化工学报 ›› 2019, Vol. 70 ›› Issue (10): 4089-4098.DOI: 10.11949/j.issn.0438-1157.20190617

• 过程安全 • 上一篇

时事成1( ),王苏盼1,2,3,潘旭海1,2,3(

),王苏盼1,2,3,潘旭海1,2,3( ),马煜衡1,蒋军成1,2,3

),马煜衡1,蒋军成1,2,3

收稿日期:2019-06-02

修回日期:2019-08-07

出版日期:2019-10-05

发布日期:2019-10-05

通讯作者:

潘旭海

作者简介:时事成(1995—),男,硕士研究生,基金资助:

Shicheng SHI1( ),Supan WANG1,2,3,Xuhai PAN1,2,3(

),Supan WANG1,2,3,Xuhai PAN1,2,3( ),Yuheng MA1,Juncheng JIANG1,2,3

),Yuheng MA1,Juncheng JIANG1,2,3

Received:2019-06-02

Revised:2019-08-07

Online:2019-10-05

Published:2019-10-05

Contact:

Xuhai PAN

摘要:

为探究储罐泄漏引发液体过热爆沸的机理及规律,实验建立了小型装置,对爆沸过程中的气泡演化、压力及介质过热度响应进行研究。根据介质过热度的变化特征,提出表征沸腾延时程度的参数——过热时间,并建立相应描述过热时间的数学模型。实验结果表明,容器破裂后,大量气泡于介质内部产生并迅速成长,其成长可分为相对稳定阶段与加速成长阶段,而后引起明显的压力反弹。整个沸腾自上而下、自内壁向介质内部进行,且介质经历过冷—饱和—过热—饱和—过冷的循环过程。此外,实验发现初始压力的升高或初始液位的降低,都会使介质达到的最大过热度提高,尤其是50%初始液位时其介质最大过热度高达9.4℃。而随着初始压力或初始液位的升高,过热时间呈明显降低趋势,且初始液位升高时还会引起更明显的压力反弹。基于实验数据,对过热时间数学模型进行验证,结果表明数学模型计算结果和实验数据基本吻合。

中图分类号:

时事成, 王苏盼, 潘旭海, 马煜衡, 蒋军成. 泄漏引发液体过热爆沸机理及规律研究[J]. 化工学报, 2019, 70(10): 4089-4098.

Shicheng SHI, Supan WANG, Xuhai PAN, Yuheng MA, Juncheng JIANG. Study on mechanism and law of liquid overheating and explosive boiling caused by leakage[J]. CIESC Journal, 2019, 70(10): 4089-4098.

