化工学报 ›› 2023, Vol. 74 ›› Issue (10): 4020-4036.DOI: 10.11949/0438-1157.20230650

收稿日期:2023-06-30

修回日期:2023-09-06

出版日期:2023-10-25

发布日期:2023-12-22

通讯作者:

黄东

作者简介:汤志轩(1999—),男,硕士研究生, tangzhixuan@stu.xjtu.edu.cn

Zhixuan TANG( ), Wenhua GUO, Siyuan WU, Rijing ZHAO, Dong HUANG(

), Wenhua GUO, Siyuan WU, Rijing ZHAO, Dong HUANG( )

)

Received:2023-06-30

Revised:2023-09-06

Online:2023-10-25

Published:2023-12-22

Contact:

Dong HUANG

摘要:

微通道蒸发器由于低充灌量、高换热性能、低成本等优点在制冷系统得以广泛应用。微通道蒸发器性能的进一步提升有助于降低制冷剂充灌量、增加微通道换热器的紧凑性。微通道蒸发器主要由集管和微通道扁管组成,优化集管内两相制冷剂分配和强化微通道扁管内流动沸腾,可有效实现微通道蒸发器整体性能提升。本文首先阐明了影响集管内两相分配的因素和微通道扁管内流动沸腾特性,然后概括了提升两相制冷剂的分配方案和强化流动沸腾的措施,最后对提升微通道蒸发器性能的方法做出进一步展望。

中图分类号:

汤志轩, 郭文华, 吴思远, 赵日晶, 黄东. 微通道蒸发器优化两相制冷剂分配及沸腾传热研究进展[J]. 化工学报, 2023, 74(10): 4020-4036.

Zhixuan TANG, Wenhua GUO, Siyuan WU, Rijing ZHAO, Dong HUANG. Research progress on optimizing two-phase refrigerant distribution and boiling heat transfer in microchannel evaporators[J]. CIESC Journal, 2023, 74(10): 4020-4036.

图3 (a) U型集管结构和Z型集管结构[13];(b)三种水平集管入口结构[16-17];(c)蒸发器不同入口方式和倾角[19];(d)可变扁管插入深度结构[20]

Fig.3 (a) U-shaped and Z-shaped manifold structure[13]; (b) Three types of horizontal header inlet structures[16-17]; (c) Different inlet modes and inclination angles of evaporators[19]; (d) Variable flat tube insertion depth structure[20]

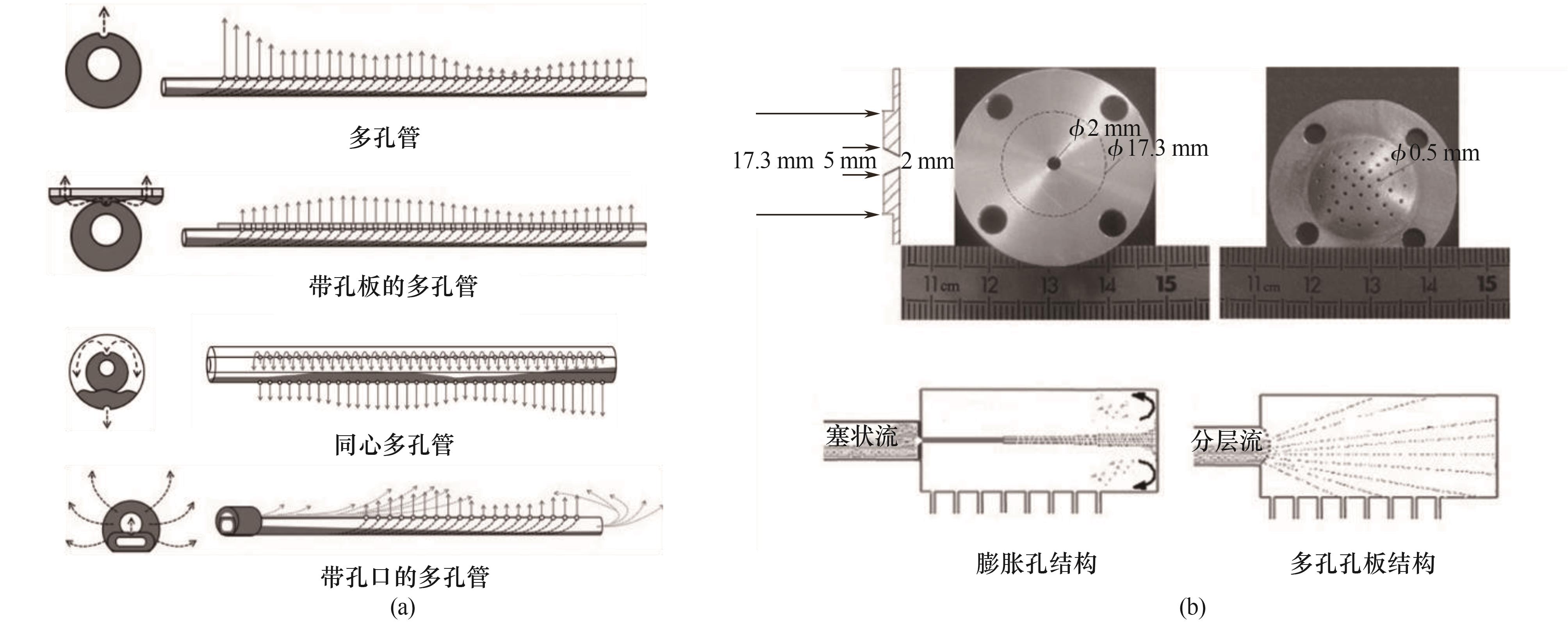

图5 (a) 四种多孔管提供的流动状态[36];(b) 孔板结构及经过孔板结构后形成的流动状态[30]

