化工学报 ›› 2019, Vol. 70 ›› Issue (5): 1702-1712.DOI: 10.11949/j.issn.0438-1157.20180962

收稿日期:2018-08-27

修回日期:2019-02-22

出版日期:2019-05-05

发布日期:2019-05-05

通讯作者:

罗坤

作者简介:<named-content content-type="corresp-name">林俊杰</named-content>(1993—), 男,硕士研究生,<email>linjunjie@zju.edu.cn</email>|罗坤(1977—),男,博士,教授,<email>zjulk@zju.edu.cn</email>

基金资助:

Junjie LIN( ),Kun LUO(

),Kun LUO( ),Shuai WANG,Chenshu HU,Jianren FAN

),Shuai WANG,Chenshu HU,Jianren FAN

Received:2018-08-27

Revised:2019-02-22

Online:2019-05-05

Published:2019-05-05

Contact:

Kun LUO

摘要:

传统CFD-DEM方法的计算量随着系统内颗粒数目的增加而显著增加,coarse-grained CFD-DEM(粗颗粒)方法将若干个真实颗粒打包成虚拟颗粒从而显著减小系统计算量。在coarse-grained CFD-DEM方法进行应用之前,对其进行广泛的验证是有必要的。采用coarse-grained CFD-DEM方法模拟得到不同流态流化床的气固流动特征(固含率、压降、颗粒速度等),与传统CFD-DEM和实验测量吻合较好。另外,系统的计算效率随着粗颗粒放大系数的增加显著提升。研究表明,粗颗粒方法能够以较小的计算精度损失而使计算速度大幅提升,能够适用于大尺度稠密气固流动系统的模拟。

中图分类号:

林俊杰, 罗坤, 王帅, 胡陈枢, 樊建人. coarse-grained CFD-DEM方法在不同流态流化床中的模拟验证[J]. 化工学报, 2019, 70(5): 1702-1712.

Junjie LIN, Kun LUO, Shuai WANG, Chenshu HU, Jianren FAN. Verification of coarse-grained CFD-DEM method in multiple flow regimes[J]. CIESC Journal, 2019, 70(5): 1702-1712.

| Parameter | Value |

|---|---|

| particle diameter/mm | 3.256 |

| particle density/(kg?m-3) | 1131 |

| original number of particles | 95000 |

| restitution coefficient | 0.97 |

| friction coefficient | 0.35 |

| collision spring constant/(N?m-1) | 800 |

| parcel diameter of CGP-k1.5/mm | 4.884 |

| parcel number of CGP-k1.5 | 28148 |

| parcel diameter of CGP-k2/mm | 6.512 |

| parcel number of CGP-k2 | 11875 |

| fluid density/(kg?m-3) | 1.205 |

| dynamic viscosity/(Pa·s) | 1.8 × 10-5 |

| superficial velocity/(m?s-1) | 2.1 |

表1 物性参数(鼓泡流化床)

Table 1 Physical properties and parameters(bubbling fluidized bed)

