化工学报 ›› 2023, Vol. 74 ›› Issue (10): 4140-4152.DOI: 10.11949/0438-1157.20230642

收稿日期:2023-06-28

修回日期:2023-08-07

出版日期:2023-10-25

发布日期:2023-12-22

通讯作者:

康灿

作者简介:徐生玮(1999—),男,硕士研究生,3326536847@qq.com

基金资助:

Shengwei XU1( ), Longbo SONG2, Can KANG1(

), Longbo SONG2, Can KANG1( )

)

Received:2023-06-28

Revised:2023-08-07

Online:2023-10-25

Published:2023-12-22

Contact:

Can KANG

摘要:

利用高速摄像技术观测了不同液体介质(去离子水、离子水、5#白油和水-白油溶液)中气泡的上升行为。采用了三种不同直径的注气喷嘴。对比分析了气泡在不同工况条件下的上升速度、当量直径、纵横比和曳力系数。结果表明,气泡在不同的单一介质中的上升轨迹及运动特征不同,介质的黏度和表面张力均对气泡的形状和尺寸有着重要影响。此外,观测并分析了气泡穿过水-白油界面的行为,发现当气泡离开界面较远时,其运动形态与在单一介质中相似;气泡穿过界面时被液膜包覆,然后液膜自气泡表面脱离。小尺寸气泡在单一油中和穿过水-白油界面后的几何形态和运动特征相似,而大尺寸气泡在穿过水-白油界面后呈现曲折的运动轨迹,其纵横比发生明显变化。

中图分类号:

徐生玮, 宋龙波, 康灿. 液体介质对上升气泡几何形态和运动特征的影响[J]. 化工学报, 2023, 74(10): 4140-4152.

Shengwei XU, Longbo SONG, Can KANG. Effects of liquid medium on geometric and kinetic characteristics of a rising bubble[J]. CIESC Journal, 2023, 74(10): 4140-4152.

| 设备名称 | 设备参数 | 用途 |

|---|---|---|

| i-SPEED 3相机 | 最大帧率150000 fps | 拍摄照片 |

| 相机镜头 | Tokina AT-X PRO Macro 100 mm F/2.8D | 聚焦 |

| LED光源 | 最大功率151 W | 照亮流场 |

| 水箱 | 15 cm×15 cm×50 cm;亚克力材质 | 透光容器 |

| LSP01-1A型注射泵 | 流量范围0.831~54.155 ml/min | 泵入稳定气流 |

表1 主要实验设备及参数

Table 1 Main experimental equipment and parameters

| 设备名称 | 设备参数 | 用途 |

|---|---|---|

| i-SPEED 3相机 | 最大帧率150000 fps | 拍摄照片 |

| 相机镜头 | Tokina AT-X PRO Macro 100 mm F/2.8D | 聚焦 |

| LED光源 | 最大功率151 W | 照亮流场 |

| 水箱 | 15 cm×15 cm×50 cm;亚克力材质 | 透光容器 |

| LSP01-1A型注射泵 | 流量范围0.831~54.155 ml/min | 泵入稳定气流 |

| 液体介质 | ρ/(kg/m3) | μ/(mPa·s) | σ/(N/m) |

|---|---|---|---|

| 去离子水 | 997.2 | 1.003 | 0.0725 |

| 20 g/L的CaCl2溶液 | 1106.4 | 1.39 | 0.0721 |

| 5#白油 | 817.7 | 5.127 | 0.0373 |

表2 25℃去离子水、离子水和白油的物理性质

Table 2 Physical properties of deionized water, ionized water, and white oil at 25℃

