化工学报 ›› 2019, Vol. 70 ›› Issue (8): 3033-3039.DOI: 10.11949/j.issn.0438-1157.20190099

黄逸群1( ),张缦1,苗苗1,邓博宇1,蔡晋2,吴玉新1,吕俊复1,金燕2,杨海瑞1(

),张缦1,苗苗1,邓博宇1,蔡晋2,吴玉新1,吕俊复1,金燕2,杨海瑞1( )

)

收稿日期:2019-01-29

修回日期:2019-03-18

出版日期:2019-08-05

发布日期:2019-08-05

通讯作者:

杨海瑞

作者简介:黄逸群(1993—),男,博士研究生,<email>huangyq1993@163.com</email>

基金资助:

Yiqun HUANG1( ),Man ZHANG1,Miao MIAO1,Boyu DENG1,Jin CAI2,Yuxin WU1,Junfu LYU1,Yan JIN2,Hairui YANG1(

),Man ZHANG1,Miao MIAO1,Boyu DENG1,Jin CAI2,Yuxin WU1,Junfu LYU1,Yan JIN2,Hairui YANG1( )

)

Received:2019-01-29

Revised:2019-03-18

Online:2019-08-05

Published:2019-08-05

Contact:

Hairui YANG

摘要:

燃烧动力学是研究油页岩半焦颗粒燃烧特性的基础。利用热重分析仪对油页岩半焦进行了恒温燃烧实验研究,在排除外扩散影响的基础上,分析了燃烧温度、氧气浓度对油页岩半焦燃烧过程的影响。在实验范围内,氧气浓度和燃烧温度均能对油页岩半焦燃烧速率产生重要影响,更高的氧气浓度和燃烧温度可以加快油页岩半焦燃烧速率。结合实验结果,建立了考虑氧气浓度影响的油页岩半焦燃烧动力学模型,发现油页岩半焦燃烧速率与氧气浓度的0.97次方呈线性关系。模型计算结果与实验结果符合较好,为进一步研究油页岩半焦大颗粒燃烧特性提供了燃烧动力学基础。

中图分类号:

黄逸群, 张缦, 苗苗, 邓博宇, 蔡晋, 吴玉新, 吕俊复, 金燕, 杨海瑞. 油页岩半焦燃烧动力学研究[J]. 化工学报, 2019, 70(8): 3033-3039.

Yiqun HUANG, Man ZHANG, Miao MIAO, Boyu DENG, Jin CAI, Yuxin WU, Junfu LYU, Yan JIN, Hairui YANG. Combustion kinetics study of oil shale semi-coke[J]. CIESC Journal, 2019, 70(8): 3033-3039.

| 样品 | 工业分析/% | Qar,net/(kJ/kg) | |||

|---|---|---|---|---|---|

| Mar | Aar | Var | FCar | ||

| 桦甸油页岩 | 7.06 | 62.08 | 26.60 | 4.26 | 9517.9 |

| 桦甸油页岩半焦 | 0.64 | 83.14 | 5.74 | 10.48 | 3767.2 |

表1 实验所用油页岩样品工业分析及发热量

Table 1 Proximate analysis and heat value of Huadian oil shale semicoke used in experiments

