化工学报 ›› 2023, Vol. 74 ›› Issue (4): 1693-1702.DOI: 10.11949/0438-1157.20221664

收稿日期:2022-12-29

修回日期:2023-03-20

出版日期:2023-04-05

发布日期:2023-06-02

通讯作者:

刘明言

作者简介:王倩倩(1998—),女,硕士研究生,w17839148667@163.com

基金资助:

Qianqian WANG1( ), Mingyan LIU1,2(

), Mingyan LIU1,2( ), Yongli MA1

), Yongli MA1

Received:2022-12-29

Revised:2023-03-20

Online:2023-04-05

Published:2023-06-02

Contact:

Mingyan LIU

摘要:

超声波脱气技术在化工、冶金、环境以及地热能利用等领域具有现实或潜在的应用价值。但是,目前对空气-水系统中超声波脱气规律的研究还相对较少。开展了空气-水系统中的超声波脱气实验研究,在不同的操作参数下,如超声波电功率、频率等,研究了超声波对气体脱除的实际效果。同时将超声波技术与真空脱气技术相结合,探究其脱气效果。结果表明,在实验条件下,随着超声波频率的升高,脱气效果下降;随着超声波电功率的升高,脱气效果提升;与单独真空脱气相比,超声波与真空脱气结合时,脱气效果显著提升;在流动条件下,随着流量增加,脱气效果降低。通过KI实验和可视化方法对超声过程中的声空化现象进行了研究,研究结果可为超声波脱气的工业应用提供基础指导。

中图分类号:

王倩倩, 刘明言, 马永丽. 水中超声波脱气的效应研究[J]. 化工学报, 2023, 74(4): 1693-1702.

Qianqian WANG, Mingyan LIU, Yongli MA. Study on the effect of ultrasonic degassing in water[J]. CIESC Journal, 2023, 74(4): 1693-1702.

图3 不同超声波频率下溶解氧浓度与时间的关系

Fig.3 Variation of dissolved oxygen concentration as a function of irradiation time during ultrasonic irradiation in the frequency range of 20—100 kHz

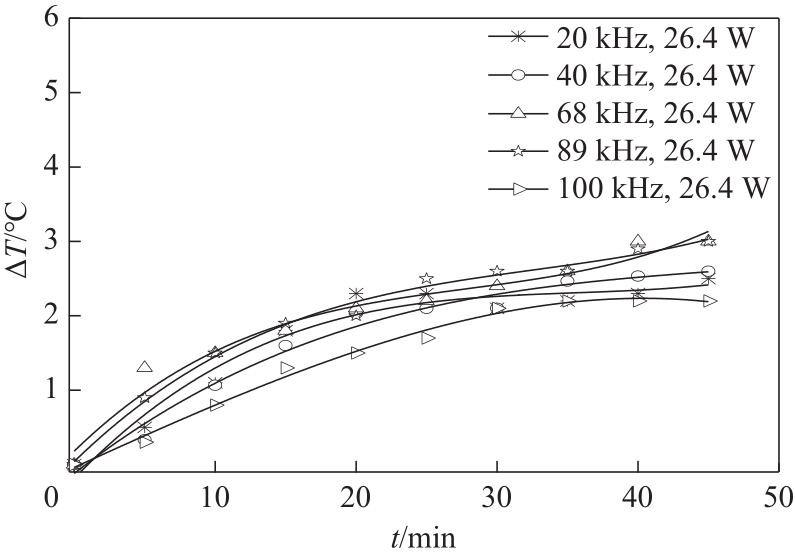

图4 不同超声波频率下温差与时间的关系

Fig.4 Variation of temperature difference as a function of irradiation time during ultrasonic irradiation in the frequency range of 20—100 kHz

