化工学报 ›› 2021, Vol. 72 ›› Issue (5): 2706-2717.DOI: 10.11949/0438-1157.20201340

收稿日期:2020-09-21

修回日期:2020-12-20

出版日期:2021-05-05

发布日期:2021-05-05

通讯作者:

祝敬涛

作者简介:侯勇俊(1967—),男,博士,教授,基金资助:

HOU Yongjun1( ),ZHU Jingtao1(

),ZHU Jingtao1( ),LI Huachuan2,WU Xianjin3,JIANG Rui2

),LI Huachuan2,WU Xianjin3,JIANG Rui2

Received:2020-09-21

Revised:2020-12-20

Online:2021-05-05

Published:2021-05-05

Contact:

ZHU Jingtao

摘要:

旋转振动筛广泛应用于各行业对于粉体和胶体的分级。单电机旋振筛的激振力不通过振动体质心,使振动体随质心作圆运动和绕质心作圆锥摆运动。这种运动使得筛面上的垂直振幅不均匀,存在着颗粒物料向筛面周边扩散较快、物料层较厚、筛分效率较低、颗粒均匀度较差的问题。因此提出了一种均衡运动原理的旋振筛,通过DEM数值模拟,从筛分效率的角度直观比较了旋振筛在常规运动和均衡运动下的筛面物料运动规律、颗粒粒度分布情况、固相筛分效率及颗粒运动速度。研究表明:均衡运动下物料向筛面周边旋转扩散更为均匀,其物料层较薄,能有效提高旋振筛的固相筛分效率及筛分颗粒的均匀度,可较好解决颗粒粒径与筛孔孔径比在0.7~1.0之间时颗粒透筛相对困难的问题。

中图分类号:

侯勇俊, 祝敬涛, 李华川, 吴先进, 蒋锐. 均衡运动旋转振动筛DEM数值模拟[J]. 化工学报, 2021, 72(5): 2706-2717.

HOU Yongjun, ZHU Jingtao, LI Huachuan, WU Xianjin, JIANG Rui. DEM numerical simulation on rotary vibrating screen under balanced motion[J]. CIESC Journal, 2021, 72(5): 2706-2717.

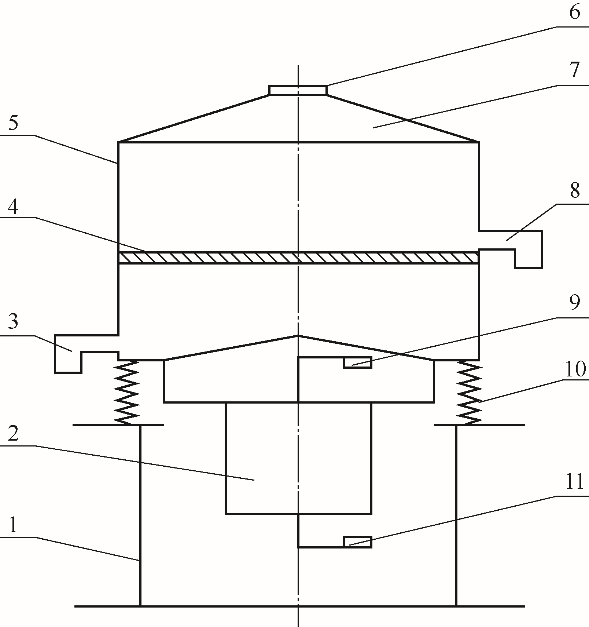

图1 单电机旋振筛结构简图1—cylinder seat; 2—vibration motor; 3—discharge tube for undersize material; 4—screen mesh; 5—screen box; 6—material inlet; 7—screen box cover; 8—discharge tube for oversize material; 9—upper eccentric block; 10—vibration isolation spring; 11—underlying eccentric block