Fig.5 (a) Flow states provided by four types of porous tubes[36]; (b) Orifice structure and the flow state formed after passing through the orifice structure[30]

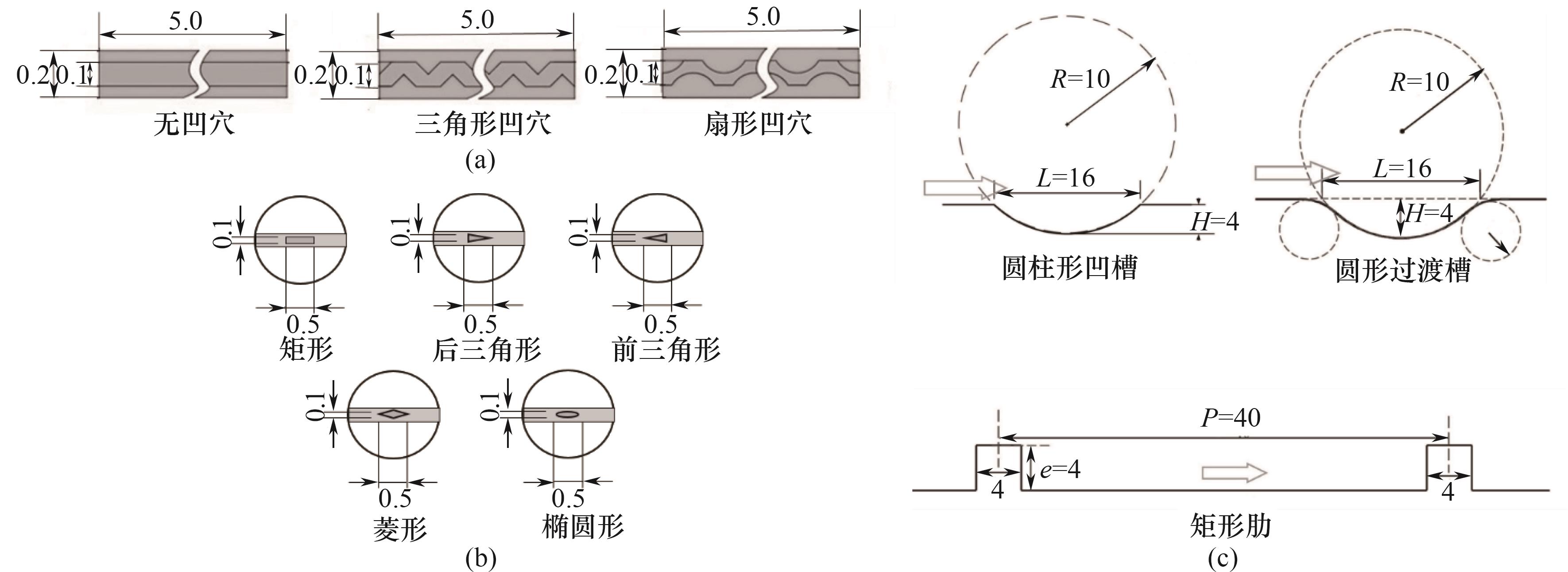

图10 (a) 传统微通道和加入三角形、扇形凹穴的微通道结构示意图[66];(b)内肋形状[67];(c) 圆柱形凹槽、圆形过渡槽和矩形肋结构示意图[73]

Fig.10 (a) Schematic diagram of traditional microchannels and microchannels with triangular and fan-shaped cavities[66]; (b) The inner rib shape[67]; (c) Schematic diagram of cylindrical groove, circular transition groove, and rectangular rib structure[73]

| 8 | Brix W, Kærn M R, Elmegaard B. Modelling distribution of evaporating CO2 in parallel minichannels[J]. International Journal of Refrigeration, 2010, 33(6): 1086-1094. |

| 9 | Kulkarni T, Bullard C W, Cho K. Header design tradeoffs in microchannel evaporators[J]. Applied Thermal Engineering, 2004, 24(5/6): 759-776. |

| 10 | Bowers C D, Mai H, Elbel S, et al. Refrigerant distribution effects on the performance of microchannel evaporators[C]//International Refrigeration and Air Conditioning Conference. Purdue: Purdue e-Pubs, 2012. |

| 11 | Cho H, Cho K. Mass flow rate distribution and phase separation of R-22 in multi-microchannel tubes under adiabatic condition[J]. Microscale Thermophysical Engineering, 2004, 8(2): 129-139. |