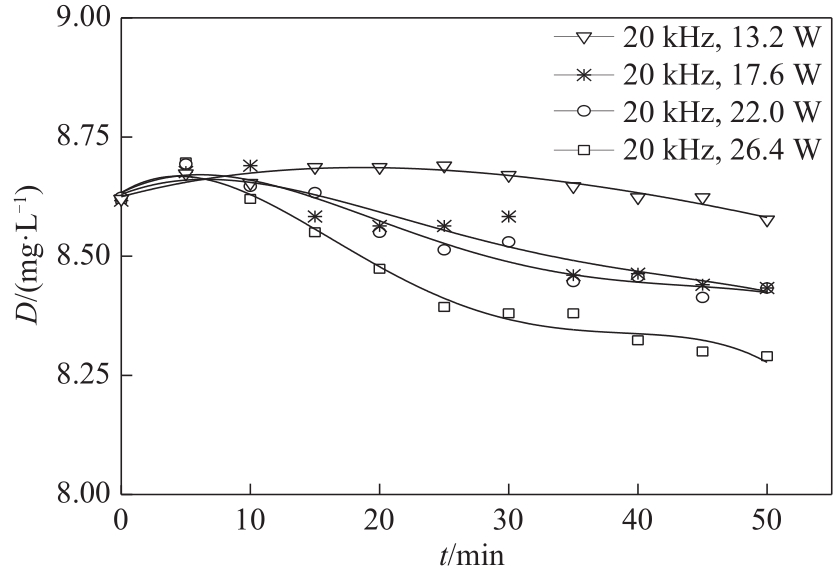

图5 不同超声波电功率下溶解氧浓度随时间的变化关系

Fig.5 Variation of dissolved oxygen concentration as a function of irradiation time during ultrasonic irradiation in the ultrasonic electric power range of 13.2—26.4 W

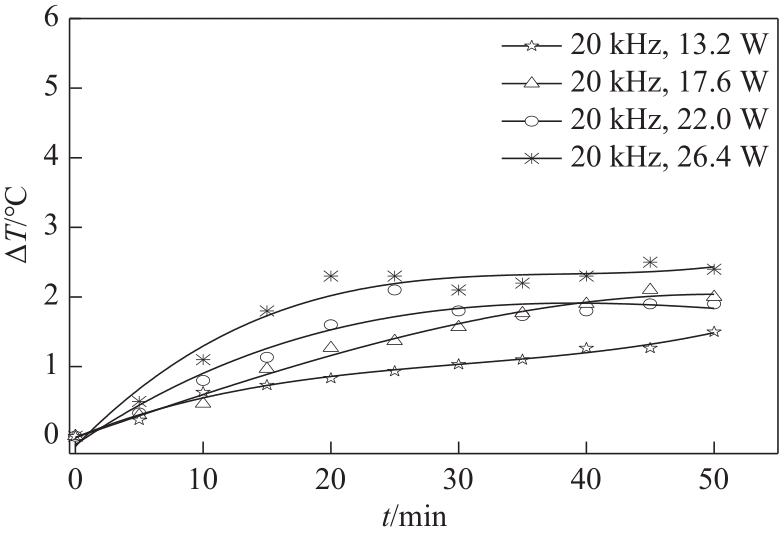

图6 不同超声波电功率下温差随时间的变化关系

Fig.6 Variation of temperature difference as a function of irradiation time during ultrasonic irradiation in the ultrasonic electric power range of 13.2—26.4 W

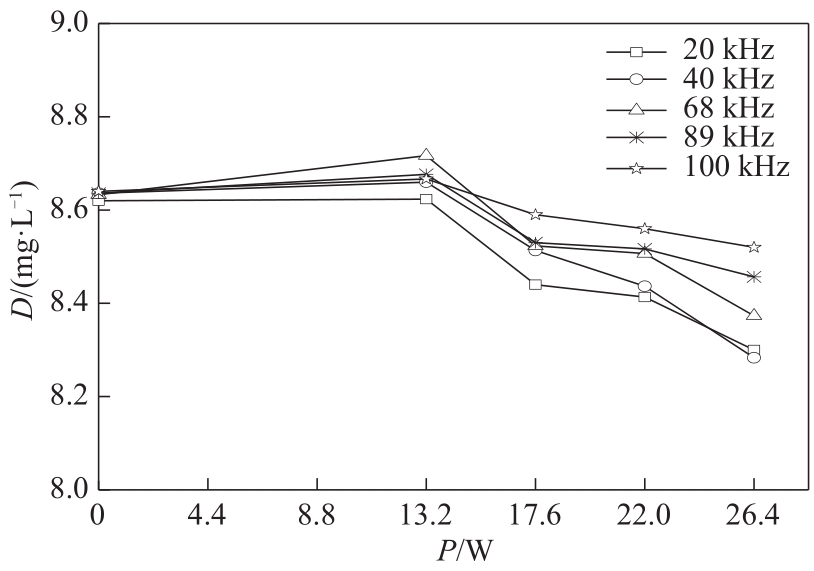

图7 不同频率下超声波电功率与溶解氧浓度关系

Fig.7 Dependence of the dissolved oxygen concentration on the ultrasonic electric power when water is irradiated with ultrasound at frequencies at 20—100 kHz

