化工学报 ›› 2022, Vol. 73 ›› Issue (1): 266-274.DOI: 10.11949/0438-1157.20211431

翁俊旗1( ),刘鑫磊1,余佳豪1,施尧1,叶光华1(

),刘鑫磊1,余佳豪1,施尧1,叶光华1( ),屈进2(

),屈进2( ),段学志1,李金兵2,周兴贵1

),段学志1,李金兵2,周兴贵1

收稿日期:2021-10-08

修回日期:2021-12-20

出版日期:2022-01-05

发布日期:2022-01-18

通讯作者:

叶光华,屈进

作者简介:翁俊旗(1998—),男,硕士研究生,基金资助:

Junqi WENG1( ),Xinlei LIU1,Jiahao YU1,Yao SHI1,Guanghua YE1(

),Xinlei LIU1,Jiahao YU1,Yao SHI1,Guanghua YE1( ),Jin QU2(

),Jin QU2( ),Xuezhi DUAN1,Jinbing LI2,Xinggui ZHOU1

),Xuezhi DUAN1,Jinbing LI2,Xinggui ZHOU1

Received:2021-10-08

Revised:2021-12-20

Online:2022-01-05

Published:2022-01-18

Contact:

Guanghua YE,Jin QU

摘要:

压降是衡量固定床反应器优劣的重要指标,直接影响了反应性能和综合能耗,催化剂颗粒的外形和尺寸是影响固定床反应器压降的关键因素。采用颗粒分辨计算流体力学模型,研究了工业上常用的蜂窝状催化剂颗粒上中空结构对固定床反应器压降的影响规律。首先,通过对比实验测量的催化剂床层空隙率和压降,验证了建立的颗粒分辨计算流体力学模型的合理性和准确性,其中模型计算获得的压降与实验值相差5%以内。接着,研究了蜂窝状催化剂颗粒开孔个数的影响,发现在催化剂颗粒体积和开孔体积相同的情况下,开孔个数不会显著影响催化剂床层的空隙率,但开孔个数增加会导致压降增大,这主要是由于孔径变小后增大了流体在孔内的动量损失。最后,考察了单孔柱催化剂颗粒尺寸的影响,发现可通过调变外圆柱半径、内孔半径和高度,进而大幅度改变催化剂床层空隙率和压降,当单孔柱壁面越薄时,空隙率越大,致使压降越低。研究结果可以为催化剂颗粒外形的优化设计提供强大的模型工具和一定的理论指导。

中图分类号:

翁俊旗, 刘鑫磊, 余佳豪, 施尧, 叶光华, 屈进, 段学志, 李金兵, 周兴贵. 蜂窝状催化剂中空结构对固定床反应器压降的影响[J]. 化工学报, 2022, 73(1): 266-274.

Junqi WENG, Xinlei LIU, Jiahao YU, Yao SHI, Guanghua YE, Jin QU, Xuezhi DUAN, Jinbing LI, Xinggui ZHOU. Influence of hollow structure of honeycomb catalysts on the pressure drop in packed bed reactors[J]. CIESC Journal, 2022, 73(1): 266-274.

| 参数 | 数值 |

|---|---|

| 进口温度Tin | 220℃ |

| 出口压力Pout | 10 atm(1 atm=101325 Pa) |

| 进口流速uin | 1 m/s |

| 进口氧气摩尔分数XO | 8% |

| 进口乙烯摩尔分数XC | 36% |

| 进口氮气摩尔分数XN | 44% |

| 进口二氧化碳摩尔分数XCO | 12% |

| 反应管内径D | 35 mm |

| 黏度μ | 2.26×10-5 Pa?s |

| 密度ρ | 6.41 kg/m3 |

表1 流动模拟所用的边界条件及模型参数

Table 1 Boundary conditions and model parameters for flow simulations

| 参数 | 数值 |

|---|---|

| 进口温度Tin | 220℃ |

| 出口压力Pout | 10 atm(1 atm=101325 Pa) |

| 进口流速uin | 1 m/s |

| 进口氧气摩尔分数XO | 8% |

| 进口乙烯摩尔分数XC | 36% |

| 进口氮气摩尔分数XN | 44% |

| 进口二氧化碳摩尔分数XCO | 12% |

| 反应管内径D | 35 mm |

| 黏度μ | 2.26×10-5 Pa?s |

| 密度ρ | 6.41 kg/m3 |

图5 单孔柱和七孔柱催化剂颗粒在床层中的角度分布和径向空隙率分布

Fig.5 Angle distributions and radial voidage distributions of Raschig ring and seven-hole cylinder catalyst pellets in the packed bed

