化工学报 ›› 2019, Vol. 70 ›› Issue (4): 1567-1574.DOI: 10.11949/j.issn.0438-1157.20181251

收稿日期:2018-10-22

修回日期:2018-12-28

出版日期:2019-04-05

发布日期:2019-04-05

通讯作者:

赵荣祥

作者简介:<named-content content-type="corresp-name">王鑫博</named-content>(1993—),男,硕士研究生,<email>724581317@qq.com</email>|赵荣祥(1971—),男,博士,副教授,<email>zylhzrx@126.com</email>

基金资助:

Xinbo WANG( ),Yanping ZHANG,Xiuping LI,Rongxiang ZHAO(

),Yanping ZHANG,Xiuping LI,Rongxiang ZHAO( )

)

Received:2018-10-22

Revised:2018-12-28

Online:2019-04-05

Published:2019-04-05

Contact:

Rongxiang ZHAO

摘要:

通过简单加热1-乙基-3-甲基咪唑硫酸乙酯(EMIES)离子液体和3-苯丙酸(C9H10O2)的混合物,制备了一系列酸性低共熔溶剂EMIES/nC9H10O2(n=0.25,0.5,1,2,4)。通过FTIR,1H NMR和TGA的表征,确定EMIES/nC9H10O2的结构。以该低共熔溶剂为催化剂和萃取剂,H2O2为氧化剂,组成氧化-萃取脱硫体系,用于脱除模拟油中的硫化物。考察了原料配比、反应温度、氧硫比(O/S)、低共熔溶剂加入量和不同硫化物对脱硫性能的影响。结果表明,在EMIES和C9H10O2摩尔比为1∶1,反应温度为50℃,O/S比为8,低共熔溶剂加入量为1.5 g和模拟油5 ml的反应条件下,二苯并噻吩、4,6-二甲基二苯并噻吩和苯并噻吩的脱除率分别为94.8%、91.6%和46.4%。低共熔溶剂可循环使用6次,活性无明显下降。此外,对该氧化-萃取脱硫体系的脱硫机理进行了探讨。

中图分类号:

王鑫博, 张延平, 李秀萍, 赵荣祥. EMIES/nC9H10O2基低共熔溶剂的制备及其氧化脱硫活性的研究[J]. 化工学报, 2019, 70(4): 1567-1574.

Xinbo WANG, Yanping ZHANG, Xiuping LI, Rongxiang ZHAO. Preparation of EMIES/nC9H10O2-based deep eutectic solvents and its oxidative desulfurization activity[J]. CIESC Journal, 2019, 70(4): 1567-1574.

