• •

李文博1( ), 王子强1, 姚利丽2,3, 谢小林1, 张小杰1(

), 王子强1, 姚利丽2,3, 谢小林1, 张小杰1( ), 安林4

), 安林4

收稿日期:2025-09-30

修回日期:2025-12-23

出版日期:2026-01-19

通讯作者:

张小杰

作者简介:李文博(1988—),男,博士,讲师,645504616@qq.com

基金资助:

Wenbo LI1( ), Ziqiang WANG1, Lili YAO2,3, Xiaolin XIE1, Xiaojie ZHANG1(

), Ziqiang WANG1, Lili YAO2,3, Xiaolin XIE1, Xiaojie ZHANG1( ), Lin AN4

), Lin AN4

Received:2025-09-30

Revised:2025-12-23

Online:2026-01-19

Contact:

Xiaojie ZHANG

摘要:

硫化工艺设计对橡胶制品的成型质量控制和生产节能减排尤为关键,而轮胎制品结构复杂,其整体传热特性和硫化效率会受到骨架结构设计的重要影响。本文基于有限元分析技术,提出对数型硫化动力学方程,并应用于模拟轮胎机内硫化和后硫化整个过程,进一步研究带束层结构设计对轮胎硫化热分布和硫化速率的影响规律。结果表明,对数型硫化动力学模型可以更精确的拟合橡胶硫化动力学行为;机内硫化时胎侧硫化速率最快,胎肩最慢,出模后轮胎后硫化效应明显,轮胎硫化程度从0.51提高到0.93;带束层钢帘线型号和排列间距对轮胎热分布和硫化程度影响较为明显,排列角度则影响不大。对不同带束层结构的轮胎硫化工艺进行等效,机内硫化时间最大相差5 min20 s。

中图分类号:

李文博, 王子强, 姚利丽, 谢小林, 张小杰, 安林. 带束层结构设计对全钢子午线轮胎硫化特性影响的研究[J]. 化工学报, DOI: 10.11949/0438-1157.20251117.

Wenbo LI, Ziqiang WANG, Lili YAO, Xiaolin XIE, Xiaojie ZHANG, Lin AN. Research on the Effect of the Design of Belt Structure on Tire Vulcanization Characteristics[J]. CIESC Journal, DOI: 10.11949/0438-1157.20251117.

| 材料类型 | 热导率/(W•(m•℃)-1) | 密度/(kg•m-3) | 比热容/(J•(kg•℃)-1) |

|---|---|---|---|

| 胎面胶 | 0.27 | 1250 | 1600 |

| 带束层挂胶 | 0.21 | 1200 | 1503 |

| 胎侧胶 | 0.25 | 1170 | 1690 |

| 三角胶 | 0.24 | 1320 | 1521 |

| 钢帘线 | 70 | 7810 | 540 |

| 钢丝圈 | 70 | 7810 | 540 |

表1 材料热物性参数

Table 1 Thermophysical parameters of material

| 材料类型 | 热导率/(W•(m•℃)-1) | 密度/(kg•m-3) | 比热容/(J•(kg•℃)-1) |

|---|---|---|---|

| 胎面胶 | 0.27 | 1250 | 1600 |

| 带束层挂胶 | 0.21 | 1200 | 1503 |

| 胎侧胶 | 0.25 | 1170 | 1690 |

| 三角胶 | 0.24 | 1320 | 1521 |

| 钢帘线 | 70 | 7810 | 540 |

| 钢丝圈 | 70 | 7810 | 540 |

| 间距/mm | Vf /% | Vm /% | kZ /(W•(m•℃)-1) | kH /(W/(m•℃)) | ρcom /(kg•m-3) | Ccom /(J•(kg•℃)-1) |

