化工学报 ›› 2021, Vol. 72 ›› Issue (11): 5653-5663.DOI: 10.11949/0438-1157.20210457

收稿日期:2021-04-06

修回日期:2021-09-27

出版日期:2021-11-05

发布日期:2021-11-12

通讯作者:

赵荣祥

作者简介:刘晓艺(1994—),女,硕士研究生,基金资助:

Xiaoyi LIU( ),Xiuping LI,Rongxiang ZHAO(

),Xiuping LI,Rongxiang ZHAO( ),Hao ZHANG

),Hao ZHANG

Received:2021-04-06

Revised:2021-09-27

Online:2021-11-05

Published:2021-11-12

Contact:

Rongxiang ZHAO

摘要:

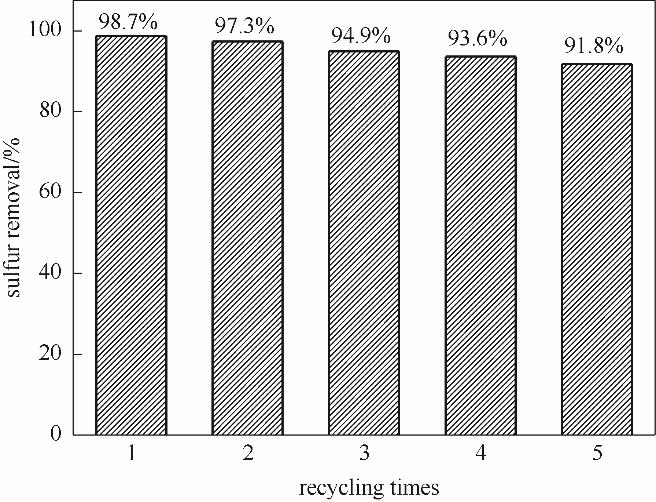

以己内酰胺-八水氧氯化锆低共熔溶剂为添加组分,采用溶胶-凝胶法合成含锆的硅胶,再经过高温煅烧得到n-ZrO2/SiO2 (n=2%,4%,6%) 负载型催化剂。并用红外光谱(FT-IR)、X射线衍射(XRD)、扫描电镜(SEM)、N2吸附-脱附、X射线光电子能谱(XPS)对其进行结构表征,确定ZrO2成功负载到SiO2上。以ZrO2/SiO2为催化剂和吸附剂,H2O2为氧化剂组成催化氧化脱硫体系,并应用于模拟油脱硫。分别考察了氧化锆负载量、反应温度、氧硫比、催化剂加入量及不同类型的硫化物对脱硫效果的影响。实验结果表明,在反应温度为70℃、n(H2O2)/n(S)=4(摩尔比)、4%-ZrO2/SiO2的加入量为0.2 g的最佳反应条件下,氧化脱硫体系对二苯并噻吩(DBT)、4,6-二甲基二苯并噻吩(4,6-DMDBT)和苯并噻吩(BT)的脱除率分别为98.7%、93%和65.9%。且4%-ZrO2/SiO2回收利用5次后,DBT脱除率仍可达到91.8%。

中图分类号:

刘晓艺, 李秀萍, 赵荣祥, 张豪. ZrO2/SiO2催化剂的制备及其氧化脱硫性能研究[J]. 化工学报, 2021, 72(11): 5653-5663.

Xiaoyi LIU, Xiuping LI, Rongxiang ZHAO, Hao ZHANG. Preparation of ZrO2/SiO2 catalyst and its oxidative desulfurization performance[J]. CIESC Journal, 2021, 72(11): 5653-5663.

