化工学报 ›› 2019, Vol. 70 ›› Issue (3): 913-921.DOI: 10.11949/j.issn.0438-1157.20181029

收稿日期:2018-09-13

修回日期:2018-12-12

出版日期:2019-03-05

发布日期:2019-03-05

通讯作者:

黄志甲

作者简介:黄志甲(1963—),男,博士,教授,<email>hzj@ahut.edu.cn</email>

基金资助:

Zhijia HUANG( ),Liang LUO,Rui KE,Feifei ZHUO,Liang ZHONG

),Liang LUO,Rui KE,Feifei ZHUO,Liang ZHONG

Received:2018-09-13

Revised:2018-12-12

Online:2019-03-05

Published:2019-03-05

Contact:

Zhijia HUANG

摘要:

将亲水无纺布PVC复合规整填料作为溶液除湿塔芯体,开展亲水无纺布PVC复合规整填料除湿性能实验,分析在不同空气流量、溶液流量、溶液温度下,亲水无纺布PVC复合规整填料除湿率、除湿效率、传质系数和传热系数的变化。在实验条件下,除湿率、除湿效率、传质系数、传热系数最大值分别为11.05 g·kg-1、86.7%、12.95 g·(m2·s)-1、10.33 W·(m2·℃)-1;与CELdek规整填料和塑料波纹孔板填料相比,亲水无纺布PVC复合规整填料除湿性能最优。对实验数据回归分析,得到亲水无纺布PVC复合规整填料除湿效率实验关联式。

中图分类号:

黄志甲, 罗良, 柯瑞, 卓飞飞, 钟亮. 亲水无纺布PVC复合规整填料除湿性能实验[J]. 化工学报, 2019, 70(3): 913-921.

Zhijia HUANG, Liang LUO, Rui KE, Feifei ZHUO, Liang ZHONG. Dehumidification performance experiment of hydrophilic non-woven PVC composite structured packing[J]. CIESC Journal, 2019, 70(3): 913-921.

| Fresh air temperature/℃ | Fresh air moisture content/ (g·kg-1) | Fresh air flow/ (kg·s-1) | Liquid temperature/ ℃ | Liquid concentration/% | Liquid flow/ (kg·s-1) |

|---|---|---|---|---|---|

| 27.7—28.7 | 15.4—16.3 | 0.067—0.2 | 7—23 | 41.2—42.4 | 0.06—0.22 |

表1 实验参数范围

Table 1 Range of experimental parameter

| Fresh air temperature/℃ | Fresh air moisture content/ (g·kg-1) | Fresh air flow/ (kg·s-1) | Liquid temperature/ ℃ | Liquid concentration/% | Liquid flow/ (kg·s-1) |

|---|---|---|---|---|---|

| 27.7—28.7 | 15.4—16.3 | 0.067—0.2 | 7—23 | 41.2—42.4 | 0.06—0.22 |

| Parameter | Equipment name | Model | Accuracy | Measuring range |

|---|---|---|---|---|

| air | ||||

| flow | air volume cover | TSI-8380 | ± 3%, ± 10 m3·h-1 | 40—4000 m3·h-1 |

| pressure drop | wind pressure meter | ZC1000-1F | ± 1 Pa | 0—±3000 Pa |

| temperature and humidity | temperature and humidity loggers | TR-72wf | ± 0.3℃,± 5% RH | -10—60℃,10%—95% RH |

| liquid | ||||

| temperature | T-type thermocouple | TT-T-24-SLE | ± 0.1℃ | -200—260℃ |

| flow | rotameter | LZT-25S25D | ± 4% | 250—2500 L·h-1 |

| concentration | electronic balance | AUW120D | ± 0.01 mg | 0.01—42 g |

表2 测试仪器参数

| Parameter | Equipment name | Model | Accuracy | Measuring range |

|---|---|---|---|---|

| air | ||||

| flow | air volume cover | TSI-8380 | ± 3%, ± 10 m3·h-1 | 40—4000 m3·h-1 |

| pressure drop | wind pressure meter | ZC1000-1F | ± 1 Pa | 0—±3000 Pa |

| temperature and humidity | temperature and humidity loggers | TR-72wf | ± 0.3℃,± 5% RH | -10—60℃,10%—95% RH |