图8 不同超声波电功率下超声前后粒径分布

Fig.8 The bubble size distribution with different ultrasonic time in the ultrasonic water under different ultrasonic electric power

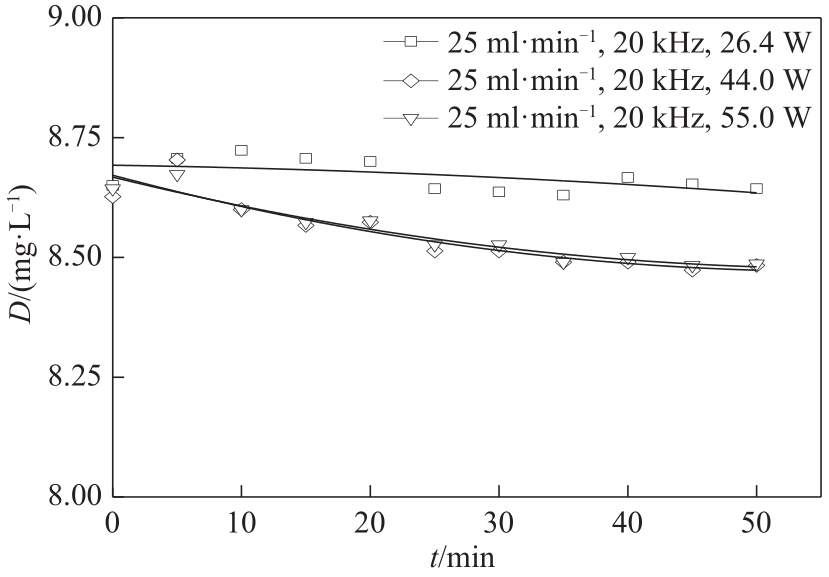

图10 不同超声波电功率下溶解氧浓度随时间的变化(25 ml·min-1)

Fig.10 Variation of dissolved oxygen concentration as a function of irradiation time during ultrasonic under different ultrasonic electric power (25 ml·min-1)

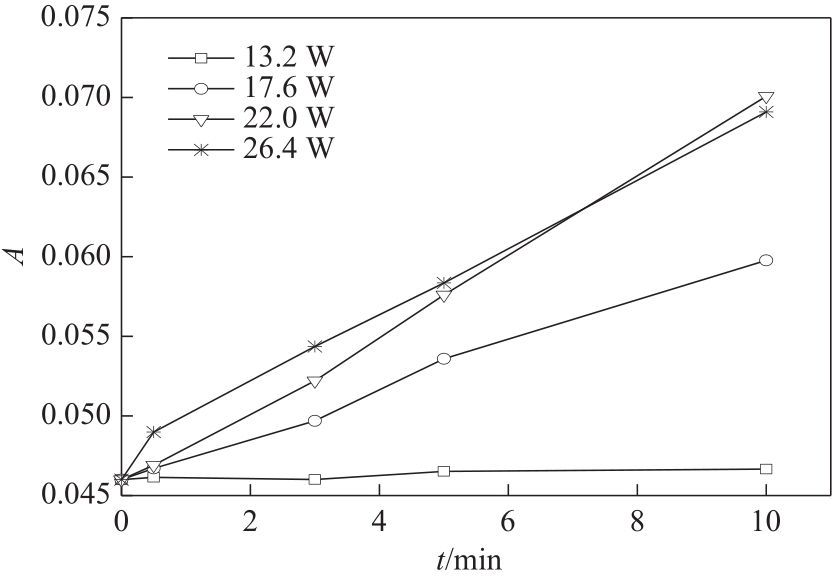

图12 不同超声波电功率下I3-吸光度随时间的变化(20 kHz)