Fig.1 Structure diagram of single motor rotary vibrating screen

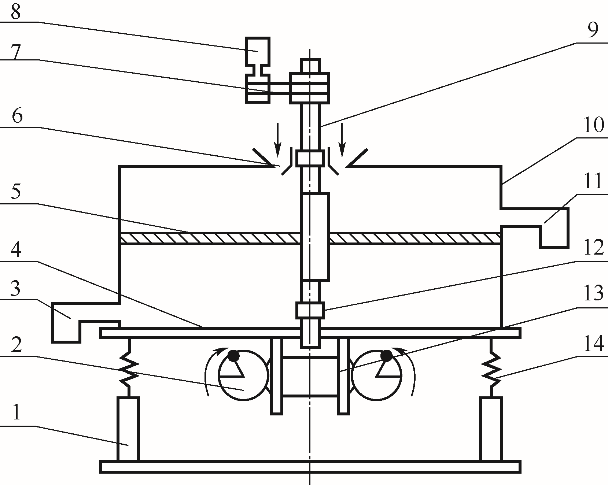

图3 一种均衡运动旋振筛结构简图1—screen frame;2—vibration motor;3—discharge tube for undersize material;4—frame;5—annular screen mesh;6—material inlet;7—conveyor belt;8—rotary motor;9—eccentric axis;10—screen box;11—discharge tube for oversize material;12—bearing;13—motor base;14—vibration isolation spring

Fig.3 Simplified structure diagram of a rotary vibrating screen under balanced motion