| liquid | ||||

| temperature | T-type thermocouple | TT-T-24-SLE | ± 0.1℃ | -200—260℃ |

| flow | rotameter | LZT-25S25D | ± 4% | 250—2500 L·h-1 |

| concentration | electronic balance | AUW120D | ± 0.01 mg | 0.01—42 g |

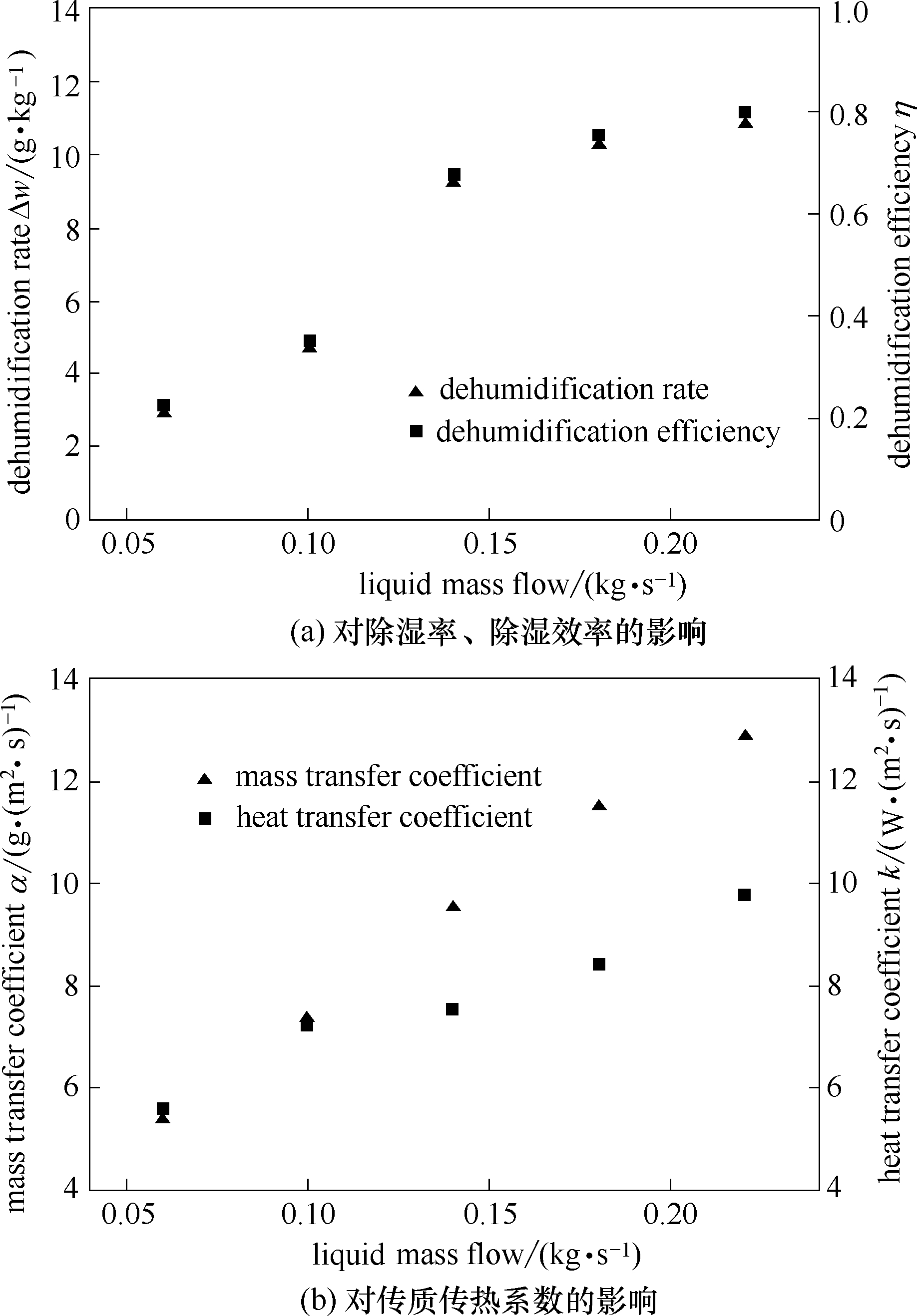

图4 溶液流量对亲水无纺布PVC复合规整填料除湿性能的影响

Fig.4 Effect of liquid flow rate on dehumidification performance of hydrophilic non-woven PVC composite structured packing