|---|---|---|---|---|---|---|

| 1.0 | 37.8 | 62.2 | 26.59 | 0.464 | 3698.58 | 734.34 |

| 1.2 | 31.5 | 68.5 | 22.19 | 0.402 | 3282.15 | 781.18 |

| 1.4 | 27.0 | 73.0 | 19.05 | 0.365 | 2984.70 | 822.64 |

| 1.6 | 19.9 | 80.1 | 14.09 | 0.314 | 2515.06 | 908.06 |

| 型号 | ||||||

| 5*0.25 | 20.5 | 79.6 | 14.48 | 0.318 | 2551.75 | 900.26 |

| 2+7*0.22 | 28.5 | 71.5 | 20.11 | 0.377 | 3084.38 | 807.85 |

| 4*0.38 | 37.8 | 62.2 | 26.59 | 0.464 | 3698.58 | 734.34 |

| 5*0.38 | 47.3 | 52.7 | 33.19 | 0.584 | 4323.75 | 680.96 |

表2 不同钢帘线型号和间距的带束层材料基本参数

Table 2 Basic parameters of strap layer materials for different steel cord types and spacings

| 间距/mm | Vf /% | Vm /% | kZ /(W•(m•℃)-1) | kH /(W/(m•℃)) | ρcom /(kg•m-3) | Ccom /(J•(kg•℃)-1) |