图6 单孔柱和七孔柱催化剂颗粒床层中流速分布和压力分布的截面图

Fig.6 Contours of flow rate and pressure in the beds packed with Raschig ring and seven-hole cylinder catalyst pellets

| 外形 | 平均空隙率 | 压降(ΔP/L)/(Pa/m) | 表观反应速率/(mol/(m3·s) |

|---|---|---|---|

| 单孔柱 | 0.582 | 3660 | 5.56 |

| 七孔柱 | 0.579 | 3982 | 7.73 |

表2 单孔柱和七孔柱催化剂颗粒堆积床层的空隙率、压降和表观反应速率

Table 2 Voidages, pressure drops, and apparent reaction rates of catalyst in the beds packed with Raschig ring and seven-hole cylinder catalyst pellets

| 外形 | 平均空隙率 | 压降(ΔP/L)/(Pa/m) | 表观反应速率/(mol/(m3·s) |

|---|---|---|---|

| 单孔柱 | 0.582 | 3660 | 5.56 |

| 七孔柱 | 0.579 | 3982 | 7.73 |

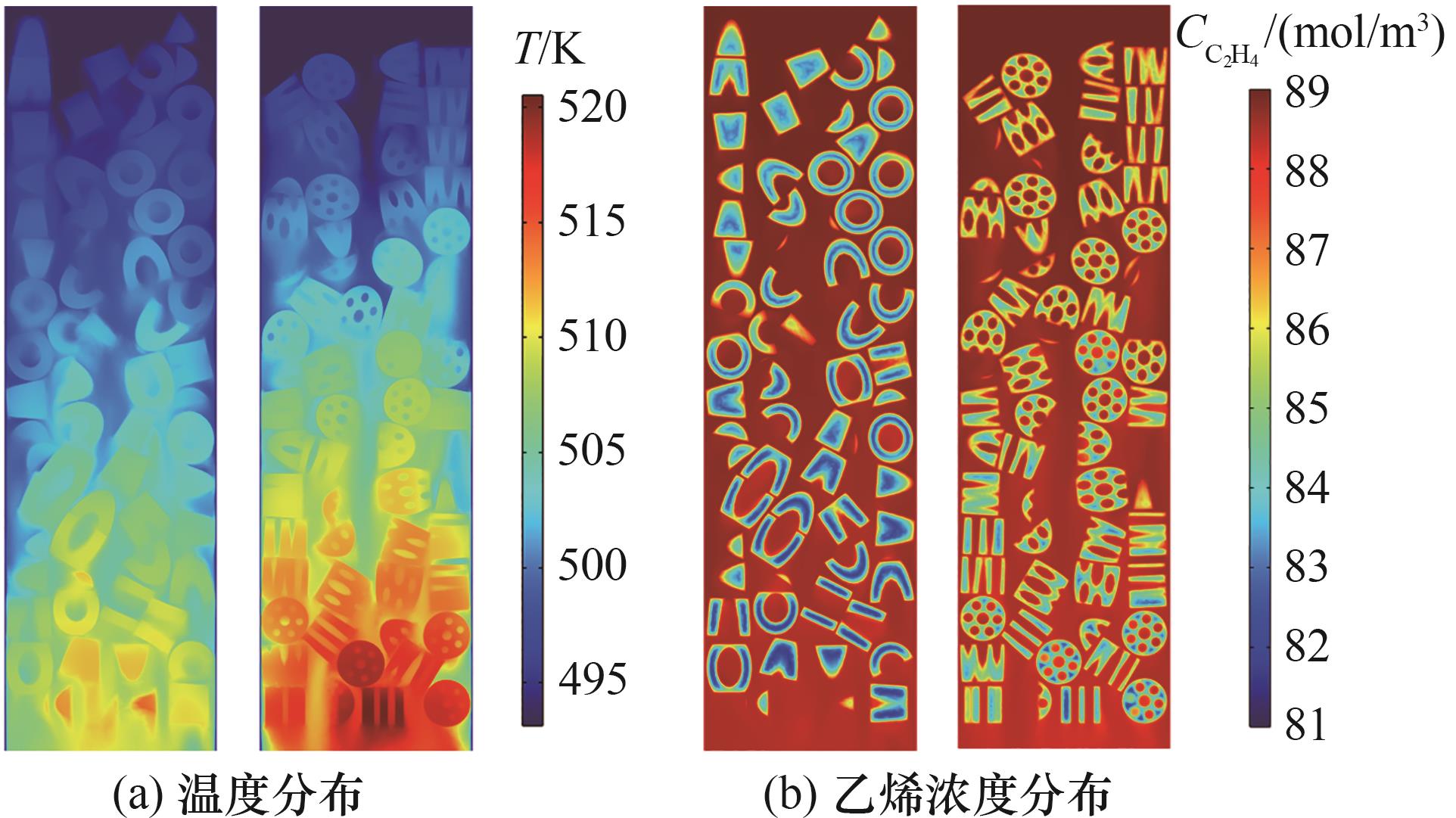

图7 单孔柱和七孔柱催化剂颗粒床层中温度分布和乙烯浓度分布的截面图

Fig.7 Contours of temperature and C2H4 concentration in the beds packed with Raschig ring and seven-hole cylinder catalyst pellets

| 外径R/mm | 内径r/mm | 高度H/mm | 平均空隙率 | 压降(ΔP/L)/(Pa/m) |

|---|---|---|---|---|

| 3.86 | 1.56 | 5.60 | 0.514 | 4501 |

| 3.86 | 1.81 | 6.00 | 0.545 | 4320 |

| 3.86 | 2.00 | 6.40 | 0.582 | 3660 |

| 3.86 | 2.15 | 6.80 | 0.599 | 3226 |

| 3.86 | 2.28 | 7.20 | 0.634 | 2802 |

表3 单孔柱催化剂外形尺寸以及相应床层空隙率和压降(R不变,变化r和H)

Table 3 Dimensions of Raschig rings, as well as the voidages and pressure drops of their corresponding beds (R unchanged, but r and H varied)