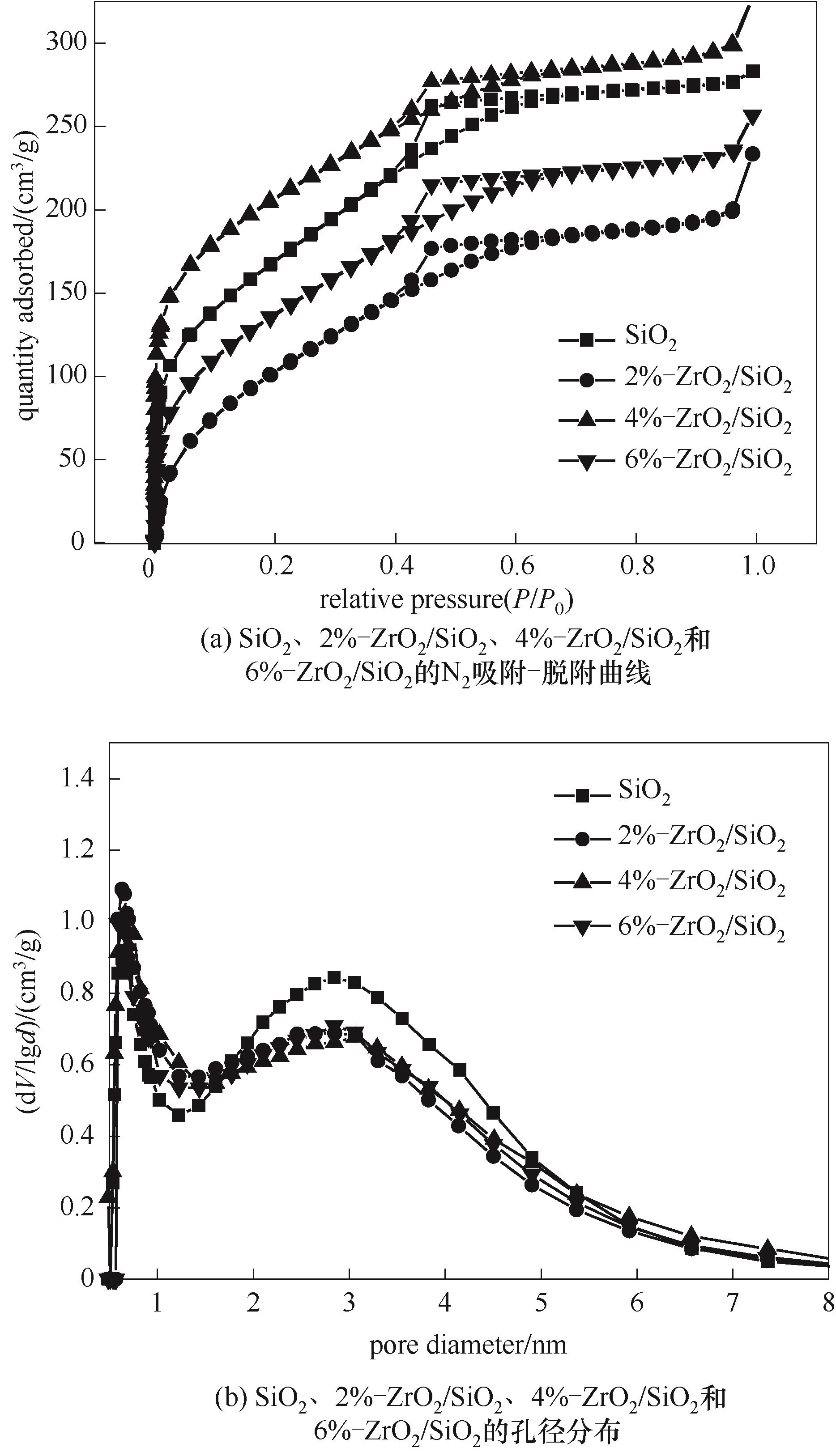

图5 SiO2、2%-ZrO2/SiO2、4%-ZrO2/SiO2和6%-ZrO2/SiO2的N2吸附-脱附曲线和孔径分布

Fig.5 N2 adsorption-desorption isotherms and pore-size distribution curves of SiO2, 2%-ZrO2/SiO2, 4%-ZrO2/SiO2 and 6%-ZrO2/SiO2