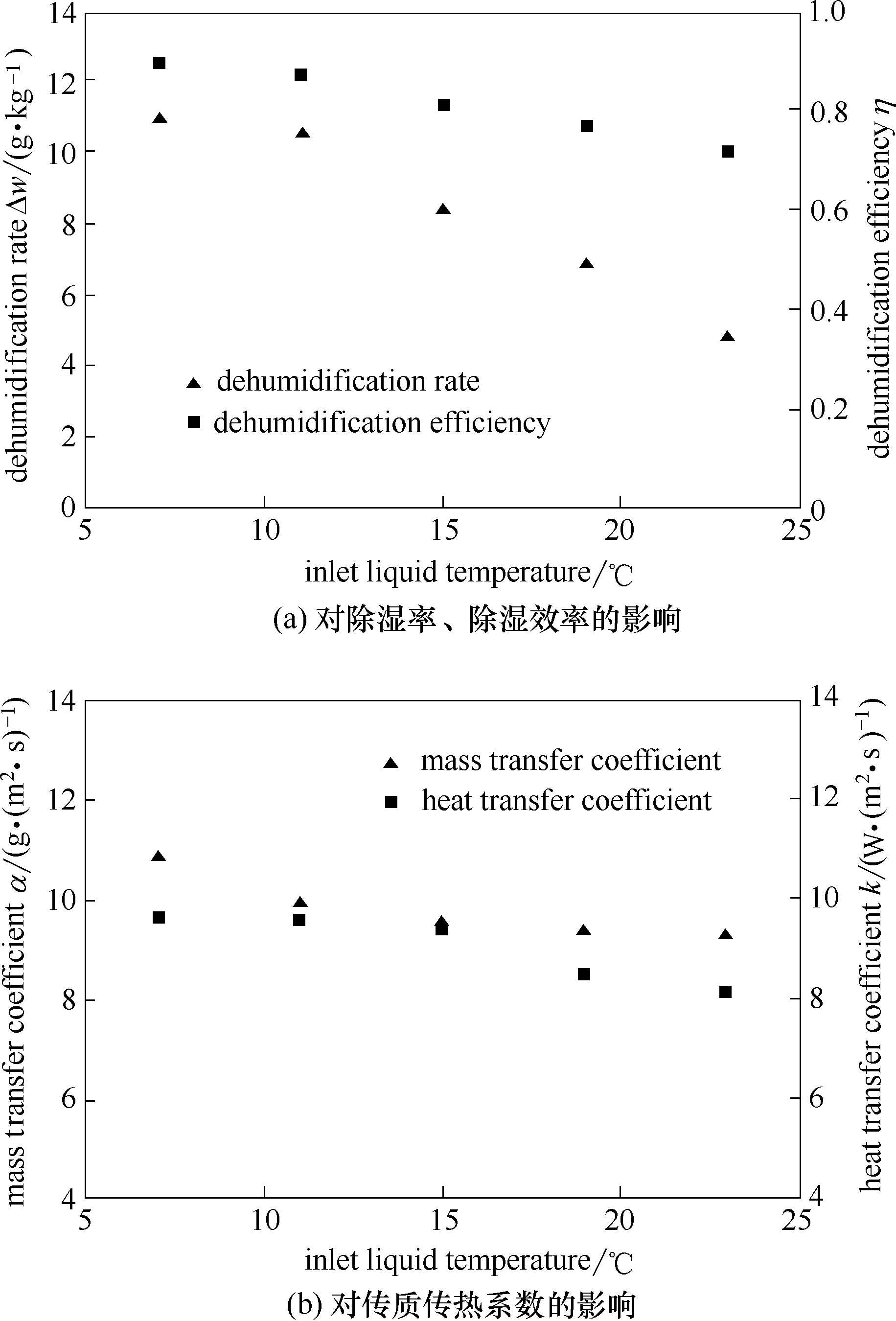

图5 进口溶液温度对亲水无纺布PVC复合规整填料除湿性能的影响

Fig.5 Effect of inlet liquid temperature on dehumidification performance of hydrophilic non-woven PVC composite structured packing