|---|---|---|---|---|---|---|

| 1.0 | 37.8 | 62.2 | 26.59 | 0.464 | 3698.58 | 734.34 |

| 1.2 | 31.5 | 68.5 | 22.19 | 0.402 | 3282.15 | 781.18 |

| 1.4 | 27.0 | 73.0 | 19.05 | 0.365 | 2984.70 | 822.64 |

| 1.6 | 19.9 | 80.1 | 14.09 | 0.314 | 2515.06 | 908.06 |

| 型号 | ||||||

| 5*0.25 | 20.5 | 79.6 | 14.48 | 0.318 | 2551.75 | 900.26 |

| 2+7*0.22 | 28.5 | 71.5 | 20.11 | 0.377 | 3084.38 | 807.85 |

| 4*0.38 | 37.8 | 62.2 | 26.59 | 0.464 | 3698.58 | 734.34 |

| 5*0.38 | 47.3 | 52.7 | 33.19 | 0.584 | 4323.75 | 680.96 |

| 模型 | K/(s-1) | E/(J•mol-1) | a | b | c | m | n |

|---|---|---|---|---|---|---|---|

自催化 模型 | 8.2236×1010 | 1.0758×105 | / | / | / | 0.6248 | 1.3649 |

多项式 模型 | 1.0059×1011 | 1.1197×105 | 4.0485×10-6 | 2.4896×10-3 | 0.8262 | / | / |

正切 模型 | 3.8816×1011 | 1.1695×105 | 2.0192 | -1.6790 | -0.3403 | / | / |

对数 模型 | 7.2645×1011 | 1.1901×105 | 2.5985 | -19.6143 | -2.5235 | / | / |

表3 硫化反应动力学模型参数

Table 3 Kinetic model parameters of the vulcanization reaction

| 模型 | K/(s-1) | E/(J•mol-1) | a | b | c | m | n |

|---|---|---|---|---|---|---|---|

自催化 模型 | 8.2236×1010 | 1.0758×105 | / | / | / | 0.6248 | 1.3649 |

多项式 模型 | 1.0059×1011 | 1.1197×105 | 4.0485×10-6 | 2.4896×10-3 | 0.8262 | / | / |

正切 模型 | 3.8816×1011 | 1.1695×105 | 2.0192 | -1.6790 | -0.3403 | / | / |

对数 模型 | 7.2645×1011 | 1.1901×105 | 2.5985 | -19.6143 | -2.5235 | / | / |

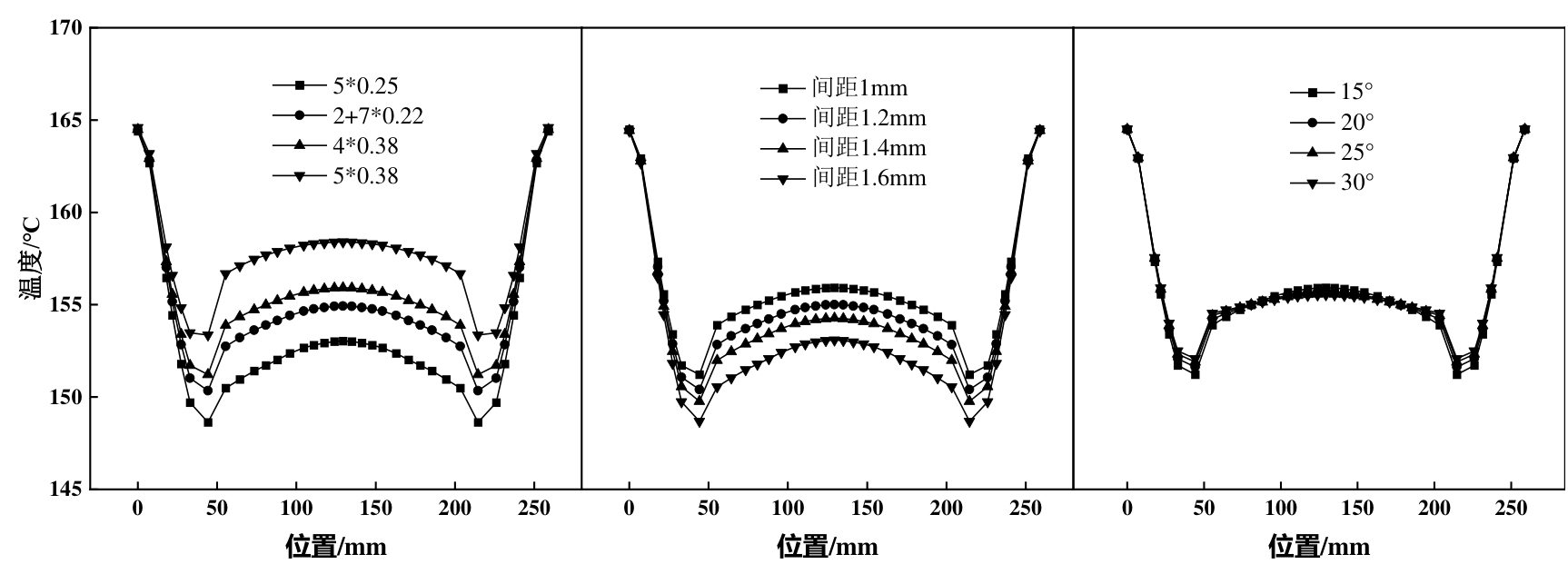

图11 不同结构带束层机内硫化结束温度分布曲线注:(a)不同型号 (b)不同排列间距 (c)不同排列角度

Fig.11 Temperature distribution curves of vulcanization completion in the machine for belt layers with different structures