| Parameter | Value |

|---|---|

| particle diameter/mm | 3.256 |

| particle density/(kg?m-3) | 1131 |

| original number of particles | 95000 |

| restitution coefficient | 0.97 |

| friction coefficient | 0.35 |

| collision spring constant/(N?m-1) | 800 |

| parcel diameter of CGP-k1.5/mm | 4.884 |

| parcel number of CGP-k1.5 | 28148 |

| parcel diameter of CGP-k2/mm | 6.512 |

| parcel number of CGP-k2 | 11875 |

| fluid density/(kg?m-3) | 1.205 |

| dynamic viscosity/(Pa·s) | 1.8 × 10-5 |

| superficial velocity/(m?s-1) | 2.1 |

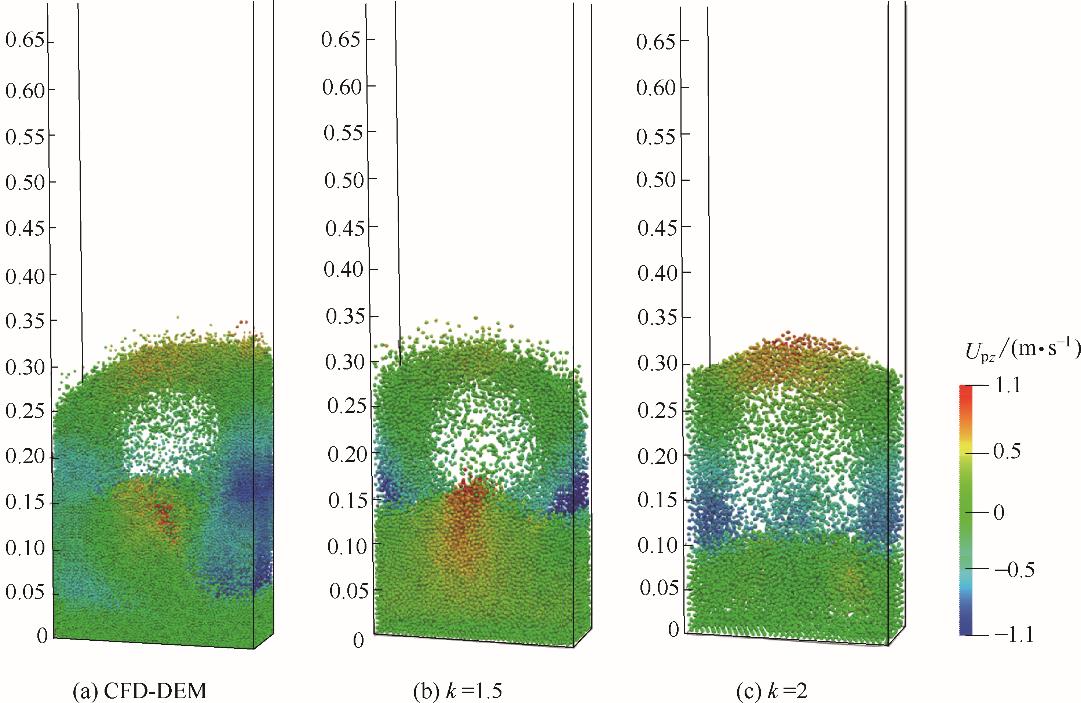

图2 传统CFD-DEM与coarse-grained CFD-DEM模拟所得鼓泡床中颗粒速度瞬态分布(t = 30 s)

Fig.2 Transient distribution of particle velocity in bubbling fluidized bed simulated by traditional and coarse-grained CFD-DEM

| Parameter | Value |

|---|---|

| particle diameter/mm | 4.04 |

| particle density/(kg?m-3) | 2526 |

| original number of particles | 44800 |

| restitution coefficient | 0.97 |

| friction coefficient | 0.33 |

| collision spring constant/(N?m-1) | 800 |

| parcel diameter of CGP-k1.5/mm | 6.06 |

| parcel number of CGP-k1.5 | 13274 |

| parcel diameter of CGP-k2/mm | 8.08 |

| parcel number of CGP-k2 | 5600 |

| fluid density/(kg?m-3) | 1.205 |

| dynamic viscosity/(Pa·s) | 1.8 × 10-5 |

| spouting velocity/(m?s-1) | 65 |

| background velocity/(m?s-1) | 3.5 |

表2 物性参数(喷动床流化床)

Table 2 Physical properties and parameters(spouting fluidized bed)