| 液体介质 | ρ/(kg/m3) | μ/(mPa·s) | σ/(N/m) |

|---|---|---|---|

| 去离子水 | 997.2 | 1.003 | 0.0725 |

| 20 g/L的CaCl2溶液 | 1106.4 | 1.39 | 0.0721 |

| 5#白油 | 817.7 | 5.127 | 0.0373 |

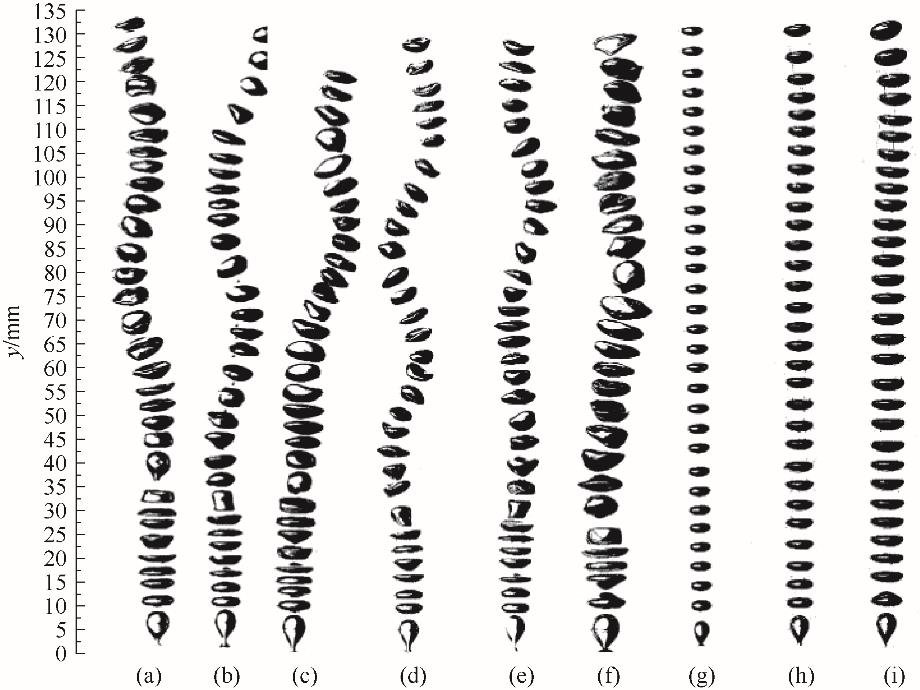

图4 气泡在不同工况下的运动轨迹(a) Dn=2.0 mm, 去离子水;(b) Dn=3.0 mm, 去离子水;(c) Dn=4.0 mm, 去离子水;(d) Dn=2.0 mm, 离子水;(e) Dn=3.0 mm, 离子水;(f) Dn=4.0 mm, 离子水;(g) Dn=2.0 mm, 5#白油;(h) Dn=3.0 mm, 5#白油;(i) Dn=4.0 mm, 5#白油

Fig.4 Trajectory of bubbles under different operating conditions(a) Dn= 2.0 mm, deionized water; (b) Dn= 3.0 mm, deionized water; (c) Dn= 4.0 mm, deionized water; (d) Dn= 2.0 mm, ionized water; (e) Dn= 3.0 mm, ionized water; (f) Dn= 4.0 mm, ionized water; (g) Dn= 2.0 mm, white oil; (h) Dn= 3.0 mm, white oil; (i) Dn=4.0 mm, white oil

| 液体介质 | Dn/mm | Demin/mm | Demax/mm |

|---|---|---|---|

| 去离子水 | 2.0 | 3.55 | 4.38 |

| 3.0 | 3.08 | 4.95 | |

| 4.0 | 3.53 | 5.47 | |

| 离子水 | 2.0 | 2.58 | 4.00 |

| 3.0 | 2.89 | 4.47 | |

| 4.0 | 3.72 | 5.57 | |

| 5#白油 | 2.0 | 2.84 | 3.03 |

| 3.0 | 3.51 | 3.96 | |

| 4.0 | 3.53 | 4.11 |

表3 不同液体介质和不同喷嘴直径条件下气泡的当量直径

Table 3 Equivalent bubble diameter for different liquid mediums and nozzle diameters

| 液体介质 | Dn/mm | Demin/mm | Demax/mm |

|---|---|---|---|

| 去离子水 | 2.0 | 3.55 | 4.38 |

| 3.0 | 3.08 | 4.95 | |

| 4.0 | 3.53 | 5.47 | |

| 离子水 | 2.0 | 2.58 | 4.00 |

| 3.0 | 2.89 | 4.47 | |

| 4.0 | 3.72 | 5.57 | |

| 5#白油 | 2.0 | 2.84 | 3.03 |

| 3.0 | 3.51 | 3.96 | |

| 4.0 | 3.53 | 4.11 |

| 1 | Zhang J Q, Chen J J J, Zhou N J. Characteristics of jet droplet produced by bubble bursting on the free liquid surface[J]. Chemical Engineering Science, 2012, 68(1): 151-156. |

