

| 9 | 陆军亮, 张学军, 邱利民, 等 . 立式径向流吸附器中流体均布的理论分析[J]. 化工学报, 2012, 63(S2): 21-25. |

| Lu J L , Zhang X J , Qiu L M , et al . Theoretical analysis of uniform flow distribution in vertical radical adsorption bed[J]. CIESC Journal, 2012, 63(S2): 21-25. | |

| 10 | 陈瑶, 张学军, 陆军亮, 等 . 径向流吸附器流体流动特性及其结构参数优化[J]. 化工学报, 2014, 65(9): 3395-3402. |

| Chen Y , Zhang X J , Lu J L , et al . Flow characteristics of radical flow adsorber and its structure parameters optimization[J]. CIESC Journal, 2014, 65(9): 3395-3402. | |

| 11 | Kareeri A A , Zughbi H D , Al-Ali H H . Simulation of flow distribution in radial flow reactors[J]. Industrial & Engineering Chemistry Research, 2006, 45(8): 2862-2874. |

| 12 | 芮道哲, 张学军, 陈瑶, 等 . 立式分层并联径向流吸附器流场数值模拟[J]. 化工学报, 2015, 66(11): 4485-4492. |

| Rui D Z , Zhang X J , Chen Y , et al . Simulation of flow field in vertical radical flow adsorber with parallel connection device[J]. CIESC Journal, 2015, 66(11): 4485-4492. | |

| 13 | Bolton G T , Hooper C W , Mann R , et al . Flow distribution and velocity measurement in a radial flow fixed bed reactor using electrical resistance tomography[J]. Chemical Engineering Science, 2004, 59(10): 1989-1997. |

| 14 | 王恒, 顾雄毅 . 丁烯氧化脱氢径向床反应器流体力学特性研究[J]. 化学工程, 2018, 46(3): 36-40. |

| Wang H , Gu X Y . Hydrodynamic characteristics of radial flow reactor for oxidative dehydrogenation of butane to butadiene[J]. Chemical Engineering(China), 2018, 46(3): 36-40. | |

| 15 | 唐忠利, 徐明杨, 张俊 . 径向流空气纯化器内流场的模拟与分析[J]. 天津大学学报(自然科学与工程技术版), 2016, 49(3): 305-313. |

| Tang Z L , Xu M Y , Zhang J . Simulation and analysis on gas flow distribution in radial flow air adsorber[J]. Journal of Tianjin University (Science and Technology), 2016, 49(3): 305-313. | |

| 16 | 郑新港, 刘应书, 杨俊峰, 等 . 基于计算流体力学的吸附过程模拟研究[J]. 北京工业大学学报, 2012, 38(1): 145-150. |

| Zheng X G , Liu Y S , Yang J F , et al . Simulation of gas adsorption based on computational fluid dynamics[J]. Journal of Beijing University of Technology, 2012, 38(1): 145-150. | |

| 17 | 马素娟, 蓝兴英, 高金森, 等 . 径向流固定床反应器内流动规律的数值模拟[J]. 石油化工高等学校学报, 2007, 20(4): 68-75. |

| Ma S J , Lan X Y , Gao J S , et al . Numerical simulation on flow performance in radical flow fixed bed reactors[J]. Journal of Petrochemical Universities, 2007, 20(4): 68-75. | |

| 18 | 田津津, 张玉文, 王锐 . 变压吸附系统气流分布器结构的数值模拟计算及分析[J]. 低温工程, 2005, 146(4): 45-48. |

| Tian J J , Zhang Y W , Wang R . Numerical simulation of flow distributor of pressure swing adsorption system[J]. Cryogenics, 2005, 146(4): 45-48. | |

| 19 | Ewing R E , Wang J P , Weekes S L . On the simulation of multicomponent gas flow in porous media[J]. Applied Numerical Mathematics, 1999, 31(4): 405-410. |

| 20 | Zheng X G , Liu Y S , Liu W H . Two-dimensional modeling of the transport phenomena in the adsorber during pressure swing adsorption process[J]. Industrial & Engineering Chemistry Research, 2010, 49(22): 11814-11824. |

| 21 | Sadeghzadeh A J , Pakseresht S , Mahdyarfar M , et al . Predictive dynamic model of air separation by pressure swing adsorption[J]. Chemical Engineering & Technology, 2006, 29(1): 58-63. |

| 22 | Celik C E , Smolarek J . Radial bed flow distributor for radial pressure adsorber vessel: US 7128775B2[P]. 2006-10-31. |

| 23 | 王浩宇, 刘应书, 孟宇 . 径向流吸附器布气系统结构对布气效果的影响[J]. 工程科学学报, 2015, 37(1): 91-96. |

| Wang H Y , Liu Y S , Meng Y . Effect of the gas distribution system structure of a radial flow adsorber on gas distribution[J]. Chinese Journal of Engineering, 2015, 37(1): 91-96. | |