| 样品 | 工业分析/% | Qar,net/(kJ/kg) | |||

|---|---|---|---|---|---|

| Mar | Aar | Var | FCar | ||

| 桦甸油页岩 | 7.06 | 62.08 | 26.60 | 4.26 | 9517.9 |

| 桦甸油页岩半焦 | 0.64 | 83.14 | 5.74 | 10.48 | 3767.2 |

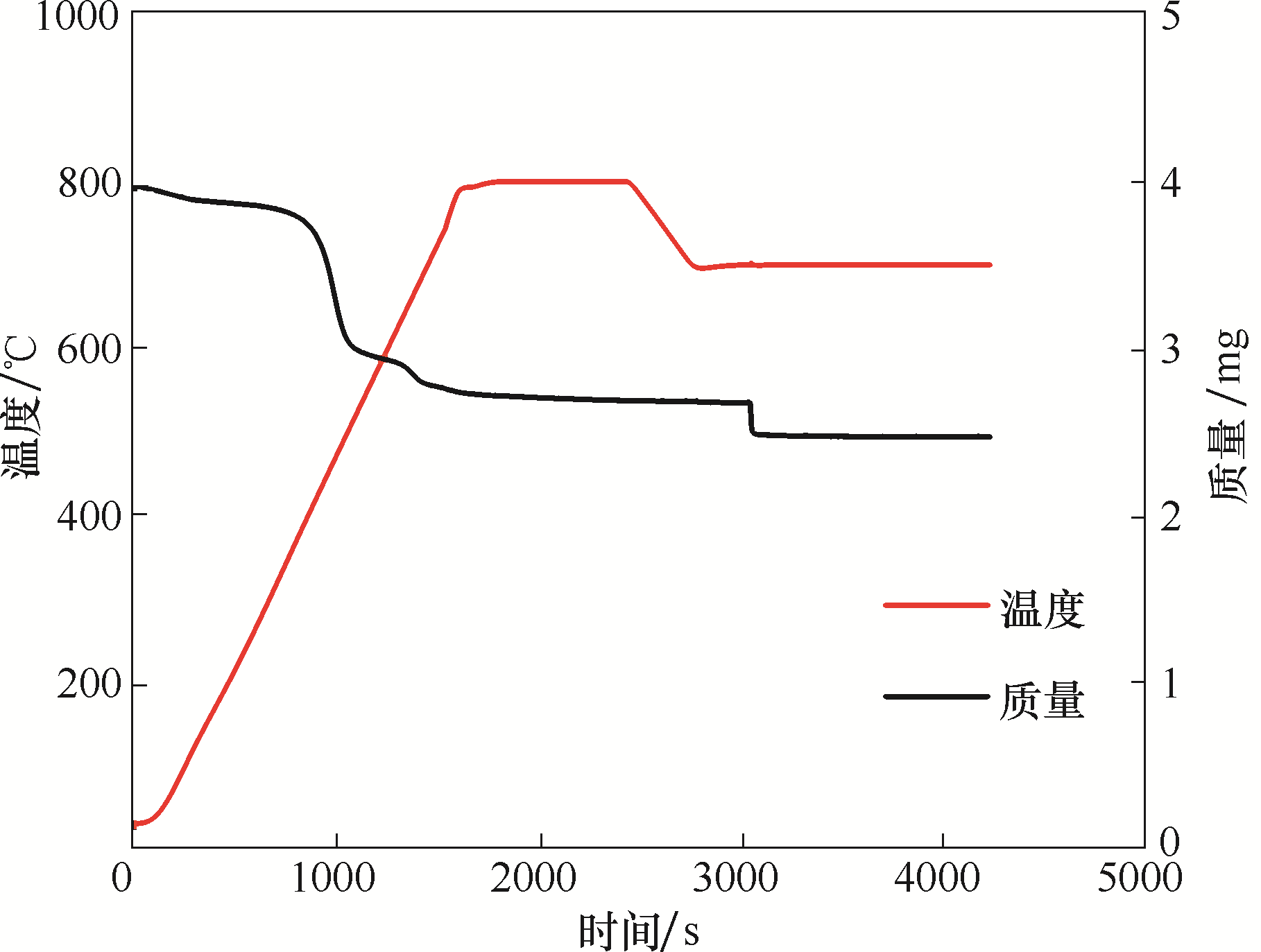

图1 实验过程中典型的升温、失重曲线(YO2=18.9%, T=700℃, 流量100 ml/min)