| m0/kg | r/m | M/kg | ω/(rad·s-1) | k/(N·m)-1 |

|---|---|---|---|---|

| 3 | 0.1 | 150 | 148 | 156000 |

| l1/m | l2/m | Jz/(kg·m2) | J/(kg·m2) | c/(N·m·rad-1) |

| 0.23 | 0.29 | 0.188 | 48.23 | 18126 |

表1 单电机旋振筛系统参数

Table 1 System parameters of single motor rotary vibrating screen

| m0/kg | r/m | M/kg | ω/(rad·s-1) | k/(N·m)-1 |

|---|---|---|---|---|

| 3 | 0.1 | 150 | 148 | 156000 |

| l1/m | l2/m | Jz/(kg·m2) | J/(kg·m2) | c/(N·m·rad-1) |

| 0.23 | 0.29 | 0.188 | 48.23 | 18126 |

| Working condition | α/rad | A/mm | θ/rad | δ/rad |

|---|---|---|---|---|

| 1 | 0.000 | 4.199 | -0.005 | 1.571 |

| 2 | 0.262 | 4.163 | -0.005 | 1.533 |

| 3 | 0.524 | 4.056 | -0.005 | 1.495 |

| 4 | 0.785 | 3.880 | -0.005 | 1.454 |

| 5 | 1.047 | 3.637 | -0.005 | 1.408 |

表2 单电机旋振筛仿真参数

Table 2 Simulation parameters of single motor rotary vibrating screen

| Working condition | α/rad | A/mm | θ/rad | δ/rad |

|---|---|---|---|---|

| 1 | 0.000 | 4.199 | -0.005 | 1.571 |

| 2 | 0.262 | 4.163 | -0.005 | 1.533 |

| 3 | 0.524 | 4.056 | -0.005 | 1.495 |

| 4 | 0.785 | 3.880 | -0.005 | 1.454 |

| 5 | 1.047 | 3.637 | -0.005 | 1.408 |

| Working condition | θz/rad | Az/mm |

|---|---|---|

| 1 | 0.021 | 1.029 |

| 2 | 0.021 | 1.021 |

| 3 | 0.020 | 0.997 |

| 4 | 0.019 | 0.958 |

| 5 | 0.018 | 0.903 |

表3 均衡运动旋振筛仿真参数

Table 3 Simulation parameters of rotary vibrating screen under balanced motion

| Working condition | θz/rad | Az/mm |

|---|---|---|

| 1 | 0.021 | 1.029 |

| 2 | 0.021 | 1.021 |

| 3 | 0.020 | 0.997 |

| 4 | 0.019 | 0.958 |

| 5 | 0.018 | 0.903 |

| Parameter | Particle | Rotary vibrating screen |

|---|---|---|

| Poisson's ratio | 0.2 | 0.3 |

| shear modulus /Pa | 5×107 | 7×1010 |

| solids density /(kg·m-3) | 2600 | 7800 |

表4 材料特性参数

Table 4 Material characteristic parameter

| Parameter | Particle | Rotary vibrating screen |

|---|---|---|

| Poisson's ratio | 0.2 | 0.3 |

| shear modulus /Pa | 5×107 | 7×1010 |

| solids density /(kg·m-3) | 2600 | 7800 |

| Parameter | Particle to particle | Particle to rotary vibrating screen |

|---|---|---|

| coefficient of restitution | 0.003 | 0.4 |

| static friction coefficient | 0.3 | 0.5 |

| rolling friction coefficient | 0.010 | 0.002 |

表5 碰撞特性参数

Table 5 Collision characteristic parameter

| Parameter | Particle to particle | Particle to rotary vibrating screen |

|---|---|---|

| coefficient of restitution | 0.003 | 0.4 |

| static friction coefficient | 0.3 | 0.5 |

| rolling friction coefficient | 0.010 | 0.002 |

| Parameter | Particle | ||

|---|---|---|---|

| d/a=0.5—0.7 | d/a=0.7—1.0 | d/a=1.0—3.0 | |

| diameter /mm | 2.4 | 3.4 | 5.0 |

| number of particles /s-1 | 500 | 1000 | 3500 |

| percentage /% | 10 | 20 | 70 |

表6 入料颗粒粒径分布情况

Table 6 The initial size distribution on particles

| Parameter | Particle | ||

|---|---|---|---|

| d/a=0.5—0.7 | d/a=0.7—1.0 | d/a=1.0—3.0 | |

| diameter /mm | 2.4 | 3.4 | 5.0 |

| number of particles /s-1 | 500 | 1000 | 3500 |

| percentage /% | 10 | 20 | 70 |

| Working condition | Solid phase screening efficiency/% | Particle screening rate/% | |

|---|---|---|---|

| d/a=0.5—0.7 | d/a=0.7—1.0 | ||

| 1 | 82.67 | 98.00 | 75.00 |

| 2 | 80.87 | 97.40 | 72.60 |

| 3 | 83.00 | 98.40 | 75.30 |

| 4 | 86.53 | 99.40 | 80.10 |

| 5 | 88.60 | 99.60 | 83.10 |

表7 常规运动旋振筛的固相筛分效率及颗粒透筛率

Table 7 Solid phase screening efficiency and particle screening rate of rotary vibrating screen under normal motion

| Working condition | Solid phase screening efficiency/% | Particle screening rate/% | |

|---|---|---|---|

| d/a=0.5—0.7 | d/a=0.7—1.0 | ||

| 1 | 82.67 | 98.00 | 75.00 |

| 2 | 80.87 | 97.40 | 72.60 |

| 3 | 83.00 | 98.40 | 75.30 |

| 4 | 86.53 | 99.40 | 80.10 |

| 5 | 88.60 | 99.60 | 83.10 |

| Working condition | Solid phase screening efficiency/% | Particle screening rate/% | |

|---|---|---|---|

| d/a=0.5—0.7 | d/a=0.7—1.0 | ||

| 1 | 90.27 | 98.60 | 86.10 |

| 2 | 89.60 | 99.40 | 84.70 |

| 3 | 90.07 | 97.80 | 86.20 |

| 4 | 91.53 | 99.00 | 87.80 |

| 5 | 93.47 | 99.20 | 90.60 |

表8 均衡运动旋振筛的固相筛分效率及颗粒透筛率

Table 8 Solid phase screening efficiency and particle screening rate of rotary vibrating screen under balanced motion

| Working condition | Solid phase screening efficiency/% | Particle screening rate/% | |

|---|---|---|---|

| d/a=0.5—0.7 | d/a=0.7—1.0 | ||

| 1 | 90.27 | 98.60 | 86.10 |

| 2 | 89.60 | 99.40 | 84.70 |

| 3 | 90.07 | 97.80 | 86.20 |

| 4 | 91.53 | 99.00 | 87.80 |

| 5 | 93.47 | 99.20 | 90.60 |

| Condition | Solid phase screening efficiency/% | Particle screening rate/% | |

|---|---|---|---|

| d/a=0.5—0.7 | d/a=0.7—1.0 | ||

| d=6 mm(normal motion) | 84.13 | 98.60 | 76.90 |

| d=6 mm(balanced motion) | 91.93 | 98.20 | 88.80 |

| d=8 mm(normal motion) | 85.53 | 99.20 | 78.70 |

| d=8 mm(balanced motion) | 91.53 | 99.60 | 87.50 |

表9 不同筛孔孔径下旋振筛的固相筛分效率及颗粒透筛率(工况3)