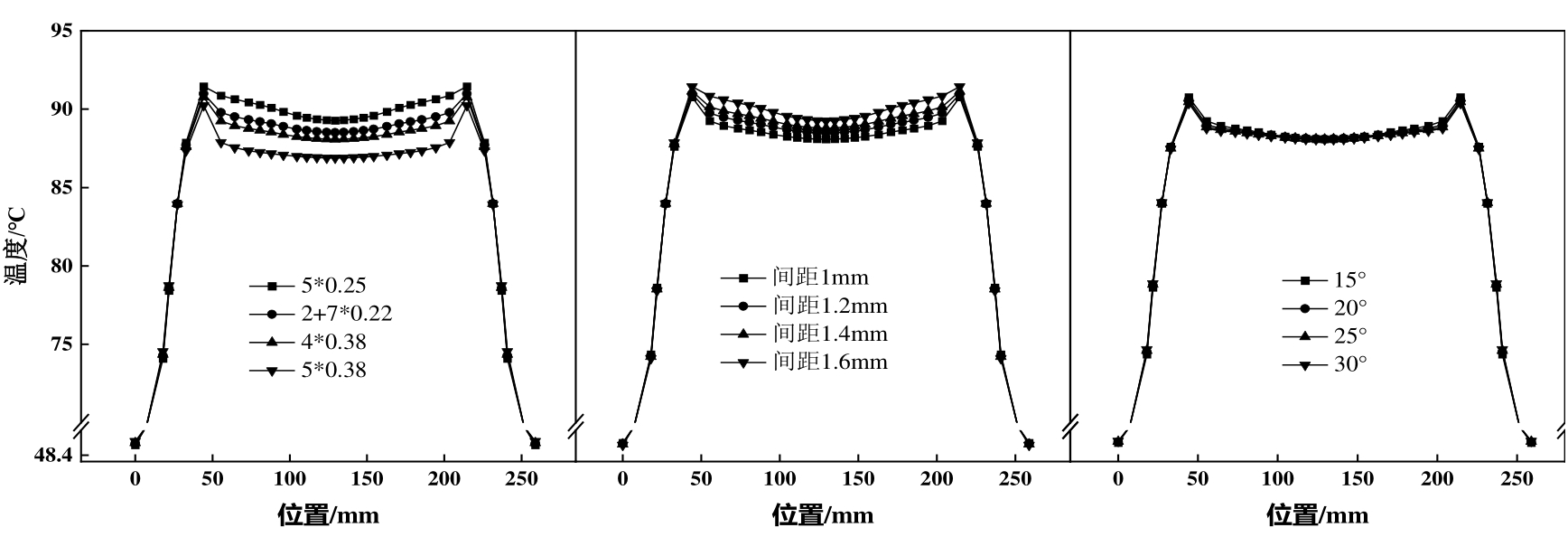

图12 不同结构带束层机外降温结束温度分布曲线注:(a) 不同型号 (b)不同排列间距 (c)不同排列角度

Fig.12 Temperature distribution curves at the end of external cooling for different structural belt layers

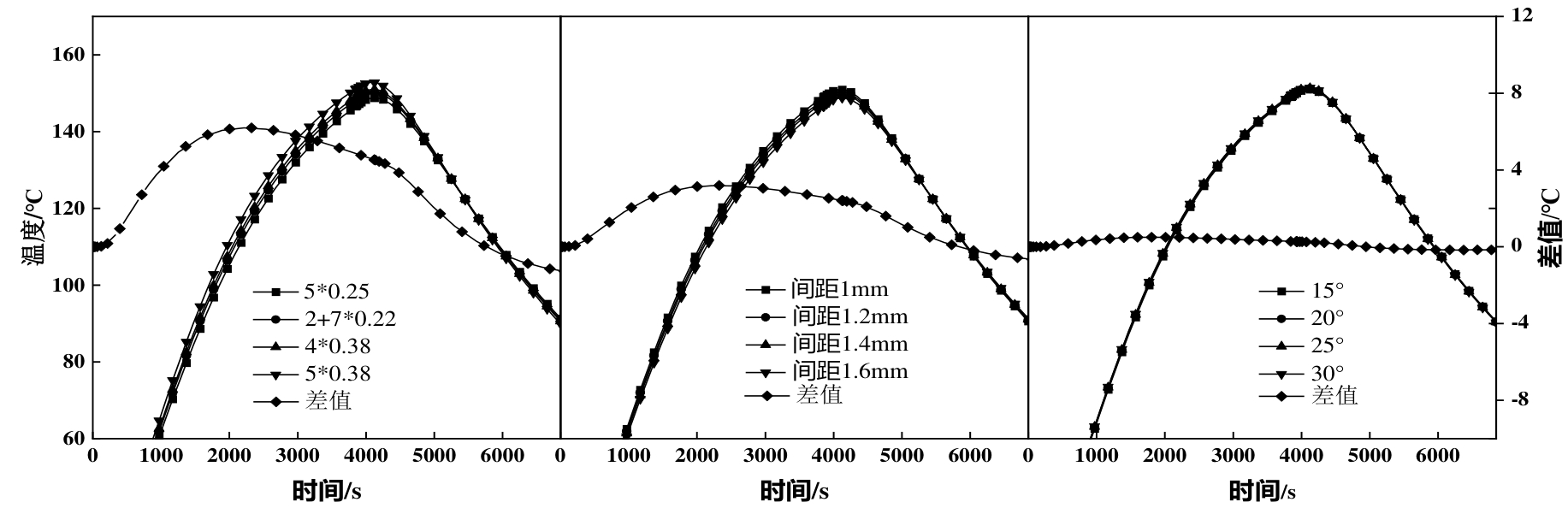

图13 不同结构带束层对胎肩部位升降温曲线影响注:(a)不同型号 (b)不同排列间距 (c)不同排列角度

Fig.13 Effect of belt layers with different structures on temperature rise and fall curves at the tire shoulder

