化工学报 ›› 2021, Vol. 72 ›› Issue (7): 3728-3737.DOI: 10.11949/0438-1157.20201919

收稿日期:2020-12-28

修回日期:2021-03-17

出版日期:2021-07-05

发布日期:2021-07-05

通讯作者:

姚传义

作者简介:姚传义(1969—),男,博士,副教授,基金资助:

YAO Chuanyi( ),ZHENG Zhenwei,TU Zhixian,LU Yinghua

),ZHENG Zhenwei,TU Zhixian,LU Yinghua

Received:2020-12-28

Revised:2021-03-17

Online:2021-07-05

Published:2021-07-05

Contact:

YAO Chuanyi

摘要:

以C18为固定相、甲醇/水=70/30(体积比)为流动相,利用三区带模拟移动床分离了两种生物碱,吴茱萸碱和吴茱萸次碱。通过前沿分析法测定了两种生物碱的吸附等温线,在实验浓度范围内符合线性吸附等温线,吴茱萸碱和吴茱萸次碱的亨利系数分别为3.11和5.25。利用经验公式估算了轴向扩散系数和有效传质系数。分别利用三角形理论和基于模型的优化方法对三区带模拟移动床的操作条件进行设计,在优化的条件下,最大进料流量为0.55 ml?min-1,两种产品纯度均大于99%。通过异步切换策略,在不增加设备投资及保证产品纯度大于99%的前提下,将进料流量提高至0.62 ml?min-1。

中图分类号:

姚传义, 郑震玮, 涂志贤, 卢英华. 模拟移动床色谱分离吴茱萸碱和吴茱萸次碱[J]. 化工学报, 2021, 72(7): 3728-3737.

YAO Chuanyi, ZHENG Zhenwei, TU Zhixian, LU Yinghua. Separation of evodiamine and rutaecarpine with simulated moving bed chromatography[J]. CIESC Journal, 2021, 72(7): 3728-3737.