Table 9 Solid phase screening efficiency and particle screening rate of rotary vibrating screen under different aperture size (working condition 3)

| Condition | Solid phase screening efficiency/% | Particle screening rate/% | |

|---|---|---|---|

| d/a=0.5—0.7 | d/a=0.7—1.0 | ||

| d=6 mm(normal motion) | 84.13 | 98.60 | 76.90 |

| d=6 mm(balanced motion) | 91.93 | 98.20 | 88.80 |

| d=8 mm(normal motion) | 85.53 | 99.20 | 78.70 |

| d=8 mm(balanced motion) | 91.53 | 99.60 | 87.50 |

| 1 | Jiang J, Liu S Y, Wen B C. Dynamics analysis, selection and calculation on the parameters of a rotary vibrating screen[J]. Transactions of the Canadian Society for Mechanical Engineering, 2016, 40(4): 563-573. |

| 2 | Winistorfer P M. A concentric rotary laboratory screen for wood particle classification[J]. Europe PMC, 1985, 35(3): 39-41. |

| 3 | 段新豪, 张春华. 摇摆筛的发展现状及趋势[J]. 中国粉体技术, 2014, 20(5): 81-83. |

| Duan X H, Zhang C H. Current technical status and future prospects of tumbler screening machines[J]. China Powder Science and Technology, 2014, 20(5): 81-83. | |

| 4 | Pocwiardowski W, Wodzinski P. Biological material sieving in rotary screen[J]. Rocznik Ochrona Srodowiska, 2011, 13(5): 1115-1131. |

| 5 | 侯彤. 旋振筛在粉体加工中的应用实践[J]. 现代经济信息, 2015, (16): 336. |

| Hou T. Spin vibration sieve practice in powder processing[J]. Modern Economic Information, 2015, (16): 336. | |

| 6 | Bellocq B, Ruiz T, Delaplace G, et al. Screening efficiency and rolling effects of a rotating screen drum used to process wet soft agglomerates[J]. Journal of Food Engineering, 2017, 195: 235-246. |

| 7 | Djoković J M, Tanikić D I, Nikolić R R, et al. Screening efficiency analysis of vibrosieves with the circular vibrations[J]. Civil and Environmental Engineering, 2017, 13(1): 77-83. |

| 8 | Wang G F, Tong X. Screening efficiency and screen length of a linear vibrating screen using DEM 3D simulation[J]. Mining Science and Technology (China), 2011, 21(3): 451-455. |

| 9 | Grozubinsky V, Sultanovitch E, Lin I J. Efficiency of solid particle screening as a function of screen slot size, particle size, and duration of screening: the theoretical approach[J]. International Journal of Mineral Processing, 1998, 52(4): 261-272. |

| 10 | Jafari A, Nezhad V S. Employing DEM to study the impact of different parameters on the screening efficiency and mesh wear[J]. Powder Technology, 2016, 297: 126-143. |

| 11 | Dong K J, Esfandiary A H, Yu A B. Discrete particle simulation of particle flow and separation on a vibrating screen: effect of aperture shape[J]. Powder Technology, 2017, 314: 195-202. |

| 12 | 陈亚哲, 姚红良, 刘刚. 振动参数对筛分效率影响的实验研究[J]. 东北大学学报(自然科学版), 2019, 40(8): 1122-1126. |

| Chen Y Z, Yao H L, Liu G. Experimental study on influence of vibration parameters on screening efficiency[J]. Journal of Northeastern University (Natural Science), 2019, 40(8): 1122-1126. | |

| 13 | 杜逸穹. 旋振筛筛分过程的DEM仿真研究[D]. 沈阳: 东北大学, 2011. |

| Du Y Q. Research on DEM simulation of spin vibration screening process[D]. Shenyang: Northeastern University, 2011. | |

| 14 | Alkhaldi H, Eberhard P. Particle screening phenomena in an oblique multi-level tumbling reservoir: a numerical study using discrete element simulation[J]. Granular Matter, 2007, 9(6): 415-429. |

| 15 | Lawinska K, Modrzewski R. Analysis of sieve holes blocking in a vibrating screen and a rotary and drum screen[J]. Physicochemical Problems of Mineral Processing, 2017, 53(2): 812-828. |

| 16 | 董杏昕, 卢亚平, 廖波兰. 胶粉生产用旋振筛的关键技术研究[J]. 矿冶, 2016, 25(2): 62-66. |

| Dong X X, Lu Y P, Liao B L. Key technical study of circular vibratory screener for gum powder production[J]. Mining and Metallurgy, 2016, 25(2): 62-66. | |

| 17 | 杨晋. 基于煤样筛分的筛上物料动态特性研究[D]. 太原: 中北大学, 2017. |

| Yang J. Study on dynamic characteristics of material on sieves based on the screening of coal samples[D]. Taiyuan: North University of China, 2017. | |