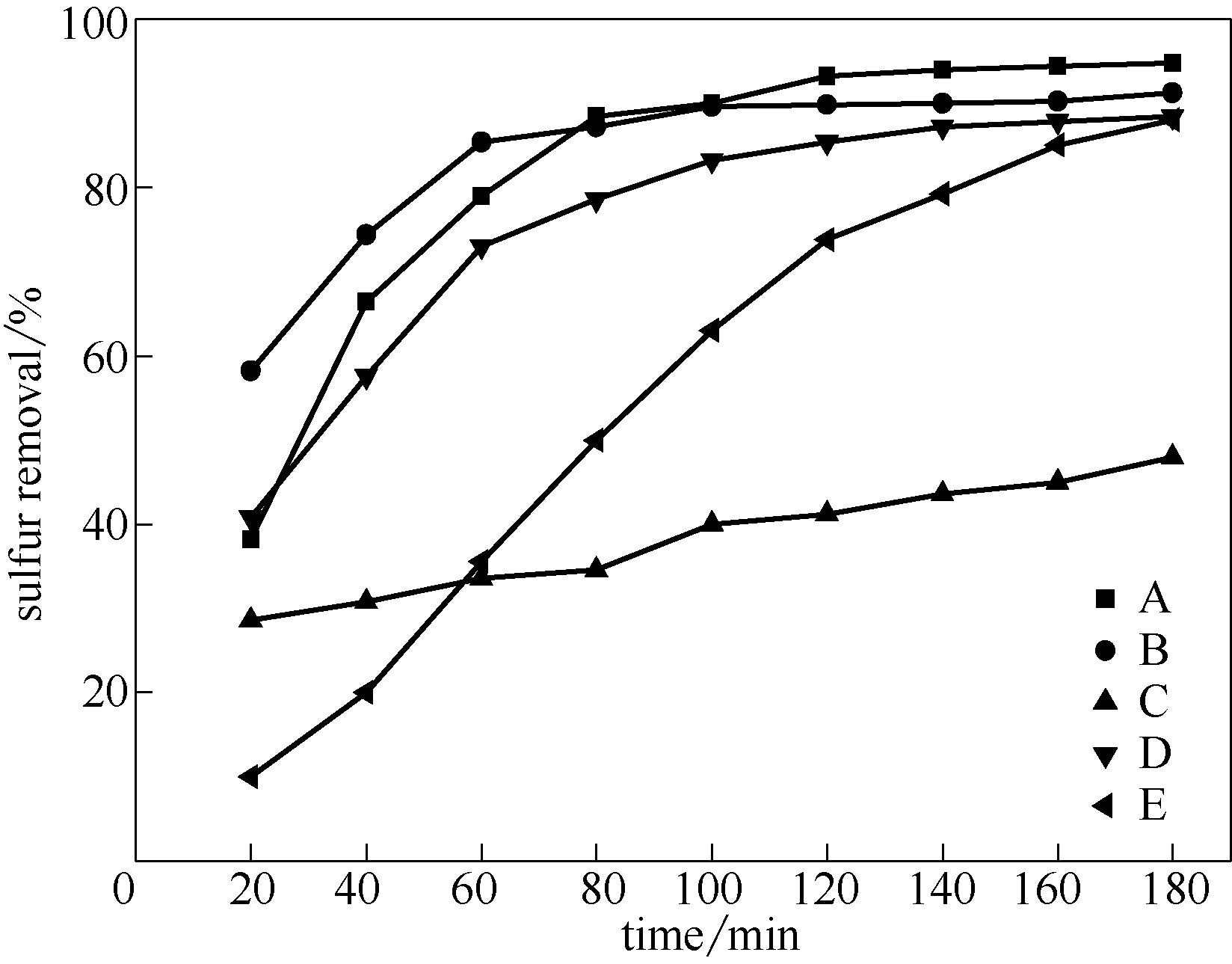

图5 1-乙基-3-甲基咪唑硫酸乙酯与3-苯丙酸摩尔比对脱硫率的影响

Fig.5 Influence of different molar ratio of EMIES to C9H10O2 on desulfurization rate(Reaction condition:V oil= 5 ml, n(H2O2)/n(S)= 8, 1.5 g DESs, 50℃)

| O/S | Sulfur removal/% |

|---|---|

| 0 | 20.4 |

| 2 | 40.2 |

| 4 | 46.2 |

| 6 | 86.4 |

| 8 | 94.8 |

| 10 | 95.1 |

表1 氧硫比对脱硫率的影响

Table 1 Influence of various O/S molar ratio on desulfurization rate

| O/S | Sulfur removal/% |

|---|---|

| 0 | 20.4 |

| 2 | 40.2 |

| 4 | 46.2 |

| 6 | 86.4 |

| 8 | 94.8 |

| 10 | 95.1 |

| Amount of DESs/g | Sulfur removal/% |

|---|---|

| 0.5 | 74.0 |

| 1.0 | 83.0 |

| 1.5 | 94.8 |

| 2.0 | 93.2 |

表2 低共熔溶剂的量对脱硫率的影响

Table 2 Influence of amount of DESs on desulfurization rate

| Amount of DESs/g | Sulfur removal/% |

|---|---|

| 0.5 | 74.0 |

| 1.0 | 83.0 |

| 1.5 | 94.8 |

| 2.0 | 93.2 |

| Recyling times | Sulfur removal/% |

|---|---|

| 1 | 94.8 |

| 2 | 94.0 |

| 3 | 92.6 |

| 4 | 92.0 |

| 5 | 90.2 |

| 6 | 89.3 |

表3 低共熔溶剂的回收对脱硫率的影响

Table 3 Influence of DESs recycling on sulfur removal

| Recyling times | Sulfur removal/% |

|---|---|

| 1 | 94.8 |

| 2 | 94.0 |

| 3 | 92.6 |

| 4 | 92.0 |

| 5 | 90.2 |

| 6 | 89.3 |

| 1 | Lü H , Li P , Deng C , et al . Deep catalytic oxidative desulfurization (ODS) of dibenzothiophene (DBT) with oxalate-based deep eutectic solvents (DESs) [J]. Chemical Communications, 2015, 51(53): 10703-10706. |

| 2 | Stanislaus A , Marafi A , Rana M S . Recent advances in the science and technology of ultra low sulfur diesel (ULSD) production [J]. Catalysis Today, 2010, 153(1/2): 1-68. |

