化工学报 ›› 2024, Vol. 75 ›› Issue (11): 4226-4236.DOI: 10.11949/0438-1157.20240548

王清莲1,2( ), 熊佩芸1, 韩俏飞1,4, 叶长燊1,2, 王红星3, 杨臣1,2(

), 熊佩芸1, 韩俏飞1,4, 叶长燊1,2, 王红星3, 杨臣1,2( ), 邱挺1,2(

), 邱挺1,2( )

)

收稿日期:2024-05-23

修回日期:2024-06-25

出版日期:2024-11-25

发布日期:2024-12-26

通讯作者:

杨臣,邱挺

作者简介:王清莲(1989—),女,博士,wqlian@fzu.edu.cn

基金资助:

Qinglian WANG1,2( ), Peiyun XIONG1, Qiaofei HAN1,4, Changshen YE1,2, Hongxing WANG3, Chen YANG1,2(

), Peiyun XIONG1, Qiaofei HAN1,4, Changshen YE1,2, Hongxing WANG3, Chen YANG1,2( ), Ting QIU1,2(

), Ting QIU1,2( )

)

Received:2024-05-23

Revised:2024-06-25

Online:2024-11-25

Published:2024-12-26

Contact:

Chen YANG, Ting QIU

摘要:

在聚多巴胺辅助二次生长法制备负载型催化填料(SCP)基础上,通过多次晶化及碱处理协同改性,开发了高性能SCP制备方法。研究结果表明,SCP的活性组分层负载量随晶化次数增加而线性增长,但过密的活性组分层结构限制了活性位点的利用。四甲基氢氧化铵(TMAOH)处理通过溶解硅原子形成介孔,提高了外比表面积和扩散效率,增强了SCP的催化活性和焦炭容纳能力。在优化的改性条件下,即晶化次数为3次、TMAOH溶液浓度为0.05 mol/L、碱处理温度为80℃、碱处理时间为120 min,SCP活性提升3.74倍。尽管SCP在乙酸环己酯合成中活性有所下降,但通过焙烧再生可恢复活性。环己烯高温聚合产生的积炭是活性降低的主要原因。

中图分类号:

王清莲, 熊佩芸, 韩俏飞, 叶长燊, 王红星, 杨臣, 邱挺. 高性能负载型催化填料的制备及其性能研究[J]. 化工学报, 2024, 75(11): 4226-4236.

Qinglian WANG, Peiyun XIONG, Qiaofei HAN, Changshen YE, Hongxing WANG, Chen YANG, Ting QIU. Preparation and performance investigation of high-performance supported catalytic packing[J]. CIESC Journal, 2024, 75(11): 4226-4236.