| 外径R/mm | 内径r/mm | 高度H/mm | 平均空隙率 | 压降(ΔP/L)/(Pa/m) |

|---|---|---|---|---|

| 3.86 | 1.56 | 5.60 | 0.514 | 4501 |

| 3.86 | 1.81 | 6.00 | 0.545 | 4320 |

| 3.86 | 2.00 | 6.40 | 0.582 | 3660 |

| 3.86 | 2.15 | 6.80 | 0.599 | 3226 |

| 3.86 | 2.28 | 7.20 | 0.634 | 2802 |

| 外径R/mm | 内径r/mm | 高度H/mm | 平均空隙率 | 压降(ΔP/L)/(Pa/m) |

|---|---|---|---|---|

| 5.09 | 2.00 | 3.20 | 0.524 | 4492 |

| 4.31 | 2.00 | 4.80 | 0.569 | 4002 |

| 3.86 | 2.00 | 6.40 | 0.582 | 3660 |

| 3.57 | 2.00 | 8.00 | 0.622 | 3500 |

| 3.36 | 2.00 | 9.60 | 0.643 | 3188 |

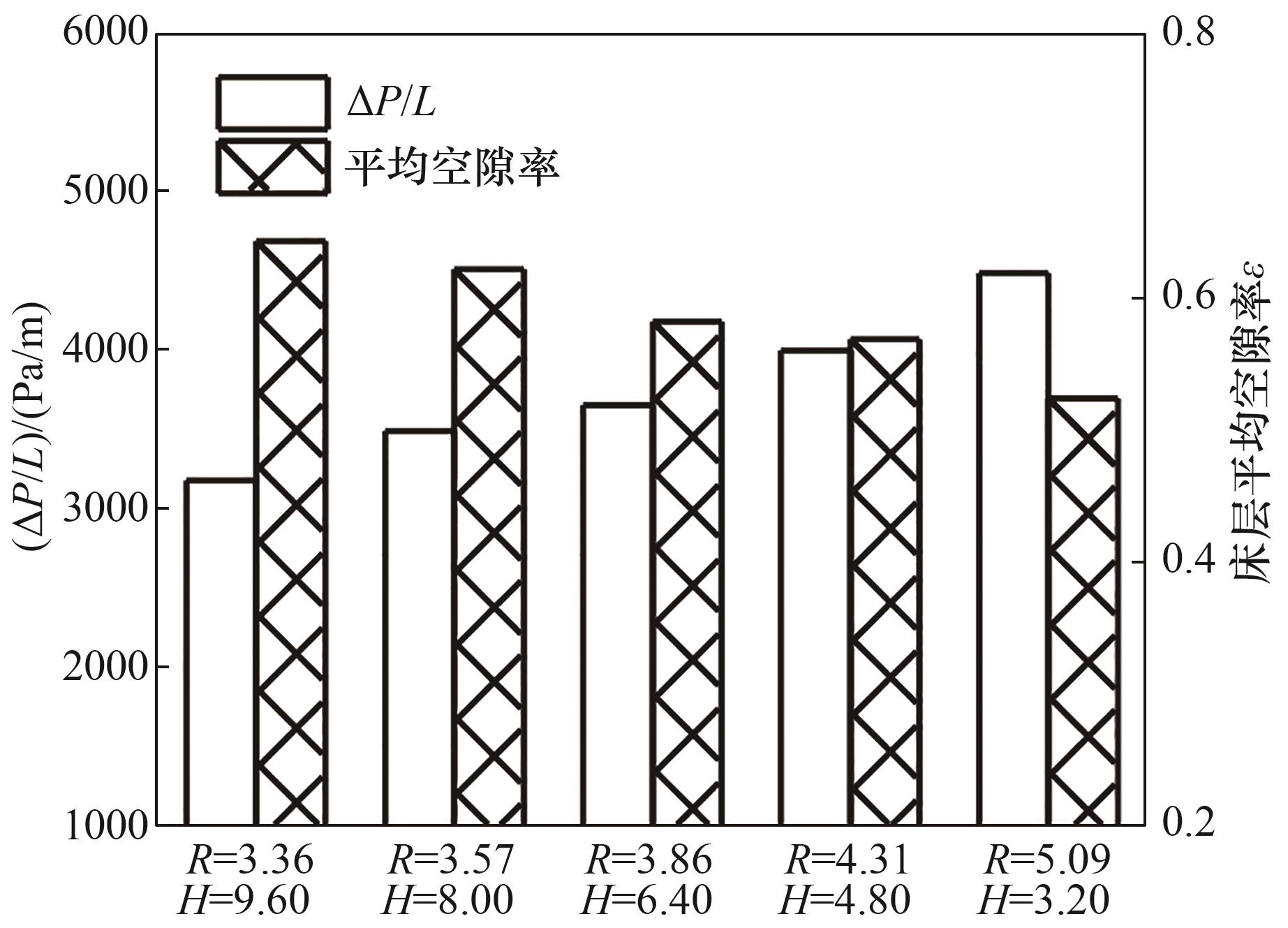

表4 单孔柱催化剂外形尺寸以及相应床层空隙率和压降(r不变,变化R和H)