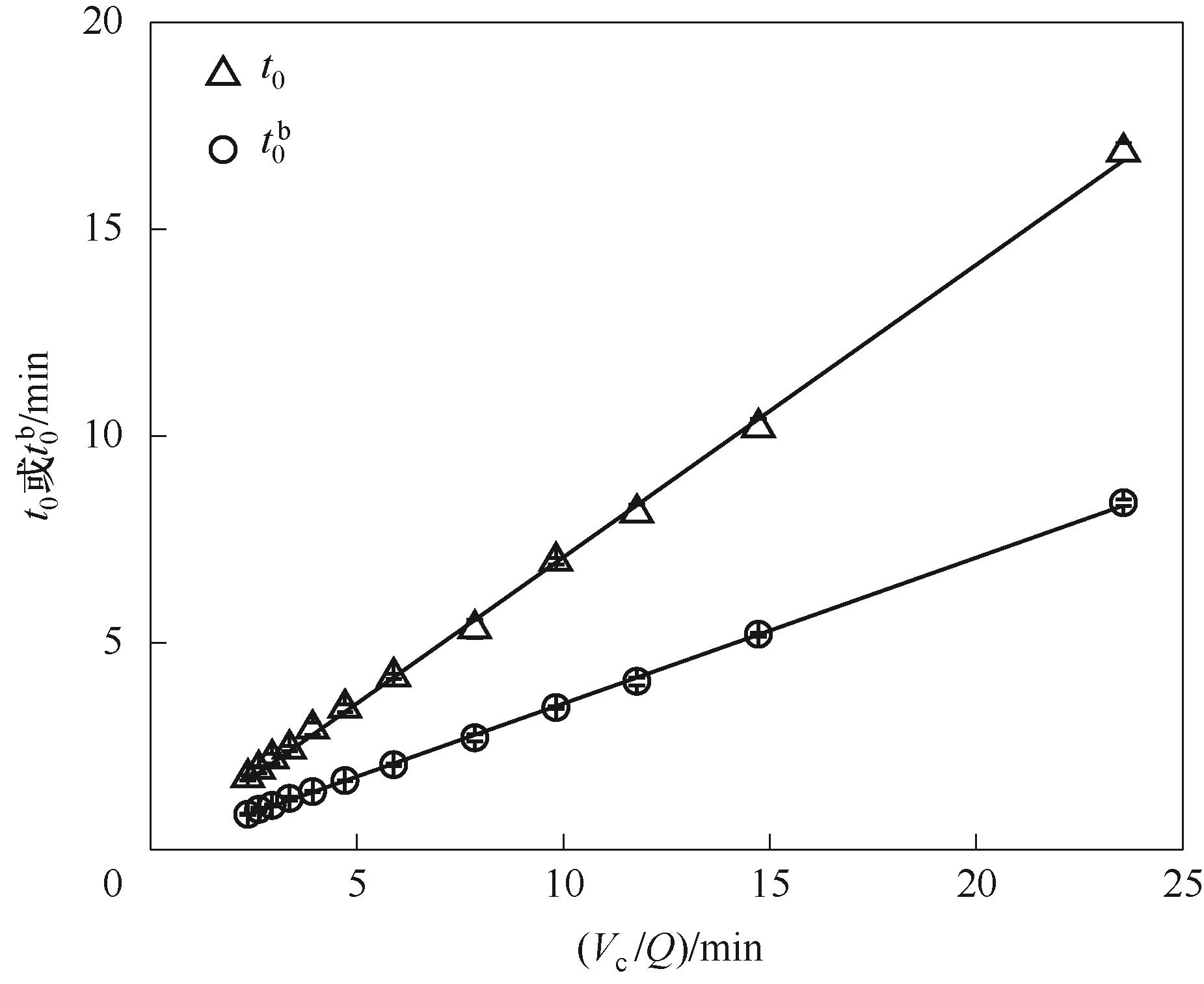

图3 C18制备柱上孔堵塞前后硫脲保留时间与Vc/Q之间的关系

Fig.3 Relationship between retention time of thiourea and Vc/Q on the C18 preparative column before and after pore blocking

| 操作点 | 构型 | 切换周期/min | QI/(ml?min-1) | QE/(ml?min-1) | QF/(ml?min-1) | PE/% | PR/% |

|---|---|---|---|---|---|---|---|

| P1 | 22.5 | 2 | 0.55 | 0.5 | 99.5±0.2 | 94.4±0.2 | |

| P2 | 22.5 | 2 | 0.60 | 0.5 | 99.4±0.3 | 95.8±0.2 | |

| P3 | 22.5 | 2 | 0.65 | 0.5 | 99.1±0.2 | 95.9±0.1 | |

| P4 | 22.5 | 2 | 0.70 | 0.5 | 98.9±0.2 | 96.0±0.2 | |

| P5 | 22.5 | 2 | 0.75 | 0.5 | 98.2±0.3 | 96.1±0.3 | |

| P6 | 24.48 | 2 | 0.78 | 0.55 | 99.6±0.3 | 99.4±0.2 | |

| P7 | [1.16, 1.16, 1.68] | 23.75 | 2 | 0.80 | 0.62 | 99.6±0.2 | 99.7±0.1 |

表1 不同操作点的操作条件及产品纯度

Table 1 Operation conditions and product purities at different operation points

| 操作点 | 构型 | 切换周期/min | QI/(ml?min-1) | QE/(ml?min-1) | QF/(ml?min-1) | PE/% | PR/% |