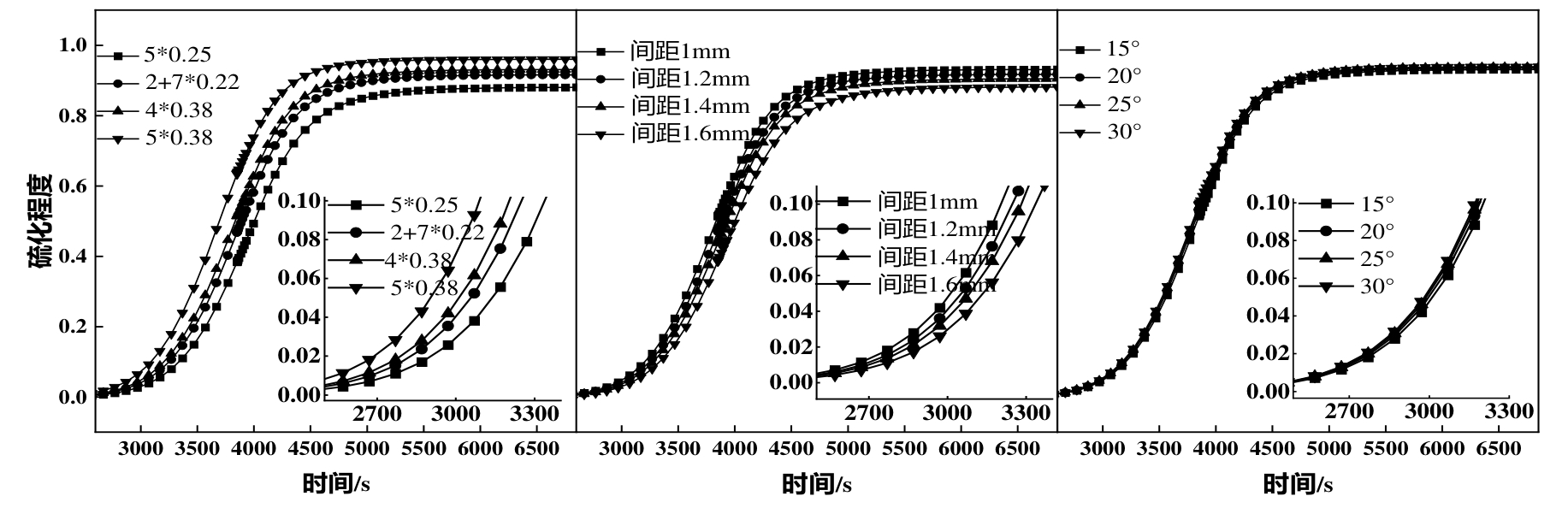

图14 不同结构带束层对胎肩部位硫化程度的影响注:(a)不同型号 (b)不同排列间距 (c)不同排列角度

Fig.14 The effect of belt layers with different structures on the vulcanization degree of the tire shoulder

| [1] | 郭飞, 张兆想, 宋炜, 等. 橡胶硫化过程数值模拟研究进展[J]. 化工学报, 2020, 71(8):3393-3402. |

| Guo F, Zhang Z X, Song W, et al. Research progress in numerical simulation of rubber vulcanization[J]. CIESC Journal, 2020, 71(8):3393-3402. | |

| [2] | Qiu W P, Wang J B, Liu W Y, et al. Structural design and mechanical analysis of a new equipment for tire vulcanization[J].Mechanics Based Design of Structures and Machines, 2023, 51(5): 2844-2860. |

