• •

关朝阳1,2( ), 黄国庆1,2, 张一喃1,2, 陈宏霞1,2(

), 黄国庆1,2, 张一喃1,2, 陈宏霞1,2( ), 杜小泽1,2

), 杜小泽1,2

收稿日期:2024-01-24

修回日期:2024-03-22

出版日期:2024-04-03

通讯作者:

陈宏霞

作者简介:关朝阳(2000—),男,硕士研究生,gzy13514512459@163.com

基金资助:

Chaoyang GUAN1,2( ), Guoqing HUANG1,2, Yinan ZHANG1,2, Hongxia CHEN1,2(

), Guoqing HUANG1,2, Yinan ZHANG1,2, Hongxia CHEN1,2( ), Xiaoze DU1,2

), Xiaoze DU1,2

Received:2024-01-24

Revised:2024-03-22

Online:2024-04-03

Contact:

Hongxia CHEN

摘要:

流动沸腾作为一种高效的换热方法,被广泛应用于高热流设备的冷却。在流动沸腾换热过程中可通过设置多孔疏水结构促进沸腾气泡脱离,为强化沸腾换热提供新思路。在截面为6 mm×4 mm的矩形通道顶部添加浸润角为140°的多孔泡沫铜;并在液相入口温度70 ℃、75 ℃和80 ℃,流速为6.94 cm/s、10.42 cm/s和13.89 cm/s的不同工况下,观测通道内沸腾两相流流型变化以及泡沫铜的吸气过程对流动沸腾换热性能的影响;基于气泡受力分析获得泡沫铜吸气强化流动沸腾的换热机理。结果显示,在本实验工况范围内添加脱气泡沫铜后,壁面过热度下降可达20.7%;泡沫铜的吸气率为0.81时,热通量可提高至152%;增大入口流速,泡沫铜强化效果显著增大,而入口温度对泡沫铜的吸气效果影响不明显。

中图分类号:

关朝阳, 黄国庆, 张一喃, 陈宏霞, 杜小泽. 泡沫铜导离气泡强化流动沸腾换热实验研究[J]. 化工学报, DOI: 10.11949/0438-1157.20240109.

Chaoyang GUAN, Guoqing HUANG, Yinan ZHANG, Hongxia CHEN, Xiaoze DU. Experimental study on enhancement of flow boiling through degassing with copper foam[J]. CIESC Journal, DOI: 10.11949/0438-1157.20240109.