Table 4 Dimensions of Raschig rings, as well as the voidages and pressure drops of their corresponding beds (r unchanged, but R and H varied)

| 外径R/mm | 内径r/mm | 高度H/mm | 平均空隙率 | 压降(ΔP/L)/(Pa/m) |

|---|---|---|---|---|

| 5.09 | 2.00 | 3.20 | 0.524 | 4492 |

| 4.31 | 2.00 | 4.80 | 0.569 | 4002 |

| 3.86 | 2.00 | 6.40 | 0.582 | 3660 |

| 3.57 | 2.00 | 8.00 | 0.622 | 3500 |

| 3.36 | 2.00 | 9.60 | 0.643 | 3188 |

| 外径R/mm | 内径r/mm | 高度H/mm | 平均空隙率 | 压降(ΔP/L)/(Pa/m) |

|---|---|---|---|---|

| 3.46 | 1.00 | 6.40 | 0.461 | 5927 |

| 3.63 | 1.50 | 6.40 | 0.516 | 4728 |

| 3.86 | 2.00 | 6.40 | 0.582 | 3660 |

| 4.15 | 2.50 | 6.40 | 0.642 | 3199 |

| 4.46 | 3.00 | 6.40 | 0.699 | 2188 |

表5 单孔柱催化剂外形尺寸以及相应床层空隙率和压降(H不变,变化R和r)