Fig.1 Typical heating and mass loss curves in experiments(YO2=18.9%, T=700℃, flow rate=100 ml/min)

| 燃烧温度/℃ | 氧气浓度/(mol/m3) | n | m | k |

|---|---|---|---|---|

800 | 2.178 | 0.995 | 1.115 | 0.112 |

| 1.936 | 0.926 | 1.115 | 0.112 | |

| 1.694 | 0.774 | 1.115 | 0.112 | |

| 1.452 | 0.703 | 1.115 | 0.112 | |

750 | 2.277 | 0.790 | 0.850 | 0.093 |

| 2.024 | 0.655 | 0.850 | 0.093 | |

| 1.771 | 0.473 | 0.850 | 0.093 | |

| 1.518 | 0.398 | 0.850 | 0.093 | |

700 | 2.394 | 0.686 | 0.815 | 0.084 |

| 2.128 | 0.609 | 0.815 | 0.084 | |

| 1.862 | 0.496 | 0.815 | 0.084 | |

| 1.596 | 0.557 | 0.815 | 0.084 | |

650 | 2.529 | 1.019 | 1.149 | 0.060 |

| 2.248 | 0.782 | 1.149 | 0.060 | |

| 1.967 | 0.805 | 1.149 | 0.060 | |

| 1.686 | 0.579 | 1.149 | 0.060 | |

600 | 2.673 | 1.055 | 0.897 | 0.055 |

| 2.376 | 0.688 | 0.897 | 0.055 | |

| 2.079 | 0.743 | 0.897 | 0.055 | |

| 1.782 | 0.503 | 0.897 | 0.055 |

表2 动力学模型参数结果

Table 2 Kinetic model parameters

| 燃烧温度/℃ | 氧气浓度/(mol/m3) | n | m | k |

|---|---|---|---|---|

800 | 2.178 | 0.995 | 1.115 | 0.112 |

| 1.936 | 0.926 | 1.115 | 0.112 | |

| 1.694 | 0.774 | 1.115 | 0.112 | |

| 1.452 | 0.703 | 1.115 | 0.112 | |

750 | 2.277 | 0.790 | 0.850 | 0.093 |

| 2.024 | 0.655 | 0.850 | 0.093 | |

| 1.771 | 0.473 | 0.850 | 0.093 | |

| 1.518 | 0.398 | 0.850 | 0.093 | |

700 | 2.394 | 0.686 | 0.815 | 0.084 |

| 2.128 | 0.609 | 0.815 | 0.084 | |

| 1.862 | 0.496 | 0.815 | 0.084 | |

| 1.596 | 0.557 | 0.815 | 0.084 | |

650 | 2.529 | 1.019 | 1.149 | 0.060 |

| 2.248 | 0.782 | 1.149 | 0.060 | |

| 1.967 | 0.805 | 1.149 | 0.060 | |

| 1.686 | 0.579 | 1.149 | 0.060 | |

600 | 2.673 | 1.055 | 0.897 | 0.055 |

| 2.376 | 0.688 | 0.897 | 0.055 | |

| 2.079 | 0.743 | 0.897 | 0.055 | |

| 1.782 | 0.503 | 0.897 | 0.055 |

| 1 | 胡文瑞, 翟光明, 李景明. 中国非常规油气的潜力和发展[J]. 中国工程科学, 2010,12(5): 25-29. |

| HuW R, ZhaiG M, LiJ M. Potential and development of unconventional hydrocarbon resources in China[J]. Engineering Sciences, 2010,12(5):25-29. | |

| 2 | 贾承造, 郑民, 张永峰. 中国非常规油气资源与勘探开发前景[J]. 石油勘探与开发, 2012, 39(2):129-136. |

| JiaC Z, ZhengM, ZhangY F. Unconventional hydrocarbon resources in China and the prospect of exploration and development[J]. Petroleum Exploration and Development, 2012, 39(2): 129-136. | |

| 3 | 王擎, 黄宗越, 迟铭书, 等. 油页岩干酪根化学结构特性分析[J]. 化工学报, 2015, 66(5): 1861-1866. |

| WangQ, HuangZ Y, ChiM S, et al. Chemical structure analysis of oil shale kerogen[J]. CIESC Journal, 2015, 66(5):1861-1866. | |