|---|---|---|---|---|---|---|---|

| P1 | 22.5 | 2 | 0.55 | 0.5 | 99.5±0.2 | 94.4±0.2 | |

| P2 | 22.5 | 2 | 0.60 | 0.5 | 99.4±0.3 | 95.8±0.2 | |

| P3 | 22.5 | 2 | 0.65 | 0.5 | 99.1±0.2 | 95.9±0.1 | |

| P4 | 22.5 | 2 | 0.70 | 0.5 | 98.9±0.2 | 96.0±0.2 | |

| P5 | 22.5 | 2 | 0.75 | 0.5 | 98.2±0.3 | 96.1±0.3 | |

| P6 | 24.48 | 2 | 0.78 | 0.55 | 99.6±0.3 | 99.4±0.2 | |

| P7 | [1.16, 1.16, 1.68] | 23.75 | 2 | 0.80 | 0.62 | 99.6±0.2 | 99.7±0.1 |

| 过程 | ts/min | QF/(ml?min-1) | QE/(ml?min-1) | 各区带流量/(ml?min-1) | 各区带柱子数目 | ||||

|---|---|---|---|---|---|---|---|---|---|

| 区带Ⅰ | 区带Ⅱ | 区带Ⅲ | 区带Ⅰ | 区带Ⅱ | 区带Ⅲ | ||||

| SMB | 24.48 | 0.55 | 0.78 | 2.0 | 1.22 | 1.77 | 1 | 1 | 2 |

| Varicol | 23.75 | 0.62 | 0.80 | 2.0 | 1.20 | 1.82 | 1.16 | 1.16 | 1.68 |

表2 SMB及Varicol过程的最优操作条件

Table 2 Optimum operation conditions for the SMB and Varicol processes

| 过程 | ts/min | QF/(ml?min-1) | QE/(ml?min-1) | 各区带流量/(ml?min-1) | 各区带柱子数目 | ||||

|---|---|---|---|---|---|---|---|---|---|

| 区带Ⅰ | 区带Ⅱ | 区带Ⅲ | 区带Ⅰ | 区带Ⅱ | 区带Ⅲ | ||||

| SMB | 24.48 | 0.55 | 0.78 | 2.0 | 1.22 | 1.77 | 1 | 1 | 2 |

| Varicol | 23.75 | 0.62 | 0.80 | 2.0 | 1.20 | 1.82 | 1.16 | 1.16 | 1.68 |

| 1 | 王宇轩, 石玉琼, 朱金花. 吴茱萸中吴茱萸碱和吴茱萸次碱的提取方法研究[J]. 化学研究, 2020, 31(4): 359-364. |

| Wang Y X, Shi Y Q, Zhu J H. Study on the extraction methods of evodiamine and rutaecarpine from Evodia rutaecarpa[J]. Chemical Research, 2020, 31(4): 359-364. | |

| 2 | Zhang C, Fan X, Xu X, et al. Evodiamine induces caspase-dependent apoptosis and S phase arrest in human colon lovo cells[J]. Anti-Cancer Drugs, 2010, 21(8): 766-776. |

| 3 | Wang C, Li S, Wang M W. Evodiamine-induced human melanoma A375-S2 cell death was mediated by PI3K/Akt/caspase and Fas-L/NF-κB signaling pathways and augmented by ubiquitin-proteasome inhibition[J]. Toxicology in Vitro, 2010, 24(3): 898-904. |

| 4 | Yuan S M, Gao K, Wang D M, et al. Evodiamine improves congnitive abilities in SAMP8 and APP(swe)/PS1(ΔE9) transgenic mouse models of Alzheimer's disease[J]. Acta Pharmacologica Sinica, 2011, 32(3): 295-302. |

| 5 | Kobayashi Y, Nakano Y, Kizaki M, et al. Capsaicin-like anti-obese activities of evodiamine from fruits of Evodia rutaecarpa, a vanilloid receptor agonist[J]. Planta Medica, 2001, 67(7): 628-633. |

| 6 | Hung P H, Lin L C, Wang G J, et al. Inhibitory effect of evodiamine on aldosterone release by zona glomerulosa cells in male rats[J]. The Chinese Journal of Physiology, 2001, 44(2): 53-57. |