| Ref. | Packing type | Air mass flow/(kg·s-1) | Liquid mass flow/(kg·s-1) | Liquid temperature/℃ | Experimental result | |

|---|---|---|---|---|---|---|

35%LiCl[ | plant fiber packing(CELdek) | range | 0.055—0.178 | 0.06—0.085 | 20.5—29.3 | |

| α | ↑ | / | ↓ | 3.1—12.3 g·(m2·s)-1 | ||

34%LiCl[ | plastic corrugated-hole plate packing | range | 0.038—0.113 | 0.005—0.2 | 15 | |

| α | ↑ | ↓ | / | 2—10 g·(m2·s)-1 | ||

33%LiCl[ | paper corrugated structured packing | range | 0.171—0.241 | 0.08—0.24 | 38.3—39.4 | |

| k | ↑ | ↑ | / | 3.1—5.3W·(m2·℃)-1 | ||

30%LiCl[ | inorganic packing(GLASdek) | range | 0.2 | 0.082—0.198 | 15.3—20.6 | |

| k | / | ↑ | ↓ | 2.8—4.3 W·(m2·℃)-1 | ||

43%LiBr[ | plant fiber packing(CELdek) | range | 0.378—0.521 | 0.475—0.994 | 22.2—26.7 | |

| η | ↓ | ↑ | ↓ | 0.552—0.639 | ||

this paper (42%LiBr) | hydrophilic non-woven PVC composite structure packing | range | 0.067—0.2 | 0.06—0.22 | 7—23 | |

| η | ↓ | ↑ | ↓ | 0.224—0.896 | ||

| α | ↑ | ↑ | ↓ | 5.39—12.95 g·(m2·s)-1 | ||

| k | ↑ | ↑ | ↓ | 5.6—10.3 W·(m2·℃)-1 |

表3 与文献中填料除湿性能的对比

Table 3 Comparison with dehumidification performance of packing in literatures

| Ref. | Packing type | Air mass flow/(kg·s-1) | Liquid mass flow/(kg·s-1) | Liquid temperature/℃ | Experimental result | |

|---|---|---|---|---|---|---|

35%LiCl[ | plant fiber packing(CELdek) | range | 0.055—0.178 | 0.06—0.085 | 20.5—29.3 | |

| α | ↑ | / | ↓ | 3.1—12.3 g·(m2·s)-1 | ||

34%LiCl[ | plastic corrugated-hole plate packing | range | 0.038—0.113 | 0.005—0.2 | 15 | |

| α | ↑ | ↓ | / | 2—10 g·(m2·s)-1 | ||

33%LiCl[ | paper corrugated structured packing | range | 0.171—0.241 | 0.08—0.24 | 38.3—39.4 | |

| k | ↑ | ↑ | / | 3.1—5.3W·(m2·℃)-1 | ||

30%LiCl[ | inorganic packing(GLASdek) | range | 0.2 | 0.082—0.198 | 15.3—20.6 | |

| k | / | ↑ | ↓ | 2.8—4.3 W·(m2·℃)-1 | ||

43%LiBr[ | plant fiber packing(CELdek) | range | 0.378—0.521 | 0.475—0.994 | 22.2—26.7 | |

| η | ↓ | ↑ | ↓ | 0.552—0.639 | ||

this paper (42%LiBr) | hydrophilic non-woven PVC composite structure packing | range | 0.067—0.2 | 0.06—0.22 | 7—23 | |

| η | ↓ | ↑ | ↓ | 0.224—0.896 | ||

| α | ↑ | ↑ | ↓ | 5.39—12.95 g·(m2·s)-1 | ||

| k | ↑ | ↑ | ↓ | 5.6—10.3 W·(m2·℃)-1 |

| Type | Specific surface area/ (m2·m-3) | Porosity/ (m3·m-3) | Peak height/mm | Peak distance/mm |

