化工学报 ›› 2022, Vol. 73 ›› Issue (11): 4903-4916.DOI: 10.11949/0438-1157.20220762

薛涵文1,2( ), 聂峰1,2, 赵延兴1, 董学强1,2, 郭浩1, 沈俊1,2, 公茂琼1,2(

), 聂峰1,2, 赵延兴1, 董学强1,2, 郭浩1, 沈俊1,2, 公茂琼1,2( )

)

收稿日期:2022-05-30

修回日期:2022-09-13

出版日期:2022-11-05

发布日期:2022-12-06

通讯作者:

公茂琼

作者简介:薛涵文(1993—),男,博士研究生,xuehanwen16@mails.ucas.ac.cn

基金资助:

Hanwen XUE1,2( ), Feng NIE1,2, Yanxing ZHAO1, Xueqiang DONG1,2, Hao GUO1, Jun SHEN1,2, Maoqiong GONG1,2(

), Feng NIE1,2, Yanxing ZHAO1, Xueqiang DONG1,2, Hao GUO1, Jun SHEN1,2, Maoqiong GONG1,2( )

)

Received:2022-05-30

Revised:2022-09-13

Online:2022-11-05

Published:2022-12-06

Contact:

Maoqiong GONG

摘要:

丙烷(R290)作为一种性能优异的自然制冷剂,其两相流动压降特性在换热器设计及制冷系统优化等方面起到重要作用,而且目前对于低质量流率以及低饱和压力条件下的压降分析相对较少,且仅有少数研究结合流型进行分析。因此,开展了R290在内径6 mm的水平光管内压降特性实验研究。在如下实验工况范围内,质量流率70~190 kg·m-2·s-1,热通量10.6~73.0 kW·m-2,饱和压力0.215~0.415 MPa,干度0~1,获取了压降实验数据,并进一步基于实验工况以及流型分析了加速压降、两相摩擦压降的变化趋势。对比了现有的摩擦压降关联式并基于Friedel模型,使用Rev/Rel 和液相Froude数Fr表征气液相相互作用,获取了一个新的基于流型的两相摩擦压降关联式。新模型可以很好地预测R290实验数据,预测结果的平均相对偏差(ARD)为-0.2%,平均绝对相对偏差(AARD)为5.2%,λ30%为97.9%。对比文献中的实验数据,10组数据预测结果的ARD为10.0%,AARD为19.3%,λ30%为80.3%,由此可见新模型具有一定的预测精度和适用性。

中图分类号:

薛涵文, 聂峰, 赵延兴, 董学强, 郭浩, 沈俊, 公茂琼. 基于流型的R290水平管内流动沸腾压降实验研究[J]. 化工学报, 2022, 73(11): 4903-4916.

Hanwen XUE, Feng NIE, Yanxing ZHAO, Xueqiang DONG, Hao GUO, Jun SHEN, Maoqiong GONG. Experimental study of flow boiling pressure drop of R290 in a horizontal tube based on flow pattern[J]. CIESC Journal, 2022, 73(11): 4903-4916.

