化工学报 ›› 2021, Vol. 72 ›› Issue (8): 4019-4029.DOI: 10.11949/0438-1157.20201442

许峻1( ),王智峰2,侯凯军2,高永福2,范怡平1(

),王智峰2,侯凯军2,高永福2,范怡平1( ),卢春喜1

),卢春喜1

收稿日期:2020-10-15

修回日期:2021-03-29

出版日期:2021-08-05

发布日期:2021-08-05

通讯作者:

范怡平

作者简介:许峻(1995—),男,硕士研究生,基金资助:

Jun XU1( ),Zhifeng WANG2,Kaijun HOU2,Yongfu GAO2,Yiping FAN1(

),Zhifeng WANG2,Kaijun HOU2,Yongfu GAO2,Yiping FAN1( ),Chunxi LU1

),Chunxi LU1

Received:2020-10-15

Revised:2021-03-29

Online:2021-08-05

Published:2021-08-05

Contact:

Yiping FAN

摘要:

为改善催化裂化工艺的产品分布,在传统单层向上原料喷嘴进料结构基础上,增加了2个对称、向下的“副喷嘴”。通过一套大型冷模实验装置,考察这种新型双层喷嘴进料段结构内气固流动混合特性,同时利用射流“二次流”理论,分析了逆向喷嘴射流二次流在提升管内的形成发展过程。实验结果表明,与传统单层向上喷嘴(主喷嘴)结构相比,双层喷嘴结构能够改善主喷嘴附近油剂匹配程度,提高气固接触效率。同时副喷嘴的加入可以将提升管进料段长度缩短1/3,减少油剂混合时间,加快气固相达到均匀稳定,实现抑制油气过度裂解,提高目标产品收率,降低生焦量的目的。

中图分类号:

许峻, 王智峰, 侯凯军, 高永福, 范怡平, 卢春喜. 双层喷嘴进料提升管内气固流动混合特性的大型冷模实验研究[J]. 化工学报, 2021, 72(8): 4019-4029.

Jun XU, Zhifeng WANG, Kaijun HOU, Yongfu GAO, Yiping FAN, Chunxi LU. Experimental and theoretical study on gas-solid flow characteristics in feedstock injection zone of FCC riser with double-layer nozzles[J]. CIESC Journal, 2021, 72(8): 4019-4029.

图4 实验装置1—罗茨鼓风机;2—缓冲罐;3—气体分配器;4—转子流量计;5—预提升段;6—up-down双层喷嘴结构;7—提升管;8—超短快分;9,10—旋风分离器;11,14—计量罐;12,15—蝶阀;13—料;16—储料伴床;17—循环斜管

Fig.4 Schematic diagram of experimental apparatus

图5 三种喷嘴气速下进料段内颗粒固含率、速度和射流特征浓度的径向分布

Fig.5 Radial distribution of solid holdup, velocity and jet characteristic concentration in the feed injection at three nozzle velocities

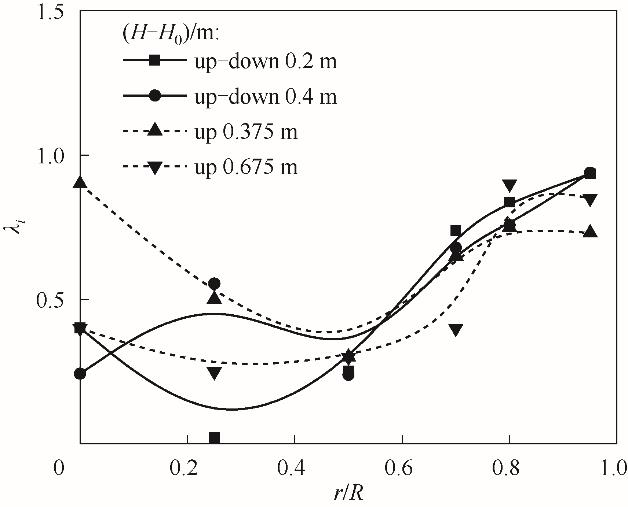

图7 双层喷嘴与传统单层向上喷嘴进料段内油剂匹配指数分布(Uj=80 m/s)