| 18 | 闫宏伟, 汪洋, 马建强, 等. 新型旋振筛电动机转速对物料运动特性的影响分析[J]. 煤炭科学技术, 2018, 46(3): 148-154. |

| Yan H W, Wang Y, Ma J Q, et al. Analysis on new motor speed of rotary vibration screen affected to material kinematic characteristics[J]. Coal Science and Technology, 2018, 46(3): 148-154. | |

| 19 | Sobolev G P. Effect of the parameters of a rotary-vibration (gyratory) screen on its performance[J]. Glass and Ceramics, 1963, 20(6): 323-327. |

| 20 | 赵平, 邱允武, 胡建国, 等. Q20湿式标准筛旋振筛机的研制及应用[J]. 有色金属(选矿部分), 2020, (2): 104-109. |

| Zhao P, Qiu Y W, Hu J G, et al. Research and application on Q20 standardized wet vibrating screen machine[J]. Nonferrous Metals (Mineral Processing Section), 2020, (2): 104-109. | |

| 21 | 谭海军. 旋转筛刚柔耦合动力学研究[D]. 成都: 西南石油大学, 2019. |

| Tan H J. Research on the dynamics of rigid-flexible coupling of rotary vibrating screen[D]. Chengdu: Southwest Petroleum University, 2019. | |

| 22 | 侯勇俊, 谭海军, 方潘, 等. 双激振电机驱动旋转振动筛系统的同步理论研究[J]. 振动与冲击, 2019, 38(7): 179-185. |

| Hou Y J, Tan H J, Fang P, et al. Self-synchronization theory for rotary vibrating screen systems driven by two motors[J]. Journal of Vibration and Shock, 2019, 38(7): 179-185. | |

| 23 | 张强, 赵光红, 王军. 提高XZS-(1.2)M型旋振筛生产效率研究[J]. 硅谷, 2014, 7(10): 187-188. |

| Zhang Q, Zhao G H, Wang J. Research on improving the production efficiency of rotary vibrating screen with XZS-(1.2)M type[J]. Silicon Valley, 2014, 7(10): 187-188. | |

| 24 | 洛传锋, 邓淑娟. 圆形转动盘离心式振动筛分机: 104275296A[P]. 2015-01-14. |

| Luo C F, Deng S J. A rotary vibrating screen with a circular rotary centrifugal disk: 104275296A[P]. 2015-01-14. | |

| 25 | 朱宏政, 刘令云, 朱金波, 等. 旋转振动筛分机: 104353608[P]. 2016-01-06. |

| Zhu H Z, Liu L Y, Zhu J B, et al. A rotary vibrating screen: 104353608[P]. 2016-01-06. | |

| 26 | 王泳嘉, 邢纪波. 离散单元法及其在岩土力学中的应用[M]. 沈阳: 东北工学院出版社, 1991. |

| Wang Y J, Xing J B. Discrete Element Method and Its Application in Geomediology[M]. Shenyang: Northeastern University Press, 1991. | |

| 27 | Gan J Q, Yu A B. DEM simulation of the packing of cylindrical particles[J]. Granular Matter, 2020, 22(1): 1-19. |

| 28 | Wu X Q, Li Z F, Xia H H, et al. Vibration parameter optimization of a linear vibrating banana screen using DEM 3D simulation[J]. Journal of Engineering and Technological Sciences, 2018, 50(3): 346-363. |

| 29 | Davoodi A, Bengtsson M, Hulthén E, et al. Effects of screen decks' aperture shapes and materials on screening efficiency[J]. Minerals Engineering, 2019, 139: 105699. |

| 30 | Chen B, Yan J W, Mo W, et al. DEM simulation and experimental study on the screening process of elliptical vibration mechanical systems[J]. Journal of Vibroengineering, 2019, 21(8): 2025-2038. |

| 31 | Qiao J P, Duan C L, Jiang H S, et al. Research on screening mechanism and parameters optimization of equal thickness screen with variable amplitude based on DEM simulation[J]. Powder Technology, 2018, 331: 296-309. |

| 32 | 胡华文. 圆形泥浆振动筛的动力学研究[D]. 南充: 西南石油学院, 1990. |

| Hu H W. A study of dynamics for the round shale shaker[D]. Nanchong: Southwest Petroleum University, 1990. | |