| Parameter | Value |

|---|---|

| particle diameter/mm | 4.04 |

| particle density/(kg?m-3) | 2526 |

| original number of particles | 44800 |

| restitution coefficient | 0.97 |

| friction coefficient | 0.33 |

| collision spring constant/(N?m-1) | 800 |

| parcel diameter of CGP-k1.5/mm | 6.06 |

| parcel number of CGP-k1.5 | 13274 |

| parcel diameter of CGP-k2/mm | 8.08 |

| parcel number of CGP-k2 | 5600 |

| fluid density/(kg?m-3) | 1.205 |

| dynamic viscosity/(Pa·s) | 1.8 × 10-5 |

| spouting velocity/(m?s-1) | 65 |

| background velocity/(m?s-1) | 3.5 |

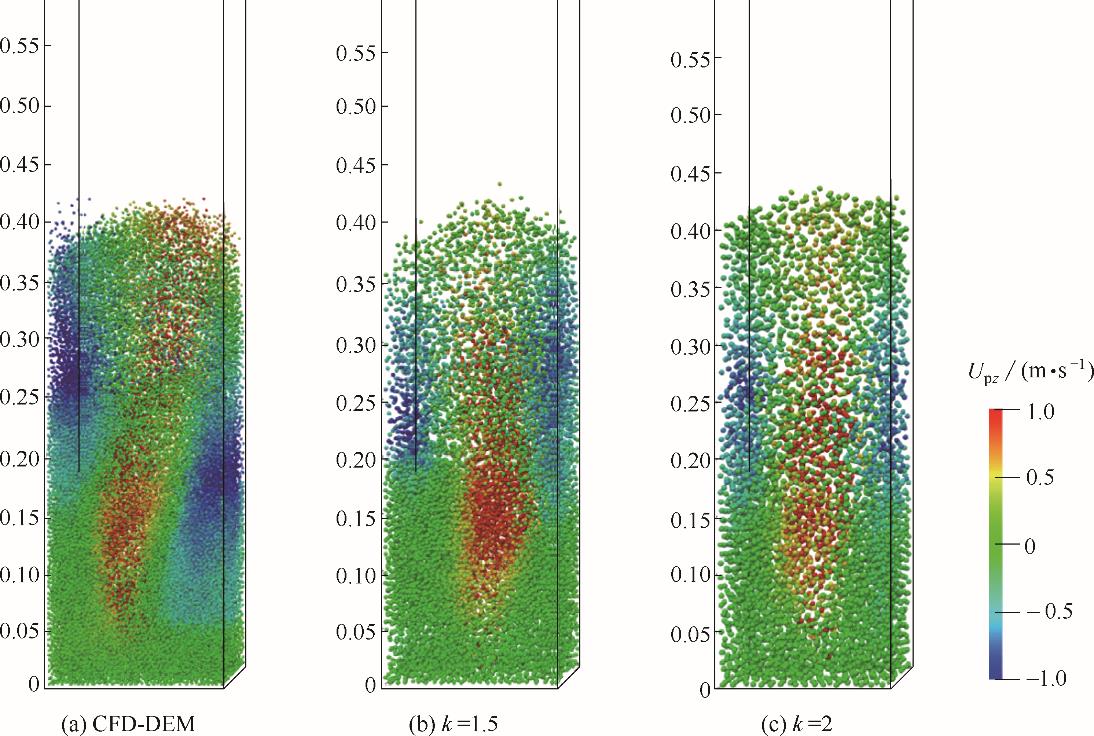

图7 传统CFD-DEM与coarse-grained CFD-DEM模拟所得喷动床中颗粒速度瞬态分布(t = 30 s)

Fig.7 Transient distribution of particle velocity in spouting fluidized bed simulated by traditional and coarse-grained CFD-DEM

| 1 | Erkiaga A , Lopez G , Amutio M , et al . Influence of operating conditions on the steam gasification of biomass in a conical spouted bed reactor[J]. Chemical Engineering Journal, 2014, 237:259-267. |

| 2 | Li T , Zhang Y , Grace J R , et al . Numerical investigation of gas mixing in gas-solid fluidized beds[J]. AIChE Journal, 2010, 56(9):2280-2296. |

| 3 | Braga M B , Wang Z , Grace J R , et al . Slot-rectangular spouted bed: hydrodynamic stability and effects of operating conditions on drying performance[J]. Drying Technology, 2015, 33(2):216-226. |

| 4 | Amirjan M , Khorsand H , Khorasani M . Fluidized bed coating efficiency and morphology of coatings for producing Al-based nanocomposite hollow spheres[J]. International Journal of Minerals, Metallurgy, and Materials, 2014, 21(11):1146-1151. |