| 2 | Aagesen L K, Casagranda A, Matthews C, et al. Phase-field simulations of fission gas bubble growth and interconnection in U-(Pu)-Zr nuclear fuel[J]. Materials Theory, 2022, 6(1): 1-20. |

| 3 | Lucas D, Ziegenhein T. Influence of the bubble size distribution on the bubble column flow regime[J]. International Journal of Multiphase Flow, 2019, 120: 103092. |

| 4 | Wu J, Chen L Y, Zheng N B, et al. Experimental investigation of the attachment of unburned carbon in coal fly ash to a stationary air bubble in aqueous solutions[J]. Fuel, 2021, 285: 119080. |

| 5 | Wang D P, Li X, Chen Z, et al. Susceptibility of chloride ion concentration, temperature, and surface roughness on pitting corrosion of CoCrFeNi medium‐entropy alloy[J]. Materials and Corrosion, 2022, 73(1): 106-115. |

| 6 | 高丹, 戈立宁, 潘勇, 等. 不同浓度离子溶液中气泡运动特性的实验研究[J]. 华北电力大学学报(自然科学版), . |

| Gao D, Ge L N, Pan Y, et al. Experimental study of bubble motion characteristics in ionic solutions with different concentrations[J]. Journal of North China Electric Power University (Natural Science Edition), | |

| 7 | Yang G Q, Du B, Fan L S. Bubble formation and dynamics in gas-liquid-solid fluidization—a review[J]. Chemical Engineering Science, 2007, 62(1/2): 2-27. |

| 8 | Pourtousi M, Sahu J N, Ganesan P. Effect of interfacial forces and turbulence models on predicting flow pattern inside the bubble column[J]. Chemical Engineering and Processing: Process Intensification, 2014, 75: 38-47. |

| 9 | Bao D, Zhang X, Dong H F, et al. Numerical simulations of bubble behavior and mass transfer in CO2 capture system with ionic liquids[J]. Chemical Engineering Science, 2015, 135: 76-88. |

| 10 | Kantarci N, Borak F, Ulgen K O. Bubble column reactors[J]. Process Biochemistry, 2005, 40(7): 2263-2283. |

| 11 | Shah Y T, Kelkar B G, Godbole S P, et al. Design parameters estimations for bubble column reactors[J]. AIChE Journal, 1982, 28(3): 353-379. |

| 12 | Ratkovich N, Chan C C V, Berube P R, et al. Experimental study and CFD modelling of a two-phase slug flow for an airlift tubular membrane[J]. Chemical Engineering Science, 2009, 64(16): 3576-3584. |

| 13 | Hessenkemper H, Ziegenhein T, Lucas D. Contamination effects on the lift force of ellipsoidal air bubbles rising in saline water solutions[J]. Chemical Engineering Journal, 2020, 386: 121589. |

| 14 | Böhm L, Kurita T, Kimura K, et al. Rising behaviour of single bubbles in narrow rectangular channels in Newtonian and non-Newtonian liquids[J]. International Journal of Multiphase Flow, 2014, 65: 11-23. |

| 15 | Talaia M A R. Terminal velocity of a bubble rise in a liquid column[J]. World Academy of Science, Engineering and Technology, 2007, 28: 264-268. |

| 16 | Wang X, Sun J, Zhao J, et al. Experimental detection of bubble-wall interactions in a vertical gas-liquid flow[J]. Chinese Journal of Chemical Engineering, 2017, 25(7): 838-847. |

| 17 | Mougin G, Magnaudet J. Path instability of a rising bubble[J]. Physical Review Letters, 2001, 88: 014502. |

| 18 | 孙姣, 姜楠, 陈文义, 等. 静止水中单个近壁大气泡运动特性的实验研究[J]. 实验力学, 2019, 34(6): 973-980. |

| Sun J, Jiang N, Chen W Y, et al. Experimental study on single large bubble rising behavior near vertical wall in stagnant water[J]. Journal of Experimental Mechanics, 2019, 34(6): 973-980. | |