| 7 | Lee H S, Oh W K, Choi H C, et al. Inhibition of angiotensin Ⅱ receptor binding by quinolone alkaloids from Evodia rutaecarpa[J]. Phytotherapy Research, 1998, 12(3): 212-214. |

| 8 | Ueng Y F, Wang J J, Lin L C, et al. Induction of cytochrome P450-dependent monooxygenase in mouse liver and kidney by rutaecarpine, an alkaloid of the herbal drug Evodia rutaecarpa[J]. Life Sciences, 2001, 70(2): 207-217. |

| 9 | Hu C P, Xiao L, Deng H W, et al. The cardioprotection of rutaecarpine is mediated by endogenous calcitonin related-gene peptide through activation of vanilloid receptors in Guinea-pig hearts[J]. Planta Medica, 2002, 68(8): 705-709. |

| 10 | Iwata H, Tezuka Y, Kadota S, et al. Mechanism-based inactivation of human liver microsomal CYP3A4 by rutaecarpine and limonin from Evodia fruit extract[J]. Drug Metabolism and Pharmacokinetics, 2005, 20(1): 34-45. |

| 11 | 张起辉, 高慧媛, 吴立军, 等. 吴茱萸的化学成分[J]. 沈阳药科大学学报, 2005, 22(1): 12-14. |

| Zhang Q H, Gao H Y, Wu L J, et al. Chemical constituents of Evodia rutaecarpa (Juss.) Benth[J]. Journal of Shenyang Pharmaceutical University, 2005, 22(1): 12-14. | |

| 12 | Liu R M, Chu X, Sun A L, et al. Preparative isolation and purification of alkaloids from the Chinese medicinal herb Evodia rutaecarpa (Juss.) Benth by high-speed counter-current chromatography[J]. Journal of Chromatography A, 2005, 1074(1/2): 139-144. |

| 13 | Shahmoradi A, Khosravi-Nikou M R, Aghajani M, et al. Mathematical modeling and optimization of industrial scale ELUXYL simulated moving bed (SMB)[J]. Separation and Purification Technology, 2020, 248: 116961. |

| 14 | Shen Y H, Fu Q, Zhang D H, et al. A systematic simulation and optimization of an industrial-scale p-xylene simulated moving bed process[J]. Separation and Purification Technology, 2018, 191: 48-60. |

| 15 | Li Y, Xu J, Yu W F, et al. Multi-objective optimization of sequential simulated moving bed for the purification of xylo-oligosaccharides[J]. Chemical Engineering Science, 2020, 211: 115279. |

| 16 | Tangpromphan P, Budman H, Jaree A. A simplified strategy to reduce the desorbent consumption and equipment installed in a three-zone simulated moving bed process for the separation of glucose and fructose[J]. Chemical Engineering and Processing-Process Intensification, 2018, 126: 23-37. |

| 17 | Yang Y, Lu K, Gong R J, et al. Separation of guaifenesin enantiomers by simulated moving bed process with four operation modes[J]. Adsorption, 2019, 25(6): 1227-1240. |

| 18 | Li L Y, Liu W X, Song D W, et al. Simulated moving bed purification for flavonoids from Tartary buckwheat shell[J]. Journal of Chromatographic Science, 2020, 58(4): 362-372. |

| 19 | Yao C Y, Chen J L, Lu Y H, et al. Construction of an asynchronous three-zone simulated-moving-bed chromatography and its application for the separation of vanillin and syringaldehyde[J]. Chemical Engineering Journal, 2018, 331: 644-651. |

| 20 | Toumi A, Hanisch F, Engell S. Optimal operation of continuous chromatographic processes: mathematical optimization of the VARICOL process[J]. Industrial & Engineering Chemistry Research, 2002, 41(17): 4328-4337. |