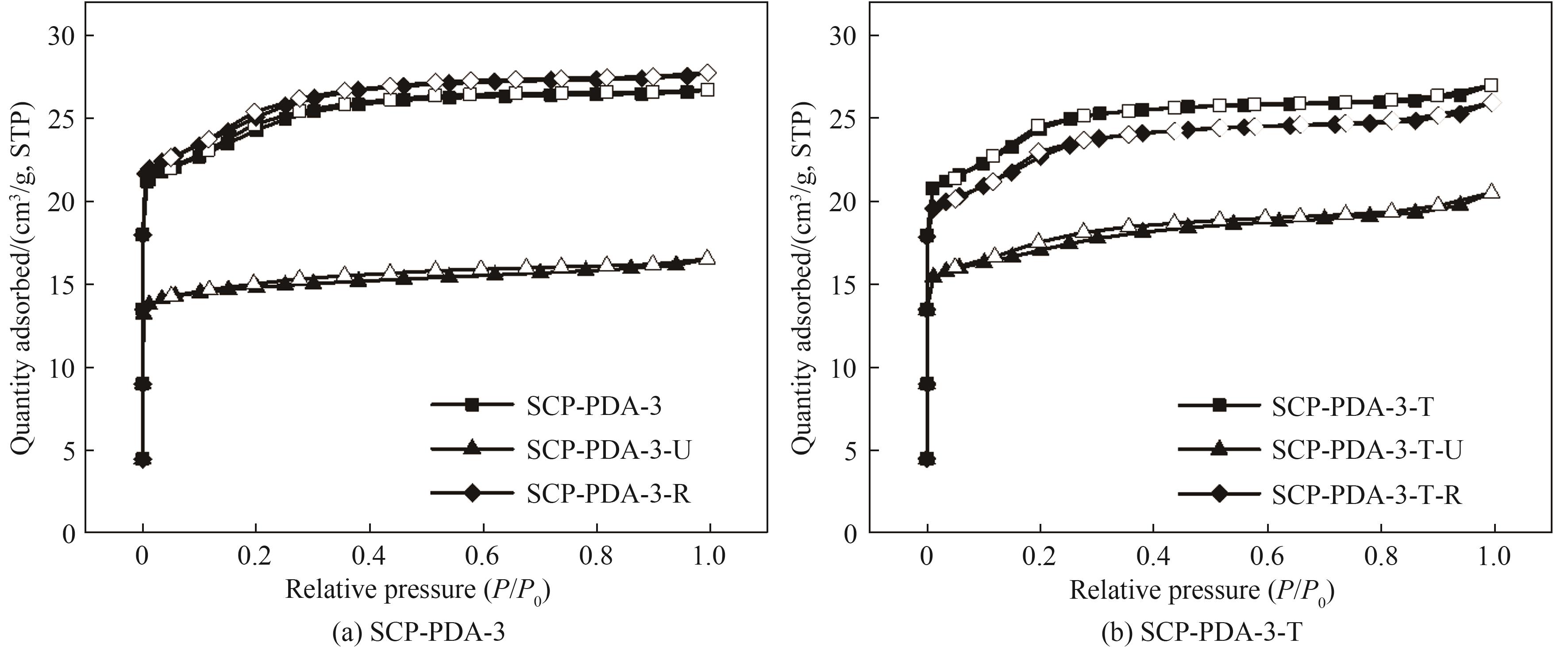

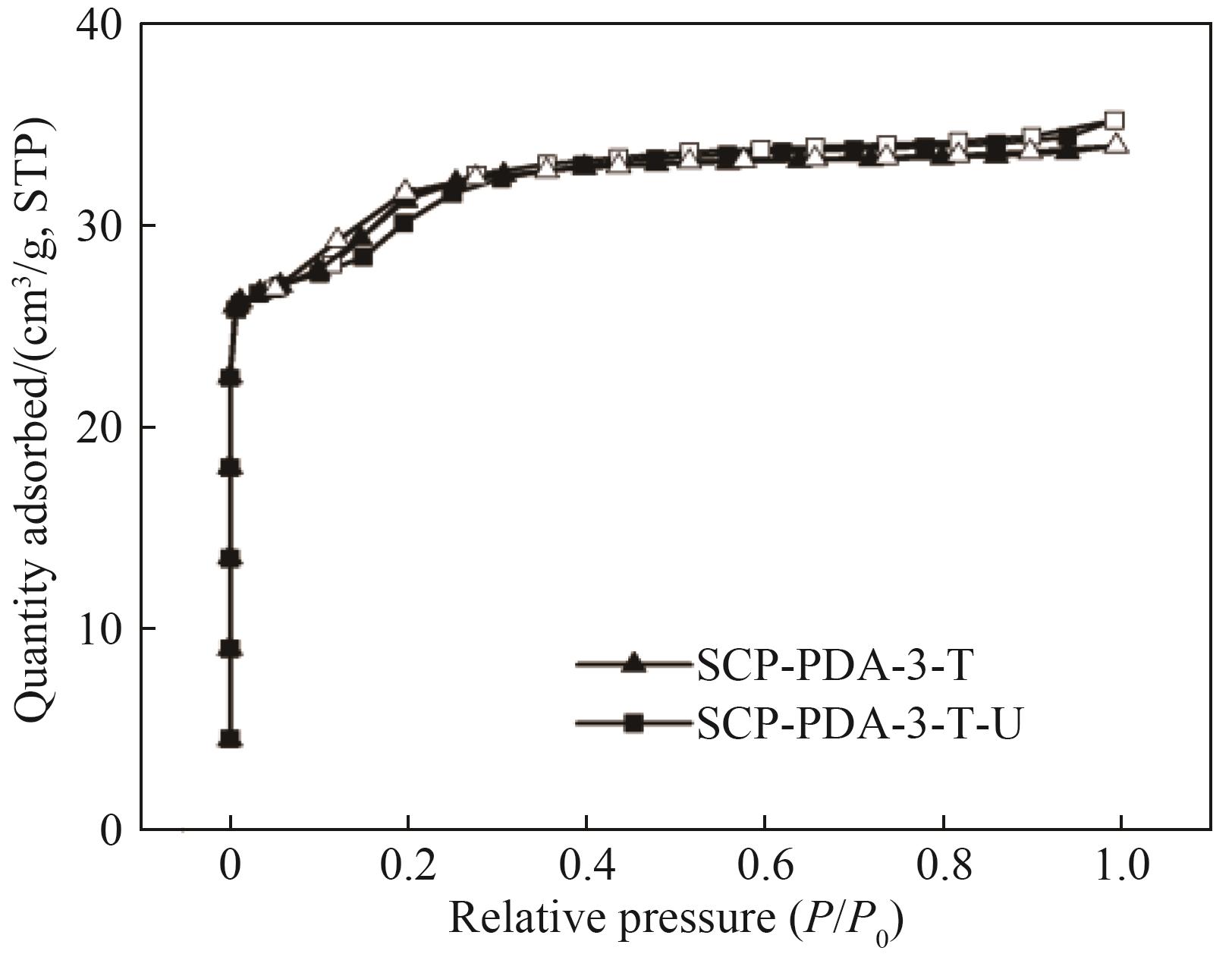

| SCP | Smicro①/(m2·g-1) | Sext②/(m2·g-1) | SBET③/(m2·g-1) | Vmicro④/(cm3·g-1) | Vmeso⑤/(cm3·g-1) |

|---|---|---|---|---|---|

| SCP-PDA-3 | 49.5 | 47.9 | 97.5 | 0.0312 | 0.0102 |

| SCP-PDA-3-U | 44.4 | 9.13 | 57.5 | 0.0221 | 0.0036 |

| SCP-PDA-3-R | 50.3 | 50.4 | 100.66 | 0.0323 | 0.0109 |

| SCP-PDA-3-T | 37.9 | 66.3 | 104.2 | 0.0302 | 0.0114 |

| SCP-PDA-3-T-U | 37.0 | 24.5 | 67.7 | 0.0238 | 0.0090 |

| SCP-PDA-3-T-R | 36.1 | 61.6 | 98.0 | 0.0283 | 0.0113 |

表1 SCP结构特性

Table 1 Textural properties for SCP

| SCP | Smicro①/(m2·g-1) | Sext②/(m2·g-1) | SBET③/(m2·g-1) | Vmicro④/(cm3·g-1) | Vmeso⑤/(cm3·g-1) |

|---|---|---|---|---|---|

| SCP-PDA-3 | 49.5 | 47.9 | 97.5 | 0.0312 | 0.0102 |

| SCP-PDA-3-U | 44.4 | 9.13 | 57.5 | 0.0221 | 0.0036 |

| SCP-PDA-3-R | 50.3 | 50.4 | 100.66 | 0.0323 | 0.0109 |

| SCP-PDA-3-T | 37.9 | 66.3 | 104.2 | 0.0302 | 0.0114 |

| SCP-PDA-3-T-U | 37.0 | 24.5 | 67.7 | 0.0238 | 0.0090 |

| SCP-PDA-3-T-R | 36.1 | 61.6 | 98.0 | 0.0283 | 0.0113 |

图10 SCP在间歇稳定性实验前后及焙烧再生后的N2吸-脱附等温线

Fig.10 N2 adsorption and desorption isotherms of SCPs before and after stability tests and after roasting regeneration

图14 SCP-PDA-3-T在乙酸与乙醇酯化反应体系重复性实验前后的N2吸-脱附等温线

Fig.14 N2 adsorption and desorption isotherms of SCP-PDA-3-T before and after the reusability test in esterification of acetic acid with ethanol