| 19 | Mikaelian D, Larcy A, Dehaeck S, et al. A new experimental method to analyze the dynamics and the morphology of bubbles in liquids: application to single ellipsoidal bubbles[J]. Chemical Engineering Science, 2013, 100: 529-538. |

| 20 | Liu L, Yan H J, Zhao G J. Experimental studies on the shape and motion of air bubbles in viscous liquids[J]. Experimental Thermal and Fluid Science, 2015, 62: 109-121. |

| 21 | Zhang L, Yang C, Mao Z S. Unsteady motion of a single bubble in highly viscous liquid and empirical correlation of drag coefficient[J]. Chemical Engineering Science, 2008, 63(8): 2099-2106. |

| 22 | Fraggedakis D, Pavlidis M, Dimakopoulos Y, et al. On the velocity discontinuity at a critical volume of a bubble rising in a viscoelastic fluid[J]. Journal of Fluid Mechanics, 2016, 789: 310-346. |

| 23 | Zeng L Y, Najjar F, Balachandar S, et al. Forces on a finite-sized particle located close to a wall in a linear shear flow[J]. Physics of Fluids, 2009, 21(3): 033302. |

| 24 | Islam M T, Ganesan P B, Billah M M, et al. A numerical study of single air bubble formation comparison between in viscous liquid and in water[J]. Asia-Pacific Journal of Chemical Engineering, 2019, 14(6): e2367. |

| 25 | Islam M T, Ganesan P B, Sahu J N, et al. Effect of orifice size and bond number on bubble formation characteristics: a CFD study[J]. The Canadian Journal of Chemical Engineering, 2015, 93(10): 1869-1879. |

| 26 | Islam T, Ganesan P, Sahu J N, et al. Numerical study to invistigate the effect of inlet gas velocity and Reynolds number on bubble formation in a viscous liquid[J]. Thermal Science, 2015, 19(6): 2127-2138. |

| 27 | 周晓琳, 田震, 王丽军, 等. 鼓泡塔中气泡群运动的实验与模拟[J]. 化学反应工程与工艺, 2016, 32(6): 481-489. |

| Zhou X L, Tian Z, Wang L J, et al. Experiment and numerical simulation of the motion of bubble swarm in a bubble column[J]. Chemical Reaction Engineering and Technology, 2016, 32(6): 481-489. | |

| 28 | Li E Q, Al-Otaibi S A, Vakarelski I U, et al. Satellite formation during bubble transition through an interface between immiscible liquids[J]. Journal of Fluid Mechanics, 2014, 744: R1. |

| 29 | Bonhomme R, Magnaudet J, Duval F, et al. Inertial dynamics of air bubbles crossing a horizontal fluid-fluid interface[J]. Journal of Fluid Mechanics, 2012, 707: 405-443. |

| 30 | Emery T S, Raghupathi P A, Kandlikar S G. Flow regimes and transition criteria during passage of bubbles through a liquid-liquid interface[J]. Langmuir, 2018, 34(23): 6766-6776. |

| 31 | Dietrich N, Poncin S, Pheulpin S, et al. Passage of a bubble through a liquid-liquid interface[J]. AIChE Journal, 2008, 54(3): 594-600. |

| 32 | 王俊, 庞明军. 剪切稀化流体中气泡界面污染对传热的影响[J]. 常州大学学报(自然科学版), 2022, 34(6): 41-53. |

| Wang J, Pang M J. Effect of bubble interface pollution on heat transfer in shear thinning fluid[J]. Journal of Changzhou University (Natural Science Edition), 2022, 34(6): 41-53. | |

| 33 | 林松, 李良超, 王嘉骏, 等. 鼓泡塔中气泡尺寸分布和局部气含率研究[J]. 化学工程, 2008, 36(2): 21-24. |

| Lin S, Li L C, Wang J J, et al. Study on bubble size distribution and local gas holdup in bubble column[J]. Chemical Engineering (China), 2008, 36(2): 21-24. | |

| 34 | Turton R, Levenspiel O. A short note on the drag correlation for spheres[J]. Powder Technology, 1986, 47(1): 83-86. |