Fig.12 Variation of I3- absorbance as a function of irradiation time under different ultrasonic electric power (20 kHz)

| 1 | Eskin D G. Ultrasonic degassing of liquids[M]//Power Ultrasonics. Amsterdam: Elsevier, 2015: 611-631. |

| 2 | Eskin G I. Cavitation mechanism of ultrasonic melt degassing[J]. Ultrasonics Sonochemistry, 1995, 2(2): S137-S141. |

| 3 | Rozenberg L D. Physical Principles of Ultrasonic Technology[M]. New York: Plenum Press, 1973. |

| 4 | 徐晖. 超声波液相脱气原理及研究进展[J]. 安全与环境工程, 2014, 21(1): 62-68. |

| Xu H. Review for the theory and research status of ultrasonic degassing in liquid phase[J]. Safety and Environmental Engineering, 2014, 21(1): 62-68. | |

| 5 | Xu H B, Han Q Y, Meek T T. Effects of ultrasonic vibration on degassing of aluminum alloys[J]. Materials Science and Engineering: A, 2008, 473(1/2): 96-104. |

| 6 | Puga H, Barbosa J, Seabra E, et al. New trends in aluminium degassing—a comparative study[C]//Fourth International Conference on Advances and Trends in Engineering Materials and Their Applications. Hamburg, 2009. |

| 7 | 陶美君, 吴晓辉, 陆晓华, 等. 垃圾渗滤液中氨氮的超声处理研究[J]. 华中科技大学学报(城市科学版), 2005, 22(1): 70-72. |

| Tao M J, Wu X H, Lu X H, et al. Removal of ammonia nitrogen in the landfill leachate by ultrasonic treatment[J]. Journal of Wuhan Urban Construction Institute, 2005, 22(1): 70-72. | |

| 8 | 李威峥, 刘宝, 王海波, 等. 超声波除沫在工业废水处理中的应用[J]. 辽宁化工, 2021, 50(4): 493-496. |

| Li W Z, Liu B, Wang H B, et al. Application of ultrasonic defoaming in industrial wastewater treatment[J]. Liaoning Chemical Industry, 2021, 50(4): 493-496. | |

| 9 | Gondrexon N, Renaudin V, Boldo P, et al. Degassing effect and gas-liquid transfer in a high frequency sonochemical reactor[J]. Chemical Engineering Journal, 1997, 66(1): 21-26. |

| 10 | Asakura Y, Yasuda K. Frequency and power dependence of ultrasonic degassing[J]. Ultrasonics Sonochemistry, 2022, 82: 105890. |

| 11 | 谢迎春, 王倩倩, 马永丽, 等. 超声波与紫外线耦合脱气杀菌[J]. 化工进展, 2023, 42(3): 1629-1637. |

| Xie Y C, Wang Q Q, Ma Y L, et al. Ultrasonic and ultraviolet coupling degassing and sterilization[J]. Chemical Industry and Engineering Progress, 2023, 42(3): 1629-1637. | |

| 12 | Roy R A, Atchley A A, Crum L A, et al. A precise technique for the measurement of acoustic cavitation thresholds and some preliminary results[J]. The Journal of the Acoustical Society of America, 1985, 78(5): 1799-1805. |

| 13 | Nguyen T T, Asakura Y, Koda S, et al. Dependence of cavitation, chemical effect, and mechanical effect thresholds on ultrasonic frequency[J]. Ultrasonics Sonochemistry, 2017, 39: 301-306. |

| 14 | Suslick K S. The chemical effects of ultrasound[J]. Scientific American, 1989, 260(2): 80-86. |

| 15 | Beckett M A, Hua I. Impact of ultrasonic frequency on aqueous sonoluminescence and sonochemistry[J]. The Journal of Physical Chemistry A, 2001, 105(15): 3796-3802. |

| 16 | Mason T J, Cobley A J, Graves J E, et al. New evidence for the inverse dependence of mechanical and chemical effects on the frequency of ultrasound[J]. Ultrasonics Sonochemistry, 2011, 18(1): 226-230. |

| 17 | Lauterborn W, Mettin R. Acoustic cavitation[M]//Power Ultrasonics. Amsterdam: Elsevier, 2015: 37-78. |

| 18 | Naji Meidani A R, Hasan M. A study of hydrogen bubble growth during ultrasonic degassing of Al–Cu alloy melts[J]. Journal of Materials Processing Technology, 2004, 147(3): 311-320. |

| 19 | Sörensen C. Absorptions-, geschwindigkeits-und entgasungsmessungen im ultraschallgebiet[J]. Annalen Der Physik, 1936, 418(2): 121-137. |