| 文献 | G/(kg·m-2·s-1) | q/(kW· m-2) | d/mm | p/MPa | x | 流向 | 材质 | 最佳预测或发展关联式 |

|---|---|---|---|---|---|---|---|---|

| [ | 250~500 | 5.0~21.0 | 2.46 | 0.46~0.71 | 0~0.9 | 水平 | 铜 | — |

| [ | 50~200 | 恒壁温287 K | 10.9, 8.0 | 0.35~0.62 | 0.1~0.9 | 水平 | 铜 | — |

| [ | 50~400 | 5.0~20.0 | 1.5, 3.0 | 0.46~0.63 | 0~1.0 | 水平 | 不锈钢 | L-M[ |

| [ | 100~500 | 5.0~280.0 | 1.7 | 0.90~1.46 | 0.1~1.0 | 竖直向上 | 不锈钢 | Friedel[ |

| [ | 200~800 | 恒壁温 | 0.96 | 1.35~1.42 | 0~0.9 | 水平 | 铜 | Friedel[ |

| [ | 62~104 | 11.7~87.1 | 6.0 | 0.15~0.45 | 0.1~1.0 | 水平 | 铜 | M-H[ |

| [ | 175~350 | 15.8~32.3 | 1.2 | 1.08~1.71 | 0.1~0.9 | 水平 | 铝 | Sun[ |

| [ | 240~480 | 5.0~60.0 | 1.0 | 0.95 | 0~0.9 | 水平 | 不锈钢 | Zhang[ |

| [ | 150~500 | 2.5~40.0 | 6.0, 8.0 | 0.95~1.21 | 0~1.0 | 水平 | 不锈钢 | Friedel[ |

| [ | 250~500 | 15.0~33.0 | 5.0(外径) | 0.46~0.63 | 0.1~0.9 | 水平 | 铜 | Xu[ |

| [ | 200~400 | 5.0 | 10.0 | 1.00~3.00 | 0.1~0.9 | 水平 | 铜 | Friedel[ |

表1 R290压降特性研究工作汇总

Table 1 The summary of the pressure drop studies of R290

| 文献 | G/(kg·m-2·s-1) | q/(kW· m-2) | d/mm | p/MPa | x | 流向 | 材质 | 最佳预测或发展关联式 |

|---|---|---|---|---|---|---|---|---|

| [ | 250~500 | 5.0~21.0 | 2.46 | 0.46~0.71 | 0~0.9 | 水平 | 铜 | — |

| [ | 50~200 | 恒壁温287 K | 10.9, 8.0 | 0.35~0.62 | 0.1~0.9 | 水平 | 铜 | — |

| [ | 50~400 | 5.0~20.0 | 1.5, 3.0 | 0.46~0.63 | 0~1.0 | 水平 | 不锈钢 | L-M[ |

| [ | 100~500 | 5.0~280.0 | 1.7 | 0.90~1.46 | 0.1~1.0 | 竖直向上 | 不锈钢 | Friedel[ |

| [ | 200~800 | 恒壁温 | 0.96 | 1.35~1.42 | 0~0.9 | 水平 | 铜 | Friedel[ |

| [ | 62~104 | 11.7~87.1 | 6.0 | 0.15~0.45 | 0.1~1.0 | 水平 | 铜 | M-H[ |

| [ | 175~350 | 15.8~32.3 | 1.2 | 1.08~1.71 | 0.1~0.9 | 水平 | 铝 | Sun[ |

| [ | 240~480 | 5.0~60.0 | 1.0 | 0.95 | 0~0.9 | 水平 | 不锈钢 | Zhang[ |

| [ | 150~500 | 2.5~40.0 | 6.0, 8.0 | 0.95~1.21 | 0~1.0 | 水平 | 不锈钢 | Friedel[ |

| [ | 250~500 | 15.0~33.0 | 5.0(外径) | 0.46~0.63 | 0.1~0.9 | 水平 | 铜 | Xu[ |

| [ | 200~400 | 5.0 | 10.0 | 1.00~3.00 | 0.1~0.9 | 水平 | 铜 | Friedel[ |

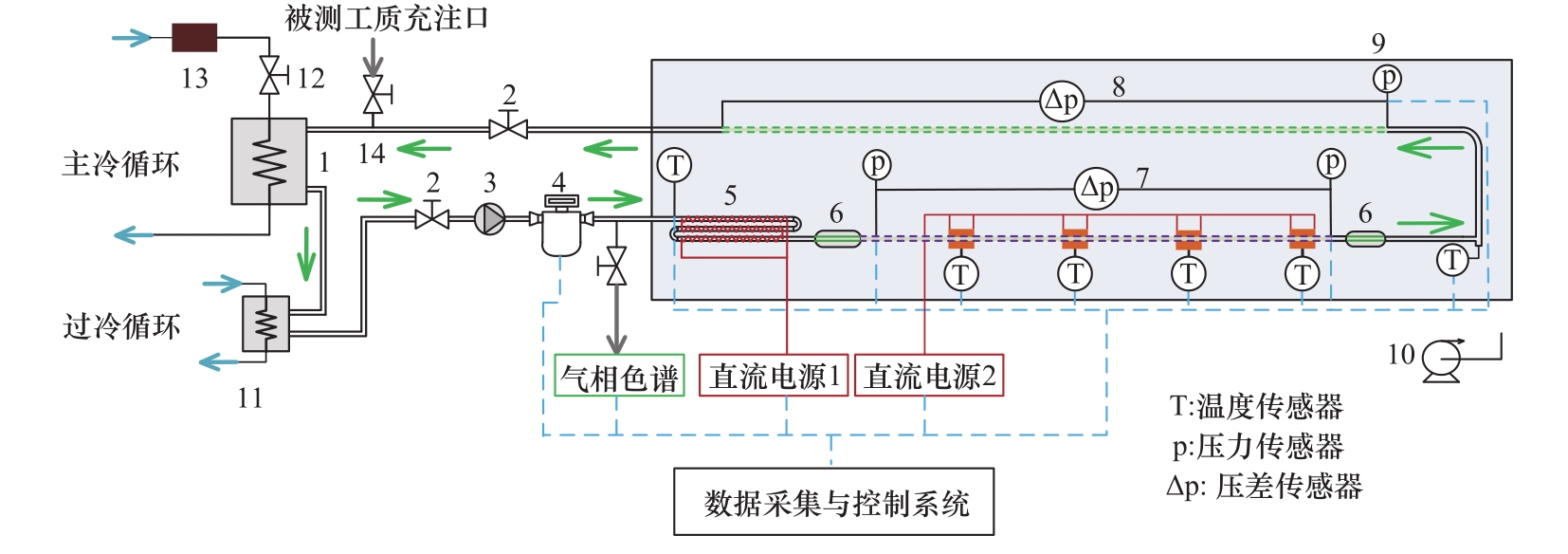

图1 实验装置简图1—主冷换热器;2—阀门;3—磁力泵;4—科氏力流量计;5—预热器;6—观察窗;7—传热测试段;8—压降测试段;9—真空罩;10—真空泵;11—过冷换热器;12—节流阀;13—制冷机加热棒;14—被测工质充注口