| 12 | Dario E R, Tadrist L, Oliveira J L G, et al. Measuring maldistribution of two-phase flows in multi-parallel microchannels[J]. Applied Thermal Engineering, 2015, 91: 924-937. |

| 13 | Wang C C, Yang K S, Tsai J S, et al. Characteristics of flow distribution in compact parallel flow heat exchangers (part Ⅰ): Typical inlet header[J]. Applied Thermal Engineering, 2011, 31(16): 3226-3234. |

| 14 | 袁培, 李丹, 康浩杰, 等. 微细平行流通道换热器流量均布性试验研究[J]. 化学工程, 2017, 45(4): 34-38. |

| Yuan P, Li D, Kang H J, et al. Experimental research on flow distribution uniformity of the micro parallel flow heat exchanger[J]. Chemical Engineering (China), 2017, 45(4): 34-38. | |

| 15 | Byun H W, Kim N H. Refrigerant distribution in a parallel flow heat exchanger having vertical headers and heated horizontal tubes[J]. Experimental Thermal and Fluid Science, 2011, 35(6): 920-932. |

| 16 | Kim N H, Kim D Y, Byun H W. Effect of inlet configuration on the refrigerant distribution in a parallel flow minichannel heat exchanger[J]. International Journal of Refrigeration, 2011, 34(5): 1209-1221. |

| 17 | Kim N H, Byun H W, Sim Y S. Upward branching of two-phase refrigerant in a parallel flow minichannel heat exchanger[J]. Experimental Thermal and Fluid Science, 2013, 51: 189-203. |

| 18 | 袁鑫森, 袁俊飞, 王林, 等. 入口结构对微通道内两相流量分配特性影响[J]. 低温与超导, 2022, 50(7): 50-56, 62. |

| Yuan X S, Yuan J F, Wang L, et al. Effect of inlet structure on two phase flow distribution in microchannel[J]. Cryogenics & Superconductivity, 2022, 50(7): 50-56, 62. | |

| 19 | Kim N H, Go M G. Horizontal distribution of two-phase refrigerant in parallel flat mini-channels[J]. Experimental Thermal and Fluid Science, 2018, 93: 139-152. |

| 20 | Marchitto A, Fossa M, Guglielmini G. Phase split in parallel vertical channels in presence of a variable depth protrusion header[J]. Experimental Thermal and Fluid Science, 2016, 74: 257-264. |

| 21 | Lee J K, Lee S Y. Distribution of two-phase annular flow at header-channel junctions[J]. Experimental Thermal and Fluid Science, 2004, 28(2/3): 217-222. |

| 22 | Kim N H, Han S P. Distribution of air-water annular flow in a header of a parallel flow heat exchanger[J]. International Journal of Heat and Mass Transfer, 2008, 51(5/6): 977-992. |

| 23 | Kim N H, Sin T R. Two-phase flow distribution of air-water annular flow in a parallel flow heat exchanger[J]. International Journal of Multiphase Flow, 2006, 32(12): 1340-1353. |

| 24 | Wijayanta A T, Miyazaki T, Koyama S. Liquid-vapor phase distribution in horizontal headers with upward minichannel-branching conduits[J]. Experimental Thermal and Fluid Science, 2016, 76: 264-274. |

| 25 | Zou Y, Hrnjak P S. Experiment and visualization on R134a upward flow in the vertical header of microchannel heat exchanger and its effect on distribution[J]. International Journal of Heat and Mass Transfer, 2013, 62: 124-134. |

| 26 | Zou Y, Hrnjak P S. Refrigerant distribution in the vertical header of the microchannel heat exchanger—measurement and visualization of R410A flow[J]. International Journal of Refrigeration, 2013, 36(8): 2196-2208. |

| 27 | Zou Y, Hrnjak P S. Effects of fluid properties on two-phase flow and refrigerant distribution in the vertical header of a reversible microchannel heat exchanger—comparing R245fa, R134a, R410A, and R32[J]. Applied Thermal Engineering, 2014, 70(1): 966-976. |

| 28 | Redo M A, Jeong J, Giannetti N, et al. Characterization of two-phase flow distribution in microchannel heat exchanger header for air-conditioning system[J]. Experimental Thermal and Fluid Science, 2019, 106: 183-193. |

| 29 | 徐肖肖, 张世杰, 李怡, 等. 制冷剂在微通道扁平T型管内的气液两相流相分配特性研究[J]. 化工学报, 2021, 72(4): 2057-2064. |

| Xu X X, Zhang S J, Li Y, et al. Study on phase distribution characteristics of gas-liquid two-phase flow in micro-channel flat T-junction[J]. CIESC Journal, 2021, 72(4): 2057-2064. | |

| 30 | Ahmad M, Berthoud G, Mercier P. General characteristics of two-phase flow distribution in a compact heat exchanger[J]. International Journal of Heat and Mass Transfer, 2009, 52(1/2): 442-450. |