| 4 | 刘德勋, 赵群, 王红岩, 等. 国内外小颗粒油页岩干馏工艺现状与展望[J]. 广州化工, 2010, 38(12): 7-11. |

| LiuD X, ZhaoQ, WangH Y, et al. Current status and prospect of small-size oil shale retort process[J]. Guangzhou Chemical Industry, 2010, 38(12): 7-11. | |

| 5 | 熊耀, 马名杰, 黄山秀, 等. 国内油页岩干馏炼油技术发展现状[J]. 现代化工, 2013,33(8):40-44. |

| XiongY, MaM J, HuangS X, et al. Current status of carbonization process of oil shale in China[J]. Modern Chemical Industry, 2013, 33(8):40-44. | |

| 6 | 杨庆春, 周怀荣, 杨思宇, 等. 油页岩开发利用技术及系统集成的研究进展[J]. 化工学报, 2016, 67(1): 109-118. |

| YangQ C, ZhouH R, YangS Y, et al. Research progress on utilization and systemic integration technologies of oil shale[J]. CIESC Journal, 2016, 67(1): 109-118. | |

| 7 | 韩向新. 油页岩半焦燃烧机理与循环流化床燃烧利用[D]. 上海: 上海交通大学, 2007. |

| HanX X. Combustion mechanism of oil shale semicoke and combustion utilization in CFB boilers[D]. Shanghai: Shanghai Jiao Tong University, 2007. | |

| 8 | 柏静儒, 王擎, 孙佰仲, 等. 桦甸油页岩半焦基础理化特性[J]. 吉林大学学报(地球科学版), 2010, 40(4): 905-911. |

| BaiJ R, WangQ, SunB Z, et al. Basic physicochemical characteristics of the Huadian oil shale semi-cokes[J]. Journal of Jilin University(Earth Science Edition) , 2010, 40(4): 905-911. | |

| 9 | 王擎, 徐峰, 柏静儒, 等. 桦甸油页岩基础物化特性研究[J]. 吉林大学学报(地球科学版), 2006, 36(6): 1006-1011. |

| WangQ, XuF, BaiJ R, et al. Study on the basic physicochemical characteristics of the Huadian oil shales[J]. Journal of Jilin University(Earth Science Edition) , 2006, 36(6): 1006-1011. | |

| 10 | 王剑秋, 王贤清. 颗粒页岩半焦燃烧反应模型的研究[J]. 石油学报(石油加工), 1987, 3(3): 4-12. |

| WangJ Q, WangX Q. A study of the combustion reaction model of oil shale particles[J]. Acta Pettrolei Sinica(Petroleum Processing Section), 1987, 3(3): 4-12. | |

| 11 | 严君伟, 姜秀民, 韩向新, 等. 油页岩半焦循环流化床燃烧的工业实验研究[J]. 动力工程学报, 2014, 34(7): 518-523. |

| YanJ W, JiangX M, HanX X, et al. Industrial experimental study on combustion of oil shale semicoke in a CFB boiler[J]. Journal of Chinese Society of Power Engineering, 2014, 34(7): 518-523. | |

| 12 | 崔志刚, 吴晓燕, 马素霞. 油页岩半焦流化床混烧特性实验研究[J]. 电站系统工程, 2015, (4): 1-5. |

| CuiZ G, WuX Y, MaS X. Experimental study on co-combustion of oil shale and its semicoke in fluidized bed[J]. Power System Engineering, 2015, (4): 1-5. | |

| 13 | 李晓栋, 樊保国, 金燕, 等. 油页岩半焦燃烧特性试验研究[J]. 煤炭学报, 2016, 41(10): 2473-2478. |

| LiX X, FanB G, JinY, et al. Experimental study on combustion characteristics of oil shale semi-coke[J]. Journal of China Coal Society, 2016, 41(10): 2473-2478. | |

| 14 | 韩向新, 姜秀民, 崔志刚, 等. 油页岩半焦燃烧特性的研究[J]. 中国电机工程学报, 2005, 25(15): 106-110. |

| HanX X, JiangX M, CuiZ G, et al. Study of combustion performance of oil shale semi-coke[J]. Proceedings of the CSEE, 2005, 25(15): 106-110. | |