Fig.1 Schematic diagram of experimental facility

| 参数 | 仪器 | 范围 | 不确定度 |

|---|---|---|---|

| m/(kg·h-1) | ULTRA MKⅡ流量计 | 0~180 | 0.1% |

| p/MPa | UNIK压力传感器 | 0~1 | 0.04% |

| pdp/kPa | UNIK压差传感器 | 0~40 | 0.04% |

| T/K | PT100铂电阻温度计 | 55~373 | 0.1 K |

| U/V | Keithley 2700数字电压表 | 0~220 | 0.005% |

| I/A | 青智1659电流表 | 0~5 | 0.2% |

| L/mm | 游标卡尺 | 0~300 | 0.02 mm |

| LT/m | 卷尺 | 0~3 | 1 mm |

表2 测量仪器与不确定度

Table 2 Measuring instruments and uncertainties

| 参数 | 仪器 | 范围 | 不确定度 |

|---|---|---|---|

| m/(kg·h-1) | ULTRA MKⅡ流量计 | 0~180 | 0.1% |

| p/MPa | UNIK压力传感器 | 0~1 | 0.04% |

| pdp/kPa | UNIK压差传感器 | 0~40 | 0.04% |

| T/K | PT100铂电阻温度计 | 55~373 | 0.1 K |

| U/V | Keithley 2700数字电压表 | 0~220 | 0.005% |

| I/A | 青智1659电流表 | 0~5 | 0.2% |

| L/mm | 游标卡尺 | 0~300 | 0.02 mm |

| LT/m | 卷尺 | 0~3 | 1 mm |

| 饱和压力p/MPa | 饱和温度 T/K | 液相密度 ρl /(kg·m-3) | 气相密度 ρv/(kg·m-3) | ρl /ρv | 表面张力 σ/(mN·m-1) | 液相黏度 μl /(μPa·s) | 气相黏度 μv/(μPa·s) |

|---|---|---|---|---|---|---|---|

| 0.215 | 249.6 | 558.8 | 4.9 | 114.6 | 13.2 | 160.7 | 6.8 |

| 0.315 | 260.4 | 545.3 | 7.0 | 78.0 | 11.8 | 143.3 | 7.1 |

| 0.415 | 268.8 | 534.4 | 9.1 | 58.7 | 10.7 | 131.3 | 7.3 |

表3 不同饱和压力下R290物性

Table 3 Thermophysical properties of R290 under different saturation pressures

| 饱和压力p/MPa | 饱和温度 T/K | 液相密度 ρl /(kg·m-3) | 气相密度 ρv/(kg·m-3) | ρl /ρv | 表面张力 σ/(mN·m-1) | 液相黏度 μl /(μPa·s) | 气相黏度 μv/(μPa·s) |

|---|---|---|---|---|---|---|---|

| 0.215 | 249.6 | 558.8 | 4.9 | 114.6 | 13.2 | 160.7 | 6.8 |

| 0.315 | 260.4 | 545.3 | 7.0 | 78.0 | 11.8 | 143.3 | 7.1 |

| 0.415 | 268.8 | 534.4 | 9.1 | 58.7 | 10.7 | 131.3 | 7.3 |

| 文献 | 间歇流 | 环状流 | 合计 | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| ARD/% | AARD/% | λ30%/% | ARD/% | AARD/% | λ30%/% | ARD/% | AARD/% | λ30%/% | ||

| 均相模型 | [ | 48.6 | 51.8 | 36.6 | -18.7 | 24.1 | 63.9 | 5.9 | 34.2 | 53.9 |

| [ | 46.1 | 54.9 | 42.0 | 55.5 | 55.5 | 30.4 | 52.1 | 55.3 | 34.6 | |

| [ | 54.8 | 57.6 | 25.0 | -18.6 | 24.1 | 63.4 | 8.3 | 36.3 | 49.3 | |

| [ | 46.4 | 49.6 | 37.5 | -24.3 | 30.3 | 47.4 | 1.6 | 37.4 | 43.8 | |

| 分相模型 | [ | 237.8 | 241.6 | 2.7 | 64.2 | 70.6 | 35.6 | 127.7 | 133.2 | 23.5 |

| [ | 384.5 | 386.4 | 0 | 137.4 | 140.8 | 11.3 | 227.8 | 230.7 | 7.2 | |

| [ | 175.8 | 178.1 | 0 | 37.1 | 38.8 | 51.5 | 87.9 | 89.8 | 32.7 | |

| [ | 29.9 | 36.9 | 53.6 | 50.9 | 66.1 | 11.9 | 43.2 | 55.4 | 27.1 | |

| [ | 72.5 | 75.7 | 13.4 | 19.5 | 22.7 | 70.1 | 38.9 | 42.1 | 49.3 | |

| [ | 186.1 | 201.9 | 2.7 | 1.7 | 39.8 | 35.6 | 69.2 | 99.1 | 23.5 | |

| [ | 42.8 | 42.9 | 32 | -6.6 | 17.7 | 84.1 | 10.5 | 26.4 | 66.1 | |

| [ | -22.8 | 34.0 | 48.2 | -69.4 | 69.4 | 2.1 | -52.4 | 56.5 | 19.0 | |

| [ | 73.7 | 76.9 | 12.5 | 21.0 | 23.2 | 68.0 | 40.3 | 42.8 | 47.7 | |

| [ | 41.2 | 45.4 | 41.1 | 16.8 | 19.4 | 75.3 | 25.7 | 28.9 | 62.7 | |

| [ | 124.9 | 130.3 | 0.9 | -10.1 | 49.4 | 35.1 | 39.4 | 79.0 | 22.5 | |

| [ | 113.3 | 116.3 | 0 | 8.1 | 22.5 | 77.8 | 46.6 | 56.8 | 49.3 | |

| [ | -4.4 | 11.6 | 93.0 | -13.2 | 14.8 | 99.5 | -8.5 | 15.8 | 97.0 | |

| [ | -53.3 | 55.2 | 8.9 | -65.4 | 65.7 | 3.1 | -61 | 61.9 | 5.2 | |

| 本文 | 3.2 | 9.4 | 94.0 | 1.3 | 3.1 | 100 | -0.2 | 5.2 | 97.9 | |

表4 摩擦压降关联式预测结果

Table 4 The prediction results of friction pressure drop correlation

| 文献 | 间歇流 | 环状流 | 合计 | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| ARD/% | AARD/% | λ30%/% | ARD/% | AARD/% | λ30%/% | ARD/% | AARD/% | λ30%/% | ||