| Sample | SBET/(m2/g) | Pore volume/ (cm3/g) | Pore diameter/nm |

|---|---|---|---|

| SiO2 | 618 | 0.7083 | 2.835 |

2%-ZrO2/SiO2 4%-ZrO2/SiO2 | 526 631 | 0.4231 0.4602 | 3.214 2.914 |

| 6%-ZrO2/SiO2 | 510 | 0.3971 | 3.112 |

表1 样品的比表面积及孔结构参数

Table 1 Specific surface area and pore structure of samples

| Sample | SBET/(m2/g) | Pore volume/ (cm3/g) | Pore diameter/nm |

|---|---|---|---|

| SiO2 | 618 | 0.7083 | 2.835 |

2%-ZrO2/SiO2 4%-ZrO2/SiO2 | 526 631 | 0.4231 0.4602 | 3.214 2.914 |

| 6%-ZrO2/SiO2 | 510 | 0.3971 | 3.112 |

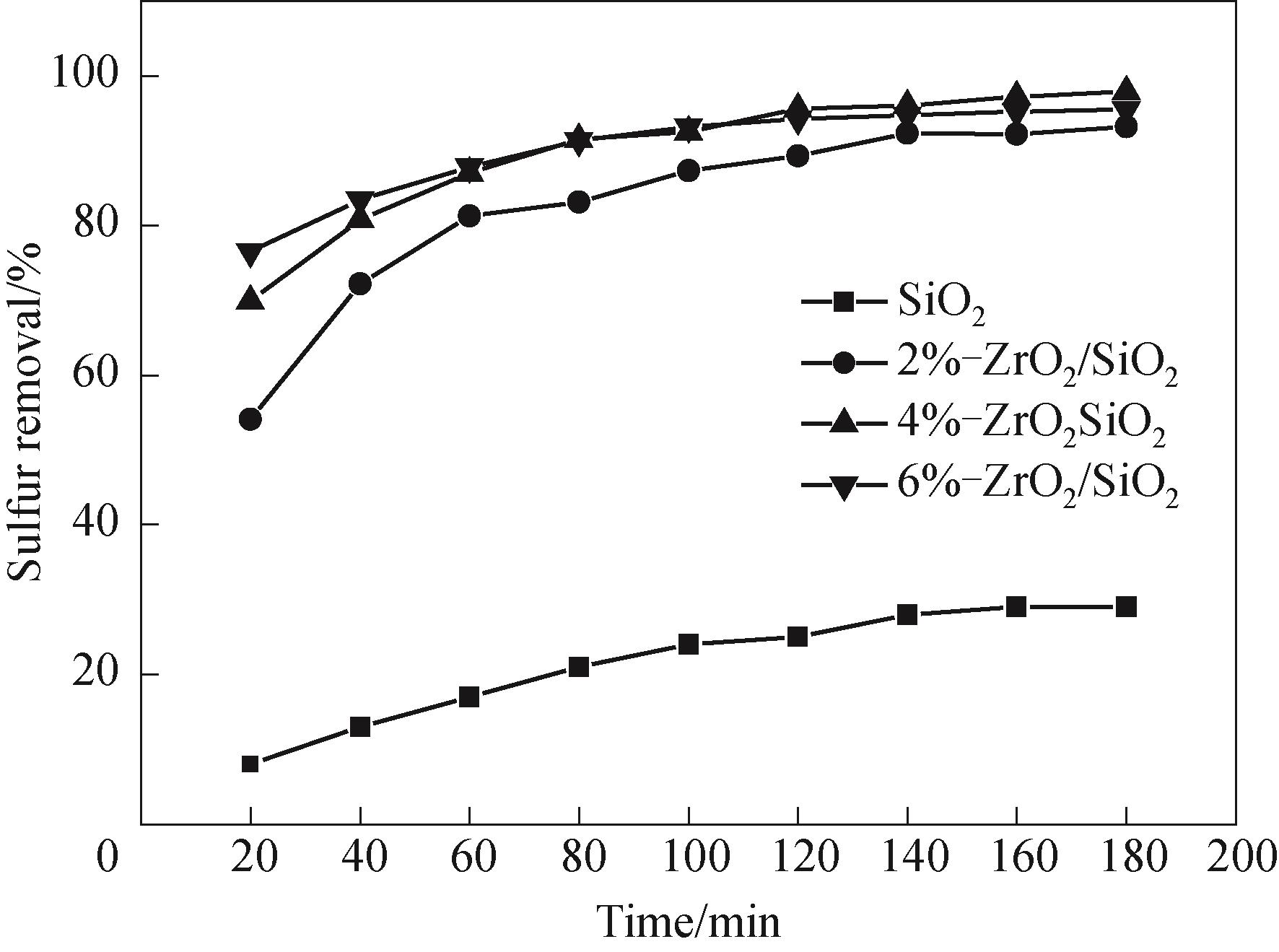

图7 氧化锆负载量对脱硫率的影响

Fig.7 Influence of zirconia loading on desulfurization rate(reaction conditions: V (model oil) =5 ml, n(H2O2)/n(S)=6, T=70℃, m4%-ZrO2/SiO2=0.2 g)

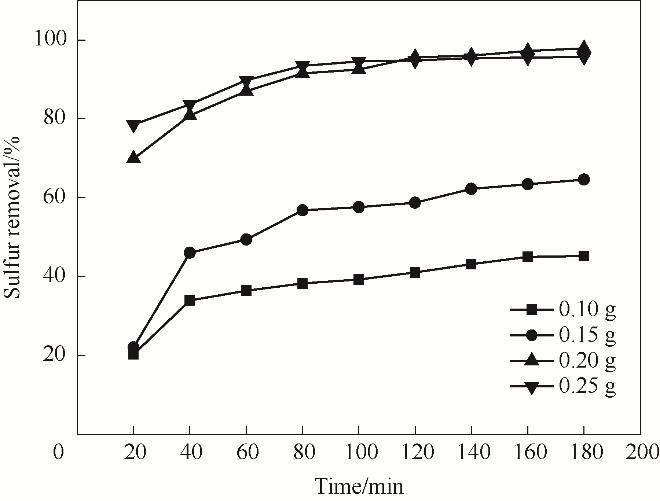

图9 4%-ZrO2/SiO2 的加入量对脱硫率的影响

Fig.9 Influence of 4%-ZrO2/SiO2 amount on desulfurization rate(reaction conditions: V (model oil) =5 ml, n(H2O2)/n(S)=6, T=70℃)