|---|---|---|---|---|

| Type 1 | 358 | 0.89 | 6 | 36 |

| Type 2 | 350 | 0.92 | 12 | 30 |

| Type 3 | 396 | 0.94 | 7 | 25 |

表4 三种规整填料的结构参数

Table 4 Structural parameters of three structured packings

| Type | Specific surface area/ (m2·m-3) | Porosity/ (m3·m-3) | Peak height/mm | Peak distance/mm |

|---|---|---|---|---|

| Type 1 | 358 | 0.89 | 6 | 36 |

| Type 2 | 350 | 0.92 | 12 | 30 |

| Type 3 | 396 | 0.94 | 7 | 25 |

| 1 | OliveiraA C, AfonsoC F, RiffatS B, et al. Thermal performance of a novel air conditioning system using a liquid desiccant [J]. Applied Thermal Engineering, 2000, 20(13): 1213-1223. |

| 2 | LazzarinR M, CastellottiF. A new heat pump desiccant dehumidifier for supermarket application[J]. Energy & Buildings, 2007, 39(1): 59-65. |

| 3 | FuH X, LiuX H. Review of the impact of liquid desiccant dehumidification on indoor air quality[J]. Building & Environment, 2017, 116: 158-172. |

| 4 | ParkJ Y, YoonD S, LiS, et al. Empirical analysis of indoor air quality enhancement potential in a liquid-desiccant assisted air conditioning system[J]. Building & Environment, 2017, 121: 11-25. |

| 5 | 黄志甲, 鲁月红, 雷博, 等. 溴化锂溶液除湿器的实验研究[J]. 化工学报, 2010, 61(S2):81-85. |

| HuangZ J, LuY H, LeiB, et al. Experiment on performance of LiBr-liquid desiccant dehumidification[J]. CIESC Journal, 2010, 61(S2): 81-85. | |

| 6 | DongC, LuL, WenT, et al. Experimental study on dehumidification performance enhancement by TiO2 superhydrophilic coating for liquid desiccant plate dehumidifiers[J]. Building & Environment, 2017, 124: 219-231. |

| 7 | 钱俊飞, 殷勇高, 潘雄伟, 等. 平板降膜溶液除湿再生过程实验研究及模型验证[J]. 化工学报, 2014, 65(6): 2070-2077. |

| QianJ F, YinY G, PanX W, et al. Experimental investigation and model validation for liquid desiccant dehumidification and regeneration in falling-film plate[J]. CIESC Journal, 2014, 65(6): 2070-2077. | |

| 8 | 李群生, 马文涛, 张泽廷. 塔填料的研究现状及发展趋势[J]. 化工进展, 2005, 24(6):619-624. |

| LiQ S , MaW T, ZhangZ T. Research and development trend of column packing[J]. Chemical Industry and Engineering Progress, 2005, 24(6): 619-624. | |

| 9 | 贾绍义, 吴松海, 李杰, 等. 聚丙烯填料表面处理对润湿及传质性能的影响[J]. 化工学报, 2000, 51(6):832-835. |

| JiaS Y, WuS H, LiJ, et al. Influence of surface treatment of polypropylene packing on its wettability and mass transfer performance[J]. Journal of Chemical Industry and Engineering(China), 2000, 51(6): 832-835. | |

| 10 | 贾绍义, 李锡源, 王恩祥. 金属填料表面处理对润湿及传质性能的影响[J]. 化工学报, 1995, 51(1): 112-116. |

| JiaS Y, LiX Y, WangE X. Influence of surface treatment of metallic packing on its wettability and mass transfer performance[J]. Journal of Chemical Industry and Engineering(China), 1995, 51(1): 112-116. | |

| 11 | LiK, ShenK, HuangZ H, et al. Wettability of natural microcrystalline graphite filler with pitch in isotropic graphite preparation[J]. Fuel, 2016, 180: 743-748. |