Table 5 Dimensions of Raschig rings, as well as the voidages and pressure drops of their corresponding beds (H unchanged, but R and r varied)

| 外径R/mm | 内径r/mm | 高度H/mm | 平均空隙率 | 压降(ΔP/L)/(Pa/m) |

|---|---|---|---|---|

| 3.46 | 1.00 | 6.40 | 0.461 | 5927 |

| 3.63 | 1.50 | 6.40 | 0.516 | 4728 |

| 3.86 | 2.00 | 6.40 | 0.582 | 3660 |

| 4.15 | 2.50 | 6.40 | 0.642 | 3199 |

| 4.46 | 3.00 | 6.40 | 0.699 | 2188 |

图8 单孔柱催化剂颗粒床层的压降和空隙率(R不变,变化r和H)

Fig.8 Pressure drops and voidages of the beds packed with Raschig ring catalyst pellets (R unchanged, but r and H varied)

图9 单孔柱催化剂颗粒床层的压降和空隙率(r不变,变化R和H)

Fig.9 Pressure drops and voidages of the beds packed with Raschig ring catalyst pellets (r unchanged, but R and H varied)

图10 单孔柱催化剂颗粒床层的压降和空隙率(H不变,变化R和r)

Fig.10 Pressure drops and voidages of the beds packed with Raschig ring catalyst pellets (H unchanged, but R and r varied)

| 1 | Afandizadeh S, Foumeny E A. Design of packed bed reactors: guides to catalyst shape, size, and loading selection[J]. Applied Thermal Engineering, 2001, 21(6): 669-682. |

| 2 | Karthik G M, Buwa V V. Effect of particle shape on fluid flow and heat transfer for methane steam reforming reactions in a packed bed[J]. AIChE Journal, 2017, 63(1): 366-377. |

| 3 | Pashchenko D. Pressure drop in the thermochemical recuperators filled with the catalysts of various shapes: a combined experimental and numerical investigation[J]. Energy, 2019, 166: 462-470. |

| 4 | Liu X L, Qin B, Zhang Q F, et al. Optimizing catalyst supports at single catalyst pellet and packed bed reactor levels: a comparison study[J]. AIChE Journal, 2021, 67(8): e17163. |

| 5 | Partopour B, Dixon A G. Effect of particle shape on methanol partial oxidation in a fixed bed using CFD reactor modeling[J]. AIChE Journal, 2020, 66(5): e16904. |

| 6 | 张楠, 孙中宁, 阎昌琪. 三维随机填充球床通道内流场数值分析[J]. 原子能科学技术, 2012, 46(S2): 792-795. |

| Zhang N, Sun Z N, Yan C Q. Numerical analysis of flow field in three-dimensional randomly packed pebble-bed channel[J]. Atomic Energy Science and Technology, 2012, 46(S2): 792-795. | |

| 7 | Mohanty R, Mohanty S, Mishra B K. Study of flow through a packed bed using discrete element method and computational fluid dynamics[J]. Journal of the Taiwan Institute of Chemical Engineers, 2016, 63: 71-80. |

| 8 | Wehinger G D, Kraume M, Berg V, et al. Investigating dry reforming of methane with spatial reactor profiles and particle-resolved CFD simulations[J]. AIChE Journal, 2016, 62(12): 4436-4452. |

| 9 | Jurtz N, Kraume M, Wehinger G D. Advances in fixed-bed reactor modeling using particle-resolved computational fluid dynamics (CFD)[J]. Reviews in Chemical Engineering, 2019, 35(2): 139-190. |

| 10 | Caulkin R, Jia X D, Fairweather M, et al. Predictions of porosity and fluid distribution through nonspherical-packed columns[J]. AIChE Journal, 2012, 58(5): 1503-1512. |

| 11 | Wehinger G D. Particle-Resolved CFD Simulations of Catalytic Flow Reactors[M]. Berlin: Technische Universitaet, 2016. |