| 24 | Liu Y S , Zheng X G , Dai R F . Numerical study of flow maldistribution and depressurization strategies in a small-scale axial absorber[J]. Adsorption, 2014, 20(5/6): 757-768. |

| 25 | Sun L M , Amar N B , Meunier F . Numerical study on coupled heat and mass transfers in an adsorber with external fluid heating[J]. Heat Recovery Systems and CHP, 1995, 15(1): 19-29. |

| 26 | Zhu X Q , Liu Y S , Yang X , et al . Study of a novel rapid vacuum pressure swing adsorption process with intermediate gas pressurization for producing oxygen[J]. Adsorption, 2017, 23(1): 175-184. |

| 27 | Li Z Y , Liu Y S , Wang H Y , et al . A numerical modelling study of SO2 adsorption on activated carbons with new rate equations[J]. Chemical Engineering Journal, 2018, 353(1): 858-866. |

| 28 | Li G , Xiao P , Zhang J , et al . The role of water on postcombustion CO2 capture by vacuum swing adsorption: bed layering and purge to feed ratio[J]. AIChE Journal, 2014, 60(2): 673-689. |

| 29 | Yang X , Epiepang F E , Li J B , et al . Sr-LSX zeolite for air separation[J]. Chemical Engineering Journal, 2019, 362(1): 482-486. |

| 30 | Epiepang F E , Yang X , Li J B , et al . Mixed-cation LiCa-LSX zeolite with minimum lithium for air separation[J]. AIChE Journal, 2018, 64(2): 406-415. |

| 31 | Sorial G A , Granville W H , Daly W O . Adsorption equilibria for oxygen and nitrogen gas mixtures on 5A molecular sieves[J]. Chemical Engineering Science, 1983, 38(9): 1517-1523. |

| [1] | 周绍华, 詹飞龙, 丁国良, 张浩, 邵艳坡, 刘艳涛, 郜哲明. 短管节流阀内流动噪声的实验研究及降噪措施[J]. 化工学报, 2023, 74(S1): 113-121. |

| [2] | 叶展羽, 山訸, 徐震原. 用于太阳能蒸发的折纸式蒸发器性能仿真[J]. 化工学报, 2023, 74(S1): 132-140. |

| [3] | 张义飞, 刘舫辰, 张双星, 杜文静. 超临界二氧化碳用印刷电路板式换热器性能分析[J]. 化工学报, 2023, 74(S1): 183-190. |

| [4] | 王志国, 薛孟, 董芋双, 张田震, 秦晓凯, 韩强. 基于裂隙粗糙性表征方法的地热岩体热流耦合数值模拟与分析[J]. 化工学报, 2023, 74(S1): 223-234. |

| [5] | 江河, 袁俊飞, 王林, 邢谷雨. 均流腔结构对微细通道内相变流动特性影响的实验研究[J]. 化工学报, 2023, 74(S1): 235-244. |

| [6] | 宋嘉豪, 王文. 斯特林发动机与高温热管耦合运行特性研究[J]. 化工学报, 2023, 74(S1): 287-294. |

| [7] | 张思雨, 殷勇高, 贾鹏琦, 叶威. 双U型地埋管群跨季节蓄热特性研究[J]. 化工学报, 2023, 74(S1): 295-301. |

| [8] | 晁京伟, 许嘉兴, 李廷贤. 基于无管束蒸发换热强化策略的吸附热池的供热性能研究[J]. 化工学报, 2023, 74(S1): 302-310. |

| [9] | 肖明堃, 杨光, 黄永华, 吴静怡. 浸没孔液氧气泡动力学数值研究[J]. 化工学报, 2023, 74(S1): 87-95. |

| [10] | 温凯杰, 郭力, 夏诏杰, 陈建华. 一种耦合CFD与深度学习的气固快速模拟方法[J]. 化工学报, 2023, 74(9): 3775-3785. |

| [11] | 王玉兵, 李杰, 詹宏波, 朱光亚, 张大林. R134a在菱形离散肋微小通道内的流动沸腾换热实验研究[J]. 化工学报, 2023, 74(9): 3797-3806. |

| [12] | 杨学金, 杨金涛, 宁平, 王访, 宋晓双, 贾丽娟, 冯嘉予. 剧毒气体PH3的干法净化技术研究进展[J]. 化工学报, 2023, 74(9): 3742-3755. |

| [13] | 袁佳琦, 刘政, 黄锐, 张乐福, 贺登辉. 泡状入流条件下旋流泵能量转换特性研究[J]. 化工学报, 2023, 74(9): 3807-3820. |

| [14] | 何松, 刘乔迈, 谢广烁, 王斯民, 肖娟. 高浓度水煤浆管道气膜减阻两相流模拟及代理辅助优化[J]. 化工学报, 2023, 74(9): 3766-3774. |

| [15] | 韩晨, 司徒友珉, 朱斌, 许建良, 郭晓镭, 刘海峰. 协同处理废液的多喷嘴粉煤气化炉内反应流动研究[J]. 化工学报, 2023, 74(8): 3266-3278. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号