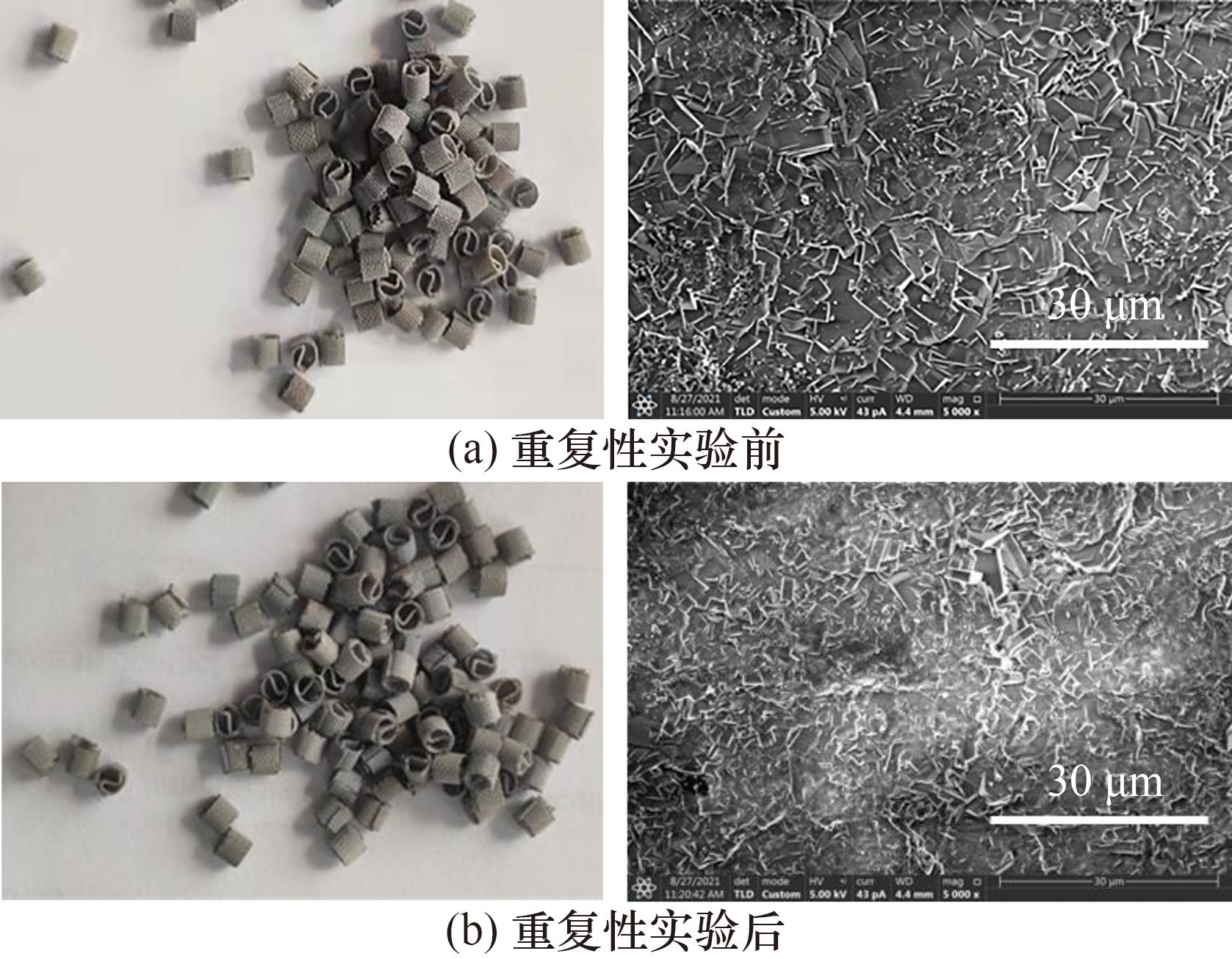

图15 SCP-PDA-3-T在乙酸与乙醇酯化反应中重复性实验前后的实物(左)及SEM照片(右)