| [3] | Liu C, DongY D, Wei Y L, et al. Image detection and parameterization for different components in cross-sections of radial tires[J]. Proceedings of the Institution of Mechanical Engineers Part D:Journal of Automobile Engineering, 2022, 236:287-298. |

| [4] | Wei L J, Liu H O, Chen H Y, et al. Finite element analysis of cross section of TBR tire[J]. Mechanics of Advanced Materials and Structures, 2020, 27(17):1509-1517. |

| [5] | Lenhard R, Kaduchova K, Mica A, et al. Theoretical and numerical investigation on heat transfer from vulcanization presses containers[J]. Processes, 2025, 13(4): 963. |

| [6] | 曾怀,张仟,杨超,等.仿真分析在弹性减振橡胶制品硫化时间测试中的应用[J]. 特种橡胶制品, 2022, 43(02): 46-50. |

| Zeng H, Zhang Q, Yang C, et al. Application of simulation analusis in curing time test of elastic vibretion damping rubber products [J]. Special Purpose Rubber Products., 2022, 43(2): 46-50. | |

| [7] | Zhao C L, Cao A J, Wang L, et al. Analysis of effect on temperature field of tire curing process by initial temperatures and condensate discharging[J]. Applied Thermal Engineering, 2024, 257: 124424. |

| [8] | 韩文彬, 严刚, 葛孚宇, 等. 添加碳纤维/碳纳米管复合填料的橡胶厚制品硫化过程中温度场和硫化程度模拟[J]. 橡胶工业, 2025, 72(5):323-332. |

| Han W B, Yan G, Ge F Y, et al. Simulation of temperature field and vulcanization degree of rubber thick product with CF/CNT composite filler during vulcanization process[J]. China Rubber Industry, 2025, 72(5):323-332. | |

| [9] | 周家智, 肖慧萍, 谢小林, 等. 基于多尺度模拟的橡胶/钢帘线复合材料辐射散热行为机制研究[J]. 复合材料学报, 2024, 41(10):5584-5598. |

| Zhou J Z, Xiao H P, Xie X L, et al. Study on the mechanism of radiation heat dissipation behavior of rubber/steel cord composites based on multi-scale simulation[J]. Acta Materiae Compositae Sinica, 2024, 41(10):5584-5598. | |

| [10] | Erfanian M R, Anbarsooz M, Moghiman M. A three dimensional simulation of a rubber curing process considering variable order of reaction[J]. Applied Mathematical Modelling, 2016, 40(19/20):8592-8604. |

| [11] | Chen M M, Zhao X G, He K, et al. A piecewise vulcanization kinetic model of rubber composites and application in curing process of suspension rubber bearings[J]. Polymer, 2025, 333:128608. |

| [12] | Skomorokhova A I, Glebov A O. Effect of heat generated in rubber compound vulcanization on the reaction kinetics: a numerical study[J]. Russian Journal of Applied Chemistry, 2023, 96(7): 757-761. |

| [13] | 刘舒豪. 硫化橡胶粉末超声模压成型与粘模机理研究[D]. 桂林: 桂林理工大学, 2025. |

| Liu S H. Ultrasonic moulding of vulcanised rubber powder and the mechanism of mould sticking[D]. Guilin: University of Technology, 2025. | |

| [14] | Wang Y B, Yao S J, Wang W, et al. Pyrolysis of vulcanized styrene-butadiene rubber via ReaxFF molecular dynamics simulation[J]. Chinese Journal of Chemical Engineering, 2021, 31: 94-102. |

| [15] | Lubura J, Kojic P, Pavlicevic J, et al. A novel approach for simulation and optimization of rubber vulcanization[J]. Polymers, 2023, 15(7): 1750. |

| [16] | 葛孚宇. EPDM胶管硫化-传热耦合模拟及实验研究[D]. 青岛:青岛科技大学, 2024. |

| Ge F Y. Simulation and experimental research on the coupling of vulcanization and heat transfer of EPDM rubber hoses[D]. Qingdao: Qingdao University of Science & Technology, 2024. | |