| 均相模型 | [ | 48.6 | 51.8 | 36.6 | -18.7 | 24.1 | 63.9 | 5.9 | 34.2 | 53.9 |

| [ | 46.1 | 54.9 | 42.0 | 55.5 | 55.5 | 30.4 | 52.1 | 55.3 | 34.6 | |

| [ | 54.8 | 57.6 | 25.0 | -18.6 | 24.1 | 63.4 | 8.3 | 36.3 | 49.3 | |

| [ | 46.4 | 49.6 | 37.5 | -24.3 | 30.3 | 47.4 | 1.6 | 37.4 | 43.8 | |

| 分相模型 | [ | 237.8 | 241.6 | 2.7 | 64.2 | 70.6 | 35.6 | 127.7 | 133.2 | 23.5 |

| [ | 384.5 | 386.4 | 0 | 137.4 | 140.8 | 11.3 | 227.8 | 230.7 | 7.2 | |

| [ | 175.8 | 178.1 | 0 | 37.1 | 38.8 | 51.5 | 87.9 | 89.8 | 32.7 | |

| [ | 29.9 | 36.9 | 53.6 | 50.9 | 66.1 | 11.9 | 43.2 | 55.4 | 27.1 | |

| [ | 72.5 | 75.7 | 13.4 | 19.5 | 22.7 | 70.1 | 38.9 | 42.1 | 49.3 | |

| [ | 186.1 | 201.9 | 2.7 | 1.7 | 39.8 | 35.6 | 69.2 | 99.1 | 23.5 | |

| [ | 42.8 | 42.9 | 32 | -6.6 | 17.7 | 84.1 | 10.5 | 26.4 | 66.1 | |

| [ | -22.8 | 34.0 | 48.2 | -69.4 | 69.4 | 2.1 | -52.4 | 56.5 | 19.0 | |

| [ | 73.7 | 76.9 | 12.5 | 21.0 | 23.2 | 68.0 | 40.3 | 42.8 | 47.7 | |

| [ | 41.2 | 45.4 | 41.1 | 16.8 | 19.4 | 75.3 | 25.7 | 28.9 | 62.7 | |

| [ | 124.9 | 130.3 | 0.9 | -10.1 | 49.4 | 35.1 | 39.4 | 79.0 | 22.5 | |

| [ | 113.3 | 116.3 | 0 | 8.1 | 22.5 | 77.8 | 46.6 | 56.8 | 49.3 | |

| [ | -4.4 | 11.6 | 93.0 | -13.2 | 14.8 | 99.5 | -8.5 | 15.8 | 97.0 | |

| [ | -53.3 | 55.2 | 8.9 | -65.4 | 65.7 | 3.1 | -61 | 61.9 | 5.2 | |

| 本文 | 3.2 | 9.4 | 94.0 | 1.3 | 3.1 | 100 | -0.2 | 5.2 | 97.9 | |

| 流型 | c1 | c2 | c3 | c4 | c5 | c6 |

|---|---|---|---|---|---|---|

| 间歇流 | 1.90 | 0.19 | 0.52 | -0.77 | 4.66 | 0.28 |

| 环状流 | 1.90 | 0.76 | 1.02 | 0.84 | 0.37 | 0.28 |

表5 式(19)中的拟合项

Table 5 The fitting parameters in Eq.(19)

| 流型 | c1 | c2 | c3 | c4 | c5 | c6 |

|---|---|---|---|---|---|---|

| 间歇流 | 1.90 | 0.19 | 0.52 | -0.77 | 4.66 | 0.28 |

| 环状流 | 1.90 | 0.76 | 1.02 | 0.84 | 0.37 | 0.28 |

| 文献 | 工质 | 数据 数量 | p/MPa | x | G/(kg· m-2 ·s-1) | d/mm | 预测结果(ARD(%)/AARD(%)/λ30%(%)) | |

|---|---|---|---|---|---|---|---|---|

| 本文 | Yang[ | |||||||

| 合计 | — | 1410 | 0.02~3.00 | 0~1 | 6.3~845 | 0.85~18.0 | 10.0/19.3/80.3 | 38.4/37.5/48.6 |

| [ | R134a | 30 | 0.35 | 0~0.9 | 200~500 | 9.52 | 5.9/20.3/82.8 | 31.4/37.1/65.5 |

| [ | R1234yf | 74 | 0.44~0.59 | 0~1 | 300~760 | 7.90~10.85 | -3.5/20.8/83.8 | 64.9/64.1/25.7 |

| [ | R410A,R32,R1234ze(E),R134a | 166 | 1.27~4.00 | 0~1 | 200~400 | 0.85 | -0.9/25.5/60.8 | -45.8/46.2/18.7 |