| 33 | Cleary P W. DEM simulation of industrial particle flows: case studies of dragline excavators, mixing in tumblers and centrifugal mills[J]. Powder Technology, 2000, 109(1/2/3): 83-104. |

| 34 | Mindlin R D, Deresiewicz H. Elastic spheres in contact under varying oblique forces[J]. Journal of Applied Mechanics, 1953, 38(20): 327-334. |

| 35 | Campbell C S. Stress-controlled elastic granular shear flows[J]. Journal of Fluid Mechanics, 2005, 539: 273. |

| 36 | 赵永志, 江茂强, 郑津洋. 巴西果效应分离过程的计算颗粒力学模拟研究[J]. 物理学报, 2009, 58(3): 1812-1818. |

| Zhao Y Z, Jiang M Q, Zheng J Y. Discrete element simulation of the segregation in Brazil nut problem[J]. Acta Physica Sinica, 2009, 58(3): 1812-1818. | |

| 37 | 鲍春永. 基于DEM的振动筛分过程机理研究[D]. 北京: 中国矿业大学, 2016. |

| Bao C Y. Study on vibrating screening process mechanism basing on DEM[D]. Beijing: China University of Mining and Technology, 2016. |

| [1] | 宋嘉豪, 王文. 斯特林发动机与高温热管耦合运行特性研究[J]. 化工学报, 2023, 74(S1): 287-294. |

| [2] | 张思雨, 殷勇高, 贾鹏琦, 叶威. 双U型地埋管群跨季节蓄热特性研究[J]. 化工学报, 2023, 74(S1): 295-301. |

| [3] | 叶展羽, 山訸, 徐震原. 用于太阳能蒸发的折纸式蒸发器性能仿真[J]. 化工学报, 2023, 74(S1): 132-140. |

| [4] | 张义飞, 刘舫辰, 张双星, 杜文静. 超临界二氧化碳用印刷电路板式换热器性能分析[J]. 化工学报, 2023, 74(S1): 183-190. |

| [5] | 王志国, 薛孟, 董芋双, 张田震, 秦晓凯, 韩强. 基于裂隙粗糙性表征方法的地热岩体热流耦合数值模拟与分析[J]. 化工学报, 2023, 74(S1): 223-234. |

| [6] | 何松, 刘乔迈, 谢广烁, 王斯民, 肖娟. 高浓度水煤浆管道气膜减阻两相流模拟及代理辅助优化[J]. 化工学报, 2023, 74(9): 3766-3774. |

| [7] | 邢雷, 苗春雨, 蒋明虎, 赵立新, 李新亚. 井下微型气液旋流分离器优化设计与性能分析[J]. 化工学报, 2023, 74(8): 3394-3406. |

| [8] | 韩晨, 司徒友珉, 朱斌, 许建良, 郭晓镭, 刘海峰. 协同处理废液的多喷嘴粉煤气化炉内反应流动研究[J]. 化工学报, 2023, 74(8): 3266-3278. |

| [9] | 郑玉圆, 葛志伟, 韩翔宇, 王亮, 陈海生. 中高温钙基材料热化学储热的研究进展与展望[J]. 化工学报, 2023, 74(8): 3171-3192. |

| [10] | 程小松, 殷勇高, 车春文. 不同工质在溶液除湿真空再生系统中的性能对比[J]. 化工学报, 2023, 74(8): 3494-3501. |

| [11] | 刘文竹, 云和明, 王宝雪, 胡明哲, 仲崇龙. 基于场协同和 耗散的微通道拓扑优化研究[J]. 化工学报, 2023, 74(8): 3329-3341. 耗散的微通道拓扑优化研究[J]. 化工学报, 2023, 74(8): 3329-3341. |

| [12] | 洪瑞, 袁宝强, 杜文静. 垂直上升管内超临界二氧化碳传热恶化机理分析[J]. 化工学报, 2023, 74(8): 3309-3319. |

| [13] | 黄可欣, 李彤, 李桉琦, 林梅. 加装旋转叶轮T型通道流场的模态分解[J]. 化工学报, 2023, 74(7): 2848-2857. |

| [14] | 史方哲, 甘云华. 超薄热管启动特性和传热性能数值模拟[J]. 化工学报, 2023, 74(7): 2814-2823. |

| [15] | 江锦波, 彭新, 许文烜, 门日秀, 刘畅, 彭旭东. 泵出型螺旋槽油气密封泄漏特性及参数影响研究[J]. 化工学报, 2023, 74(6): 2538-2554. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号