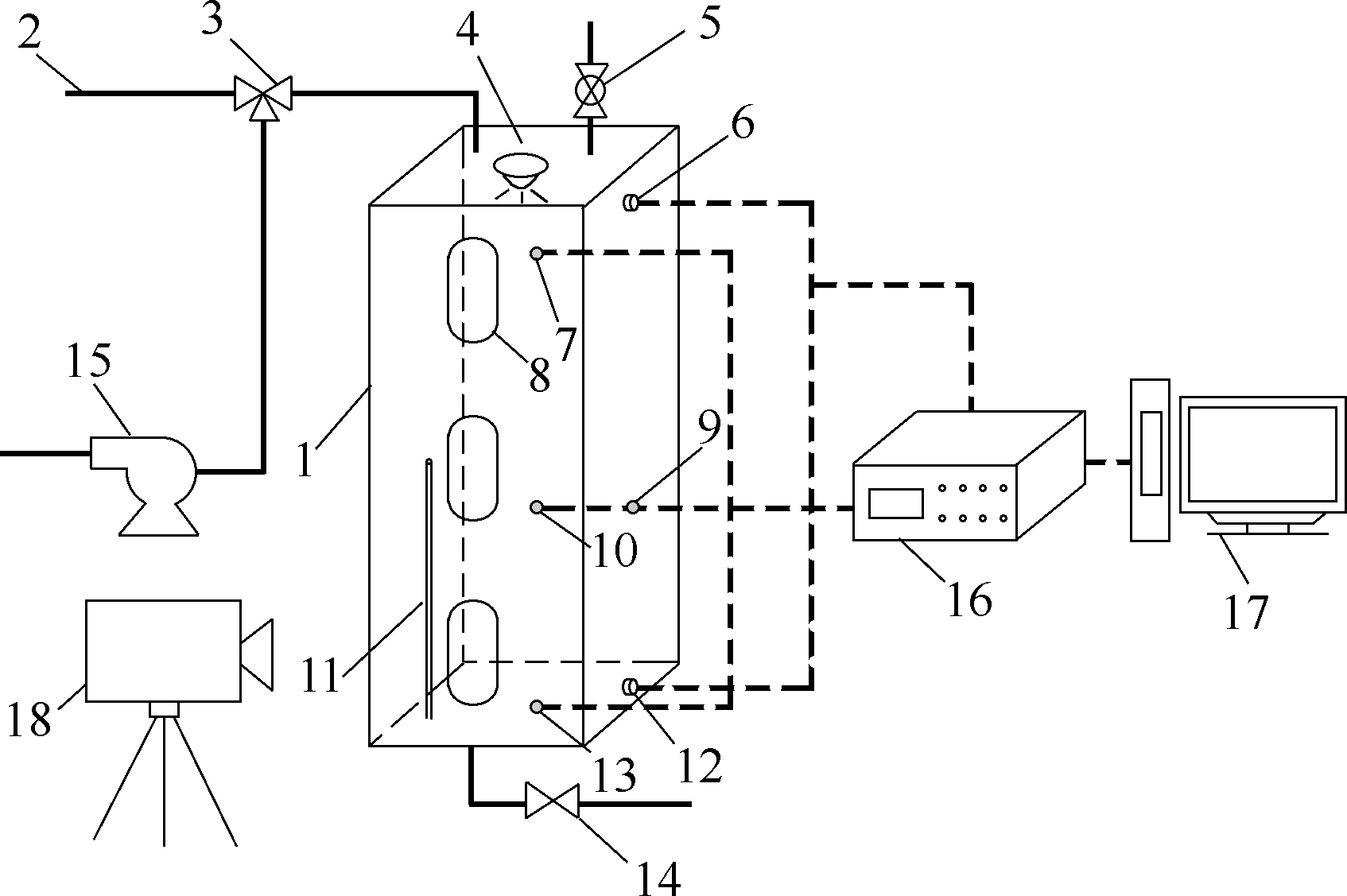

图1 爆沸实验装置1—压力储罐; 2—进水口; 3—三通阀; 4—照明灯; 5—气动球阀; 6—压力变送器(PT1); 7—热电偶(TT1); 8—观察窗; 9—热电偶(TT2); 10—热电偶(TT3); 11—加热棒; 12—压力变送器(PT2); 13—热电偶(TT4); 14—排水阀; 15—水环真空泵; 16—记录仪; 17—计算机; 18—高速摄像机