| 20 | 薛娟琴, 兰新哲, 杜士毅, 等. 超声波作用下柠檬酸盐溶液中SO2的解吸机理[J]. 化工学报, 2007, 58(4): 944-950. |

| Xue J Q, Lan X Z, Du S Y, et al. Mechanism of SO2 ultrasonic desorption from citrate solution[J]. Journal of Chemical Industry and Engineering (China), 2007, 58(4): 944-950. | |

| 21 | Grieser F. Sonochemistry and the Acoustic Bubble[M]. UK: Elsevier, 2015. |

| 22 | Leighton T G. The Acoustic Bubble[M]. USA: Academic Press, 1994. |

| 23 | Neppiras E A. Acoustic cavitation[J]. Physics Reports, 1980, 61(3): 159-251. |

| 24 | Komarov S, Oda K, Ishiwata Y, et al. Characterization of acoustic cavitation in water and molten aluminum alloy[J]. Ultrasonics Sonochemistry, 2013, 20(2): 754-761. |

| 25 | Eller A, Flynn H G. Rectified diffusion during nonlinear pulsations of cavitation bubbles[J]. The Journal of the Acoustical Society of America, 1965, 37(3): 493-503. |

| 26 | Leong T, Collis J, Manasseh R, et al. The role of surfactant headgroup, chain length, and cavitation microstreaming on the growth of bubbles by rectified diffusion[J]. The Journal of Physical Chemistry C, 2011, 115(49): 24310-24316. |

| 27 | Mettin R, Luther S, Lauterborn W. Bubble size distribution and structures in acoustic cavitation[C]//2nd Conf. on Applications of Power Ultrasound in Physical and Chemical Processing. Toulouse, 1999: 125-129. |

| 28 | Monnier H, Wilhelm A M, Delmas H. Effects of ultrasound on micromixing in flow cell[J]. Chemical Engineering Science, 2000, 55(19): 4009-4020. |

| 29 | Eskin D G, Al-Helal K, Tzanakis I. Application of a plate sonotrode to ultrasonic degassing of aluminum melt: acoustic measurements and feasibility study[J]. Journal of Materials Processing Technology, 2015, 222: 148-154. |

| 30 | Xu H B, Meek T T, Han Q Y. Effects of ultrasonic field and vacuum on degassing of molten aluminum alloy[J]. Materials Letters, 2007, 61(4/5): 1246-1250. |

| 31 | Wang Q X, Manmi K. Three dimensional microbubble dynamics near a wall subject to high intensity ultrasound[J]. Physics of Fluids, 2014, 26(3): 032104. |

| 32 | Tuziuti T, Yasui K, Sivakumar M, et al. Correlation between acoustic cavitation noise and yield enhancement of sonochemical reaction by particle addition[J]. The Journal of Physical Chemistry A, 2005, 109(21): 4869-4872. |

| 33 | Kentish S, Ashokkumar M. The physical and chemical effects of ultrasound[M]//Feng H, Barbosa-Canovas G, Weiss J. Ultrasound Technologies for Food and Bioprocessing. New York: Springer, 2011: 1-12. |

| 34 | Ma Y H, Zeng Z J, Xu W L, et al. Directional transport and random motion of particles in ALF ultrasonic cavitation structure[J]. Ultrasonics Sonochemistry, 2021, 72: 105439. |

| 35 | Wu P F, Bai L X, Lin W J, et al. Mechanism and dynamics of hydrodynamic-acoustic cavitation (HAC)[J]. Ultrasonics Sonochemistry, 2018, 49: 89-96. |

| 36 | Parlitz U, Mettin R, Luther S, et al. Spatio-temporal dynamics of acoustic cavitation bubble clouds[J]. Philosophical Transactions of the Royal Society of London Series A: Mathematical, Physical and Engineering Sciences, 1999, 357(1751): 313-334. |

| 37 | Lauterborn W, Schmitz E, Judt A. Experimental approach to a complex acoustic system[J]. International Journal of Bifurcation and Chaos, 1993, 3(3): 635-642. |

| 38 | Leighton T G. Bubble population phenomena in acoustic cavitation[J]. Ultrasonics Sonochemistry, 1995, 2(2): S123-S136. |