| 5 | 周池楼, 赵永志 . 离散单元法及其在流态化领域的应用 [J]. 化工学报, 2014, 65(7): 2520-2534. |

| Zhou C L , Zhao Y Z . Discrete element method and its applications in fluidization[J]. CIESC Journal, 2014, 65(7):2520-2534. | |

| 6 | Zhang K , Luo K , Fan J R . TFM and DEM numerical simulation of bubbling fluidized bed with uniform gas inlet [J]. Journal of Engineering Thermophysics, 2011, 32(12): 2076-2079. |

| 7 | Sun L Y , Luo K , Fan J R . Numerical investigation on methanation kinetic and flow behavior in full-loop fluidized bed reactor [J]. Fuel, 2018, 231: 85-93. |

| 8 | Sun L Y , Luo K , Fan J R . Production of synthetic natural gas by CO methanation over Ni/Al2O3 catalyst in fluidized bed reactor [J]. Catal. Commun., 2018, 105: 37-42. |

| 9 | Sun L Y , Luo K , Fan J R . Numerical study on flow behavior of ultrafine powders in conical spouted bed with coarse particles[J]. Chemical Engineering Research and Design, 2017, 125 :461-470. |

| 10 | Wang Q G , Feng Y Q , Lu J F , et al . Numerical study of particle segregation in a coal beneficiation fluidized bed by a TFM-DEM hybrid model: influence of coal particle size and density[J]. Chemical Engineering Journal, 2015, 260:240-257. |

| 11 | 万晓涛, 郑雨, 魏飞, 等 . 循环流化床提升管气固湍流的计算流体力学模拟——k-ε-k p-ε p-Θ 5参数双流体模型 [J]. 化工学报, 2002, 53(5): 461-468. |

| Wan X T , Zheng Y , Wei F , et al .Numerical simulation of gas-solid turbulent flow in riser reactor——k-ε-k p-ε p-Θ two-phase flow model[J]. Journal of Chemical Industry and Engineering (China), 2002, 53(5): 461-468. | |

| 12 | Wang S , Luo K , HU C S , et al . CFD-DEM study of the effect of cyclone arrangements on the gas-solid flow dynamics in the full-loop circulating fluidized bed [J]. Chemical Engineering Science, 2017, 172: 199-215. |

| 13 | Luo K , Wang S , Yang S L , et al . Computational fluid dynamics-discrete element method investigation of pressure signals and solid back-mixing in a full-loop circulating fluidized bed [J]. Industrial & Engineering Chemistry Research, 2017, 56(3): 799-813. |

| 14 | Yang S L , Luo K , Fan J R , et al . Particle-scale investigation of the solid dispersion and residence properties in a 3-D spout-fluid bed [J]. AIChE Journal, 2014, 60(8): 2788-2804. |

| 15 | Yang S L , Sun Y H , Wang J W , et al . Influence of operating parameters and flow regime on solid dispersion behavior in a gas-solid spout-fluid bed[J]. Chemical Engineering Science, 2016, 142:112-125. |

| 16 | Wang S , Luo K , Yang S , et al . Parallel LES-DEM simulation of dense flows in fluidized beds[J]. Applied Thermal Engineering, 2017, 111: 1523-1535. |

| 17 | Tsuji Y , Kawaguchi T , Tanaka T . Discrete particle simulation of two-dimensional fluidized bed[J]. Powder Technology, 1993, 77(1): 79-87. |

| 18 | Washino K , Hsu C H , Kawaguchi T , et al . Similarity model for DEM simulation of fluidized bed[J]. Journal of the Society of Powder Technology, 2007, 44(3): 198-205. |

| 19 | Sakai M , Abe M , Shigeto Y , et al . Verification and validation of a coarse grain model of the DEM in a bubbling fluidized bed[J]. Chemical Engineering Journal, 2014, 244:33-43. |

| 20 | Sakai M , Yamada Y , Shigeto Y , et al . Large-scale discrete element modeling in a fluidized bed[J]. International Journal for Numerical Methods in Fluids, 2010, 64(10/11/12):1319-1335. |