Fig.1 Experiment setup of explosion boiling

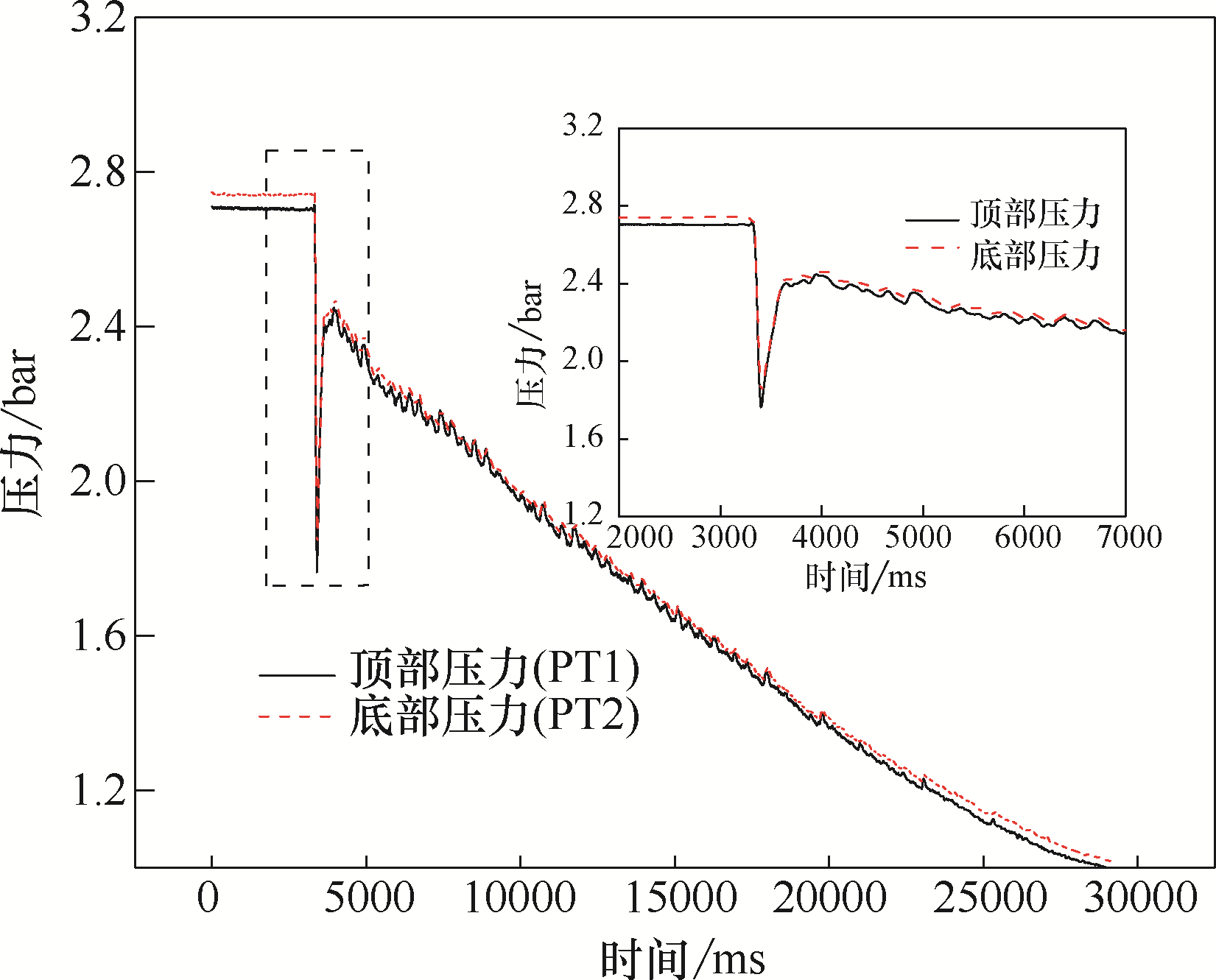

图2 初始压力为2.7 bar、初始液位为70%时的压力响应图及局部放大图

Fig.2 Pressure response and partial magnification diagram at initial pressure of 2.7 bar and initial liquid level of 70%