| 39 | Ashokkumar M. The characterization of acoustic cavitation bubbles—an overview[J]. Ultrasonics Sonochemistry, 2011, 18(4): 864-872. |

| 40 | Apfel R E. Acoustic cavitation[M]//Methods in Experimental Physics. Amsterdam: Elsevier, 1981: 355-411. |

| 41 | Apfel R E. Acoustic cavitation prediction[J]. The Journal of the Acoustical Society of America, 1981, 69(6): 1624-1633. |

| 42 | Mettin R. Bubble structures in acoustic cavitation[M]//Doinikov A A. Bubble and Particle Dynamics in Acoustic Fields: Modern Trends and Applications. Kalala: Research Signpost, 2005: 1-36. |

| [1] | 金伟其, 吴月荣, 王霞, 李力, 裘溯, 袁盼, 王铭赫. 化工园区工业气体泄漏气云红外成像检测技术与国产化装备进展[J]. 化工学报, 2023, 74(S1): 32-44. |

| [2] | 程成, 段钟弟, 孙浩然, 胡海涛, 薛鸿祥. 表面微结构对析晶沉积特性影响的格子Boltzmann模拟[J]. 化工学报, 2023, 74(S1): 74-86. |

| [3] | 宋瑞涛, 王派, 王云鹏, 李敏霞, 党超镔, 陈振国, 童欢, 周佳琦. 二氧化碳直接蒸发冰场排管内流动沸腾换热数值模拟分析[J]. 化工学报, 2023, 74(S1): 96-103. |

| [4] | 吴馨, 龚建英, 靳龙, 王宇涛, 黄睿宁. 超声波激励下铝板表面液滴群输运特性的研究[J]. 化工学报, 2023, 74(S1): 104-112. |

| [5] | 周绍华, 詹飞龙, 丁国良, 张浩, 邵艳坡, 刘艳涛, 郜哲明. 短管节流阀内流动噪声的实验研究及降噪措施[J]. 化工学报, 2023, 74(S1): 113-121. |

| [6] | 张义飞, 刘舫辰, 张双星, 杜文静. 超临界二氧化碳用印刷电路板式换热器性能分析[J]. 化工学报, 2023, 74(S1): 183-190. |

| [7] | 王玉兵, 李杰, 詹宏波, 朱光亚, 张大林. R134a在菱形离散肋微小通道内的流动沸腾换热实验研究[J]. 化工学报, 2023, 74(9): 3797-3806. |

| [8] | 陈美思, 陈威达, 李鑫垚, 李尚予, 吴有庭, 张锋, 张志炳. 硅基离子液体微颗粒强化气体捕集与转化的研究进展[J]. 化工学报, 2023, 74(9): 3628-3639. |

| [9] | 陈杰, 林永胜, 肖恺, 杨臣, 邱挺. 胆碱基碱性离子液体催化合成仲丁醇性能研究[J]. 化工学报, 2023, 74(9): 3716-3730. |

| [10] | 郑玉圆, 葛志伟, 韩翔宇, 王亮, 陈海生. 中高温钙基材料热化学储热的研究进展与展望[J]. 化工学报, 2023, 74(8): 3171-3192. |

| [11] | 张瑞航, 曹潘, 杨锋, 李昆, 肖朋, 邓春, 刘蓓, 孙长宇, 陈光进. ZIF-8纳米流体天然气乙烷回收工艺的产品纯度关键影响因素分析[J]. 化工学报, 2023, 74(8): 3386-3393. |

| [12] | 汪林正, 陆俞冰, 张睿智, 罗永浩. 基于分子动力学模拟的VOCs热氧化特性分析[J]. 化工学报, 2023, 74(8): 3242-3255. |

| [13] | 张蒙蒙, 颜冬, 沈永峰, 李文翠. 电解液类型对双离子电池阴阳离子储存行为的影响[J]. 化工学报, 2023, 74(7): 3116-3126. |

| [14] | 陈吉, 洪泽, 雷昭, 凌强, 赵志刚, 彭陈辉, 崔平. 基于分子动力学的焦炭溶损反应及其机理研究[J]. 化工学报, 2023, 74(7): 2935-2946. |

| [15] | 何晓崐, 刘锐, 薛园, 左然. MOCVD生长AlN单晶薄膜的气相和表面化学反应综述[J]. 化工学报, 2023, 74(7): 2800-2813. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号