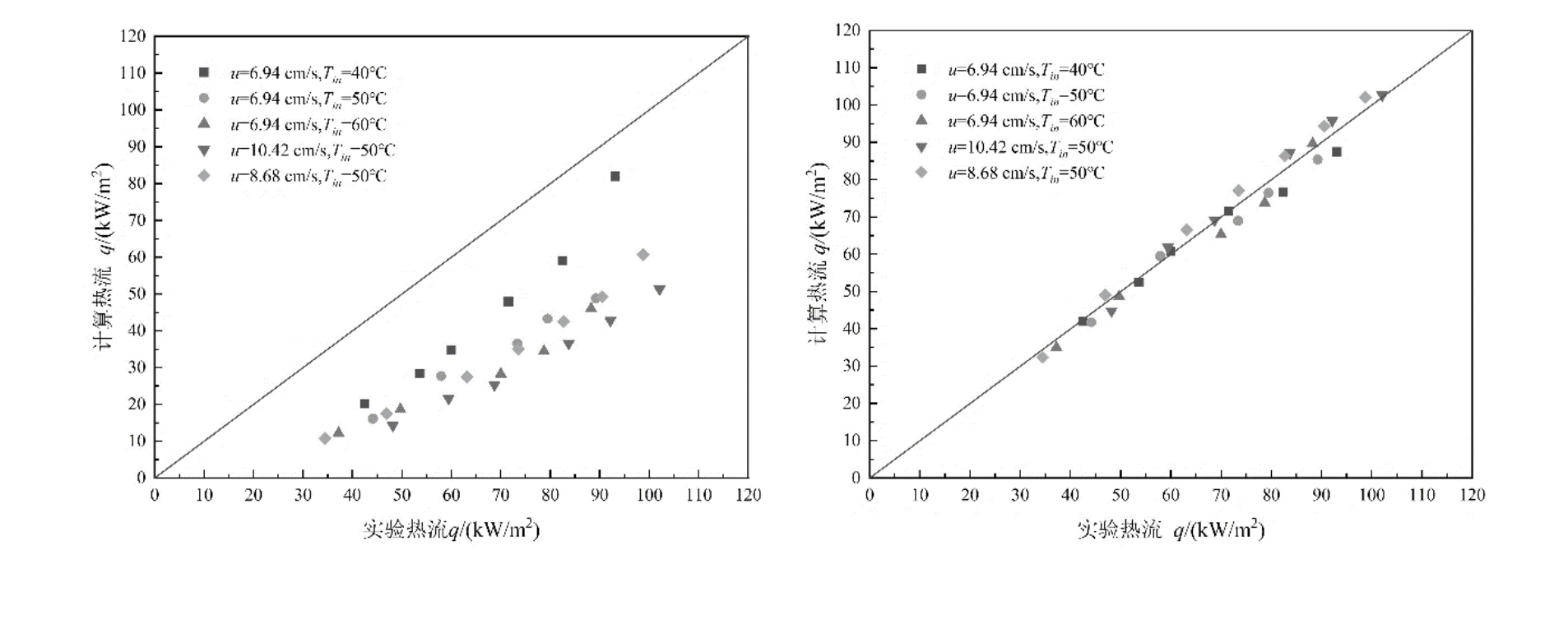

图4 基于实验数据修正计算公式 (a) 经典Sieder-Tate公式 (b) 修正后公式

Fig.4 Model modification based on experimental results (a) Classic Sieder-Tate formula (b) Modified formula

| 1 | 党超, 贾力, 黄浅. 矩形微槽道内R134a流动沸腾换热特性的实验研究[J]. 工程热物理学报, 2017, 38(6): 1327-1332. |

| Dang C, Jia L, Huang Q. Experimental study on flow boiling heat transfer characteristics of R134a in a rectangular micro-channel[J]. Journal of Engineering Thermophysics, 2017, 38(6): 1327-1332. | |

| 2 | Wang J, Cheng Y, Li X B, et al. Experimental and LBM simulation study on the effect of bubbles merging on flow boiling[J]. International Journal of Heat and Mass Transfer, 2019, 132: 1053-1061. |

| 3 | Bi Q.C Characteristics of two-phase flow and boiling heat transfer in miniature non-circular channels[D]. University of Science and Technology Library, Ph.D., 2000. DOI: 10.14711/thesis-b678763 . |

| 4 | 罗炜, 贺静, 罗兵, 等. 截面形状对微通道流动沸腾影响的数值研究[J]. 西安交通大学学报, 2019, 53(11): 101-111. |

| Luo W, He J, Luo B, et al. Numerical study on the effect of cross-sectional shape of microchannels on flow boiling[J]. Journal of Xi'an Jiaotong University, 2019, 53(11): 101-111. | |

| 5 | Jiang Y, Xu Y, Qin J, et al. The flow rate distribution of hydrocarbon fuel in parallel channels with different cross section shapes[J]. Applied Thermal Engineering, 2018, 137: 173-183. |

| 6 | Sempértegui-Tapia D F, Ribatski G. The effect of the cross-sectional geometry on saturated flow boiling heat transfer in horizontal micro-scale channels[J]. Experimental Thermal and Fluid Science, 2017, 89: 98-109. |

| 7 | 邓聪, 罗小平, 冯振飞, 等. 矩形微通道内制冷剂流动沸腾传热特性及可视化研究[J]. 制冷学报, 2015, 36(6): 1-5. |

| Deng C, Luo X P, Feng Z F, et al. Research on boiling heat transfer characteristics and visualization of refrigerant in rectangular microchannels[J]. Journal of Refrigeration, 2015, 36(6): 1-5. | |

| 8 | Kuo C J, Peles Y. Flow boiling instabilities in microchannels and means for mitigation by reentrant cavities[J]. Journal of Heat Transfer, 2008, 130(7):1. |

| 9 | Xia G D, Ma D D, Zhai Y L, et al. Experimental and numerical study of fluid flow and heat transfer characteristics in microchannel heat sink with complex structure[J]. Energy Conversion and Management, 2015, 105: 848-857. |

| 10 | Sitar A, Golobic I. Effect of nucleation cavities on enhanced boiling heat transfer in microchannels[J]. Nanoscale and Microscale Thermophysical Engineering, 2016, 20(1): 33-50. |