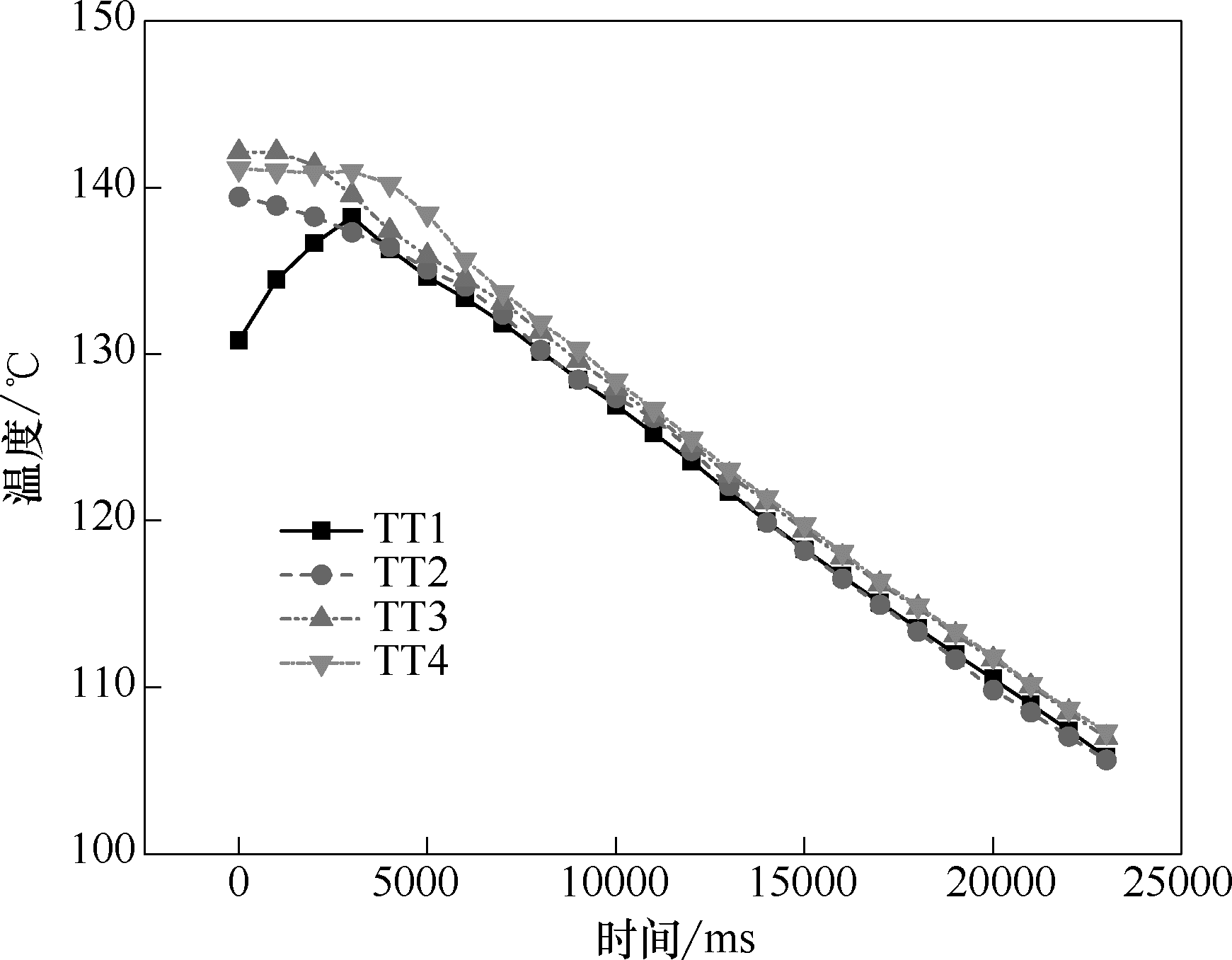

图5 初始压力为3.7 bar、初始液位为70%时泄压后介质温度响应曲线

Fig.5 Medium temperature curves after pressure relief at initial pressure of 3.7 bar and initial liquid level of 70%

| 实验序号 | 初始压力/bar | 初始 液位/% | 平均最大 过热度/℃ | 标准偏差 |

|---|---|---|---|---|

| 1 | 1.7 | 70 | 6.8 | 0.25 |

| 2 | 2.7 | 70 | 7.3 | 0.15 |

| 3 | 3.7 | 70 | 8.2 | 0.25 |

| 4 | 4.7 | 70 | 8.9 | 0.21 |

| 5 | 2.7 | 50 | 9.4 | 0.32 |

| 6 | 2.7 | 60 | 7.9 | 0.15 |

| 7 | 2.7 | 80 | 3.0 | 0.21 |

表1 不同工况下介质沸腾所能达到的最大过热度值汇总

Table 1 Summary of maximum superheat degree that medium can achieve during boiling under different conditions

| 实验序号 | 初始压力/bar | 初始 液位/% | 平均最大 过热度/℃ | 标准偏差 |

|---|---|---|---|---|

| 1 | 1.7 | 70 | 6.8 | 0.25 |

| 2 | 2.7 | 70 | 7.3 | 0.15 |

| 3 | 3.7 | 70 | 8.2 | 0.25 |

| 4 | 4.7 | 70 | 8.9 | 0.21 |

| 5 | 2.7 | 50 | 9.4 | 0.32 |

| 6 | 2.7 | 60 | 7.9 | 0.15 |

| 7 | 2.7 | 80 | 3.0 | 0.21 |

| 序号 | 初始压力/bar | 初始液位/% | 初始气相体积/L | 理论过热时间 t/ms | 实验测量平均过热时间 | 相对误差/% | 平均误差/% |