| 21 | Ludemann-Hombourger O, Nicoud R M, Bailly M. The “VARICOL” process: a new multicolumn continuous chromatographic process[J]. Separation Science and Technology, 2000, 35(12): 1829-1862. |

| 22 | Lin X J, Gong R J, Li J X, et al. Enantioseparation of racemic aminoglutethimide using asynchronous simulated moving bed chromatography[J]. Journal of Chromatography A, 2016, 1467: 347-355. |

| 23 | Yao C Y, Tang S K, Yao H M, et al. Study on the number of decision variables in design and optimization of Varicol process[J]. Computers & Chemical Engineering, 2014, 68: 114-122. |

| 24 | Zhang Z Y, Mazzotti M, Morbidelli M. Power feed operation of simulated moving bed units: changing flow-rates during the switching interval[J]. Journal of Chromatography A, 2003, 1006(1/2): 87-99. |

| 25 | Schramm H, Kienle A, Kaspereit M, et al. Improved operation of simulated moving bed processes through cyclic modulation of feed flow and feed concentration[J]. Chemical Engineering Science, 2003, 58(23/24): 5217-5227. |

| 26 | 姚传义. 异步切换的三区带模拟移动床: 105617714B[P]. 2017-05-31. |

| Yao C Y. Three zone simulated moving bed with asynchronous switching: 105617714B[P]. 2017-05-31. | |

| 27 | Yao H M, Tian Y C, Tadé M O. Using wavelets for solving SMB separation process models[J]. Industrial & Engineering Chemistry Research, 2008, 47(15): 5585-5593. |

| 28 | Yao C Y, Jing K J, Ling X P, et al. Application of dodecahedron to describe the switching strategies of asynchronous simulated-moving-bed[J]. Computers & Chemical Engineering, 2017, 96: 69-74. |

| 29 | Pous-Torres S, Torres-Lapasió J R, García-Álvarez-coque M C. Performance of markers and the homologous series method for dead time estimation in reversed-phase liquid chromatography[J]. Journal of Liquid Chromatography & Related Technologies, 2009, 32(8): 1065-1083. |

| 30 | Cabooter D, Lynen F, Sandra P, et al. Total pore blocking as an alternative method for the on-column determination of the external porosity of packed and monolithic reversed-phase columns[J]. Journal of Chromatography A, 2007, 1157(1/2): 131-141. |

| 31 | Chung S F, Wen C Y. Longitudinal dispersion of liquid flowing through fixed and fluidized beds[J]. AIChE Journal, 1968, 14(6): 857-866. |

| 32 | Kim T H, Yi S C, Suh Y W, et al. Effect of ethanol content on mass-transfer parameters and HETP indexes of amino acids in a poly-4-vinylpyridine chromatography[J]. Journal of Liquid Chromatography & Related Technologies, 2011, 34(6): 456-475. |

| 33 | Mazzotti M, Storti G, Morbidelli M. Robust design of countercurrent adsorption separation processes (4): Desorbent in the feed[J]. AIChE Journal, 1997, 43(1): 64-72. |

| 34 | 姚传义. 数值分析[M]. 北京: 中国轻工业出版社, 2009: 177-187. |

| Yao C Y. Numerical Analysis[M]. Beijing: China Light Industry Press, 2009: 177-187. | |

| 35 | Kurup A S, Subramani H J, Hidajat K, et al. Optimal design and operation of SMB bioreactor for sucrose inversion[J]. Chemical Engineering Journal, 2005, 108(1/2): 19-33. |

| 36 | Subramani H J, Zhang Z Y, Hidajat K, et al. Multiobjective optimization of simulated moving bed reactor and its modification—Varicol process[J]. The Canadian Journal of Chemical Engineering, 2004, 82(3): 590-598. |

| 37 | Toumi A, Engell S. Optimization-based control of a reactive simulated moving bed process for glucose isomerization[J]. Chemical Engineering Science, 2004, 59(18): 3777-3792. |