| 21 | Lu L Q , Benyahia S , Li T . An efficient and reliable predictive method for fluidized bed simulation[J]. AIChE Journal, 2017, 63(12): 5320-5334. |

| 22 | Yang S L , Cahyadi A , Sun Y , et al . CFD-DEM investigation into the scaling up of spout-fluid beds via two interconnected chambers [J]. AIChE Journal, 2016, 62(6): 1898-1916. |

| 23 | Yang S L , Cahyadi A , Wang J , et al . DEM study of granular flow characteristics in the active and passive regions of a three-dimensional rotating drum [J]. AIChE Journal, 2016, 62(11): 3874-3888. |

| 24 | Yang S L , Luo K , Qiu K , et al . Coupled computational fluid dynamics and discrete element method study of the solid dispersion behavior in an internally circulating fluidized bed [J]. Industrial & Engineering Chemistry Research, 2014, 53(16): 6759-6772. |

| 25 | Yang S L , Luo K , Fang M , et al . Discrete element study of solid mixing behavior with temperature difference in three-dimensional bubbling fluidized bed [J]. Industrial & Engineering Chemistry Research, 2014, 53(17): 7043-7055. |

| 26 | Hu C S , Luo K , Yang S L , et al . A comprehensive numerical investigation on the hydrodynamics and erosion characteristics in a pressurized fluidized bed with dense immersed tube bundles [J]. Chemical Engineering Science, 2016, 153: 129-145. |

| 27 | Smagorinsky J . General circulation experiments with the primitive equations [J]. Monthly Weather Review, 1963, 91(3): 99-164. |

| 28 | Gidaspow D . Multiphase Flow and Fluidization: Continuum and Kinetic Theory Descriptions[M]. New York:Academic Press, 1994. |

| 29 | Lu B , Wang W , Li J . Eulerian simulation of gas-solid flows with particles of Geldart groups A, B and D using EMMS-based meso-scale model[J]. Chemical Engineering Science, 2011, 66(20): 4624-4635. |

| 30 | Lu L Q , Xu J , Ge W , et al . EMMS-based discrete particle method (EMMS-DPM) for simulation of gas-solid flows[J]. Chemical Engineering Science, 2014, 120:67-87. |

| 31 | Gopalan B , Shahnam M , Panday R , et al . Measurements of pressure drop and particle velocity in a pseudo 2-D rectangular bed with Geldart group D particles[J]. Powder Technology, 2016, 291: 299-310. |

| 32 | Luo K , Yang S L , Fang M M , et al . LES-DEM investigation of the solid transportation mechanism in a 3-D bubbling fluidized bed(I): Hydrodynamics [J]. Powder Technology, 2014, 256: 385-394. |

| 33 | Link J M , Deen N G , Kuipers J A M , et al . PEPT and discrete particle simulation study of spout‐fluid bed regimes[J]. AIChE Journal, 2008, 54(5): 1189-1202. |

| 34 | Yang S L , Luo K , Fang M M , et al . Influences of operating parameters on the hydrodynamics of a 3-D spout-fluid bed based on DEM modeling approach [J]. Chemical Engineering Journal, 2014, 247: 161-173. |

| 35 | Wang S , Luo K , Hu C S , et al . Effect of superficial gas velocity on solid behaviors in a full-loop CFB [J]. Powder Technology, 2018, 333: 91-105. |

| 36 | Luo K , Wu F , Yang S L , et al . High-fidelity simulation of the 3-D full-loop gas-solid flow characteristics in the circulating fluidized bed [J]. Chemical Engineering Science, 2015, 123: 22-38. |

| 37 | 燕兰玲, 蓝兴英, 吴迎亚, 等 . FCC提升管内气体流经颗粒聚团流动特性的模拟研究 [J]. 化学反应工程与工艺, 2014, 30(1): 41-47. |

| Yan L L , Lan X Y , Wu Y Y , et al . Numerical simulation of flow behavior of gas flowing through clusters in FCC risers [J]. Chemical Reaction Engineering and Technology, 2014, 30(1):41-47. | |