Fig.15 Pictures (left) and SEM images (right) of SCP-PDA-3-T before and after the reusability test in esterification of acetic acid with ethanol

| 1 | Kiss A A, Jobson M, Gao X. Reactive distillation: stepping up to the next level of process intensification[J]. Industrial & Engineering Chemistry Research, 2019, 58(15): 5909-5918. |

| 2 | Hiwale R S, Bhate N, Mahajan Y S, et al. Industrial applications of reactive distillation: recent trends[J]. International Journal of Chemical Reactor Engineering, 2004, 2(1): 1-52. |

| 3 | Wang Q L, Le K Y, Lin Y, et al. Investigation on catalytic distillation dehydrogenation of perhydro-benzyltoluene: reaction kinetics, modeling and process analysis[J]. Chemical Engineering Journal, 2024, 482: 148591. |

| 4 | Wang Q L, Yang Z, Wang J N, et al. A multi-scale and multi-objective optimization strategy for catalytic distillation process[J]. Chemical Engineering Science, 2023, 265: 118221. |

| 5 | Wang Q L, Yang C, Wang H X, et al. Optimization of process-specific catalytic packing in catalytic distillation process: a multi-scale strategy[J]. Chemical Engineering Science, 2017, 174: 472-486. |

| 6 | Ding Q Y, Yan P, Li H, et al. Kinetics and structural design of ZSM-5@SiC foam catalytic packing in RD column for ethyl levulinate synthesis[J]. Chemical Engineering Science, 2023, 265: 118258. |

| 7 | Hou Z K, Ding Q Y, Geng X L, et al. Pilot-scale validation and novel design of reactive distillation with HY@SiC foam catalytic packing for cyclohexyl acetate production[J]. Separation and Purification Technology, 2023, 317: 123935. |

| 8 | Wang Z W, Shi J N, Liu X N, et al. Supported catalytic packing prepared from ceramic packing for reactive distillation of ethyl acetate[J]. Chinese Journal of Chemical Engineering, 2022, 50: 205-214. |

| 9 | Ambrosetti M, Bracconi M, Maestri M, et al. Packed foams for the intensification of catalytic processes: assessment of packing efficiency and pressure drop using a combined experimental and numerical approach[J]. Chemical Engineering Journal, 2020, 382: 122801. |

| 10 | Beers A E W, Nijhuis T A, Aalders N, et al. BEA coating of structured supports—performance in acylation[J]. Applied Catalysis A: General, 2003, 243(2): 237-250. |

| 11 | Tian Y J, Liu H, Wang L, et al. Controllable fabrication and catalytic performance of nanosheet HZSM-5 films by vertical secondary growth[J]. AIChE Journal, 2018, 64(6): 1923-1927. |

| 12 | Bernal M P, Xomeritakis G, Tsapatsis M. Tubular MFI zeolite membranes made by secondary (seeded) growth[J]. Catalysis Today, 2001, 67(1/2/3): 101-107. |

| 13 | Ueno K, Negishi H, Okuno T, et al. High-performance silicalite-1 membranes on porous tubular silica supports for separation of ethanol/water mixtures[J]. Separation and Purification Technology, 2017, 187: 343-354. |

| 14 | Abdollahi M, Ashrafizadeh S N, Malekpour A. Preparation of zeolite ZSM-5 membrane by electrophoretic deposition method[J]. Microporous and Mesoporous Materials, 2007, 106(1/2/3): 192-200. |

| 15 | Oudshoorn O L, Janissen M, van Kooten W E J, et al. A novel structured catalyst packing for catalytic distillation of ETBE[J]. Chemical Engineering Science, 1999, 54(10): 1413-1418. |

| 16 | Seijger G B F, Oudshoorn O L, van Kooten W E J, et al. In situ synthesis of binderless ZSM-5 zeolitic coatings on ceramic foam supports[J]. Microporous and Mesoporous Materials, 2000, 39(1/2): 195-204. |

| 17 | Shan Z, van Kooten W E J, Oudshoorn O L, et al. Optimization of the preparation of binderless ZSM-5 coatings on stainless steel monoliths by in situ hydrothermal synthesis[J]. Microporous and Mesoporous Materials, 2000, 34(1): 81-91. |