| 31 | 池帮杰, 代苏苏, 鲁进利, 等. 集流管结构对微通道蒸发器流量分配均匀性影响[J]. 制冷与空调, 2018, 18(4): 34-39. |

| Chi B J, Dai S S, Lu J L, et al. Effect of header pipe structure on the uniformity of flow distribution in micro-channel evaporator[J]. Refrigeration and Air-Conditioning, 2018, 18(4): 34-39. | |

| 32 | 白璐, 朱春英, 付涛涛, 等. 并行微通道内气液相分配规律[J]. 化工学报, 2014, 65(1): 108-115. |

| Bai L, Zhu C Y, Fu T T, et al. Gas-liquid flow distribution of parallel microchannels[J]. CIESC Journal, 2014, 65(1): 108-115. | |

| 33 | Kim N H, Lee E J, Byun H W. Two-phase refrigerant distribution in a parallel flow minichannel heat exchanger having horizontal headers[J]. International Journal of Heat and Mass Transfer, 2012, 55(25/26): 7747-7759. |

| 34 | Zhang Q M, Hrnjak P S, Newell P A. An experimental investigation of R134a flow distribution in horizontal microchannel manifolds[R]. Urbana: USA, 2003. |

| 35 | Kim N H, Lee E J, Byun H W. Improvement of two-phase refrigerant distribution in a parallel flow minichannel heat exchanger using insertion devices[J]. Applied Thermal Engineering, 2013, 59(1/2): 116-130. |

| 36 | Kim N H, Kim C H, Shah Y, et al. Improvement of two-phase refrigerant distribution for upward flow of a parallel flow minichannel heat exchanger using insertion devices[J]. Applied Thermal Engineering, 2019, 160: 114065. |

| 37 | 袁培, 常宏旭, 李丹, 等. 微通道平行流换热器流量分配均匀性研究[J]. 低温与超导, 2019, 47(3): 44-48. |

| Yuan P, Chang H X, Li D, et al. The flow distribution uniformity research on the microchannel parallel flow heat exchanger[J]. Cryogenics & Superconductivity, 2019, 47(3): 44-48. | |

| 1 | 张朝晖, 刘璐璐, 王若楠, 等. “双碳”目标下制冷空调行业技术发展的思考[J]. 制冷与空调, 2022, 22(1): 1-10. |

| Zhang Z H, Liu L L, Wang R N, et al. Thoughts on technical development of refrigeration and air-conditioning industry under carbon peaking and carbon neutrality goals[J]. Refrigeration and Air-Conditioning, 2022, 22(1): 1-10. | |

| 2 | McNeil M A, Feng W, de la Rue du Can S, et al. Energy efficiency outlook in China’s urban buildings sector through 2030[J]. Energy Policy, 2016, 97: 532-539. |

| 3 | 张朝晖, 陈敬良, 高钰, 等. 《蒙特利尔议定书》基加利修正案对制冷空调行业的影响分析[J]. 制冷与空调, 2017, 17(1): 1-7, 15. |

| Zhang Z H, Chen J L, Gao Y, et al. Analysis on the influence of Kigali Amendment to Montreal Protocol to refrigeration and air-conditioning industry[J]. Refrigeration and Air-Conditioning, 2017, 17(1): 1-7, 15. | |

| 4 | 葛洋, 姜未汀. 微通道换热器的研究及应用现状[J]. 化工进展, 2016, 35(S1): 10-15. |

| Ge Y, Jiang W T. The research progress and application of the micro-channel heat exchanger[J]. Chemical Industry and Engineering Progress, 2016, 35(S1): 10-15. | |

| 5 | Zhang P, Hrnjak P S. Effect of some geometric parameters on performance of PF2 heat exchangers in periodic frosting[J]. International Journal of Refrigeration, 2010, 33(2): 334-346. |

| 6 | Li F, Wu S Y, Ma Z H, et al. Effect of surface coating on defrosting water drainage characteristics of vertical-fin microchannel frosting evaporator[J]. Applied Thermal Engineering, 2022, 208: 118220. |

| 7 | Brix W, Kærn M R, Elmegaard B. Modelling refrigerant distribution in microchannel evaporators[J]. International Journal of Refrigeration, 2009, 32(7): 1736-1743. |

| 38 | Marchitto A, Fossa M. Enhancing the phase distribution in parallel vertical channels with single and double chamber coaxial headers[J]. Applied Thermal Engineering, 2019, 155: 239-246. |

| 39 | Yu D J, Liu J W, Lv H B, et al. Effect of header configuration on refrigerant distribution in parallel flow microchannel evaporators[J]. Journal of Shanghai Jiao Tong University (Science), 2019, 24(3): 273-280. |

| 40 | 刘巍, 朱春玲. 分流板结构对微通道平行流蒸发器性能的影响[J]. 化工学报, 2012, 63(3): 761-766. |

| Liu W, Zhu C L. Effects of deflector structure on performance of micro-channel evaporator with parallel flow[J]. CIESC Journal, 2012, 63(3): 761-766. | |