图10 氧硫比对脱硫率的影响

Fig.10 Influence of n(H2O2)/n(S) molar rate on desulfurization rate(reaction conditions: V (model oil) =5 ml, T=70℃, m4%-ZrO2/SiO2=0.2 g)

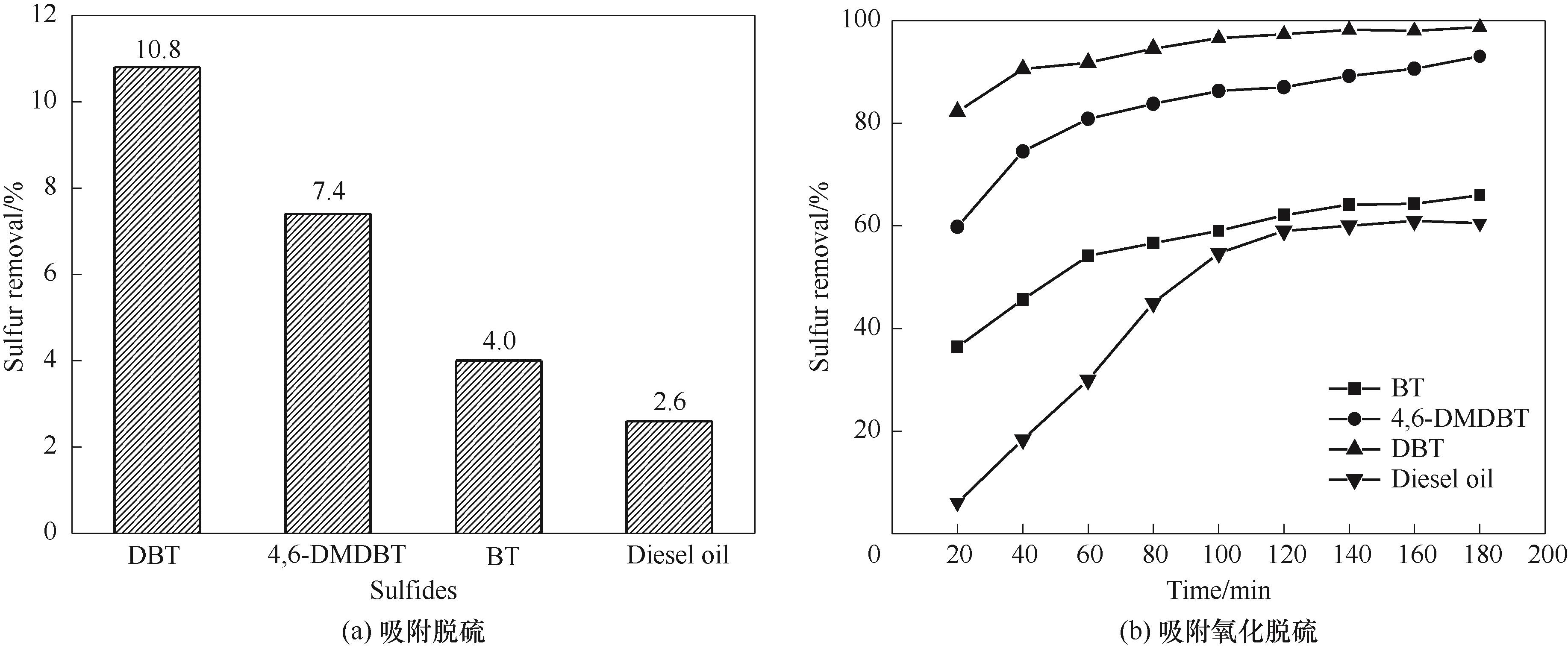

图11 不同硫化物的脱除效果(reaction conditions: (a) V (model oil) =5 ml, T=70℃, m4%-ZrO2/SiO2=0.2 g, t=180 min; (b) V (model oil) =5 ml, T=70℃, m4%-ZrO2/SiO2=0.2 g, n(H2O2)/n(S)=4)

Fig.11 Removal efficiency of different sulfides

图12 氧化脱硫反应中不同硫化物脱除的动力学分析(reaction conditions: V (model oil) =5 ml, n(H2O2)/n(S)=4, T=70℃, m4%-ZrO2/SiO2=0.2 g)

Fig.12 Kinetic analysis of removal of different sulfides in oxidative desulphurization

图13 ZrO2/SiO2催化剂循环使用性能(reaction conditions: V (model oil) =5 ml, n(H2O2)/n(S)=4, T=70℃, m4%-ZrO2/SiO2=0.2 g)