| 15 | HanX X, JiangX M, CuiZ G. Study of the combustion mechanism of oil shale semicoke in a thermogravimetric analyzer[J]. Journal of Thermal Analysis & Calorimetric, 2008, 92(2): 595-600. |

| 16 | 王擎, 吴吓华, 孙佰仲, 等. 桦甸油页岩半焦燃烧反应动力学研究[J]. 中国电机工程学报, 2006, 26(7): 29-34. |

| WangQ, WuX H, SunB Z, et al. Combustion reaction kinetics study of Huadian oil shale semi-coke[J]. Proceeding of the CSEE, 2006, 26(7):29-34. | |

| 17 | GoldfarbJ L, Amico AD, CulinC, et al. Oxidation kinetics of oil shale semicokes: reactivity as a function of pyrolysis temperature and shale origin[J]. Energy & Fuels, 2013, 27(2): 666-672. |

| 18 | BaiF, SunY, LiuY, et al. Kinetic investigation on partially oxidized Huadian oil shale by thermogravimetric analysis[J]. Oil Shale, 2014, 4(31): 377-393. |

| 19 | 张少冲. 油页岩半焦燃烧过程中含氧官能团和孔隙结构的演变研究[D]. 吉林: 东北电力大学, 2017. |

| ZhangS C. Study on the changes of oxygen containing functional group and pore structure during oil shale semi-coke combustion[D]. Jilin: Northeast Electric Power University, 2017. | |

| 20 | LooL, MaatenB, NeshumayevD, et al. Oxygen influence on Estonian Kukersite oil shale devolatilization and char combustion[J]. Oil Shale, 2017, 3(34): 219-231. |

| 21 | FujimotoF D, BraunR L, TaylorR W, et al. Intrinsic kinetics of oxidation of residual organic carbon in rapidly pyrolyzed oil shale[J]. Energy & Fuels, 1987, 1(4): 320-323. |

| 22 | HongY S, SunK K. Intrinsic kinetics of the reaction between oxygen and carbonaceous residue in retorted oil shale[J]. Industrial & Engineering Chemistry Process Design & Development, 1980, 19(4): 550-555. |

| 23 | 王贤清, 王剑秋, 钱家麟, 等. 油页岩半焦燃烧中灰分层的扩散动力学研究[J]. 石油学报(石油加工), 1987, 3(4): 4-11. |

| WangX Q, WangJ Q, QianJ L, et al. Diffusion effects in the ash layer of the oil shale char combustion[J]. Acta Petrolei Sinica(Petroleum Processing Section) , 1987, 3(4): 4-11. | |

| 24 | 梅琳. 高灰分低热值工业固体废弃物流化床燃烧特性的实验研究[D]. 重庆:重庆大学, 2015. |

| MeiL. Experimental study on combustion characteristics of high ash content and low calorific value industrial solid waste in a CFB combustor[D]. Chongqing: Chongqing University, 2015. | |

| 25 | 张守玉, 吕俊复, 王文选, 等. 热处理对煤焦反应性及微观结构的影响[J]. 燃料化学学报, 2004, 32(6): 673-678. |

| ZhangS Y, LyuJ F, WangW X, et al. Effect of heat treatment on the reactivity and microstructure of coal-char[J]. Journal of Fuel Chemistry and Technology, 2004, 32(6): 673-678. | |

| 26 | YoshizawaN, MaruyamaK, YamashitaT, et al. Dependence of microscopic structure and swelling property of DTF chars upon heat-treatment temperature[J]. Fuel, 2006, 85(14): 2064-2070. |

| 27 | SalatinoP, SennecaO, MasiS. Assessment of thermodeactivation during gasification of a bituminous coal char[J]. Energy & Fuels, 1999, 13(6): 1154-1159. |

| 28 | SennecaO, SalatinoP. Loss of gasification reactivity toward O2 and CO2 upon heat treatment of carbons[J]. Proceedings of the Combustion Institute, 2002, 29(1): 485-493. |