| 18 | Deng T, Zhao G F, Liu Y, et al. Catalytic distillation for one-step cyclohexyl acetate production and cyclohexene-cyclohexane separation via esterification of cyclohexene with acetic acid over microfibrous-structured Nafion-SiO2/SS-fiber packings[J]. Chemical Engineering and Processing-Process Intensification, 2018, 131: 215-226. |

| 19 | Deng T, Li Y K, Zhao G F, et al. Catalytic distillation for ethyl acetate synthesis using microfibrous-structured Nafion-SiO2/SS-fiber solid acid packings[J]. Reaction Chemistry & Engineering, 2016, 1(4): 409-417. |

| 20 | Han Q F, Wang J N, Li M T, et al. A method to fabricate supported catalytic packing: polydopamine as a “double-sided adhesive” to prepare the fully covered seeding layer[J]. Journal of the Taiwan Institute of Chemical Engineers, 2022, 132: 104116. |

| 21 | Wang L, Wang Y, Hao J G, et al. Synthesis of HZSM-5 coatings on the inner surface of stainless steel tubes and their catalytic performance in n-dodecane cracking[J]. Applied Catalysis A: General, 2013, 462: 271-277. |

| 22 | Corma A. From microporous to mesoporous molecular sieve materials and their use in catalysis[J]. Chemical Reviews, 1997, 97(6): 2373-2420. |

| 23 | Chal R, Gérardin C, Bulut M, et al. Overview and industrial assessment of synthesis strategies towards zeolites with mesopores[J]. ChemCatChem, 2011, 3(1): 67-81. |

| 24 | Na K, Choi M, Ryoo R. Recent advances in the synthesis of hierarchically nanoporous zeolites[J]. Microporous and Mesoporous Materials, 2013, 166: 3-19. |

| 25 | Shen Y, Han Z Z, Li H, et al. Cooperative structure direction of organosilanes and tetrapropylammonium hydroxide to generate hierarchical ZSM-5 zeolite with controlled porous structure[J]. CrystEngComm, 2018, 20(40): 6319-6327. |

| 26 | Yu Q Q, Sun H Y, Sun H X, et al. Highly mesoporous IM-5 zeolite prepared by alkaline treatment and its catalytic cracking performance[J]. Microporous and Mesoporous Materials, 2019, 273: 297-306. |

| 27 | Verboekend D, Pérez-Ramírez J. Desilication mechanism revisited: highly mesoporous all-silica zeolites enabled through pore-directing agents[J]. Chemistry, 2011, 17(4): 1137-1147. |

| 28 | Ding K, Zhong Z P, Wang J, et al. Effects of alkali-treated hierarchical HZSM-5 zeolites on the production of aromatic hydrocarbons from catalytic fast pyrolysis of waste cardboard[J]. Journal of Analytical and Applied Pyrolysis, 2017, 125: 153-161. |

| 29 | Hou X, Qiu Y, Tian Y J, et al. Reaction pathways of n-pentane cracking on the fresh and regenerated Sr, Zr and La-loaded ZSM-5 zeolites[J]. Chemical Engineering Journal, 2018, 349: 297-308. |

| 30 | Liu G Z, Zhao G L, Meng F X, et al. Catalytic cracking of supercritical n-dodecane over wall-coated HZSM-5 zeolites with micro- and nanocrystal sizes[J]. Energy & Fuels, 2012, 26(2): 1220-1229. |

| 31 | Jiao Y L, Jiang C H, Yang Z M, et al. Controllable synthesis of ZSM-5 coatings on SiC foam support for MTP application[J]. Microporous and Mesoporous Materials, 2012, 162: 152-158. |

| 32 | Ong L H, Dömök M, Olindo R, et al. Dealumination of HZSM-5 via steam-treatment[J]. Microporous and Mesoporous Materials, 2012, 164: 9-20. |

| 33 | Ibáñez M, Gamero M, Ruiz-Martínez J, et al. Simultaneous coking and dealumination of zeolite H-ZSM-5 during the transformation of chloromethane into olefins[J]. Catalysis Science & Technology, 2016, 6(1): 296-306. |