Fig.13 ZrO2/SiO2 recycling performance of catalyst

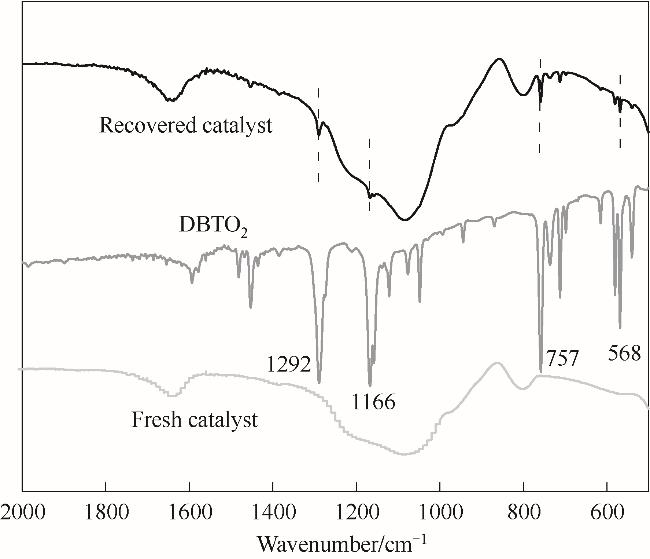

图14 新鲜催化剂与回收催化剂的红外谱图

Fig.14 Infrared spectra of fresh and recovered catalysts(reaction conditions: V (model oil) =5 ml, n(H2O2)/n(S)=4, T=70℃, m4%-ZrO2/SiO2=0.2 g)

| 1 | 纪桂杰, 张耀兵, 付宁宁, 等. Mn/Al-SBA-15 的制备及吸附脱硫性能[J]. 燃料化学学报, 2015, 43(4): 449-455. |

| Ji G J, Zhang Y B, Fu N N, et al. Study on the preparation of Mn/Al-SBA-15 and its adsorption desulfurization performance[J]. Journal of Fuel Chemistry and Technology, 2015, 43(4): 449-455. | |

| 2 | 张智勇, 周二鹏, 刘翠微, 等. 轻质油品氧化脱硫技术进展[J]. 河北化工, 2004, 27(3): 1-4. |

| Zhang Z Y,Zhou E P, Liu C W, et al. Development of desulphurization technology of light oil[J]. Hebei Chemical, 2004, 27(3): 1-4. | |

| 3 | Chen X, Guo H, Abdeltawab A A, et al. Brønsted-Lewis acidic ionic liquids and application in oxidative desulfurization of diesel fuel[J]. Energy & Fuels, 2015, 29(5): 2998-3003. |

| 4 | Zhang K, Liu Y, Tian S, et al. Preparation of bifunctional NiPb/ZnO-diatomite-ZSM-5 catalyst and its reactive adsorption desulfurization coupling aromatization performance in FCC gasoline upgrading process[J]. Fuel, 2013, 104: 201-207. |

| 5 | Kobayashi T, Li Y Y. Performance and characterization of a newly developed self-agitated anaerobic reactor with biological desulfurization[J]. Bioresource Technology, 2011, 102(10): 5580-5588. |

| 6 | Aguiar A, Ribeiro S, Silva A M N, et al. An efficient eco-sustainable oxidative desulfurization process using μ-oxo-bridged Fe (Ⅲ) complex of meso-tetrakis (pentafluorophenyl) porphyrin[J]. Applied Catalysis A: General, 2014, 478: 267-274. |

| 7 | Dooley K M, Liu D, Madrid A M, et al. Oxidative desulfurization of diesel with oxygen: reaction pathways on supported metal and metal oxide catalysts[J]. Applied Catalysis A: General, 2013, 468: 143-149. |

| 8 | Hou L, Zhao R, Li X, et al. Preparation of MoO2/g-C3N4 composites with a high surface area and its application in deep desulfurization from model oil[J]. Applied Surface Science, 2018, 434: 1200-1209. |

| 9 | Luo Q, Zhou Q, Lin Y, et al. Fast and deep oxidative desulfurization of dibenzothiophene with catalysts of MoO3-TiO2@ MCM-22 featuring adjustable Lewis and Brønsted acid sites[J]. Catalysis Science & Technology, 2019, 9(21): 6166-6179. |

| 10 | Shen D, Dai Y, Han J, et al. A nanocellulose template strategy for the controllable synthesis of tungsten-containing mesoporous silica for ultra-deep oxidative desulfurization[J]. Chemical Engineering Journal, 2018, 332: 563-571. |

| 11 | 郝阳阳, 李秀萍, 赵荣祥. MoO3/MIL-101 (Cr) 负载型催化剂的制备及其氧化脱硫性能[J]. 化学工程, 2019, 47(9): 24-28. |