Fig.7 Distribution of oil/catalyst matching index in feed injection of double nozzle and traditional single upward nozzle (Uj=80 m/s)

| 1 | 卢春喜, 范怡平, 刘梦溪, 等. 催化裂化反应系统关键装备技术研究进展[J]. 石油学报(石油加工), 2018, 34(3): 441-454. |

| Lu C X, Fan Y P, Liu M X, et al. Advances in key equipment technologies of reaction system in RFCC unit[J]. Acta Petrolei Sinica (Petroleum Processing Section), 2018, 34(3): 441-454. | |

| 2 | 汪申, 时铭显. 我国催化裂化提升管反应系统设备技术的进展[J]. 石油化工动态, 2000, 8(5): 46-50. |

| Wang S, Shi M X. Progress of domestic FCC riser reactor technology[J]. Petrochemical Industry Trends, 2000, 8(5): 46-50. | |

| 3 | 王钊, 闫子涵, 范怡平, 等. 催化裂化提升管进料混合段研究进展[J]. 当代化工, 2015, 44(5): 997-1000. |

| Wang Z, Yan Z H, Fan Y P, et al. Research progress of feed injection-mixing zone in FCC riser[J]. Contemporary Chemical Industry, 2015, 44(5): 997-1000. | |

| 4 | 邓任生, 魏飞, 胡永琪, 等. 流态化及流固接触技术[J]. 现代化工, 1999, 19(12): 11-14. |

| Deng R S, Wei F, Hu Y Q, et al. Fluidization and fluid solids contact technique[J]. Modern Chemical Industry, 1999, 19(12): 11-14. | |

| 5 | 黄卫星, 漆小波, 潘永亮, 等. 气固循环床提升管内的局部颗粒浓度及流动发展[J]. 高校化学工程学报, 2002, 16(6): 626-631. |

| Huang W X, Qi X B, Pan Y L, et al. Local solid-particle concentration and flow development in a long CFB riser[J]. Journal of Chemical Engineering of Chinese Universities, 2002, 16(6): 626-631. | |

| 6 | 鄂承林, 范怡平, 卢春喜, 等. 喷嘴进料对提升管进料段内颗粒浓度径向分布的影响[J]. 过程工程学报, 2008, 8(1): 18-22. |

| E C L, Fan Y P, Lu C X, et al. Effect of jet gas on solid hold-up profile in the feed injection section of the riser[J]. The Chinese Journal of Process Engineering, 2008, 8(1): 18-22. | |

| 7 | Bai D R, Jin Y, Yu Z Q, et al. The axial distribution of the cross-sectionally averaged voidage in fast fluidized beds[J]. Powder Technology, 1992, 71(1): 51-58. |

| 8 | 鄂承林, 范怡平, 卢春喜, 等. 提升管喷嘴进料段内油、剂两相接触状况研究[J]. 高校化学工程学报, 2008, 22(3): 447-453. |

| E C L, Fan Y P, Lu C X, et al. Matching of the catalysts with feed jet gas in the feed injection section of FCC riser[J]. Journal of Chemical Engineering of Chinese Universities, 2008, 22(3): 447-453. | |

| 9 | 刘丙超, 苏鲁书, 张善鹤, 等. 新型变径提升管冷模实验研究[J]. 石油炼制与化工, 2018, 49(3): 48-53. |

| Liu B C, Su L S, Zhang S H, et al. Cold mold study of a novel diameter-changing riser reactor[J]. Petroleum Processing and Petrochemicals, 2018, 49(3): 48-53. | |