| 38 | Yu W F, Hidajat K, Ray A K. Optimal operation of reactive simulated moving bed and Varicol systems[J]. Journal of Chemical Technology & Biotechnology, 2003, 78(2/3): 287-293. |

| [1] | 杨欣, 王文, 徐凯, 马凡华. 高压氢气加注过程中温度特征仿真分析[J]. 化工学报, 2023, 74(S1): 280-286. |

| [2] | 何松, 刘乔迈, 谢广烁, 王斯民, 肖娟. 高浓度水煤浆管道气膜减阻两相流模拟及代理辅助优化[J]. 化工学报, 2023, 74(9): 3766-3774. |

| [3] | 赵亚欣, 张雪芹, 王荣柱, 孙国, 姚善泾, 林东强. 流穿模式离子交换层析去除单抗聚集体[J]. 化工学报, 2023, 74(9): 3879-3887. |

| [4] | 陈哲文, 魏俊杰, 张玉明. 超临界水煤气化耦合SOFC发电系统集成及其能量转化机制[J]. 化工学报, 2023, 74(9): 3888-3902. |

| [5] | 齐聪, 丁子, 余杰, 汤茂清, 梁林. 基于选择吸收纳米薄膜的太阳能温差发电特性研究[J]. 化工学报, 2023, 74(9): 3921-3930. |

| [6] | 刘爽, 张霖宙, 许志明, 赵锁奇. 渣油及其组分黏度的分子层次组成关联研究[J]. 化工学报, 2023, 74(8): 3226-3241. |

| [7] | 张曼铮, 肖猛, 闫沛伟, 苗政, 徐进良, 纪献兵. 危废焚烧处理耦合有机朗肯循环系统工质筛选与热力学优化[J]. 化工学报, 2023, 74(8): 3502-3512. |

| [8] | 诸程瑛, 王振雷. 基于改进深度强化学习的乙烯裂解炉操作优化[J]. 化工学报, 2023, 74(8): 3429-3437. |

| [9] | 张佳怡, 何佳莉, 谢江鹏, 王健, 赵鹬, 张栋强. 渗透汽化技术用于锂电池生产中N-甲基吡咯烷酮回收的研究进展[J]. 化工学报, 2023, 74(8): 3203-3215. |

| [10] | 陈国泽, 卫东, 郭倩, 向志平. 负载跟踪状态下的铝空气电池堆最优功率点优化方法[J]. 化工学报, 2023, 74(8): 3533-3542. |

| [11] | 刘文竹, 云和明, 王宝雪, 胡明哲, 仲崇龙. 基于场协同和 耗散的微通道拓扑优化研究[J]. 化工学报, 2023, 74(8): 3329-3341. 耗散的微通道拓扑优化研究[J]. 化工学报, 2023, 74(8): 3329-3341. |

| [12] | 张瑞航, 曹潘, 杨锋, 李昆, 肖朋, 邓春, 刘蓓, 孙长宇, 陈光进. ZIF-8纳米流体天然气乙烷回收工艺的产品纯度关键影响因素分析[J]. 化工学报, 2023, 74(8): 3386-3393. |

| [13] | 邢雷, 苗春雨, 蒋明虎, 赵立新, 李新亚. 井下微型气液旋流分离器优化设计与性能分析[J]. 化工学报, 2023, 74(8): 3394-3406. |

| [14] | 文兆伦, 李沛睿, 张忠林, 杜晓, 侯起旺, 刘叶刚, 郝晓刚, 官国清. 基于自热再生的隔壁塔深冷空分工艺设计及优化[J]. 化工学报, 2023, 74(7): 2988-2998. |

| [15] | 吴文涛, 褚良永, 张玲洁, 谭伟民, 沈丽明, 暴宁钟. 腰果酚生物基自愈合微胶囊的高效制备工艺研究[J]. 化工学报, 2023, 74(7): 3103-3115. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号