| 34 | Schmidt F, Hoffmann C, Giordanino F, et al. Coke location in microporous and hierarchical ZSM-5 and the impact on the MTH reaction[J]. Journal of Catalysis, 2013, 307: 238-245. |

| 35 | Devaraj A, Vijayakumar M, Bao J, et al. Discerning the location and nature of coke deposition from surface to bulk of spent zeolite catalysts[J]. Scientific Reports, 2016, 6(1): 37586. |

| 36 | Santaella M A, Orjuela A, Narváez P C. Comparison of different reactive distillation schemes for ethyl acetate production using sustainability indicators[J]. Chemical Engineering and Processing: Process Intensification, 2015, 96: 1-13. |

| [1] | 石美琳, 赵连达, 邓行健, 王静松, 左海滨, 薛庆国. 催化甲烷重整工艺的研究进展[J]. 化工学报, 2024, 75(S1): 25-39. |

| [2] | 赵昂然, 韩永强, 王志鹏, 李鹏飞, 许亚伟, 佟会玲. 常温条件下赤泥同时脱硫脱硝实验研究[J]. 化工学报, 2024, 75(S1): 276-282. |

| [3] | 赵焕娟, 包颖昕, 于康, 刘婧, 钱新明. 多元组分爆轰不稳定性定量实验研究[J]. 化工学报, 2024, 75(S1): 339-348. |

| [4] | 胡俭, 姜静华, 范生军, 刘建浩, 邹海江, 蔡皖龙, 王沣浩. 中深层U型地埋管换热器取热特性研究[J]. 化工学报, 2024, 75(S1): 76-84. |

| [5] | 钟屹, 周仕遇, 纠连朝, 李钰晓, 吴豪江, 周智勇. 废旧磷酸铁锂电池正极材料直接修复再生研究进展[J]. 化工学报, 2024, 75(S1): 1-13. |

| [6] | 刘亚超, 谭晓杰, 李旭东, 王瑞, 王慧, 韩璇, 赵青山. DES合成高活性CoCO3纳米片及析氧反应性能研究[J]. 化工学报, 2024, 75(9): 3320-3328. |

| [7] | 张梦婷, 王书林, 桑熙, 元兴昊, 徐刚. 人工Cu-TM1459金属酶催化不对称迈克尔加成反应[J]. 化工学报, 2024, 75(9): 3255-3265. |

| [8] | 杨子驰, 谢冰琪, 石瑞莘, 雷虹, 陈晨, 周才金, 张吉松. 套管膜式微反应器内高效安全的气液传质-反应过程研究进展[J]. 化工学报, 2024, 75(9): 3011-3027. |

| [9] | 丁家琦, 刘海涛, 赵普, 朱香凝, 王晓放, 谢蓉. 煤炭超临界水制氢反应器内多相流场智能滚动预测研究[J]. 化工学报, 2024, 75(8): 2886-2896. |

| [10] | 黄晓峰, 刘朝晖, 杨帆. 高密度碳氢燃料JP-10流动换热及热裂解结焦实验研究[J]. 化工学报, 2024, 75(8): 2917-2928. |

| [11] | 赵帅琪, 张瑞, 黄瀚, 赵昆鹏, 白博峰. 水气转化对超临界水煤气化的抑制特性[J]. 化工学报, 2024, 75(8): 2960-2969. |

| [12] | 姚宏哲, 黄飞宇, 杨松, 钟梅, 代正华. 重质油高温快速热解自动反应网络的动力学建模[J]. 化工学报, 2024, 75(7): 2644-2655. |

| [13] | 黄静茹, 陈佳轩, 张群锋, 阮晋, 朱来, 叶光华, 周兴贵. ZSM-5分子筛结构对苯烷基化反应性能影响的数值模拟研究[J]. 化工学报, 2024, 75(7): 2544-2555. |

| [14] | 刘旭升, 李泽洋, 杨宇森, 卫敏. 电催化二氧化碳还原制备气态产物的研究进展[J]. 化工学报, 2024, 75(7): 2385-2408. |

| [15] | 王芝安, 兰忠, 马学虎. 喷嘴参数对超临界水热燃烧特性影响的模拟[J]. 化工学报, 2024, 75(6): 2190-2200. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号