| [ | R134a | 33 | 0.61~0.82 | 0~1 | 750~845 | 1.0 | 15.2/17.2/84.8 | -44.1/44.1/18.2 |

| [ | H2O | 24 | 0.02 | 0.2~0.9 | 6.3~9.8 | 18.0 | -3.2/12.3/92.0 | 25.1/35.6/62.5 |

| [ | R600a | 418 | 0.22~0.42 | 0~1 | 67~190 | 6.0 | -3.0/13.4/86.7 | -12.6/18.5/84.7 |

| [ | R1234ze(E) | 520 | 0.22~0.42 | 0~1 | 67~190 | 6.0 | -15.4/16.2/84.8 | -7.2/13.9/89.8 |

| [ | R290 | 50 | 0.95~1.21 | 0~1 | 150~500 | 6.0 | -16.6/23.9/70.0 | -13.8/33.3/40.0 |

| [ | R14 | 66 | 1.00~3.00 | 0~0.9 | 200~650 | 4.0 | -19.3/24.4/70.1 | 32.1/56.4/22.7 |

| [ | R290 | 29 | 0.46~0.63 | 0.1~0.9 | 250~500 | 5.0 | 9.0/19.1/86.2 | -20.0/25.8/58.6 |

表6 新模型对文献数据的预测结果

Table 6 Prediction results of the new model on literature data

| 文献 | 工质 | 数据 数量 | p/MPa | x | G/(kg· m-2 ·s-1) | d/mm | 预测结果(ARD(%)/AARD(%)/λ30%(%)) | |

|---|---|---|---|---|---|---|---|---|

| 本文 | Yang[ | |||||||

| 合计 | — | 1410 | 0.02~3.00 | 0~1 | 6.3~845 | 0.85~18.0 | 10.0/19.3/80.3 | 38.4/37.5/48.6 |

| [ | R134a | 30 | 0.35 | 0~0.9 | 200~500 | 9.52 | 5.9/20.3/82.8 | 31.4/37.1/65.5 |

| [ | R1234yf | 74 | 0.44~0.59 | 0~1 | 300~760 | 7.90~10.85 | -3.5/20.8/83.8 | 64.9/64.1/25.7 |

| [ | R410A,R32,R1234ze(E),R134a | 166 | 1.27~4.00 | 0~1 | 200~400 | 0.85 | -0.9/25.5/60.8 | -45.8/46.2/18.7 |

| [ | R134a | 33 | 0.61~0.82 | 0~1 | 750~845 | 1.0 | 15.2/17.2/84.8 | -44.1/44.1/18.2 |

| [ | H2O | 24 | 0.02 | 0.2~0.9 | 6.3~9.8 | 18.0 | -3.2/12.3/92.0 | 25.1/35.6/62.5 |

| [ | R600a | 418 | 0.22~0.42 | 0~1 | 67~190 | 6.0 | -3.0/13.4/86.7 | -12.6/18.5/84.7 |

| [ | R1234ze(E) | 520 | 0.22~0.42 | 0~1 | 67~190 | 6.0 | -15.4/16.2/84.8 | -7.2/13.9/89.8 |

| [ | R290 | 50 | 0.95~1.21 | 0~1 | 150~500 | 6.0 | -16.6/23.9/70.0 | -13.8/33.3/40.0 |

| [ | R14 | 66 | 1.00~3.00 | 0~0.9 | 200~650 | 4.0 | -19.3/24.4/70.1 | 32.1/56.4/22.7 |

| [ | R290 | 29 | 0.46~0.63 | 0.1~0.9 | 250~500 | 5.0 | 9.0/19.1/86.2 | -20.0/25.8/58.6 |

| 1 | Granryd E. Hydrocarbons as refrigerants—an overview[J]. International Journal of Refrigeration, 2001, 24(1): 15-24. |

| 2 | 安青松, 闫若雪, 孙博阳, 等. “双碳”背景下天然工质的改革及减排潜力[J]. 华电技术, 2021, 43(11): 85-90. |

| An Q S, Yan R X, Sun B Y, et al. Natural working fluids transformation and carbon emission reduction potential on the path to carbon peaking and carbon neutrality[J]. Huadian Technology, 2021, 43(11): 85-90. | |

| 3 | Mauro A W, Napoli G, Pelella F, et al. Flow pattern, condensation and boiling inside and outside smooth and enhanced surfaces of propane (R290). State of the art review[J]. International Journal of Heat and Mass Transfer, 2021, 174: 121316. |

| 4 | Yadav S, Liu J, Kim S C. A comprehensive study on 21st-century refrigerants—R290 and R1234yf: a review[J]. International Journal of Heat and Mass Transfer, 2022, 182: 121947. |

| 5 | Allymehr E, Pardiñas Á Á, Eikevik T M, et al. Characteristics of evaporation of propane (R290) in compact smooth and microfinned tubes[J]. Applied Thermal Engineering, 2020, 181: 115880. |

| 6 | Zhou W J, Gan Z H. A potential approach for reducing the R290 charge in air conditioners and heat pumps[J]. International Journal of Refrigeration, 2019, 101: 47-55. |

| 7 | Thome J R, Cheng L X, Ribatski G, et al. Flow boiling of ammonia and hydrocarbons: a state-of-the-art review[J]. International Journal of Refrigeration, 2008, 31(4): 603-620. |