| 3 | Soleimani M , Bassi A , Margaritis A . Biodesulfurization of refractory organic sulfur compounds in fossil fuels [J]. Biotechnology Advances, 2007, 25(6): 570-596. |

| 4 | Ma X , Zhou A , Song C . A novel method for oxidative desulfurization of liquid hydrocarbon fuels based on catalytic oxidation using molecular oxygen coupled with selective adsorption [J]. Catalysis Today, 2007, 123(1/2/3/4): 276-284. |

| 5 | Ko N H , Lee J S , Huh E S , et al . Extractive desulfurization using Fe-containing ionic liquids [J]. Energy & Fuels, 2008, 22(3): 1687-1690. |

| 6 | Park J G , Ko C H , Yi K B , et al . Reactive adsorption of sulfur compounds in diesel on nickel supported on mesoporous silica [J]. Applied Catalysis B: Environmental, 2008, 81(3/4): 244-250. |

| 7 | Zhang S , Zhang Q , Zhang Z C . Extractive desulfurization and denitrogenation of fuels using ionic liquids [J]. Industrial & Engineering Chemistry Research, 2004, 43(2): 614-622. |

| 8 | Wu Z , Xue Y , Zhang Y , et al . SnS2 nanosheet-based microstructures with high adsorption capabilities and visible light photocatalytic activities [J]. RSC Advances, 2015, 5(31): 24640-24648. |

| 9 | Abbott A P , Capper G , Davies D L , et al . Novel solvent properties of choline chloride/urea mixtures [J]. Chemical Communications, 2003, (1): 70-71. |

| 10 | Li C , Li D , Zou S , et al . Extraction desulfurization process of fuels with ammonium-based deep eutectic solvents [J]. Green Chemistry, 2013, 15(10): 2793-2799. |

| 11 | Li J , Xiao H , Tang X , et al . Green carboxylic acid-based deep eutectic solvents as solvents for extractive desulfurization [J]. Energy & Fuels, 2016, 30(7): 5411-5418. |

| 12 | Gano Z S , Mjalli F S , Al-Wahaibi T , et al . Extractive desulfurization of liquid fuel with FeCl3-based deep eutectic solvents: experimental design and optimization by central-composite design [J]. Chemical Engineering and Processing: Process Intensification, 2015, 93: 10-20. |

| 13 | Li C , Zhang J , Li Z , et al . Extraction desulfurization of fuels with ‘metal ions based deep eutectic solvents (MDESs) [J]. Green Chemistry, 2016, 18(13): 3789-3795. |

| 14 | Ekezie F G C , Sun D W , Cheng J H . Acceleration of microwave-assisted extraction processes of food components by integrating technologies and applying emerging solvents: a review of latest developments [J]. Trends in Food Science & Technology, 2017, 67: 160-172. |

| 15 | Dai D , Wang L , Chen Q , et al . Selective oxidation of sulfides to sulfoxides catalysed by deep eutectic solvent with H2O2 [J]. Journal of Chemical Research, 2014, 38(3): 183-185. |

| 16 | Yin J , Wang J , Li Z , et al . Deep desulfurization of fuels based on an oxidation-extraction process with acidic deep eutectic solvents [J].Green Chemistry, 2015, 17(9): 4552-4559. |

| 17 | Kudtak B , Owczarek K , Namieśnik J . Selected issues related to the toxicity of ionic liquids and deep eutectic solvents—a review [J]. Environmental Science and Pollution Research, 2015, 22(16): 11975-11992. |

| 18 | Leclercq L , Suisse I , Nowogrocki G , et al . Halide-free highly-pure imidazolium triflate ionic liquids: preparation and use in palladium-catalysed allylic alkylation [J]. Green Chemistry, 2007, 9(10): 1097-1103. |

| 19 | Jiang X , Nie Y , Li C , et al . Imidazolium-based alkylphosphate ionic liquids—a potential solvent for extractive desulfurization of fuel[J]. Fuel, 2008, 87(1): 79-84. |

| 20 | 邢鹏飞, 赵荣祥, 李秀萍, 等 . Bi2WO6 的制备及其在离子液体中的超深度氧化脱硫[J]. 中国炼油与石油化工, 2017, 19(1): 99-105. |

| Xing P F , Zhao R X , Li X P , et al . Preparation of Bi2WO6 and its ultra-deep oxidative desulfurization performance in ionic liquids[J]. China Petroleum Processing and Petrochemical Technology, 2017, 19(1): 99-105. | |