| 12 | YangJ, HuangJ, YeZ, et al. Influence of interfacial reaction on reactive wettability of molten Ag-Cu-X wt.%Ti filler metal on SiC ceramic substrate and mechanism analysis[J]. Applied Surface Science, 2018, 436: 768-778. |

| 13 | ChenH Y, WangX C, FuL, et al. Effects of surface microstructure on the active element content and wetting behavior of brazing filler metal during brazing Ti3SiC2 ceramic and Cu[J]. Vacuum, 2018, 156: 256-263. |

| 14 | DongC, LuL, WenT, et al. Experimental study on dehumidification performance enhancement by TiO2 superhydrophilic coating for liquid desiccant plate dehumidifiers[J]. Building & Environment, 2017, 124: 219-231. |

| 15 | QiR, HuY, WangY, et al. A new approach to enhance the heat and mass transfer of liquid desiccant dehumidification with a titanium dioxide superhydrophilic self-cleaning coating[J]. Journal of Cleaner Production, 2016, 112: 3555-3561. |

| 16 | LiZ, HiharaE, MatsuokaF, et al. Experimental analysis of mass transfer in adiabatic structured packing dehumidifier/regenerator with liquid desiccant[J]. International Journal of Heat & Mass Transfer, 2010, 53(13): 2856-2863. |

| 17 | WangL, XiaoF, ZhangX, et al. An experimental study on the dehumidification performance of a counter flow liquid desiccant dehumidifier[J]. International Journal of Refrigeration, 2016, 70: 289-301. |

| 18 | 张欢, 李春茹, 李博佳. 金属填料型吸收式除湿器的除湿性能研究[J]. 暖通空调, 2009, 39(9): 46-50. |

| ZhangH, LiC R, LiB J. Research of dehumidification performance of a metal filler absorbing-type dehumidifier[J]. Heating Ventilating & Air Conditioning, 2009, 39(9): 46-50. | |

| 19 | FuX, GeG, NiuX. Control performance of a dedicated outdoor air system adopting liquid desiccant dehumidification[J]. Applied Energy, 2011, 88(1): 143-149. |

| 20 | YinY, ZhangX. A new method for determining coupled heat and mass transfer coefficients between air and liquid desiccant[J]. International Journal of Heat & Mass Transfer, 2008, 51(13): 3287-3297. |

| 21 | ElsarragE, MagzoubE E M, JainS. Mass-transfer correlations for dehumidification of air by triethylene glycol in a structured packed column[J]. Industrial & Engineering Chemistry Research, 2004, 43(23): 7676-7681. |

| 22 | 王凌士, 肖赋, 陆韬. 高效填料型除湿器新传质关联式实验研究 [J]. 制冷学报, 2017, 38(6): 1-6. |

| WangL S, XiaoF, LuT. New experimental correlations for the mass transfer of a high-efficiency packed-type dehumidifier[J]. Journal of Refrigeration, 2017, 38(6): 1-6. | |

| 23 | ChungT W. Predictions of moisture removal efficiencies for packed-bed dehumidification systems[J]. Gas Separation & Purification, 1994, 8(4): 265-268. |

| 24 | TsairW C, ChungL M. Vapor pressures of the aqueous desiccants[J]. Journal of Chemical & Engineering Data, 1999, 44(5): 1024-1027. |

| 25 | ZurigatY H, Abu-ArabiM K, Abdul-WahabS A. Dehumidification by triethylene glycol desiccant in a packed column[J]. Energy Conversion & Management, 2004, 45(1): 141-155. |

| 26 | YinY G, ZhangX S. A new method for determining coupled heat and mass transfer coefficients between air and liquid desiccant[J]. International Journal of Heat & Mass Transfer, 2008, 51(13): 3287-3297. |

| 27 | LiZ, HiharaE, MatsuokaF, et al. Experimental analysis of mass transfer in adiabatic structured packing dehumidifier/regenerator with liquid desiccant[J]. International Journal of Heat & Mass Transfer, 2010, 53(13): 2856-2863. |