| 8 | Lee H S, Yoon J I, Kim J D, et al. Evaporating heat transfer and pressure drop of hydrocarbon refrigerants in 9.52 and 12.70 mm smooth tube[J]. International Journal of Heat and Mass Transfer, 2005, 48(12): 2351-2359. |

| 9 | Choi K I, Pamitran A S, Oh J T, et al. Pressure drop and heat transfer during two-phase flow vaporization of propane in horizontal smooth minichannels[J]. International Journal of Refrigeration, 2009, 32(5): 837-845. |

| 10 | Lockhart R W, Martinelli R C. Proposed correlation of data for isothermal two-phase, two-component flow in pipes[J]. Chemical Engineering Progress, 1949, 45: 39-48. |

| 11 | Maqbool M H, Palm B, Khodabandeh R. Investigation of two phase heat transfer and pressure drop of propane in a vertical circular minichannel[J]. Experimental Thermal and Fluid Science, 2013, 46: 120-130. |

| 12 | Friedel L. Improved friction pressure drop correlations for horizontal and vertical two-phase pipe flow[C]// Proc. of European Two-Phase Flow Group Meet. Ispra, Italy, 1979. |

| 13 | Müller-Steinhagen H, Heck K. A simple friction pressure drop correlation for two-phase flow in pipes[J]. Chemical Engineering and Processing: Process Intensification, 1986, 20(6): 297-308. |

| 14 | Wang S, Gong M Q, Chen G F, et al. Two-phase heat transfer and pressure drop of propane during saturated flow boiling inside a horizontal tube[J]. International Journal of Refrigeration, 2014, 41: 200-209. |

| 15 | López-Belchí A, Illán-Gómez F, García-Cascales J R, et al. Condensing two-phase pressure drop and heat transfer coefficient of propane in a horizontal multiport mini-channel tube: experimental measurements[J]. International Journal of Refrigeration, 2016, 68: 59-75. |

| 16 | Sun L C, Mishima K. Evaluation analysis of prediction methods for two-phase flow pressure drop in mini-channels[J]. International Journal of Multiphase Flow, 2009, 35(1): 47-54. |

| 17 | Agarwal A, Garimella S. Modeling of pressure drop during condensation in circular and noncircular microchannels[J]. Journal of Fluids Engineering, Transactions of the ASME, 2009, 131(1): 113021-113028. |

| 18 | Lillo G, Mastrullo R, Mauro A W, et al. Flow boiling heat transfer, dry-out vapor quality and pressure drop of propane (R290): experiments and assessment of predictive methods[J]. International Journal of Heat and Mass Transfer, 2018, 126: 1236-1252. |

| 19 | Xu Y, Fang X D. A new correlation of two-phase frictional pressure drop for evaporating flow in pipes[J]. International Journal of Refrigeration, 2012, 35(7): 2039-2050. |

| 20 | Diani A, Mancin S, Rossetto L. R1234ze(E) flow boiling inside a 3.4 mm ID microfin tube[J]. International Journal of Refrigeration, 2014, 47: 105-119. |

| 21 | 刘文红, 郭烈锦, 张西民, 等. 水平直圆管内油气两相流的压降[J]. 化工学报, 2004, 55(6): 907-912. |

| Liu W H, Guo L J, Zhang X M, et al. Pressure drop for oil-gas two-phase flow through straight horizontal pipe[J]. Journal of Chemical Industry and Engineering (China), 2004, 55(6): 907-912. | |

| 22 | Cheng L X, Xia G D, Thome J R. Flow boiling heat transfer and two-phase flow phenomena of CO2 in macro- and micro-channel evaporators: fundamentals, applications and engineering design[J]. Applied Thermal Engineering, 2021, 195: 117070. |

| 23 | Song Q L, Wang D C, Shen J, et al. Flow condensation pressure drop characteristics of zeotropic mixtures of tetrafluoromethane/ethane: experimental and analytical investigation[J]. International Journal of Heat and Mass Transfer, 2022, 182: 122045. |

| 24 | Li H P, Hrnjak P. Heat transfer coefficient, pressure gradient, and flow patterns of R1233zd(E) and R1336mzz(Z) evaporating in a microchannel tube[J]. International Journal of Heat and Mass Transfer, 2022, 182: 121992. |

| 25 | Huang Y, Shu B F, Zhou S N, et al. Experimental investigation and prediction on pressure drop during flow boiling in horizontal microchannels[J]. Micromachines, 2021, 12(5): 510. |

| 26 | Feng K, Zhang H C. Pressure drop and flow pattern of gas-non-Newtonian fluid two-phase flow in a square microchannel[J]. Chemical Engineering Research and Design, 2021, 173: 158-169. |

| 27 | Col D D, Bortolato M, Bortolin S. Comprehensive experimental investigation of two-phase heat transfer and pressure drop with propane in a minichannel[J]. International Journal of Refrigeration, 2014, 47: 66-84. |

| 28 | Col D D, Bisetto A, Bortolato M, et al. Experiments and updated model for two phase frictional pressure drop inside minichannels[J]. International Journal of Heat and Mass Transfer, 2013, 67: 326-337. |

| 29 | de Oliveira J D, Copetti J B, Passos J C. Experimental investigation on flow boiling pressure drop of R-290 and R-600a in a horizontal small tube[J]. International Journal of Refrigeration, 2017, 84: 165-180. |