| 10 | 钟孝湘, 侯拴弟, 郑茂军, 等. 抗滑落提升管反应器流体力学性能的研究[J]. 石油炼制与化工, 2000, 31(7): 45-50. |

| Zhong X X, Hou S D, Zheng M J, et al. Study on flow hydrodynamics of anti-down-slipping riser[J]. Petroleum Processing and Petrochemicals, 2000, 31(7): 45-50. | |

| 11 | 郑茂军, 侯栓弟, 钟孝湘, 等. 两种提升管反应器中颗粒速度分布的测定[J]. 石油炼制与化工, 2000, 31(2): 45-51. |

| Zheng M J, Hou S D, Zhong X X, et al. Determining the particle velocity distribution in FCC riser with different structure[J]. Petroleum Processing and Petrochemicals, 2000, 31(2): 45-51. | |

| 12 | Mauleon J L, Demar M, Jean-Bernard S. Method for the injection of catalyst in a fluid catalytic cracking process, especially for heavy feedstocks: US4832825[P]. 1989-05-23. |

| 13 | 范怡平, 叶盛, 卢春喜, 等. 提升管反应器进料混合段内气固两相流动特性(Ⅰ): 实验研究[J]. 化工学报, 2002, 53(10): 1003-1008. |

| Fan Y P, Ye S, Lu C X, et al. Gas-solid two phase flow in feed injection zone of FCC riser reactors (Ⅰ): Experimental research[J]. Journal of Chemical Industry and Engineering (China), 2002, 53(10): 1003-1008. | |

| 14 | 范怡平, 叶盛, 卢春喜, 等. 提升管反应器进料混合段内气固两相流动特性(Ⅱ):理论分析[J]. 化工学报, 2002, 53(10): 1009-1014. |

| Fan Y P, Ye S, Lu C X, et al. Gas-solid two phase flow in feed injection zone of FCC riser reactors (Ⅱ): Analytical research[J]. Journal of Chemical Industry and Engineering (China), 2002, 53(10): 1009-1014. | |

| 15 | 范怡平, 鄂承林, 卢春喜, 等. 矢量优化技术在FCC进料喷嘴开发中的应用(Ⅰ): “外部矢量”的优化[J]. 炼油技术与工程, 2011, 41(4): 28-33. |

| Fan Y P, E C L, Lu C X, et al. Application of vector-optimization in FCC feed nozzle development(Ⅰ): Optimization of external vectors[J]. Petroleum Refinery Engineering, 2011, 41(4): 28-33. | |

| 16 | 范怡平, 鄂承林, 卢春喜, 等. 矢量优化技术在FCC进料雾化喷嘴开发中的应用(Ⅱ): 喷嘴“内部矢量”的优化[J]. 炼油技术与工程, 2011, 41(5): 29-34. |

| Fan Y P, E C L, Lu C X, et al. Application of vector-optimization in FCC feed nozzle development(Ⅱ): Optimization of internal vectors[J]. Petroleum Refinery Engineering, 2011, 41(5): 29-34. | |

| 17 | 许峻, 范怡平, 钱筱婕, 等. 催化裂化提升管进料段喷嘴射流运动-扩散特性的分析[J]. 化工学报, 2020, 71(4): 1450-1459. |

| Xu J, Fan Y P, Qian X J, et al. Theoretical analysis of motion-diffusion characteristics in feed injection zone of FCC riser[J]. CIESC Journal, 2020, 71(4): 1450-1459. | |

| 18 | Yan Z H, Fan Y P, Wang Z, et al. Dispersion of feed spray in a new type of FCC feed injection scheme[J]. AIChE Journal, 2016, 62(1): 46-61. |

| 19 | 闫子涵, 秦小刚, 陈昇, 等. 油剂逆流接触提升管进料段固含率及颗粒速度的径向分布[J]. 过程工程学报, 2014, 14(5): 721-729. |