| 35 | Carvajal D, Carlesi C, Meléndez-Vejar V, et al. Numerical simulation of single-bubble dynamics in high-viscosity ionic liquids using the level-set method[J]. Chemical Engineering & Technology, 2015, 38(3): 473-481. |

| 36 | Mao N, Kang C, Teng S A, et al. Quantitative characterization of bubble evolution in mineral oil for different air-injection nozzles[J]. Asia-Pacific Journal of Chemical Engineering, 2020, 15(3): e2446. |

| 37 | Manga M, Stone H A. Low Reynolds number motion of bubbles, drops and rigid spheres through fluid-fluid interfaces[J]. Journal of Fluid Mechanics, 1995, 287: 279-298. |

| [1] | 邵苛苛, 宋孟杰, 江正勇, 张旋, 张龙, 高润淼, 甄泽康. 水平方向上冰中受陷气泡形成和分布实验研究[J]. 化工学报, 2023, 74(S1): 161-164. |

| [2] | 江河, 袁俊飞, 王林, 邢谷雨. 均流腔结构对微细通道内相变流动特性影响的实验研究[J]. 化工学报, 2023, 74(S1): 235-244. |

| [3] | 肖明堃, 杨光, 黄永华, 吴静怡. 浸没孔液氧气泡动力学数值研究[J]. 化工学报, 2023, 74(S1): 87-95. |

| [4] | 袁佳琦, 刘政, 黄锐, 张乐福, 贺登辉. 泡状入流条件下旋流泵能量转换特性研究[J]. 化工学报, 2023, 74(9): 3807-3820. |

| [5] | 邢雷, 苗春雨, 蒋明虎, 赵立新, 李新亚. 井下微型气液旋流分离器优化设计与性能分析[J]. 化工学报, 2023, 74(8): 3394-3406. |

| [6] | 岳林静, 廖艺涵, 薛源, 李雪洁, 李玉星, 刘翠伟. 凹坑缺陷对厚孔板喉部空化流动特性影响研究[J]. 化工学报, 2023, 74(8): 3292-3308. |

| [7] | 高燕, 伍鹏, 尚超, 胡泽君, 陈晓东. 基于双流体喷嘴的磁性琼脂糖微球的制备及其蛋白吸附性能探究[J]. 化工学报, 2023, 74(8): 3457-3471. |

| [8] | 王海, 林宏, 王晨, 许浩洁, 左磊, 王军锋. 高压静电场强化多孔介质表面沸腾传热特性研究[J]. 化工学报, 2023, 74(7): 2869-2879. |

| [9] | 高金明, 郭玉娇, 鄂承林, 卢春喜. 一种封闭罩内顺流多旋臂气液分离器的分离特性研究[J]. 化工学报, 2023, 74(7): 2957-2966. |

| [10] | 张贲, 王松柏, 魏子亚, 郝婷婷, 马学虎, 温荣福. 超亲水多孔金属结构驱动的毛细液膜冷凝及传热强化[J]. 化工学报, 2023, 74(7): 2824-2835. |

| [11] | 刘起超, 周云龙, 陈聪. 起伏振动垂直上升管气液两相流截面含气率分析与计算[J]. 化工学报, 2023, 74(6): 2391-2403. |

| [12] | 江锦波, 彭新, 许文烜, 门日秀, 刘畅, 彭旭东. 泵出型螺旋槽油气密封泄漏特性及参数影响研究[J]. 化工学报, 2023, 74(6): 2538-2554. |

| [13] | 董鑫, 单永瑞, 刘易诺, 冯颖, 张建伟. 非牛顿流体气泡羽流涡特性数值模拟研究[J]. 化工学报, 2023, 74(5): 1950-1964. |

| [14] | 袁子涵, 王淑彦, 邵宝力, 谢磊, 陈曦, 马一玫. 基于幂律液固曳力模型流化床内湿颗粒流动特性的研究[J]. 化工学报, 2023, 74(5): 2000-2012. |

| [15] | 王泽栋, 石至平, 刘丽艳. 考虑气泡非均匀耗散的矩形反应器声流场数值模拟及结构优化[J]. 化工学报, 2023, 74(5): 1965-1973. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号