| 30 | Zhang W, Hibiki T, Mishima K. Correlations of two-phase frictional pressure drop and void fraction in mini-channel[J]. International Journal of Heat and Mass Transfer, 2010, 53(1/2/3): 453-465. |

| 31 | Wen M Y, Ho C Y. Evaporation heat transfer and pressure drop characteristics of R-290 (propane), R-600 (butane), and a mixture of R-290/R-600 in the three-lines serpentine small-tube bank[J]. Applied Thermal Engineering, 2005, 25(17/18): 2921-2936. |

| 32 | Yu J W, Chen J, Lu L Y, et al. Void fraction and pressure drop of hydrocarbon mixture during condensation in a helically coiled tube[J]. International Journal of Heat and Mass Transfer, 2021, 178: 121618. |

| 33 | Yang Z Q, Chen G F, Zhao Y X, et al. Experimental study on flow boiling heat transfer of a new azeotropic mixture of R1234ze(E)/R600a in a horizontal tube[J]. International Journal of Refrigeration, 2018, 93: 224-235. |

| 34 | 杨志强, 公茂琼, 陈高飞, 等. R600a水平管内两相流型转换及摩擦压降特性[J]. 科学通报, 2018, 63(1): 98-107. |

| Yang Z Q, Gong M Q, Chen G F, et al. Experiment investigation of two-phase flow pattern transition and frictional pressure drop of R600a in a horizontal tube[J]. Chinese Science Bulletin, 2018, 63(1): 98-107. | |

| 35 | Rouhani S Z, Axelsson E. Calculation of void volume fraction in the subcooled and quality boiling regions[J]. International Journal of Heat and Mass Transfer, 1970, 13(2): 383-393. |

| 36 | Lemmon E, Huber M, Refprop Mclinden M., NIST standard reference database 23, v. 9.1[DB]. Gaithersburg, MD, USA: National Institute of Standards, 2013. |

| 37 | Collier J G, Thome J R. Convective Boiling and Condensation[M]. 3rd ed. USA: Oxford University Press, 1994: 12-15. |

| 38 | Xue H W, Shen J, Zhao Y X, et al. Experimental study on boiling flow patterns of the zeotropic mixtures of R290/R600a in a horizontal smooth tube[J]. International Journal of Heat and Mass Transfer, 2022, 196: 123268. |

| 39 | Chen I Y, Yang K S, Chang Y J, et al. Two-phase pressure drop of air-water and R-410A in small horizontal tubes[J]. International Journal of Multiphase Flow, 2001, 27(7): 1293-1299. |

| 40 | Padilla M, Revellin R, Haberschill P, et al. Flow regimes and two-phase pressure gradient in horizontal straight tubes: experimental results for HFO-1234yf, R-134a and R-410A[J]. Experimental Thermal and Fluid Science, 2011, 35(6): 1113-1126. |

| 41 | 姜林林, 柳建华, 张良, 等. 水平微细管内CO2流动沸腾压降特性[J]. 化工学报, 2017, 68(12): 4576-4584. |

| Jiang L L, Liu J H, Zhang L, et al. Flow boiling pressure drop characteristics of CO2 in horizontal micro tube[J]. CIESC Journal, 2017, 68(12): 4576-4584. | |

| 42 | Xu Y, Fang X D. A new correlation of two-phase frictional pressure drop for condensing flow in pipes[J]. Nuclear Engineering and Design, 2013, 263: 87-96. |

| 43 | 陈冲, 高璞珍, 余志庭, 等. 摇摆工况下窄矩形通道内两相沸腾摩擦压降特性[J]. 化工学报, 2015, 66(10): 3874-3880. |

| Chen C, Gao P Z, Yu Z T, et al. Two-phase frictional pressure drop characteristics of boiling flow in rectangular narrow channel under rolling motion[J]. CIESC Journal, 2015, 66(10): 3874-3880. | |

| 44 | Mcadams W. Vaporization inside horizontal tubes(Ⅱ): Benzene oil mixtures[J]. Trans. ASME, 1942, 64: 193-200. |

| 45 | Davidson W F, Hardie P H, Humphreys C, et al. Studies of heat transmission through boiler tubing at pressures from 500 to 3300 pounds[J]. Trans. ASME, 1943, 65: 553-591. |

| 46 | Beattie D R H, Whalley P B. A simple two-phase frictional pressure drop calculation method[J]. International Journal of Multiphase Flow, 1982, 8(1): 83-87. |

| 47 | Awad M M, Muzychka Y S. Effective property models for homogeneous two-phase flows[J]. Experimental Thermal and Fluid Science, 2008, 33(1): 106-113. |

| 48 | Chisholm D. Pressure gradients due to friction during the flow of evaporating two-phase mixtures in smooth tubes and channels[J]. International Journal of Heat and Mass Transfer, 1973, 16(2): 347-358. |

| 49 | Grönnerud R. Investigation in Liquid Holdup. Flow Resistance and Heat Transfer in Circular Type Evaporators (part Ⅳ): Two-phase Resistance in Boiling Refrigerants[M]. Du Froid, Annexe: Bulletin de l’Hnst, 1979: 1972-1981. |

| 50 | Yan Y Y, Lio H C, Lin T F. Condensation heat transfer and pressure drop of refrigerant R-134a in a plate heat exchanger[J]. International Journal of Heat and Mass Transfer, 1999, 42(6): 993-1006. |