| Yan Z H, Qin X G, Chen S, et al. Radial distributions of solids hold-up and particle velocity in FCC riser feed injection zone with catalyst-feed oil countercurrent contact[J]. The Chinese Journal of Process Engineering, 2014, 14(5): 721-729. | |

| 20 | 边京, 赵凤静, 范怡平, 等. 油剂逆流接触FCC提升管进料段内喷嘴射流浓度的分布[J]. 高校化学工程学报, 2017, 31(6): 1276-1284. |

| Bian J, Zhao F J, Fan Y P, et al. Distribution of feed jet concentration in catalyst-feed countercurrent contacting injection zone of a FCC riser[J]. Journal of Chemical Engineering of Chinese Universities, 2017, 31(6): 1276-1284. | |

| 21 | 赵凤静, 边京, 范怡平. 新型提升管进料段内压力脉动强度分布的影响因素[J]. 过程工程学报, 2018, 18(1): 69-74. |

| Zhao F J, Bian J, Fan Y P. Influencing factors on distribution of pressure pulsation intensity in injection zone of a novel FCC riser[J]. The Chinese Journal of Process Engineering, 2018, 18(1): 69-74. | |

| 22 | 范怡平, 卢春喜. 催化裂化提升管进料段内多相流动及其结构优化[J]. 化工学报, 2018, 69(1): 249-258. |

| Fan Y P, Lu C X. Multiphase flow characteristics and structural optimization in feed injection zone of FCC riser[J]. CIESC Journal, 2018, 69(1): 249-258. | |

| 23 | Wang W, Li J H. Simulation of gas-solid two-phase flow by a multi-scale CFD approach—extension of the EMMS model to the sub-grid level[J]. Chemical Engineering Science, 2007, 62(1/2): 208-231. |

| 24 | 王维, 洪坤, 鲁波娜, 等. 流态化模拟: 基于介尺度结构的多尺度CFD[J]. 化工学报, 2013, 64(1): 95-106. |

| Wang W, Hong K, Lu B N, et al. Fluidized bed simulation: structure-dependent multiscale CFD[J]. CIESC Journal, 2013, 64(1): 95-106. | |

| 25 | 刘德烈, 韩剑敏. LPC型催化裂化反应进料喷嘴工业应用评价[J]. 炼油设计, 1992, 22(2): 49-52. |

| Liu D L, Han J M. Evaluation on commercial application of LPC type nozzle for FCC feed[J]. Petroleum Refinery Engineering, 1992, 22(2): 49-52. | |

| 26 | Zhu L Y, Fan Y P, Lu C X. Mixing of cold and hot particles in a pre-lifting scheme with two strands of catalyst inlets for FCC riser[J]. Powder Technology, 2014, 268: 126-138. |

| 27 | 闫子涵, 许峻, 范怡平, 等. 喷嘴射流在气固提升管内的扩散和混合行为[J]. 过程工程学报, 2020, 20(7): 798-806. |

| Yan Z H, Xu J, Fan Y P, et al. Diffusion and mixing behaviors of nozzle jet in the gas-solid riser[J]. The Chinese Journal of Process Engineering, 2020, 20(7): 798-806. | |

| 28 | 王钊, 闫子涵, 范怡平, 等. 新型催化裂化提升管进料段内原料射流浓度分布的大型冷模实验研究[J]. 过程工程学报, 2016, 16(1): 34-40. |

| Wang Z, Yan Z H, Fan Y P, et al. Experimental study on distribution of feed jet gas concentration in the injection zone of a novel riser in a large scale cold mold[J]. The Chinese Journal of Process Engineering, 2016, 16(1): 34-40. | |

| 29 | 费广平, 李瑞军, 解东来, 等. 利用热导检测器实时检测混合气体组分含量的方法及装置[J]. 化工进展, 2009, 28(12): 2257-2260. |

| Fei G P, Li R J, Xie D L, et al. Method and apparatus for real-time gas concentration detection in gas mixture[J]. Chemical Industry and Engineering Progress, 2009, 28(12): 2257-2260. | |