|---|---|---|---|---|---|---|---|

| 1 | 1.7 | 70 | 5.2 | 54.4 | 49.6 | 9.7 | 9.2 |

| 2 | 2.7 | 70 | 5.2 | 49.9 | 46.3 | 7.8 | |

| 3 | 3.7 | 70 | 5.2 | 20.5 | 23.3 | 12.0 | |

| 4 | 4.7 | 70 | 5.2 | 12.3 | 13.6 | 9.6 | |

| 5 | 2.7 | 50 | 8.6 | 74.2 | 68.3 | 8.6 | |

| 6 | 2.7 | 60 | 6.9 | 60.6 | 55.7 | 8.8 | |

| 7 | 2.7 | 80 | 3.5 | 34.2 | 31.7 | 7.9 |

表2 过热时间理论值与实验结果对比

Table 2 Comparison of theoretical and experimental results of overheat time

| 序号 | 初始压力/bar | 初始液位/% | 初始气相体积/L | 理论过热时间 t/ms | 实验测量平均过热时间 | 相对误差/% | 平均误差/% |

|---|---|---|---|---|---|---|---|

| 1 | 1.7 | 70 | 5.2 | 54.4 | 49.6 | 9.7 | 9.2 |

| 2 | 2.7 | 70 | 5.2 | 49.9 | 46.3 | 7.8 | |

| 3 | 3.7 | 70 | 5.2 | 20.5 | 23.3 | 12.0 | |

| 4 | 4.7 | 70 | 5.2 | 12.3 | 13.6 | 9.6 | |

| 5 | 2.7 | 50 | 8.6 | 74.2 | 68.3 | 8.6 | |

| 6 | 2.7 | 60 | 6.9 | 60.6 | 55.7 | 8.8 | |

| 7 | 2.7 | 80 | 3.5 | 34.2 | 31.7 | 7.9 |

| 1 | AbbasiT, AbbasiS A. The boiling liquid expanding vapour explosion (BLEVE): mechanism, consequence assessment, management[J]. Journal of Hazardous Materials, 2007, 141(3): 489-519. |

| 2 | 王晓东, 田勇, 彭晓峰, 等. 沸腾核心内部结构及其演化特性[J]. 化工学报, 2005, 56(5): 812-815. |

| WangX D, TianY, PengX F, et al. Inner structure and evolution of boiling nucleus[J]. Journal of Chemical Industry and Engineering(China), 2005, 56(5): 812-815. | |

| 3 | HemmatianB, PlanasE, CasalJ. Fire as a primary event of accident domino sequences: the case of BLEVE[J]. Reliability Engineering & System Safety, 2015, 139: 141-148. |

| 4 | TauseefS M, AbbasiT, AbbasiS A. Risks of fire and explosion associated with the increasing use of liquefied petroleum gas[J]. Journal of Failure Analysis and Prevention, 2010, 10(4): 322-333. |

| 5 | 陈思凝. 沸腾液体膨胀蒸气爆炸(BLEVE)动力演化机理的小尺寸模拟试验研究[D]. 合肥: 中国科学技术大学, 2007. |

| ChenS N. Small scale experimental study on boiling liquid expanding vapor explosions mechanism[D]. Hefei: University of Science and Technology of China, 2007. | |

| 6 | 石剑云. 液化气体的热分层及爆沸机理研究[D]. 大连: 大连理工大学, 2015. |

| ShiJ Y. Research on the mechanisms of thermal stratification and explosive boiling of liquefied gas[D]. Dalian: Dalian University of Technology, 2015. | |

| 7 | BartákJ. A study of the rapid depressurization of hot water and the dynamics of vapor bubble generation in superheated water[J]. International Journal of Multiphase Flow, 1990, 16(5): 789-798. |

| 8 | 李清, 张德平, 孙瑞艳, 等. 固态CO2-BLEVE过程中的压力与温度变化试验研究[J]. 安全与环境学报, 2018, 18(6): 103-109. |

| LiQ, ZhangD P, SunR Y, et al. Experimental approach to the pressure and temperature changes in the solid CO2-BLEVE process[J]. Journal of Safety and Environment, 2018, 18(6): 103-109. | |

| 9 | REIDR C. Possible mechanism for pressurized-liquid tank explosions or BLEVE’s[J]. Science, 1979, 203(4386): 1263-1265. |