| 41 | 刘巍, 朱春玲. 分流板开孔面积对微通道换热器流量分配的影响[J]. 流体机械, 2014, 42(1): 6-10, 74. |

| Liu W, Zhu C L. Flow distribution characteristics of deflector with different opening area[J]. Fluid Machinery, 2014, 42(1): 6-10, 74. | |

| 42 | 刘巍, 朱春玲. 分流板开孔面积对微通道平行流蒸发器性能的影响[J]. 制冷学报, 2014, 35(3): 58-64. |

| Liu W, Zhu C L. Effects of open area of holes in deflector on performance of micro-channel evaporator with parallel flow[J]. Journal of Refrigeration, 2014, 35(3): 58-64. | |

| 43 | 高志成, 孟浩, 王燕令, 等. 平行流换热器内变孔径分流板分流特性研究[J]. 低温与超导, 2018, 46(5): 63-68, 87. |

| Gao Z C, Meng H, Wang Y L, et al. Study on distribution characteristics of aperture—changeable deflector in parallel flow heat exchanger[J]. Cryogenics & Superconductivity, 2018, 46(5): 63-68, 87. | |

| 44 | Mahvi A J, Garimella S. Visualization of flow distribution in rectangular and triangular header geometries[J]. International Journal of Refrigeration, 2017, 76: 170-183. |

| 45 | Wu G M, Yan Z T, Zhuang D W, et al. Design method and application effects of embedded-clapboard distributor on refrigerant distribution among multi-tubes of micro-channel heat exchangers[J]. International Journal of Refrigeration, 2020, 119: 420-433. |

| 46 | Redo M A, Jeong J, Yamaguchi S, et al. Characterization and improvement of flow distribution in a vertical dual-compartment header of a microchannel heat exchanger[J]. International Journal of Refrigeration, 2020, 116: 36-48. |

| 47 | Park N H, Ha M Y. An experimental study on the effect of vertical header geometry on the two-phase refrigerant distribution and performance of a microchannel heat exchanger[J]. Applied Thermal Engineering, 2022, 209: 118287. |

| 48 | Panda K, Hirokawa T, Huang L. Design study of microchannel heat exchanger headers using experimentally validated multiphase flow CFD simulation[J]. Applied Thermal Engineering, 2020, 178: 115585. |

| 49 | Kawahara A, Chung P M Y, Kawaji M. Investigation of two-phase flow pattern void fraction and pressure drop in a microchannel[J]. International Journal of Multiphase Flow, 2002, 28(9): 1411-1435. |

| 50 | 马虎根, 涂文静, 谢荣建, 等. 微尺度通道内气液两相流型可视化研究[J]. 中国电机工程学报, 2011, 31(29): 85-90. |

| Ma H G, Tu W J, Xie R J, et al. Visualization on flow pattern with vapor-liquid two-phase flow in microchannel[J]. Proceedings of the CSEE, 2011, 31(29): 85-90. | |

| 51 | Triplett K A, Ghiaasiaan S M, Abdel-Khalik S I, et al. Gas-liquid two-phase flow in microchannels (part Ⅰ): Two-phase flow patterns[J]. International Journal of Multiphase Flow, 1999, 25(3): 377-394. |

| 52 | Sur A, Liu D. Adiabatic air-water two-phase flow in circular microchannels[J]. International Journal of Thermal Sciences, 2012, 53: 18-34. |

| 53 | Cubaud T, Ho C M. Transport of bubbles in square microchannels[J]. Physics of Fluids, 2004, 16(12): 4575-4585. |

| 54 | Li H Z, Hrnjak P. Visualization and measurement of reverse flow in an actual channel of a microchannel evaporator[J]. International Journal of Heat and Mass Transfer, 2017, 108: 2346-2354. |

| 55 | Li H P, Hrnjak P. Flow visualization of R32 in parallel-port microchannel tube[J]. International Journal of Heat and Mass Transfer, 2019, 128: 1-11. |

| 56 | Li H P, Hrnjak P. Flow patterns and plug/slug flow characteristic of R134a in a 0.643 mm microchannel tube[J]. International Journal of Heat and Mass Transfer, 2019, 132: 1062-1073. |

| 57 | Li H P, Hrnjak P. Flow visualization of R1234ze(E) in a 0.643 mm microchannel tube[J]. International Journal of Heat and Mass Transfer, 2019, 136: 950-961. |

| 58 | Wang G D, Hao L, Cheng P. A four-zone model for saturated flow boiling in a microchannel of rectangular cross-section[J]. International Journal of Heat and Mass Transfer, 2010, 53(17/18): 3439-3448. |

| 59 | Vinoth R, Senthil Kumar D. Channel cross section effect on heat transfer performance of oblique finned microchannel heat sink[J]. International Communications in Heat and Mass Transfer, 2017, 87: 270-276. |

| 60 | Moradikazerouni A, Afrand M, Alsarraf J, et al. Comparison of the effect of five different entrance channel shapes of a micro-channel heat sink in forced convection with application to cooling a supercomputer circuit board[J]. Applied Thermal Engineering, 2019, 150: 1078-1089. |

| 61 | Ghule K, Soni M S. Numerical heat transfer analysis of wavy micro channels with different cross sections[J]. Energy Procedia, 2017, 109: 471-478. |