| Hao Y Y, Li X P, Zhao R X. Preparation of MoO3 loading on MIL-101 (Cr) and its performance of oxidation desulfurization[J]. Chemical Engineering(China), 2019, 47(9): 24-28. | |

| 12 | González J, Wang J A, Chen L, et al. Quantitative determination of oxygen defects, surface Lewis acidity, and catalytic properties of mesoporous MoO3/SBA-15 catalysts[J]. Journal of Solid State Chemistry, 2018, 263: 100-114. |

| 13 | Kumar S, Srivastava V C, Badoni R P. Oxidative desulfurization by chromium promoted sulfated zirconia[J]. Fuel Processing Technology, 2012, 93(1): 18-25. |

| 14 | Du Y, Zhou L, Liu Z, et al. Polyoxometalate-based 3DOM ZrO2 material for deep oxidative desulfurization of DBT with ultrahigh stability[J]. Journal of Porous Materials, 2021, 28(1): 109-116. |

| 15 | Rodriguez-Gattorno G, Galano A, Torres-García E. Surface acid-basic properties of WOx-ZrO2 and catalytic efficiency in oxidative desulfurization[J]. Applied Catalysis B: Environmental, 2009, 92(1/2): 1-8. |

| 16 | Zhang P, Tong Y, Zhu M, et al. Oxidative desulfurization of dibenzothiophene catalyzed by molybdenum dioxide immobilized on zirconia-modified silica[J]. New Journal of Chemistry, 2020, 44(9): 3786-3793. |

| 17 | Fabian-Mijangos L, Cedeno-Caero L. V loading effect on V2O5/ZrO2 catalysts for oxidative desulfurization[J]. Industrial & Engineering Chemistry Research, 2011, 50(5): 2659-2664. |

| 18 | Liao X, Wang X, Wang F, et al. Ligand modified metal organic framework UiO-66: a highly efficient and stable catalyst for oxidative desulfurization[J]. Journal of Inorganic and Organometallic Polymers and Materials, 2021, 31(2): 756-762. |

| 19 | Zheng H Q, Zeng Y N, Chen J, et al. Zr-based metal-organic frameworks with intrinsic peroxidase-like activity for ultradeep oxidative desulfurization: mechanism of H2O2 decomposition[J]. Inorganic Chemistry, 2019, 58(10): 6983-6992. |

| 20 | Zhang X, Huang P, Liu A, et al. A metal-organic framework for oxidative desulfurization: UIO-66 (Zr) as a catalyst[J]. Fuel, 2017, 209: 417-423. |

| 21 | Xiao W, Dong Q, Wang Y, et al. Time modulation of defects in UiO-66 and application in oxidative desulfurization[J]. CrystEngComm, 2018, 20(38): 5658-5662. |

| 22 | Zhang P, Kang L, Zhu M, et al. Oxidative desulfurization catalyzed by a novel ZrP/MCM-41 catalyst with high performance[J]. Sustainable Energy & Fuels, 2020, 4(8): 4293-4300. |

| 23 | Smith E L, Abbott A P, Ryder K S. Deep eutectic solvents (DESs) and their applications[J]. Chemical Reviews, 2014, 114(21): 11060-11082. |

| 24 | Hao L, Su T, Hao D, et al. Oxidative desulfurization of diesel fuel with caprolactam-based acidic deep eutectic solvents: tailoring the reactivity of DESs by adjusting the composition[J]. Chinese Journal of Catalysis, 2018, 39(9): 1552-1559. |

| 25 | Mao C, Zhao R, Li X, et al. Trifluoromethanesulfonic acid-based DESs as extractants and catalysts for removal of DBT from model oil[J]. RSC Advances, 2017, 7(21): 12805-12811. |

| 26 | Datta S, Jo C, De Volder M, et al. Morphological control of nanostructured V2O5 by deep eutectic solvents[J]. ACS Applied Materials & Interfaces, 2020, 12(16): 18803-18812. |

| 27 | Cun T, Dong C, Huang Q. Ionothermal precipitation of highly dispersive ZnO nanoparticles with improved photocatalytic performance[J]. Applied Surface Science, 2016, 384: 73-82. |

| 28 | Wang Q, Dong B, Zhao Y, et al. Controllable green synthesis of crassula peforata-like TiO2 with high photocatalytic activity based on deep eutectic solvent (DES)[J]. Chemical Engineering Journal, 2018, 348: 811-819. |

| 29 | Mou H, Wang J, Zhang D, et al. A one-step deep eutectic solvent assisted synthesis of carbon nitride/metal oxide composites for photocatalytic nitrogen fixation[J]. Journal of Materials Chemistry A, 2019, 7(10): 5719-5725. |