| 21 | Wheeler J L , Pugh M K , Atkins S J , et al . Thermal breakdown kinetics of 1-ethyl-3-methylimidazolium ethylsulfate measured using quantitative infrared spectroscopy [J]. Applied Spectroscopy, 2017, 71(12): 2626-2631. |

| 22 | Dubey S , Bharmoria P , Gehlot P S , et al . 1-Ethyl-3-methylimidazolium diethylphosphate based extraction of bioplastic “polyhydroxyalkanoates” from bacteria: green and sustainable approach [J]. ACS Sustainable Chemistry & Engineering, 2017, 6(1): 766-773. |

| 23 | Stack R J , Cotta M A . Effect of 3-phenylpropanoic acid on growth of and cellulose utilization by cellulolytic ruminal bacteria [J]. Applied and Environmental Microbiology, 1986, 52(1): 209-210. |

| 24 | Wilkes J S , Zaworotko M J . Air and water stable 1-ethyl-3-methylimidazolium based ionic liquids [J]. Journal of the Chemical Society, Chemical Communications, 1992, (13): 965-967 |

| 25 | Yuan B , Li Y , Yu F , et al . Benzylation with benzyl alcohol catalyzed by [ChCl][TfOH]2, a Brønsted acidic DES with reaction control self-separation performance [J]. Catalysis Letters, 2018, 148(7): 2133-2138. |

| 26 | Jiang Y , Zhu W , Li H , et al . Oxidative desulfurization of fuels catalyzed by Fenton‐like ionic liquids at room temperature [J]. ChemSusChem, 2011, 4(3): 399-403. |

| 27 | Mokhtar W N A W , Bakar W A W A , Ali R , et al . Deep desulfurization of model diesel by extraction with N,N-dimethylformamide: optimization by Box–Behnken design [J]. Journal of the Taiwan Institute of Chemical Engineers, 2014, 45(4): 1542-1548. |

| 28 | Li F , Liu R , Wen J , et al . Desulfurization of dibenzothiophene by chemical oxidation and solvent extraction with Me3NCH2C6H5Cl·2ZnCl2 ionic liquid [J]. Green Chemistry, 2009, 11(6): 883-888. |

| 29 | Qiu L , Cheng Y , Yang C , et al . Oxidative desulfurization of dibenzothiophene using a catalyst of molybdenum supported on modified medicinal stone [J]. RSC Advances, 2016, 6(21): 17036-17045. |

| 30 | Ede S R , Kundu S . Microwave synthesis of SnWO4 nanoassemblies on DNA scaffold: a novel material for high performance supercapacitor and as catalyst for butanol oxidation[J]. ACS Sustainable Chemistry & Engineering, 2015, 3(9): 2321-2336. |

| 31 | Dong Y , Nie Y , Zhou Q . Highly efficient oxidative desulfurization of fuels by Lewis acidic ionic liquids based on iron chloride [J]. Chemical Engineering & Technology, 2013, 36(3): 435-442. |

| 32 | Chen J , Chen C , Zhang R , et al . Deep oxidative desulfurization catalyzed by an ionic liquid-type peroxotungsten catalyst [J]. RSC Advances, 2015, 5(33): 25904-25910. |

| 33 | Chen X , Song D , Asumana C , et al . Deep oxidative desulfurization of diesel fuels by Lewis acidic ionic liquids based on 1-n-butyl-3-methylimidazolium metal chloride [J]. Journal of Molecular Catalysis A: Chemical, 2012, 359: 8-13. |

| 34 | Zhu W S , Li H , Gu Q Q , et al . Kinetics and mechanism for oxidative desulfurization of fuels catalyzed by peroxo-molybdenum amino acid complexes in water-immiscible ionic liquids [J]. Journal of Molecular Catalysis A: Chemical, 2011, 336(1/2): 16-22. |

| 35 | Komintarachat C , Trakarnpruk W . Oxidative desulfurization using polyoxometalates [J]. Industrial & Engineering Chemistry Research, 2006, 45(6): 1853-1856. |

| 36 | Wei L , Zhou Z Y , Chen S P , et al . Electrochemically shape-controlled synthesis in deep eutectic solvents: triambic icosahedral platinum nanocrystals with high-index facets and their enhanced catalytic activity [J]. Chemical Communications, 2013, 49(95): 11152-11154. |