| 29 | DongS, AlvarezP, PatersonN, et al. Study on the effect of heat treatment and gasification on the carbon structure of coal chars and metallurgical cokes using Fourier transform Raman spectroscopy[J]. Energy & Fuels, 2013, 23(3): 1651-1661. |

| 30 | 张志, 李振山, 蔡宁生. 焦炭燃烧模型的改进及其Fluent实现与实验验证[J]. 中国电机工程学报, 2015, 35(7): 1681-1688. |

| ZhangZ, LiZ S, CaiN S. An improved char combustion model and its implement in Fluent and experimental validation[J]. Proceedings of the CSEE, 2015, 35(7): 1681-1688. |

| [1] | 毕丽森, 刘斌, 胡恒祥, 曾涛, 李卓睿, 宋健飞, 吴翰铭. 粗糙界面上纳米液滴蒸发模式的分子动力学研究[J]. 化工学报, 2023, 74(S1): 172-178. |

| [2] | 于宏鑫, 邵双全. 水结晶过程的分子动力学模拟分析[J]. 化工学报, 2023, 74(S1): 250-258. |

| [3] | 宋嘉豪, 王文. 斯特林发动机与高温热管耦合运行特性研究[J]. 化工学报, 2023, 74(S1): 287-294. |

| [4] | 连梦雅, 谈莹莹, 王林, 陈枫, 曹艺飞. 地下水预热新风一体化热泵空调系统制热性能研究[J]. 化工学报, 2023, 74(S1): 311-319. |

| [5] | 吴曦, 区祖迪, 张鑫杰, 徐士鸣, 朱晓静. HFO-1243zf爆燃特性实验研究[J]. 化工学报, 2023, 74(S1): 346-352. |

| [6] | 金正浩, 封立杰, 李舒宏. 氨水溶液交叉型再吸收式热泵的能量及 分析[J]. 化工学报, 2023, 74(S1): 53-63. 分析[J]. 化工学报, 2023, 74(S1): 53-63. |

| [7] | 程成, 段钟弟, 孙浩然, 胡海涛, 薛鸿祥. 表面微结构对析晶沉积特性影响的格子Boltzmann模拟[J]. 化工学报, 2023, 74(S1): 74-86. |

| [8] | 肖明堃, 杨光, 黄永华, 吴静怡. 浸没孔液氧气泡动力学数值研究[J]. 化工学报, 2023, 74(S1): 87-95. |

| [9] | 李艺彤, 郭航, 陈浩, 叶芳. 催化剂非均匀分布的质子交换膜燃料电池操作条件研究[J]. 化工学报, 2023, 74(9): 3831-3840. |

| [10] | 范孝雄, 郝丽芳, 范垂钢, 李松庚. LaMnO3/生物炭催化剂低温NH3-SCR催化脱硝性能研究[J]. 化工学报, 2023, 74(9): 3821-3830. |

| [11] | 郑佳丽, 李志会, 赵新强, 王延吉. 离子液体催化合成2-氰基呋喃反应动力学研究[J]. 化工学报, 2023, 74(9): 3708-3715. |

| [12] | 王浩, 王振雷. 基于自适应谱方法的裂解炉烧焦模型化简策略[J]. 化工学报, 2023, 74(9): 3855-3864. |

| [13] | 陈哲文, 魏俊杰, 张玉明. 超临界水煤气化耦合SOFC发电系统集成及其能量转化机制[J]. 化工学报, 2023, 74(9): 3888-3902. |

| [14] | 李科, 文键, 忻碧平. 耦合蒸气冷却屏的真空多层绝热结构对液氢储罐自增压过程的影响机制研究[J]. 化工学报, 2023, 74(9): 3786-3796. |

| [15] | 曾如宾, 沈中杰, 梁钦锋, 许建良, 代正华, 刘海峰. 基于分子动力学模拟的Fe2O3纳米颗粒烧结机制研究[J]. 化工学报, 2023, 74(8): 3353-3365. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号