| 11 | Zhu Y, Hu H, Sun S, et al. Heat transfer measurements and correlation of refrigerant flow boiling in tube filled with copper foam[J]. International Journal of Refrigeration-Revue Internationale Du Froid, 2014, 38: 215-226. |

| 12 | Min D H, Hwang G S, Usta Y, et al. 2-D and 3-D modulated porous coatings for enhanced pool boiling[J]. International Journal of Heat and Mass Transfer, 2009, 52(11/12): 2607-2613. |

| 13 | Law M, Lee P S. A comparative study of experimental flow boiling heat transfer and pressure characteristics in straight- and oblique-finned microchannels[J]. International Journal of Heat and Mass Transfer, 2015, 85: 797-810. |

| 14 | Filho E P B, Jabardo J M S, Barbieri P E L. Convective boiling pressure drop of refrigerant R-134a in horizontal smooth and microfin tubes[J]. International Journal of Refrigeration, 2004, 27(8): 895-903. |

| 15 | Kim C H, Bang I C, Chang S H. Critical heat flux performance for flow boiling of R-134a in vertical uniformly heated smooth tube and rifled tubes[J]. International Journal of Heat and Mass Transfer, 2005, 48(14): 2868-2877. |

| 16 | Cheng L, Xia G. Experimental study of CHF in a vertical spirally internally ribbed tube under the condition of high pressures[J]. International Journal of Thermal Sciences, 2002, 41(4): 396-400. |

| 17 | Ma A X, Wei J J, Yuan M Z, et al. Enhanced flow boiling heat transfer of FC-72 on micro-pin-finned surfaces[J]. International Journal of Heat and Mass Transfer, 2009, 52(13/14): 2925-2931. |

| 18 | Wan W, Deng D X, Huang Q S, et al. Experimental study and optimization of pin fin shapes in flow boiling of micro pin fin heat sinks[J]. Applied Thermal Engineering, 2017, 114: 436-449. |

| 19 | Koşar A, Peles Y. Boiling heat transfer in a hydrofoil-based micro pin fin heat sink[J]. International Journal of Heat and Mass Transfer, 2007, 50(5-6): 1018-1034. |

| 20 | 陈宏霞, 肖红洋, 孙源, 等. 微柱表面液滴定壁温沸腾实验研究[J]. 化工学报, 2019, 70(9): 3363-3369. |

| Chen H X, Xiao H Y, Sun Y, et al. Experimental study on droplets boiling on micro-pillar structure surface with constant temperatures[J]. CIESC Journal, 2019, 70(9): 3363-3369. | |

| 21 | Choi C, Shin J S, Yu D I, et al. Flow boiling behaviors in hydrophilic and hydrophobic microchannels[J]. Experimental Thermal and Fluid Science, 2010, 35(5): 816-824. |

| 22 | Kousalya A S, Singh K P, Fisher T S. Heterogeneous wetting surfaces with graphitic petal-decorated carbon nanotubes for enhanced flow boiling[J]. International Journal of Heat and Mass Transfer, 2015, 87: 380-389. |

| 23 | Kim J M, Kim T, Yu D I, et al. Effect of heterogeneous wetting surface characteristics on flow boiling performance[J]. International Journal of Heat and Fluid Flow, 2018, 70: 141-151. |

| 24 | 陈宏霞, 马福民, 黄林滨. 超浸润性金属丝网的制备及工艺优化[J]. 材料工程, 2017, 45(9): 59-65. |

| Chen H X, Ma F M, Huang L B. Fabrication and process optimization of super-wettability metal mesh[J]. Journal of Materials Engineering, 2017, 45(9): 59-65. | |

| 25 | Chen H X, Xu J L, Li Z J, et al. Stratified two-phase flow pattern modulation in a horizontal tube by the mesh pore cylinder surface[J]. Applied Energy, 2013, 112: 1283-1290. |

| 26 | Peng X F, Peterson G P, Wang B X. Heat transfer characteristics of water flowing through microchannels[J]. Experimental Heat Transfer, 1994, 7(4): 265-283. |

| 27 | Matsuda Y, Kawanami O, Orimo R, et al. Simultaneous measurement of gas-liquid interface motion and temperature distribution on heated surface using temperature-sensitive paint[J]. International Journal of Heat and Mass Transfer, 2020, 153: 119567 |

| 28 | Lee H S. Heat Transfer Predictions using the Chen Correlation on Subcooled Flow Boiling in a Standard IC Engine[C]//SAE Technical Paper Series. 400 Commonwealth Drive, Warrendale, PA, United States: SAE International, 2009: 2009-01-1530. |