| 10 | BjerketvedtD, EgebergK, KeW, et al. Boiling liquid expanding vapour explosion in CO2 small scale experiments[J]. Energy Procedia, 2011, 4(1): 2285-2292. |

| 11 | BartakJ. A study of the rapid depressurization of hot water and the dynamics of vapour bubble generation in superheated water[J]. International Journal of Multiphase Flow, 1990, 16(5): 789-798. |

| 12 | ZhangQ, BiQ, WuJ, et al. Experimental investigation on the rapid evaporation of high-pressure R113 liquid due to sudden depressurization[J]. International Journal of Heat and Mass Transfer, 2013, 61: 646-653. |

| 13 | McDevittC A, ChanC K, StewardF R, et al. Initiation step of boiling liquid expanding vapor explosions[J]. Journal of Hazardous Materials, 1990, 25(1): 169-180. |

| 14 | NutterD W, O'nealD L. Modeling the transient outlet pressure and mass flow during flashing of HCFC-22 in a small nonadiabatic vessel[J]. Mathematical & Computer Modelling An International Journal, 1999, 29(8): 105-116. |

| 15 | SumathipalaK, VenartJ E S, StewardF R. Two-phase swelling and entrainment during pressure relief valve discharges[J]. Journal of Hazardous Materials, 1990, 25(1): 219-236. |

| 16 | StawczykJ. Experimental evaluation of LPG tank explosion hazards[J]. Journal of Hazardous Materials, 2003, 96(2/3): 189-200. |

| 17 | ChenS N, SunJ H, ChuG Q. Small scale experiments on boiling liquid expanding vapor explosions: vessel over-pressure[J]. Journal of Loss Prevention in the Process Industries, 2007, 20(1): 45-51. |

| 18 | ChenS N, SunJ, WeiW. Boiling liquid expanding vapor explosion: experimental research in the evolution of the two-phase flow and over-pressure[J]. Journal of Hazardous Materials, 2008, 156(1): 530-537. |

| 19 | BirkA M, PoirierD, DavisonC. On the response of 500 gal propane tanks to a 25% engulfing fire[J]. Journal of Loss Prevention in the Process Industries, 2006, 19(6): 527-541. |

| 20 | BirkA M, DavisonC, CunninghamM. Blast overpressures from medium scale BLEVE tests[J]. Journal of Loss Prevention in the Process Industries, 2007, 20(3): 194-206. |

| 21 | ShiJ Y, RenJ J, LiuP, et al. Experimental research on the effects of fluid and heater on thermal stratification of liquefied gas[J]. Experimental Thermal and Fluid Science, 2013, 50: 29-36. |

| 22 | 任婧杰. 热环境下液化气体储罐热质耦合响应机制研究[D]. 大连: 大连理工大学, 2014. |

| RenJ J. Research on heat-mass coupling response mechanism of liquefied gas tanks under thermal environments[D]. Dalian: Dalian University of Technology, 2015. | |

| 23 | RenJ J, ShiJ Y, LiuP, et al. Simulation on thermal stratification and de-stratification in liquefied gas tanks[J]. International Journal of Hydrogen Energy, 2013, 38(10): 4017-4023. |

| 24 | 周轶. 驱油过程中二氧化碳BLEVE机理及破坏效应研究[D]. 北京: 北京理工大学, 2015. |

| ZhouY. Study on the mechanism and damage effect of CO2 boiling liquid expanding vapor explosion in CO2 flooding[D]. Beijing: Beijing Institute of Technology, 2015. | |

| 25 | LiM Z, LiuZ Y, ZhouY, et al. A small-scale experimental study on the initial burst and the heterogeneous evolution process before CO2 BLEVE[J]. Journal of Hazardous Materials, 2017, 342: 634-642. |

| 26 | TosseS, VaagsaetherK, BjerketvedtD. An experimental investigation of rapid boiling of CO2[J]. Shock Waves, 2014, 25(3): 277-282. |

| 27 | PetersonR J, GrewalS S, Ei-WakilM M. Investigations of liquid flashing and evaporation due to sudden depressurization[J]. International Journal of Heat & Mass Transfer, 1984, 27(2): 301-310. |