| 30 | Naseri M, Kamalianfar A, Naderi E, et al. The effect of Ag nanoparticles on physical and photocatalytic properties of ZnFe2O4/SiO2 nanocomposite[J]. Journal of Molecular Structure, 2020, 1206: 127706-127715. |

| 31 | Liu X, Wang T, Liu J, et al. Preparation, characterization and growth mechanism of ZrO2 nanosheets[J]. Ceramics International, 2020, 46(4): 4864-4869. |

| 32 | Yu H, Tong Z, Qiao Y, et al. High thermal stability of SiO2-ZrO2 aerogels using solvent-thermal aging[J]. Journal of Solid State Chemistry, 2020, 291: 121624-121631. |

| 33 | Shu Z, Jiao X, Chen D. Synthesis and photocatalytic properties of flower-like zirconia nanostructures[J]. CrystEngComm, 2012, 14(3): 1122-1127. |

| 34 | Safa M, Mokhtarani B, Mortaheb H R, et al. Oxidative desulfurization of diesel fuel using a Brønsted acidic ionic liquid supported on silica gel[J]. Energy & Fuels, 2017, 31(9): 10196-10205. |

| 35 | Mokhtari B, Akbari A, Omidkhah M. Superior deep desulfurization of real diesel over MoO3/silica gel as an efficient catalyst for oxidation of refractory compounds[J]. Energy & Fuels, 2019, 33(8): 7276-7286. |

| 36 | 车剑飞, 谢毅哲, 杨绪杰, 等. 纳米二氧化硅表面接枝的X射线光电子能谱研究[J]. 南京理工大学学报, 2005, 29(3): 330-333. |

| Che J F, Xie Y Z, Yang X J. et al. XPS of modified nano-SiO2 by surface grafting[J]. Journal of Nanjing University of Science and Technology, 2005, 29(3): 330-333. | |

| 37 | Bosman H J M, Pijpers A P, Jaspers A. An X-ray photoelectron spectroscopy study of the acidity of SiO2-ZrO2 mixed oxides[J]. Journal of Catalysis, 1996, 161(2): 551-559. |

| 38 | Dongare M K, Dongare A M, Tare V B, et al. Synthesis and characterization of copper-stabilized zirconia as an anode material for SOFC[J]. Solid State Ionics, 2002, 152: 455-462. |

| 39 | Reddy B M, Chowdhury B, Smirniotis P G. An XPS study of the dispersion of MoO3 on TiO2-ZrO2, TiO2-SiO2, TiO2-Al2O3, SiO2-ZrO2, and SiO2-TiO2-ZrO2 mixed oxides[J]. Applied Catalysis A: General, 2001, 211(1): 19-30. |

| 40 | Wang D, Liu N, Zhang J, et al. Oxidative desulfurization using ordered mesoporous silicas as catalysts[J]. Journal of Molecular Catalysis A: Chemical, 2014, 393: 47-55. |

| 41 | Shen C, Wang Y J, Xu J H, et al. Oxidative desulfurization of DBT with H2O2 catalysed by TiO2/porous glass[J]. Green Chemistry, 2016, 18(3): 771-781. |

| 42 | Zhao D, Wang J, Zhou E. Oxidative desulfurization of diesel fuel using a Brønsted acid room temperature ionic liquid in the presence of H2O2[J]. Green Chemistry, 2007, 9(11): 1219-1222. |

| 43 | Collins F M, Lucy A R, Sharp C. Oxidative desulphurisation of oils via hydrogen peroxide and heteropolyanion catalysis[J]. Journal of Molecular Catalysis A: Chemical, 1997, 117(1/2/3): 397-403. |

| 44 | Ndiaye E H I, Habrioux M, Coutinho J A P, et al. Speed of sound, density, and derivative properties of ethyl myristate, methyl myristate, and methyl palmitate under high pressure[J]. Journal of Chemical & Engineering Data, 2013, 58(5): 1371-1377. |

| 45 | Zhao R, Li X, Su J, et al. Preparation of WO3/g-C3N4 composites and their application in oxidative desulfurization[J]. Applied Surface Science, 2017, 392: 810-816. |

| 46 | Mao C, Zhao R, Li X. Propionic acid-based deep eutectic solvents: synthesis and ultra-deep oxidative desulfurization activity[J]. RSC Advances, 2017, 7(67): 42590-42596. |

| 47 | Jiang W, Dong L, Liu W, et al. Designing multifunctional SO3H-based polyoxometalate catalysts for oxidative desulfurization in acid deep eutectic solvents[J]. RSC Advances, 2017, 7(87): 55318-55325. |

| 48 | Zhu W S, Li H, Gu Q Q, et al. Kinetics and mechanism for oxidative desulfurization of fuels catalyzed by peroxo-molybdenum amino acid complexes in water-immiscible ionic liquids[J]. Journal of Molecular Catalysis A: Chemical, 2011, 336(1/2): 16-22. |