| 12 | Jurtz N, Wehinger G D, Srivastava U, et al. Validation of pressure drop prediction and bed generation of fixed-beds with complex particle shapes using discrete element method and computational fluid dynamics[J]. AIChE Journal, 2020, 66(6): e16967. |

| 13 | Dong Y, Sosna B, Korup O, et al. Investigation of radial heat transfer in a fixed-bed reactor: CFD simulations and profile measurements[J]. Chemical Engineering Journal, 2017, 317: 204-214. |

| 14 | Wehinger G D. Radiation matters in fixed-bed CFD simulations[J]. Chemie Ingenieur Technik, 2019, 91(5): 583-591. |

| 15 | Eppinger T, Wehinger G D. A generalized contact modification for fixed-bed reactor CFD simulations[J]. Chemie Ingenieur Technik, 2021, 93(1/2): 143-153. |

| 16 | Dixon A G, Boudreau J, Rocheleau A, et al. Flow, transport, and reaction interactions in shaped cylindrical particles for steam methane reforming[J]. Industrial & Engineering Chemistry Research, 2012, 51(49): 15839-15854. |

| 17 | Wehinger G D, Eppinger T, Kraume M. Detailed numerical simulations of catalytic fixed-bed reactors: heterogeneous dry reforming of methane[J]. Chemical Engineering Science, 2015, 122: 197-209. |

| 18 | Karthik G M, Buwa V V. A computational approach for the selection of optimal catalyst shape for solid-catalysed gas-phase reactions[J]. Reaction Chemistry & Engineering, 2020, 5(1): 163-182. |

| 19 | Dixon A G. Particle-resolved CFD simulation of fixed bed pressure drop at moderate to high Reynolds number[J]. Powder Technology, 2021, 385: 69-82. |

| 20 | Dixon A G. Local transport and reaction rates in a fixed bed reactor tube: exothermic partial oxidation of ethylene[J]. Chemical Engineering Science, 2021, 231: 116305. |

| 21 | Dixon A G, Nijemeisland M. CFD as a design tool for fixed-bed reactors[J]. Industrial & Engineering Chemistry Research, 2001, 40(23): 5246-5254. |

| 22 | Liu X L, Peng C, Bai H X, et al. A pore network model for calculating pressure drop in packed beds of arbitrary-shaped particles[J]. AIChE Journal, 2020, 66(9): e16258. |

| 23 | Bender J, Erleben K, Trinkle J. Interactive simulation of rigid body dynamics in computer graphics[J]. Computer Graphics Forum, 2014, 33(1): 246-270. |

| 24 | Moghaddam E M, Foumeny E A, Stankiewicz A I, et al. Rigid body dynamics algorithm for modeling random packing structures of nonspherical and nonconvex pellets[J]. Industrial & Engineering Chemistry Research, 2018, 57(44): 14988-15007. |

| 25 | Dixon A G, Ertan Taskin M, Hugh Stitt E, et al. 3D CFD simulations of steam reforming with resolved intraparticle reaction and gradients[J]. Chemical Engineering Science, 2007, 62(18/19/20): 4963-4966. |

| 26 | Seguin D, Montillet A, Comiti J. Experimental characterisation of flow regimes in various porous media(I): Limit of laminar flow regime[J]. Chemical Engineering Science, 1998, 53(21): 3751-3761. |

| 27 | Sosnowski M, Krzywanski J, Grabowska K, et al. Polyhedral meshing in numerical analysis of conjugate heat transfer[J]. EPJ Web of Conferences, 2018, 180: 02096. |

| 28 | Eppinger T, Seidler K, Kraume M. DEM-CFD simulations of fixed bed reactors with small tube to particle diameter ratios[J]. Chemical Engineering Journal, 2011, 166(1): 324-331. |

| 29 | Giese M, Rottschäfer K, Vortmeyer D. Measured and modeled superficial flow profiles in packed beds with liquid flow[J]. AIChE Journal, 1998, 44(2): 484-490. |

| 30 | Ribeiro A M, Neto P, Pinho C. Mean porosity and pressure drop measurements in packed beds of monosized spheres: side wall effects[J]. International Review of Chemical Engineering, 2010, 2(1): 40-46. |