| 62 | Sempértegui-Tapia D F, Ribatski G. The effect of the cross-sectional geometry on saturated flow boiling heat transfer in horizontal micro-scale channels[J]. Experimental Thermal and Fluid Science, 2017, 89: 98-109. |

| 63 | 罗炜, 贺静, 罗兵, 等. 截面形状对微通道流动沸腾影响的数值研究[J]. 西安交通大学学报, 2019, 53(11): 101-111. |

| Luo W, He J, Luo B, et al. Numerical study on the effect of cross-sectional shape of microchanneis on flow boiling[J]. Journal of Xi’an Jiaotong University, 2019, 53(11): 101-111. | |

| 64 | 马圣洁, 江海河, 程庭清. 分流式微通道换热器的结构设计和性能优化[J]. 工程热物理学报, 2023, 44(5): 1296-1303. |

| Ma S J, Jiang H H, Cheng T Q. Structural design and performance optimization of manifold microchannel heat exchangers[J]. Journal of Engineering Thermophysics, 2023, 44(5): 1296-1303. | |

| 65 | Yu M, Diallo T M O, Zhao X D, et al. Analytical study of impact of the wick’s fractal parameters on the heat transfer capacity of a novel micro-channel loop heat pipe[J]. Energy, 2018, 158: 746-759. |

| 66 | Xia G D, Ma D D, Wang W, et al. Effects of different structures and allocations on fluid flow and heat transfer performance in 3D-IC integrated micro-channel interlayer cooling[J]. International Journal of Heat and Mass Transfer, 2015, 91: 1167-1175. |

| 67 | Chai L, Xia G D, Wang H S. Laminar flow and heat transfer characteristics of interrupted microchannel heat sink with ribs in the transverse microchambers[J]. International Journal of Thermal Sciences, 2016, 110: 1-11. |

| 68 | Chai L, Xia G D, Wang H S. Parametric study on thermal and hydraulic characteristics of laminar flow in microchannel heat sink with fan-shaped ribs on sidewalls (Part 1): Heat transfer[J]. International Journal of Heat and Mass Transfer, 2016, 97: 1069-1080. |

| 69 | Chai L, Xia G D, Wang H S. Parametric study on thermal and hydraulic characteristics of laminar flow in microchannel heat sink with fan-shaped ribs on sidewalls (Part 2): Pressure drop[J]. International Journal of Heat and Mass Transfer, 2016, 97: 1081-1090. |

| 70 | 朱飞跃, 朱崎峰, 苏瑞瑞, 等. 肋槽组合式微通道流动与传热特性研究[J]. 工程热物理学报, 2023, 44(9): 2504-2513. |

| Zhu F Y, Zhu Q F, Su R R, et al. Study on flow and heat transfer characteristics of microchannel with combined ribs and grooves[J]. Journal of Engineering Thermophysics, 2023, 44(9): 2504-2513. | |

| 71 | Chuan L, Wang X D, Wang T H, et al. Fluid flow and heat transfer in microchannel heat sink based on porous fin design concept[J]. International Communications in Heat and Mass Transfer, 2015, 65: 52-57. |

| 72 | 张哲, 张智弘, 赵恩惠, 等. 微通道散热器新型结构设计及流动与散热分析[J]. 低温工程, 2023(4): 38-47. |

| Zhang Z, Zhang Z H, Zhao E H, et al. New structure design and analysis of flow and heat dissipation performance of microchannel heat sink[J]. Cryogenics, 2023(4): 38-47. | |

| 73 | Liu J, Xie G N, Simon T W. Turbulent flow and heat transfer enhancement in rectangular channels with novel cylindrical grooves[J]. International Journal of Heat and Mass Transfer, 2015, 81: 563-577. |

| 74 | Li P, Zhang D, Xie Y H, et al. Flow structure and heat transfer of non-Newtonian fluids in microchannel heat sinks with dimples and protrusions[J]. Applied Thermal Engineering, 2016, 94: 50-58. |

| 75 | Li P, Zhang D, Xie Y H. Heat transfer and flow analysis of Al2O3-water nanofluids in microchannel with dimple and protrusion[J]. International Journal of Heat and Mass Transfer, 2014, 73: 456-467. |

| 76 | Shen B B, Yan H B, Sunden B, et al. Forced convection and heat transfer of water-cooled microchannel heat sinks with various structured metal foams[J]. International Journal of Heat and Mass Transfer, 2017, 113: 1043-1053. |

| 77 | 江河, 袁俊飞, 王林, 等. 均流腔结构对微细通道内相变流动特性影响的实验研究[J]. 化工学报, 2023, 74(S1): 235-244. |

| Jiang H, Yuan J F, Wang L, et al. Experimental study on the effect of flow sharing cavity structure on phase change flow characteristics in microchannels[J]. CIESC Journal, 2023, 74(S1): 235-244. | |

| 78 | Prajapati Y K. Influence of fin height on heat transfer and fluid flow characteristics of rectangular microchannel heat sink[J]. International Journal of Heat and Mass Transfer, 2019, 137: 1041-1052. |