| 38 | Li J , Cheng C , Zhang Z , et al . The EMMS model — its application, development and updated concepts [J]. Chemical Engineering Science, 1999, 54(22): 5409-5425. |

| 39 | 陈程, 祁海鹰 . EMMS曳力模型及其颗粒团模型的构建和检验 [J]. 化工学报, 2014, 65(6): 2003-2012. |

| Chen C , Qi H Y . Development and validation of cluster and EMMS drag model[J]. CIESC Journal, 2014, 65(6): 2003-2012. |

| [1] | 张思雨, 殷勇高, 贾鹏琦, 叶威. 双U型地埋管群跨季节蓄热特性研究[J]. 化工学报, 2023, 74(S1): 295-301. |

| [2] | 肖明堃, 杨光, 黄永华, 吴静怡. 浸没孔液氧气泡动力学数值研究[J]. 化工学报, 2023, 74(S1): 87-95. |

| [3] | 温凯杰, 郭力, 夏诏杰, 陈建华. 一种耦合CFD与深度学习的气固快速模拟方法[J]. 化工学报, 2023, 74(9): 3775-3785. |

| [4] | 汪林正, 陆俞冰, 张睿智, 罗永浩. 基于分子动力学模拟的VOCs热氧化特性分析[J]. 化工学报, 2023, 74(8): 3242-3255. |

| [5] | 邢雷, 苗春雨, 蒋明虎, 赵立新, 李新亚. 井下微型气液旋流分离器优化设计与性能分析[J]. 化工学报, 2023, 74(8): 3394-3406. |

| [6] | 岳林静, 廖艺涵, 薛源, 李雪洁, 李玉星, 刘翠伟. 凹坑缺陷对厚孔板喉部空化流动特性影响研究[J]. 化工学报, 2023, 74(8): 3292-3308. |

| [7] | 牛超, 沈胜强, 杨艳, 潘泊年, 李熠桥. 甲烷BOG喷射器流动过程计算与性能分析[J]. 化工学报, 2023, 74(7): 2858-2868. |

| [8] | 何晓崐, 刘锐, 薛园, 左然. MOCVD生长AlN单晶薄膜的气相和表面化学反应综述[J]. 化工学报, 2023, 74(7): 2800-2813. |

| [9] | 杨峥豪, 何臻, 常玉龙, 靳紫恒, 江霞. 生物质快速热解下行式流化床反应器研究进展[J]. 化工学报, 2023, 74(6): 2249-2263. |

| [10] | 陈巨辉, 张谦, 舒崚峰, 李丹, 徐鑫, 刘晓刚, 赵晨希, 曹希峰. 基于DEM方法的旋转流化床纳米颗粒流动特性研究[J]. 化工学报, 2023, 74(6): 2374-2381. |

| [11] | 张媛媛, 曲江源, 苏欣欣, 杨静, 张锴. 循环流化床燃煤机组SNCR脱硝过程气液传质和反应特性[J]. 化工学报, 2023, 74(6): 2404-2415. |

| [12] | 刘道银, 陈柄岐, 张祖扬, 吴琰. 颗粒聚团结构对曳力特性影响的数值模拟[J]. 化工学报, 2023, 74(6): 2351-2362. |

| [13] | 李晨曦, 刘永峰, 张璐, 刘海峰, 宋金瓯, 何旭. O2/CO2氛围下正庚烷的燃烧机理研究[J]. 化工学报, 2023, 74(5): 2157-2169. |

| [14] | 董鑫, 单永瑞, 刘易诺, 冯颖, 张建伟. 非牛顿流体气泡羽流涡特性数值模拟研究[J]. 化工学报, 2023, 74(5): 1950-1964. |

| [15] | 袁子涵, 王淑彦, 邵宝力, 谢磊, 陈曦, 马一玫. 基于幂律液固曳力模型流化床内湿颗粒流动特性的研究[J]. 化工学报, 2023, 74(5): 2000-2012. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号