| 49 | Andevary H H, Akbari A, Rajabi Z, et al. Towards a room temperature oxidative desulfurization of refractory compounds over 1-octyl-3-methylimidazolium tetrachloroferrates/silica gel: the beneficial effects of immobilization[J]. Process Safety and Environmental Protection, 2020, 136: 343-352. |

| 50 | Sobańska K, Pietrzyk P, Sojka Z. Generation of reactive oxygen species via electroprotic interaction of H2O2 with ZrO2 gel: ionic sponge effect and pH-switchable peroxidase-and catalase-like activity[J]. ACS Catalysis, 2017, 7(4): 2935-2947. |

| 51 | Yang C, Hou Y F, Liu M, et al. Optimization and evaluation of preparation process of activated carbon loaded ZrO2 catalyst for oxidative desulfurization[J]. Advanced Materials Research, 2014, 936: 881-886. |

| 52 | Yang M, Jonsson M. Surface reactivity of hydroxyl radicals formed upon catalytic decomposition of H2O2 on ZrO2[J]. Journal of Molecular Catalysis A: Chemical, 2015, 400: 49-55. |

| [1] | 张义飞, 刘舫辰, 张双星, 杜文静. 超临界二氧化碳用印刷电路板式换热器性能分析[J]. 化工学报, 2023, 74(S1): 183-190. |

| [2] | 胡超, 董玉明, 张伟, 张红玲, 周鹏, 徐红彬. 浓硫酸活化五氧化二钒制备高浓度全钒液流电池正极电解液[J]. 化工学报, 2023, 74(S1): 338-345. |

| [3] | 宋瑞涛, 王派, 王云鹏, 李敏霞, 党超镔, 陈振国, 童欢, 周佳琦. 二氧化碳直接蒸发冰场排管内流动沸腾换热数值模拟分析[J]. 化工学报, 2023, 74(S1): 96-103. |

| [4] | 米泽豪, 花儿. 基于DFT和COSMO-RS理论研究多元胺型离子液体吸收SO2气体[J]. 化工学报, 2023, 74(9): 3681-3696. |

| [5] | 陈美思, 陈威达, 李鑫垚, 李尚予, 吴有庭, 张锋, 张志炳. 硅基离子液体微颗粒强化气体捕集与转化的研究进展[J]. 化工学报, 2023, 74(9): 3628-3639. |

| [6] | 程业品, 胡达清, 徐奕莎, 刘华彦, 卢晗锋, 崔国凯. 离子液体基低共熔溶剂在转化CO2中的应用[J]. 化工学报, 2023, 74(9): 3640-3653. |

| [7] | 范孝雄, 郝丽芳, 范垂钢, 李松庚. LaMnO3/生物炭催化剂低温NH3-SCR催化脱硝性能研究[J]. 化工学报, 2023, 74(9): 3821-3830. |

| [8] | 杨百玉, 寇悦, 姜峻韬, 詹亚力, 王庆宏, 陈春茂. 炼化碱渣湿式氧化预处理过程DOM的化学转化特征[J]. 化工学报, 2023, 74(9): 3912-3920. |

| [9] | 陈哲文, 魏俊杰, 张玉明. 超临界水煤气化耦合SOFC发电系统集成及其能量转化机制[J]. 化工学报, 2023, 74(9): 3888-3902. |

| [10] | 杨学金, 杨金涛, 宁平, 王访, 宋晓双, 贾丽娟, 冯嘉予. 剧毒气体PH3的干法净化技术研究进展[J]. 化工学报, 2023, 74(9): 3742-3755. |

| [11] | 孟令玎, 崇汝青, 孙菲雪, 孟子晖, 刘文芳. 改性聚乙烯膜和氧化硅固定化碳酸酐酶[J]. 化工学报, 2023, 74(8): 3472-3484. |

| [12] | 汪林正, 陆俞冰, 张睿智, 罗永浩. 基于分子动力学模拟的VOCs热氧化特性分析[J]. 化工学报, 2023, 74(8): 3242-3255. |

| [13] | 李锦潼, 邱顺, 孙文寿. 煤浆法烟气脱硫中草酸和紫外线强化煤砷浸出过程[J]. 化工学报, 2023, 74(8): 3522-3532. |

| [14] | 杨菲菲, 赵世熙, 周维, 倪中海. Sn掺杂的In2O3催化CO2选择性加氢制甲醇[J]. 化工学报, 2023, 74(8): 3366-3374. |

| [15] | 洪瑞, 袁宝强, 杜文静. 垂直上升管内超临界二氧化碳传热恶化机理分析[J]. 化工学报, 2023, 74(8): 3309-3319. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号