| 79 | Mandev E, Manay E. Effects of surface roughness in multiple microchannels on mixed convective heat transfer[J]. Applied Thermal Engineering, 2022, 217: 119102. |

| 80 | 蓝伟, 钟显朴, 王亮, 等. 基于格子Boltzmann方法表面形貌对微通道对流换热的影响[J]. 推进技术, 2020, 41(12): 2774-2781. |

| Lan W, Zhong X P, Wang L, et al. Effects of surface morphology on convection heat transfer in microchannels based on lattice boltzmann method[J]. Journal of Propulsion Technology, 2020, 41(12): 2774-2781. | |

| 81 | Taufiqurrakhman M, Istiyanto J, Putra N. Application of biomachining on copper for a minichannel heat exchanger[J]. Thermal Science and Engineering Progress, 2021, 26: 101128. |

| 82 | 叶仪, 殷晨波, 贾文华, 等. Gauss型粗糙表面对微通道流动与换热的影响[J]. 农业机械学报, 2013, 44(12): 294-300. |

| Ye Y, Yin C B, Jia W H, et al. Effects of Guassian rough surface on fluid flow and heat transfer in microchannels[J]. Transactions of the Chinese Society for Agricultural Machinery, 2013, 44(12): 294-300. | |

| 83 | 高超, 朱志冰, 李海旺. 宽高比及表面粗糙度对矩形微尺度通道流动特性的影响[J]. 航空动力学报, 2018, 33(5): 1173-1177. |

| Gao C, Zhu Z B, Li H W. Influence of aspect ratio and roughness on flow behavior in rectangle microchannels[J]. Journal of Aerospace Power, 2018, 33(5): 1173-1177. | |

| 84 | Ansari M Q, Zhou G B. Influence of structured surface roughness peaks on flow and heat transfer performances of micro- and mini-channels[J]. International Communications in Heat and Mass Transfer, 2020, 110: 104428. |

| 85 | Cui J, Cui Y Y. Effects of surface wettability and roughness on the heat transfer performance of fluid flowing through microchannels[J]. Energies, 2015, 8(6): 5704-5724. |

| 86 | Yuan X, Tao Z, Li H W, et al. Experimental investigation of surface roughness effects on flow behavior and heat transfer characteristics for circular microchannels[J]. Chinese Journal of Aeronautics, 2016, 29(6): 1575-1581. |

| 87 | Wu H Y, Cheng P. An experimental study of convective heat transfer in silicon microchannels with different surface conditions[J]. International Journal of Heat and Mass Transfer, 2003, 46(14): 2547-2556. |

| 88 | Dai B M, Li M X, Ma Y T. Effect of surface roughness on liquid friction and transition characteristics in micro- and mini-channels[J]. Applied Thermal Engineering, 2014, 67(1/2): 283-293. |

| 89 | Choi C, Shin J S, Yu D I,et al. Flow boiling behaviors in hydrophilic and hydrophobic microchannels[J]. Experimental Thermal and Fluid Science, 2011, 35(5): 816-824. |

| 90 | 周刊, 李蔚, 李俊业, 等. 微细通道内超亲水改性表面饱和沸腾的传热特性[J]. 化工学报, 2018, 69(S2): 82-88. |

| Zhou K, Li W, Li J Y, et al. Flow boiling heat transfer characteristics of superhydrophilic modified surface in microchannels[J]. CIESC Journal, 2018, 69(S2): 82-88. | |

| 91 | Kim J, Lee J S. Numerical study on the effects of inertia and wettability on subcooled flow boiling in microchannels[J]. Applied Thermal Engineering, 2019, 152: 175-183. |

| 92 | Phan H T, Caney N, Marty P, et al. Flow boiling of water in a minichannel: the effects of surface wettability on two-phase pressure drop[J]. Applied Thermal Engineering, 2011, 31(11/12): 1894-1905. |

| 93 | 喻祖康,舒碧芬,黄妍,等. 基于表面亲水改性的微通道高热流流动沸腾换热性能优化[J].热能动力工程,2020, 35(12): 94-100. |

| Yu Z K, Shu B F, Huang Y, et al. Optimization of flow boiling heat transfer performance in micro-channel under high heat flux based on surface hydrophilic modification[J]. Journal of Engineering for Thermal Energy and Power, 2020, 35(12): 94-100. | |

| 94 | 周正龙, 舒碧芬, 江景祥, 等. 疏水表面改性对微通道换热和压降性能的影响[J]. 应用能源技术, 2019(7): 1-3. |

| Zhou Z L, Shu B F, Jiang J X, et al. Effects of hydrophobic surface on heat transfer and pressure drop in microchannel[J]. Applied Energy Technology, 2019(7): 1-3. | |

| 95 | Zhou K, Coyle C, Li J Y, et al. Flow boiling in vertical narrow microchannels of different surface wettability characteristics[J]. International Journal of Heat and Mass Transfer, 2017, 109: 103-114. |