| 29 | Hua S Y, Huang R H, Li Z, et al. Experimental study on the heat transfer characteristics of subcooled flow boiling with cast iron heating surface[J]. Applied Thermal Engineering, 2015, 77: 180-191. |

| 30 | Chen J C. Correlation for boiling heat transfer to saturated fluids in convective flow[J]. Industrial & Engineering Chemistry Process Design and Development, 1966, 5(3): 322-329. |

| 31 | Rohsenow W M. A method of correlating heat-transfer data for surface boiling of liquids[J]. Journal of Fluids Engineering, 1952, 74(6): 969-975. |

| 32 | Reddy Karri S B. Dynamics of bubble departure in micro-gravity[J]. Chemical Engineering Communications, 1988, 70(1): 127-135. |

| 33 | Levy S. Forced convection subcooled boiling—prediction of vapor volumetric fraction[J]. International Journal of Heat and Mass Transfer, 1967, 10(7): 951-965. |

| [1] | 赵碧丹, 代伊杨, 王军武, 张永民. CFD-DEM-IBM方法探究流化床倾斜挡板内构件受力特性[J]. 化工学报, 2024, 75(1): 255-267. |

| [2] | 崔怡洲, 李成祥, 翟霖晓, 刘束玉, 石孝刚, 高金森, 蓝兴英. 亚毫米气泡和常规尺寸气泡气液两相流流动与传质特性对比[J]. 化工学报, 2024, 75(1): 197-210. |

| [3] | 周尧, 杨小平, 倪一程, 刘继平, 魏进家, 严俊杰. 应用于新型环路热管的两相引射器数值模拟[J]. 化工学报, 2024, 75(1): 268-278. |

| [4] | 李晓阳, 李东, 陶明磊, 周致富, 张灵怡, 苏力争, 张天宁, 李智, 陈斌. 多喷嘴喷雾冷却表面传热特性实验研究[J]. 化工学报, 2024, 75(1): 231-241. |

| [5] | 王义江, 孙莉, 刘梦涵, 杨金宏, 王国元. 基于响应面法的矿用翅片管空冷器参数优化[J]. 化工学报, 2024, 75(1): 279-291. |

| [6] | 邵苛苛, 宋孟杰, 江正勇, 张旋, 张龙, 高润淼, 甄泽康. 水平方向上冰中受陷气泡形成和分布实验研究[J]. 化工学报, 2023, 74(S1): 161-164. |

| [7] | 张双星, 刘舫辰, 张义飞, 杜文静. R-134a脉动热管相变蓄放热实验研究[J]. 化工学报, 2023, 74(S1): 165-171. |

| [8] | 张义飞, 刘舫辰, 张双星, 杜文静. 超临界二氧化碳用印刷电路板式换热器性能分析[J]. 化工学报, 2023, 74(S1): 183-190. |

| [9] | 陈爱强, 代艳奇, 刘悦, 刘斌, 吴翰铭. 基板温度对HFE7100液滴蒸发过程的影响研究[J]. 化工学报, 2023, 74(S1): 191-197. |

| [10] | 刘明栖, 吴延鹏. 导光管直径和长度对传热影响的模拟分析[J]. 化工学报, 2023, 74(S1): 206-212. |

| [11] | 王志国, 薛孟, 董芋双, 张田震, 秦晓凯, 韩强. 基于裂隙粗糙性表征方法的地热岩体热流耦合数值模拟与分析[J]. 化工学报, 2023, 74(S1): 223-234. |

| [12] | 江河, 袁俊飞, 王林, 邢谷雨. 均流腔结构对微细通道内相变流动特性影响的实验研究[J]. 化工学报, 2023, 74(S1): 235-244. |

| [13] | 晁京伟, 许嘉兴, 李廷贤. 基于无管束蒸发换热强化策略的吸附热池的供热性能研究[J]. 化工学报, 2023, 74(S1): 302-310. |

| [14] | 程成, 段钟弟, 孙浩然, 胡海涛, 薛鸿祥. 表面微结构对析晶沉积特性影响的格子Boltzmann模拟[J]. 化工学报, 2023, 74(S1): 74-86. |

| [15] | 肖明堃, 杨光, 黄永华, 吴静怡. 浸没孔液氧气泡动力学数值研究[J]. 化工学报, 2023, 74(S1): 87-95. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号