| [17] | 孙滔, 程志, 曹广如, 等. 后硫化效应对厚锥形橡胶弹簧性能影响的研究[J]. 特种橡胶制品, 2023, 44(1):50-53. |

| Sun T, Cheng Z, Cao G R, et al. Influence of post curing effect on properties of thicker conical rubber spring[J].Special Purpose Rubber Products, 2023, 44(1):50-53. | |

| [18] | 张兆想, 蔡茂坤, 任志英, 等. 温度及其波动对橡胶密封硫化过程影响的仿真分析[J]. 化工学报, 2024, 75(2):715-726. |

| Zhang Z X, Cai M K, Ren Z Y, et al. Numerical analysis of the effect of temperature and its fluctuations on the vulcanization process of rubber seals[J]. CIESC Journal, 2024, 75(2):715-726. | |

| [19] | Zhang Z X, Jia X H, Guo F, et al. Numerical analysis of heat transfer and chemical reaction coupling in the rubber seal vulcanization process[J]. Rubber Chemistry and Technology, 2022, 95(2): 342-358. |

| [20] | 蔡茂坤, 郭飞, 李凡珠, 等. 硫化成型工艺对橡胶密封服役性能影响的数值分析:由材料属性到制品性能[J/OL].机械工程学报,1-14[2025-08-28].. |

| Cai M K, Guo F, Li F Z, et al. Numerical analysis of the effect of vulcanization process on the service performance of rubber seals: from material properties to product performance[J/OL]. Journal of Mechanical Engineering,1-14[2025-08-28]. . | |

| [21] | Zhang Z X, Guo F, Ke Y C, et al. Effect of vulcanization on deformation behavior of rubber seals: Thermal–mechanical–chemical coupling model, numerical studies, and experimental validation[J]. Materials & Design, 2022, 224:111314. |

| [22] | Su B L, Wu J, Cui Z B, et al. Modeling of truck tire curing process by an experimental and numerical method[J]. Iranian Polymer Journal, 2015, 24(7):583-593. |

| [23] | 王小娟, 张淦超, 梁孟珠, 等. 工程机械子午线轮胎硫化仿真精度的提升[J]. 轮胎工业, 2025, 45(8):504-511. |

| Wang X J, Zhang G C, Liang M Z, et al. Improvement of vulcanization simulation accuracy for off-the-road radial tire[J]. Tire Industry, 2025, 45(8):504-511. | |

| [24] | 王梦如, 罗吉良. 12R22.5轮胎硫化过程温度场的仿真分析[J]. 中国橡胶, 2011, 27(16):36-39. |

| Wang M R, Luo J L. Simulation analysis of temperature field in 12R22.5 tire vulcanization process of 12R22.5 tire[J]. China Rubber, 2011, 27(16):36-39. | |

| [25] | 赵俣, 于庆波, 王俊博, 等. 基于CFD仿真与遗传算法的高速氧枪多参数协同优化机制[J/OL]. 吉林大学学报(工学版), 1-10[2025-12-25]. . |

| Zhao W, Yu Q B, Wang J B, et al. Multi-parameter collaborative optimization mechanism for high-speed oxygenlance based on CFD simulation and genetic algorithm[J/OL]. Journal of Jilin University (Engineering and Technology Edition), 1-10[2025-12-25]. . | |

| [26] | 李涛, 肖磊, 祝海洋,等. 基于CFD的GMAW熔滴过渡行为数值模拟研究现状[J/OL]. 机械工程学报, 1-14[2025-12-25]. . |

| Li T, Xiao L, Zhu H Y, et al. Research status of numerical simulation of GMAW metal transfer behavior based on CFD[J/OL]. Journal of Mechanical Engineering, 1-14[2025-12-25]. . | |

| [27] | 张建. 轮胎硫化特性及影响规律研究[D]. 镇江: 江苏大学, 2014. |

| Zhang J. Research on tire curing characteristics and influencing rule[D]. Zhenjiang: Jiangsu University, 2014. | |