| 28 | 王庆慧, 邹伟, 荣皓月. BLEVE超压模型与试验对比分析[J]. 安全与环境学报, 2016, 16(4): 116-120. |

| WangQ H, ZouW, RongH Y. BLEVE overpressure model and its experimental comparative analysis[J]. Journal of Safety and Environment, 2016, 16(4): 116-120. | |

| 29 | 王庆慧. 压力容器蒸汽爆炸临界条件分析及后果仿真[D]. 大庆: 东北石油大学, 2011. |

| WangQ H. On vapor explosion critical condition analysis and simulation of the pressure vessel[D]. Daqing: Northeast Petroleum University, 2011. | |

| 30 | 王庆慧. 实验测定过热水发生BLEVE现象的反应时间[J]. 科学技术与工程, 2010, 10(26):6477-6480. |

| WangQ H. The experimental determination reaction time of BLEVE phenomenon produced by superheated water[J]. Science Technology and Engineering, 2010, 10(26): 6477-6480. |

| [1] | 周绍华, 詹飞龙, 丁国良, 张浩, 邵艳坡, 刘艳涛, 郜哲明. 短管节流阀内流动噪声的实验研究及降噪措施[J]. 化工学报, 2023, 74(S1): 113-121. |

| [2] | 江河, 袁俊飞, 王林, 邢谷雨. 均流腔结构对微细通道内相变流动特性影响的实验研究[J]. 化工学报, 2023, 74(S1): 235-244. |

| [3] | 宋嘉豪, 王文. 斯特林发动机与高温热管耦合运行特性研究[J]. 化工学报, 2023, 74(S1): 287-294. |

| [4] | 连梦雅, 谈莹莹, 王林, 陈枫, 曹艺飞. 地下水预热新风一体化热泵空调系统制热性能研究[J]. 化工学报, 2023, 74(S1): 311-319. |

| [5] | 金正浩, 封立杰, 李舒宏. 氨水溶液交叉型再吸收式热泵的能量及 分析[J]. 化工学报, 2023, 74(S1): 53-63. 分析[J]. 化工学报, 2023, 74(S1): 53-63. |

| [6] | 肖明堃, 杨光, 黄永华, 吴静怡. 浸没孔液氧气泡动力学数值研究[J]. 化工学报, 2023, 74(S1): 87-95. |

| [7] | 温凯杰, 郭力, 夏诏杰, 陈建华. 一种耦合CFD与深度学习的气固快速模拟方法[J]. 化工学报, 2023, 74(9): 3775-3785. |

| [8] | 王玉兵, 李杰, 詹宏波, 朱光亚, 张大林. R134a在菱形离散肋微小通道内的流动沸腾换热实验研究[J]. 化工学报, 2023, 74(9): 3797-3806. |

| [9] | 李科, 文键, 忻碧平. 耦合蒸气冷却屏的真空多层绝热结构对液氢储罐自增压过程的影响机制研究[J]. 化工学报, 2023, 74(9): 3786-3796. |

| [10] | 何松, 刘乔迈, 谢广烁, 王斯民, 肖娟. 高浓度水煤浆管道气膜减阻两相流模拟及代理辅助优化[J]. 化工学报, 2023, 74(9): 3766-3774. |

| [11] | 王浩, 王振雷. 基于自适应谱方法的裂解炉烧焦模型化简策略[J]. 化工学报, 2023, 74(9): 3855-3864. |

| [12] | 陈哲文, 魏俊杰, 张玉明. 超临界水煤气化耦合SOFC发电系统集成及其能量转化机制[J]. 化工学报, 2023, 74(9): 3888-3902. |

| [13] | 袁佳琦, 刘政, 黄锐, 张乐福, 贺登辉. 泡状入流条件下旋流泵能量转换特性研究[J]. 化工学报, 2023, 74(9): 3807-3820. |

| [14] | 韩晨, 司徒友珉, 朱斌, 许建良, 郭晓镭, 刘海峰. 协同处理废液的多喷嘴粉煤气化炉内反应流动研究[J]. 化工学报, 2023, 74(8): 3266-3278. |

| [15] | 李锦潼, 邱顺, 孙文寿. 煤浆法烟气脱硫中草酸和紫外线强化煤砷浸出过程[J]. 化工学报, 2023, 74(8): 3522-3532. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号