| 37 | Gao H , Guo C , Xing J , et al . Deep desulfurization of diesel oil with extraction using pyridinium-based ionic liquids [J]. Separation Science and Technology, 2012, 47(2): 325-330. |

| 38 | Mao C , Zhao R , Li X . Phenylpropanoic acid-based DESs as efficient extractants and catalysts for the removal of sulfur compounds from oil [J]. Fuel, 2017, 189: 400-407. |

| 39 | Zaid H F M , Chong F K , Mutalib M I A . Extractive deep desulfurization of diesel using choline chloride-glycerol eutectic-based ionic liquid as a green solvent [J]. Fuel, 2017, 192: 10-17. |

| 40 | Maggi R , Piscopo C G , Sartori G , et al . Supported sulfonic acids: metal-free catalysts for the oxidation of hydroquinones to benzoquinones with hydrogen peroxide [J]. Applied Catalysis A: General, 2012, 411: 146-152. |

| [1] | 黄琮琪, 吴一梅, 陈建业, 邵双全. 碱性电解水制氢装置热管理系统仿真研究[J]. 化工学报, 2023, 74(S1): 320-328. |

| [2] | 李艺彤, 郭航, 陈浩, 叶芳. 催化剂非均匀分布的质子交换膜燃料电池操作条件研究[J]. 化工学报, 2023, 74(9): 3831-3840. |

| [3] | 程业品, 胡达清, 徐奕莎, 刘华彦, 卢晗锋, 崔国凯. 离子液体基低共熔溶剂在转化CO2中的应用[J]. 化工学报, 2023, 74(9): 3640-3653. |

| [4] | 陈杰, 林永胜, 肖恺, 杨臣, 邱挺. 胆碱基碱性离子液体催化合成仲丁醇性能研究[J]. 化工学报, 2023, 74(9): 3716-3730. |

| [5] | 杨学金, 杨金涛, 宁平, 王访, 宋晓双, 贾丽娟, 冯嘉予. 剧毒气体PH3的干法净化技术研究进展[J]. 化工学报, 2023, 74(9): 3742-3755. |

| [6] | 杨欣, 彭啸, 薛凯茹, 苏梦威, 吴燕. 分子印迹-TiO2光电催化降解增溶PHE废水性能研究[J]. 化工学报, 2023, 74(8): 3564-3571. |

| [7] | 张佳怡, 何佳莉, 谢江鹏, 王健, 赵鹬, 张栋强. 渗透汽化技术用于锂电池生产中N-甲基吡咯烷酮回收的研究进展[J]. 化工学报, 2023, 74(8): 3203-3215. |

| [8] | 张瑞航, 曹潘, 杨锋, 李昆, 肖朋, 邓春, 刘蓓, 孙长宇, 陈光进. ZIF-8纳米流体天然气乙烷回收工艺的产品纯度关键影响因素分析[J]. 化工学报, 2023, 74(8): 3386-3393. |

| [9] | 杨菲菲, 赵世熙, 周维, 倪中海. Sn掺杂的In2O3催化CO2选择性加氢制甲醇[J]. 化工学报, 2023, 74(8): 3366-3374. |

| [10] | 李凯旋, 谭伟, 张曼玉, 徐志豪, 王旭裕, 纪红兵. 富含零价钴活性位点的钴氮碳/活性炭设计及甲醛催化氧化应用研究[J]. 化工学报, 2023, 74(8): 3342-3352. |

| [11] | 余娅洁, 李静茹, 周树锋, 李清彪, 詹国武. 基于天然生物模板构建纳米材料及集成催化剂研究进展[J]. 化工学报, 2023, 74(7): 2735-2752. |

| [12] | 涂玉明, 邵高燕, 陈健杰, 刘凤, 田世超, 周智勇, 任钟旗. 钙基催化剂的设计合成及应用研究进展[J]. 化工学报, 2023, 74(7): 2717-2734. |

| [13] | 张琦钰, 高利军, 苏宇航, 马晓博, 王翊丞, 张亚婷, 胡超. 碳基催化材料在电化学还原二氧化碳中的研究进展[J]. 化工学报, 2023, 74(7): 2753-2772. |

| [14] | 李盼, 马俊洋, 陈志豪, 王丽, 郭耘. Ru/α-MnO2催化剂形貌对NH3-SCO反应性能的影响[J]. 化工学报, 2023, 74(7): 2908-2918. |

| [15] | 张谭, 刘光, 李晋平, 孙予罕. Ru基氮还原电催化剂性能调控策略[J]. 化工学报, 2023, 74(6): 2264-2280. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号