| 31 | Eisfeld B, Schnitzlein K. The influence of confining walls on the pressure drop in packed beds[J]. Chemical Engineering Science, 2001, 56(14): 4321-4329. |

| 32 | 高崇, 潘银珍, 朱炳辰. 环柱状催化剂内强放热复合反应-传质-传热耦合过程研究(Ⅱ):本征反应动力学及反应-传质-传热耦合过程数学模型[J]. 化工学报, 1998, 49(5): 610-616. |

| Gao C, Pan Y Z, Zhu B C. Study on coupling process of multiple reactions-mass transfer-heat transfer in hollow cylindrical catalysts with strong heat effect(Ⅱ): Intrinsic kinetics and mathematical model of coupling process of reaction-mass transfer-heat transfer[J]. Journal of Chemical Industry and Engineering (China), 1998, 49(5): 610-616. |

| [1] | 叶展羽, 山訸, 徐震原. 用于太阳能蒸发的折纸式蒸发器性能仿真[J]. 化工学报, 2023, 74(S1): 132-140. |

| [2] | 张龙, 宋孟杰, 邵苛苛, 张旋, 沈俊, 高润淼, 甄泽康, 江正勇. 管翅式换热器迎风侧翅片末端霜层生长模拟研究[J]. 化工学报, 2023, 74(S1): 179-182. |

| [3] | 张义飞, 刘舫辰, 张双星, 杜文静. 超临界二氧化碳用印刷电路板式换热器性能分析[J]. 化工学报, 2023, 74(S1): 183-190. |

| [4] | 王志国, 薛孟, 董芋双, 张田震, 秦晓凯, 韩强. 基于裂隙粗糙性表征方法的地热岩体热流耦合数值模拟与分析[J]. 化工学报, 2023, 74(S1): 223-234. |

| [5] | 江河, 袁俊飞, 王林, 邢谷雨. 均流腔结构对微细通道内相变流动特性影响的实验研究[J]. 化工学报, 2023, 74(S1): 235-244. |

| [6] | 宋嘉豪, 王文. 斯特林发动机与高温热管耦合运行特性研究[J]. 化工学报, 2023, 74(S1): 287-294. |

| [7] | 张思雨, 殷勇高, 贾鹏琦, 叶威. 双U型地埋管群跨季节蓄热特性研究[J]. 化工学报, 2023, 74(S1): 295-301. |

| [8] | 李艺彤, 郭航, 陈浩, 叶芳. 催化剂非均匀分布的质子交换膜燃料电池操作条件研究[J]. 化工学报, 2023, 74(9): 3831-3840. |

| [9] | 陈哲文, 魏俊杰, 张玉明. 超临界水煤气化耦合SOFC发电系统集成及其能量转化机制[J]. 化工学报, 2023, 74(9): 3888-3902. |

| [10] | 宋明昊, 赵霏, 刘淑晴, 李国选, 杨声, 雷志刚. 离子液体脱除模拟油中挥发酚的多尺度模拟与研究[J]. 化工学报, 2023, 74(9): 3654-3664. |

| [11] | 杨学金, 杨金涛, 宁平, 王访, 宋晓双, 贾丽娟, 冯嘉予. 剧毒气体PH3的干法净化技术研究进展[J]. 化工学报, 2023, 74(9): 3742-3755. |

| [12] | 胡建波, 刘洪超, 胡齐, 黄美英, 宋先雨, 赵双良. 有机笼跨细胞膜易位行为的分子动力学模拟研究[J]. 化工学报, 2023, 74(9): 3756-3765. |

| [13] | 赵佳佳, 田世祥, 李鹏, 谢洪高. SiO2-H2O纳米流体强化煤尘润湿性的微观机理研究[J]. 化工学报, 2023, 74(9): 3931-3945. |

| [14] | 何松, 刘乔迈, 谢广烁, 王斯民, 肖娟. 高浓度水煤浆管道气膜减阻两相流模拟及代理辅助优化[J]. 化工学报, 2023, 74(9): 3766-3774. |

| [15] | 刘远超, 关斌, 钟建斌, 徐一帆, 蒋旭浩, 李耑. 单层XSe2(X=Zr/Hf)的热电输运特性研究[J]. 化工学报, 2023, 74(9): 3968-3978. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号