| 51 | Kim S M, Mudawar I. Review of databases and predictive methods for heat transfer in condensing and boiling mini/micro-channel flows[J]. International Journal of Heat and Mass Transfer, 2014, 77(4): 627-652. |

| 52 | Jige D, Inoue N, Koyama S. Condensation of refrigerants in a multiport tube with rectangular minichannels[J]. International Journal of Refrigeration, 2016, 67: 202-213. |

| 53 | Yang Z Q, Gong M Q, Chen G F, et al. Two-phase flow patterns, heat transfer and pressure drop characteristics of R600a during flow boiling inside a horizontal tube[J]. Applied Thermal Engineering, 2017, 120: 654-671. |

| 54 | Song Q L, Chen G F, Guo H, et al. Two-phase flow condensation pressure drop of R14 in a horizontal tube: experimental investigation and correlation development[J]. International Journal of Heat and Mass Transfer, 2019, 139: 330-342. |

| 55 | Whalley P B. Boiling, Condensation, and Gas-liquid Flow[M]. USA: Oxford University Press, 1987: 38-39. |

| 56 | Filho E P B, Jabardo J M S, Barbieri P E L. Convective boiling pressure drop of refrigerant R-134a in horizontal smooth and microfin tubes[J]. International Journal of Refrigeration, 2004, 27(8): 895-903. |

| 57 | Xu Y, Fang X D, Li D K, et al. An experimental study of flow boiling frictional pressure drop of R134a and evaluation of existing correlations[J]. International Journal of Heat and Mass Transfer, 2016, 98: 150-163. |

| 58 | Wang Y X, Shen S Q, Yuan D Y. Frictional pressure drop during steam stratified condensation flow in vacuum horizontal tube[J]. International Journal of Heat and Mass Transfer, 2017, 115: 979-990. |

| 59 | Yang Z Q, Chen G F, Yao Y, et al. Experimental study on flow boiling heat transfer and pressure drop in a horizontal tube for R1234ze(E) versus R600a[J]. International Journal of Refrigeration, 2018, 85: 334-352. |

| [1] | 宋嘉豪, 王文. 斯特林发动机与高温热管耦合运行特性研究[J]. 化工学报, 2023, 74(S1): 287-294. |

| [2] | 连梦雅, 谈莹莹, 王林, 陈枫, 曹艺飞. 地下水预热新风一体化热泵空调系统制热性能研究[J]. 化工学报, 2023, 74(S1): 311-319. |

| [3] | 吴曦, 区祖迪, 张鑫杰, 徐士鸣, 朱晓静. HFO-1243zf爆燃特性实验研究[J]. 化工学报, 2023, 74(S1): 346-352. |

| [4] | 金正浩, 封立杰, 李舒宏. 氨水溶液交叉型再吸收式热泵的能量及 分析[J]. 化工学报, 2023, 74(S1): 53-63. 分析[J]. 化工学报, 2023, 74(S1): 53-63. |

| [5] | 肖明堃, 杨光, 黄永华, 吴静怡. 浸没孔液氧气泡动力学数值研究[J]. 化工学报, 2023, 74(S1): 87-95. |

| [6] | 高润淼, 宋孟杰, 高恩元, 张龙, 张旋, 邵苛苛, 甄泽康, 江正勇. 冷链装备制冷剂相关温室气体减排研究进展[J]. 化工学报, 2023, 74(S1): 1-7. |

| [7] | 周绍华, 詹飞龙, 丁国良, 张浩, 邵艳坡, 刘艳涛, 郜哲明. 短管节流阀内流动噪声的实验研究及降噪措施[J]. 化工学报, 2023, 74(S1): 113-121. |

| [8] | 江河, 袁俊飞, 王林, 邢谷雨. 均流腔结构对微细通道内相变流动特性影响的实验研究[J]. 化工学报, 2023, 74(S1): 235-244. |

| [9] | 温凯杰, 郭力, 夏诏杰, 陈建华. 一种耦合CFD与深度学习的气固快速模拟方法[J]. 化工学报, 2023, 74(9): 3775-3785. |

| [10] | 王玉兵, 李杰, 詹宏波, 朱光亚, 张大林. R134a在菱形离散肋微小通道内的流动沸腾换热实验研究[J]. 化工学报, 2023, 74(9): 3797-3806. |

| [11] | 李科, 文键, 忻碧平. 耦合蒸气冷却屏的真空多层绝热结构对液氢储罐自增压过程的影响机制研究[J]. 化工学报, 2023, 74(9): 3786-3796. |

| [12] | 何松, 刘乔迈, 谢广烁, 王斯民, 肖娟. 高浓度水煤浆管道气膜减阻两相流模拟及代理辅助优化[J]. 化工学报, 2023, 74(9): 3766-3774. |

| [13] | 王浩, 王振雷. 基于自适应谱方法的裂解炉烧焦模型化简策略[J]. 化工学报, 2023, 74(9): 3855-3864. |

| [14] | 袁佳琦, 刘政, 黄锐, 张乐福, 贺登辉. 泡状入流条件下旋流泵能量转换特性研究[J]. 化工学报, 2023, 74(9): 3807-3820. |

| [15] | 邢雷, 苗春雨, 蒋明虎, 赵立新, 李新亚. 井下微型气液旋流分离器优化设计与性能分析[J]. 化工学报, 2023, 74(8): 3394-3406. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号