| [28] | 陈则韶, 钱军, 叶一火. 复合材料等效导热系数的理论推算[J]. 中国科学技术大学学报, 1992, 22(4):416-424. |

| Chen Z S, Qian J, Ye Y H. Predicting theory of effective thermal conductivity of complex material[J]. Journal of University of Science and Technology, 1992, 22(4):416-424. | |

| [29] | Kamal M R, Sourour S. Kinetics and thermal characterization of thermoset cure[J]. Polymer Engineering & Science, 1973, 13(1):59-64. |

| [30] | Shao Y R, Wang G F, Han Z J,et al. Vulcanization and stress analysis of heat vulcanizing bonding joints in fabric rubber seals[J].Composite Structures,2023, 319:117180. |

| [1] | 徐佳琪, 张文君, 余燕萍, 苏宝根, 任其龙, 杨启炜. 热等离子体重整炼厂气制合成气过程数值模拟与实验研究[J]. 化工学报, 2025, 76(9): 4462-4473. |

| [2] | 赵清萍, 张敏, 赵辉, 王刚, 邱永福. 乙烯氢甲酯化合成丙酸甲酯的氢键作用机制及反应动力学研究[J]. 化工学报, 2025, 76(6): 2701-2713. |

| [3] | 麦棹铭, 武颖韬, 王维, 穆海宝, 黄佐华, 汤成龙. 正十二烷-甲烷双燃料非线性着火特性及稀释气体效应研究[J]. 化工学报, 2025, 76(6): 3115-3124. |

| [4] | 杨猛, 丁晓倩, 余涛, 刘畅, 汤成龙, 黄佐华. 甲烷/氧化亚氮绿色推进剂自着火特性实验及动力学[J]. 化工学报, 2025, 76(3): 1221-1229. |

| [5] | 雷宇寰, 赵秋阳, 董宇, 张延龙, 郭烈锦. 超临界水稠油改质反应动力学研究[J]. 化工学报, 2025, 76(11): 5544-5553. |

| [6] | 张延龙, 赵秋阳, 李章剑, 陈引, 金辉, 郭烈锦. 超临界水转化页岩生烃气反应动力学研究[J]. 化工学报, 2025, 76(11): 5594-5603. |

| [7] | 郭珊, 田雨, 徐永滨, 王朋, 刘治明. 废旧电池再资源化制备高性能中熵合金催化剂及其性能研究[J]. 化工学报, 2025, 76(1): 231-240. |

| [8] | 赵焕娟, 包颖昕, 于康, 刘婧, 钱新明. 多元组分爆轰不稳定性定量实验研究[J]. 化工学报, 2024, 75(S1): 339-348. |

| [9] | 张兆想, 蔡茂坤, 任志英, 贾晓红, 郭飞. 温度及其波动对橡胶密封硫化过程影响的仿真分析[J]. 化工学报, 2024, 75(2): 715-726. |

| [10] | 王学云, 郁肖兵, 彭万旺, 沈岩松. 熔渣气化炉喷嘴燃烧区行为的数值模拟研究[J]. 化工学报, 2024, 75(2): 659-674. |

| [11] | 卓红英, 赵忠正, 沈铮, 杨小峰, 黄延强. 正-仲氢催化转化研究进展[J]. 化工学报, 2024, 75(11): 3883-3895. |

| [12] | 程成, 段钟弟, 孙浩然, 胡海涛, 薛鸿祥. 表面微结构对析晶沉积特性影响的格子Boltzmann模拟[J]. 化工学报, 2023, 74(S1): 74-86. |

| [13] | 汪林正, 陆俞冰, 张睿智, 罗永浩. 基于分子动力学模拟的VOCs热氧化特性分析[J]. 化工学报, 2023, 74(8): 3242-3255. |

| [14] | 张蒙蒙, 颜冬, 沈永峰, 李文翠. 电解液类型对双离子电池阴阳离子储存行为的影响[J]. 化工学报, 2023, 74(7): 3116-3126. |

| [15] | 禹进, 余彬彬, 蒋新生. 一种基于虚拟组分的燃烧调控化学作用量化及分析方法研究[J]. 化工学报, 2023, 74(3): 1303-1312. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号