| 96 | Tan K Y, Hu Y W, He Y R. Effect of wettability on flow boiling heat transfer in a microtube[J]. Case Studies in Thermal Engineering, 2021, 26: 101018. |

| 97 | 王宜飞, 王清强, 姬德生, 等. 微通道壁面浸润性对气-液两相流的影响规律研究[J]. 化工学报, 2022, 73(4): 1501-1514. |

| Wang Y F, Wang Q Q, Ji D S, et al. Effects of the wall wettability of microchannel on the gas-liquid two-phase flow hydrodynamics[J]. CIESC Journal, 2022, 73(4): 1501-1514. | |

| 98 | Motezakker A R, Sadaghiani A K, Çelik S, et al. Optimum ratio of hydrophobic to hydrophilic areas of biphilic surfaces in thermal fluid systems involving boiling[J]. International Journal of Heat and Mass Transfer, 2019, 135: 164-174. |

| 99 | Gong S, Cheng P. Numerical simulation of pool boiling heat transfer on smooth surfaces with mixed wettability by lattice Boltzmann method[J]. International Journal of Heat and Mass Transfer, 2015, 80: 206-216. |

| 100 | Ahmadi V E, Aboubakri A, Sadaghiani A K, et al. Effect of functional surfaces with gradient mixed wettability on flow boiling in a high aspect ratio microchannel[J]. Fluids, 2020, 5(4): 239. |

| 101 | Aboubakri A, Ahmadi V E, Celik S, et al. Effect of surface biphilicity on FC-72 flow boiling in a rectangular minichannel[J]. Frontiers in Mechanical Engineering, 2021, 7: 755580. |

| 102 | Wang H Z, Yang Y C, He M H, et al. Subcooled flow boiling heat transfer in a microchannel with chemically patterned surfaces[J]. International Journal of Heat and Mass Transfer, 2019,140: 587-597. |

| [1] | 晁京伟, 许嘉兴, 李廷贤. 基于无管束蒸发换热强化策略的吸附热池的供热性能研究[J]. 化工学报, 2023, 74(S1): 302-310. |

| [2] | 程成, 段钟弟, 孙浩然, 胡海涛, 薛鸿祥. 表面微结构对析晶沉积特性影响的格子Boltzmann模拟[J]. 化工学报, 2023, 74(S1): 74-86. |

| [3] | 张化福, 童莉葛, 张振涛, 杨俊玲, 王立, 张俊浩. 机械蒸汽压缩蒸发技术研究现状与发展趋势[J]. 化工学报, 2023, 74(S1): 8-24. |

| [4] | 吴馨, 龚建英, 靳龙, 王宇涛, 黄睿宁. 超声波激励下铝板表面液滴群输运特性的研究[J]. 化工学报, 2023, 74(S1): 104-112. |

| [5] | 叶展羽, 山訸, 徐震原. 用于太阳能蒸发的折纸式蒸发器性能仿真[J]. 化工学报, 2023, 74(S1): 132-140. |

| [6] | 张双星, 刘舫辰, 张义飞, 杜文静. R-134a脉动热管相变蓄放热实验研究[J]. 化工学报, 2023, 74(S1): 165-171. |

| [7] | 毕丽森, 刘斌, 胡恒祥, 曾涛, 李卓睿, 宋健飞, 吴翰铭. 粗糙界面上纳米液滴蒸发模式的分子动力学研究[J]. 化工学报, 2023, 74(S1): 172-178. |

| [8] | 张义飞, 刘舫辰, 张双星, 杜文静. 超临界二氧化碳用印刷电路板式换热器性能分析[J]. 化工学报, 2023, 74(S1): 183-190. |

| [9] | 陈爱强, 代艳奇, 刘悦, 刘斌, 吴翰铭. 基板温度对HFE7100液滴蒸发过程的影响研究[J]. 化工学报, 2023, 74(S1): 191-197. |

| [10] | 刘明栖, 吴延鹏. 导光管直径和长度对传热影响的模拟分析[J]. 化工学报, 2023, 74(S1): 206-212. |

| [11] | 王志国, 薛孟, 董芋双, 张田震, 秦晓凯, 韩强. 基于裂隙粗糙性表征方法的地热岩体热流耦合数值模拟与分析[J]. 化工学报, 2023, 74(S1): 223-234. |

| [12] | 江河, 袁俊飞, 王林, 邢谷雨. 均流腔结构对微细通道内相变流动特性影响的实验研究[J]. 化工学报, 2023, 74(S1): 235-244. |

| [13] | 袁佳琦, 刘政, 黄锐, 张乐福, 贺登辉. 泡状入流条件下旋流泵能量转换特性研究[J]. 化工学报, 2023, 74(9): 3807-3820. |

| [14] | 齐聪, 丁子, 余杰, 汤茂清, 梁林. 基于选择吸收纳米薄膜的太阳能温差发电特性研究[J]. 化工学报, 2023, 74(9): 3921-3930. |

| [15] | 李艺彤, 郭航, 陈浩, 叶芳. 催化剂非均匀分布的质子交换膜燃料电池操作条件研究[J]. 化工学报, 2023, 74(9): 3831-3840. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号