| 30 | 闫子涵, 王钊, 陈昇, 等. 新型催化裂化提升管进料段油、剂两相混合特性[J]. 化工学报, 2016, 67(8): 3304-3312. |

| Yan Z H, Wang Z, Chen S, et al. Matching between oil and catalyst in new scheme of FCC feed injection[J]. CIESC Journal, 2016, 67(8): 3304-3312. |

| [1] | 肖明堃, 杨光, 黄永华, 吴静怡. 浸没孔液氧气泡动力学数值研究[J]. 化工学报, 2023, 74(S1): 87-95. |

| [2] | 宋瑞涛, 王派, 王云鹏, 李敏霞, 党超镔, 陈振国, 童欢, 周佳琦. 二氧化碳直接蒸发冰场排管内流动沸腾换热数值模拟分析[J]. 化工学报, 2023, 74(S1): 96-103. |

| [3] | 杨越, 张丹, 郑巨淦, 涂茂萍, 杨庆忠. NaCl水溶液喷射闪蒸-掺混蒸发的实验研究[J]. 化工学报, 2023, 74(8): 3279-3291. |

| [4] | 何宣志, 何永清, 闻桂叶, 焦凤. 磁液液滴颈部自相似破裂行为[J]. 化工学报, 2023, 74(7): 2889-2897. |

| [5] | 董明, 徐进良, 刘广林. 超临界水非均质特性分子动力学研究[J]. 化工学报, 2023, 74(7): 2836-2847. |

| [6] | 郑志航, 马郡男, 闫子涵, 卢春喜. 提升管射流影响区内压力脉动特性研究[J]. 化工学报, 2023, 74(6): 2335-2350. |

| [7] | 张伟政, 赵吉军, 马学忠, 张琦璇, 庞益祥, 张俊涛. 湍流效应对高速机械密封端面型槽冷却性能影响分析[J]. 化工学报, 2023, 74(3): 1228-1238. |

| [8] | 李新亚, 邢雷, 蒋明虎, 赵立新. 倒锥注气强化井下油水分离水力旋流器性能研究[J]. 化工学报, 2023, 74(3): 1134-1144. |

| [9] | 颜少航, 赖天伟, 王彦武, 侯予, 陈双涛. 微间隙内R134a空化可视化实验研究[J]. 化工学报, 2023, 74(3): 1054-1061. |

| [10] | 章承浩, 罗京, 张吉松. 微反应器内基于氮氧自由基催化剂连续氧气/空气氧化反应的研究进展[J]. 化工学报, 2023, 74(2): 511-524. |

| [11] | 熊昊, 梁潇予, 张晨曦, 白浩隆, 范晓宇, 魏飞. 重质油直接制化工品:多级逆流下行催化裂解技术[J]. 化工学报, 2023, 74(1): 86-104. |

| [12] | 郝泽光, 张乾, 高增林, 张宏文, 彭泽宇, 杨凯, 梁丽彤, 黄伟. 生物质与催化裂化油浆共热解协同作用研究[J]. 化工学报, 2022, 73(9): 4070-4078. |

| [13] | 陈昇, 王梦钶, 鲁波娜, 李秀峰, 刘岑凡, 刘梦溪, 范怡平, 卢春喜. 原料油汽化特性对催化裂化反应结焦过程影响的CFD模拟[J]. 化工学报, 2022, 73(7): 2982-2995. |

| [14] | 罗佳, 吴双应, 肖兰, 周世耀, 陈志莉. 撞击速度对连续液滴撞击热圆柱壁面局部传热特性影响的实验[J]. 化工学报, 2022, 73(7): 2944-2951. |

| [15] | 孔令菲, 陈延佩, 王维. 气固流态化中颗粒介尺度结构的动力学研究[J]. 化工学报, 2022, 73(6): 2486-2495. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号