| 28 | 戴智超, 殷勇高, 张小松. 波纹填料叉流除湿性能实验研究[J]. 建筑科学, 2014, 30(12): 102-105. |

| DaiZ C, YinY G, ZhangX S. Experimental research on the performance of cross-flow dehumidification of corrugated packing[J]. Building Science, 2014, 30(12): 102-105. | |

| 29 | 陈瑶. 基于非常温溶液除湿的新型复合型空调系统研究[D]. 南京: 东南大学, 2016. |

| ChenY. Analysis of a new hybrid air-condition system dehumidified by liquid desiccant with special temperature range[D]. Nanjing:Southeast University, 2016. | |

| 30 | LiuX H, ZhangY, QuK Y, et al. Experimental study on mass transfer performances of cross flow dehumidifier using liquid desiccant[J]. Energy Conversion & Management, 2006, 47(15/16): 2682-2692. |

| [1] | 晁京伟, 许嘉兴, 李廷贤. 基于无管束蒸发换热强化策略的吸附热池的供热性能研究[J]. 化工学报, 2023, 74(S1): 302-310. |

| [2] | 常明慧, 王林, 苑佳佳, 曹艺飞. 盐溶液蓄能型热泵循环特性研究[J]. 化工学报, 2023, 74(S1): 329-337. |

| [3] | 金正浩, 封立杰, 李舒宏. 氨水溶液交叉型再吸收式热泵的能量及 分析[J]. 化工学报, 2023, 74(S1): 53-63. 分析[J]. 化工学报, 2023, 74(S1): 53-63. |

| [4] | 程成, 段钟弟, 孙浩然, 胡海涛, 薛鸿祥. 表面微结构对析晶沉积特性影响的格子Boltzmann模拟[J]. 化工学报, 2023, 74(S1): 74-86. |

| [5] | 张双星, 刘舫辰, 张义飞, 杜文静. R-134a脉动热管相变蓄放热实验研究[J]. 化工学报, 2023, 74(S1): 165-171. |

| [6] | 张义飞, 刘舫辰, 张双星, 杜文静. 超临界二氧化碳用印刷电路板式换热器性能分析[J]. 化工学报, 2023, 74(S1): 183-190. |

| [7] | 陈爱强, 代艳奇, 刘悦, 刘斌, 吴翰铭. 基板温度对HFE7100液滴蒸发过程的影响研究[J]. 化工学报, 2023, 74(S1): 191-197. |

| [8] | 刘明栖, 吴延鹏. 导光管直径和长度对传热影响的模拟分析[J]. 化工学报, 2023, 74(S1): 206-212. |

| [9] | 王志国, 薛孟, 董芋双, 张田震, 秦晓凯, 韩强. 基于裂隙粗糙性表征方法的地热岩体热流耦合数值模拟与分析[J]. 化工学报, 2023, 74(S1): 223-234. |

| [10] | 李科, 文键, 忻碧平. 耦合蒸气冷却屏的真空多层绝热结构对液氢储罐自增压过程的影响机制研究[J]. 化工学报, 2023, 74(9): 3786-3796. |

| [11] | 李艺彤, 郭航, 陈浩, 叶芳. 催化剂非均匀分布的质子交换膜燃料电池操作条件研究[J]. 化工学报, 2023, 74(9): 3831-3840. |

| [12] | 王玉兵, 李杰, 詹宏波, 朱光亚, 张大林. R134a在菱形离散肋微小通道内的流动沸腾换热实验研究[J]. 化工学报, 2023, 74(9): 3797-3806. |

| [13] | 赵佳佳, 田世祥, 李鹏, 谢洪高. SiO2-H2O纳米流体强化煤尘润湿性的微观机理研究[J]. 化工学报, 2023, 74(9): 3931-3945. |

| [14] | 齐聪, 丁子, 余杰, 汤茂清, 梁林. 基于选择吸收纳米薄膜的太阳能温差发电特性研究[J]. 化工学报, 2023, 74(9): 3921-3930. |

| [15] | 杨越, 张丹, 郑巨淦, 涂茂萍, 杨庆忠. NaCl水溶液喷射闪蒸-掺混蒸发的实验研究[J]. 化工学报, 2023, 74(8): 3279-3291. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号