化工学报 ›› 2021, Vol. 72 ›› Issue (1): 569-577.DOI: 10.11949/0438-1157.20201083

收稿日期:2020-08-03

修回日期:2020-10-28

出版日期:2021-01-05

发布日期:2021-01-05

通讯作者:

顾学红

作者简介:彭莉(1976—),女,博士,副教授,基金资助:

PENG Li( ),WU Zhengqi,WANG Boxuan,WANG Xing,GU Xuehong(

),WU Zhengqi,WANG Boxuan,WANG Xing,GU Xuehong( )

)

Received:2020-08-03

Revised:2020-10-28

Online:2021-01-05

Published:2021-01-05

Contact:

GU Xuehong

摘要:

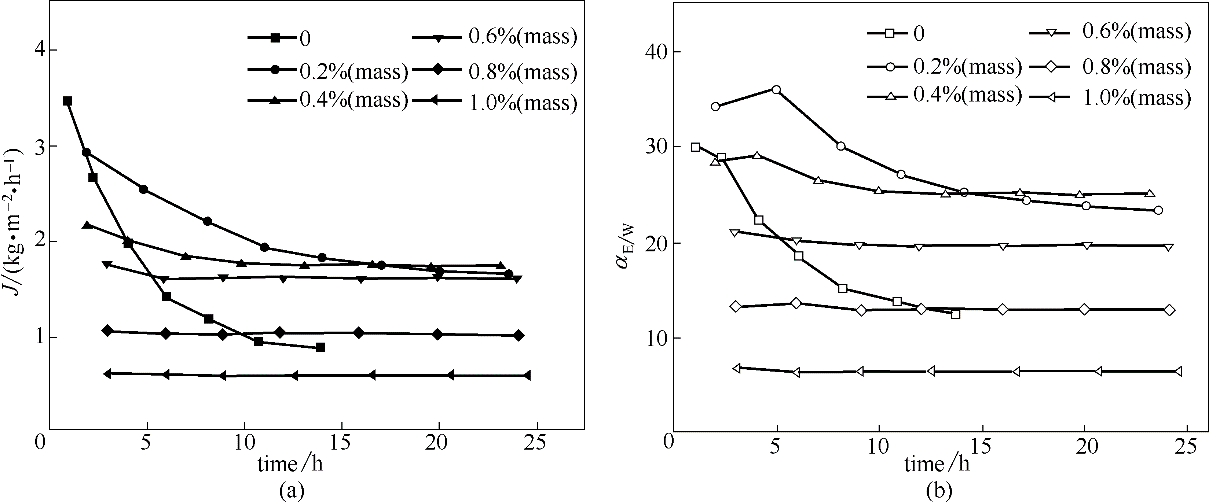

采用三甲基氯硅烷(TMCS)作为修饰源对MFI分子筛膜进行表面改性,系统考察了TMCS浓度以及修饰时间对于MFI分子筛膜在分离乙醇/水混合物时的性能影响。SEM、XRD、29Si NMR、FT-IR、接触角实验及分离实验结果表明,TMCS可以与硅羟基反应,嫁接分子筛膜表面,在消除膜表面硅缺陷的同时提高膜的疏水性及膜分离性能的稳定性。随着TMCS浓度以及反应时间的增加,修饰后MFI分子筛膜的通量及分离因子略有下降,但稳定性增强。在TMCS的浓度为0.4%(质量),修饰时间为2 h时,所得到的膜具有最佳渗透汽化分离性能,并可在60℃下分离5%(质量)乙醇/水混合物时保持良好的稳定性。在连续90 h渗透汽化分离过程中,其渗透通量稳定在1.61 kg·m-2·h-1 左右,分离因子保持在20以上。

中图分类号:

彭莉, 吴政奇, 王博轩, 王兴, 顾学红. TMCS修饰MFI分子筛膜的制备及乙醇/水分离稳定性的研究[J]. 化工学报, 2021, 72(1): 569-577.

PENG Li, WU Zhengqi, WANG Boxuan, WANG Xing, GU Xuehong. Preparation and stability study of TMCS modified MFI zeolite for ethanol/water separation[J]. CIESC Journal, 2021, 72(1): 569-577.

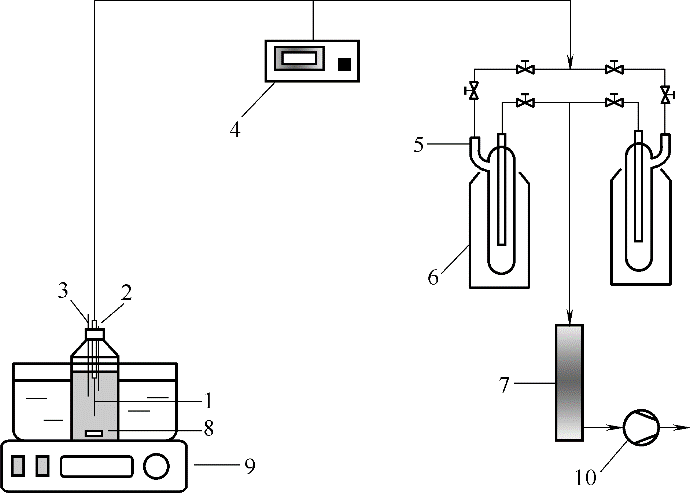

图1 MFI分子筛膜渗透汽化装置1—MFI molecular sieve membrane; 2—sampling tube; 3—thermometer; 4—vacuum gauge; 5—cold hydrazine; 6—liquid nitrogen tank; 7—drying tower; 8—rotor; 9—water bath heating stirrer; 10—vacuum pump

Fig.1 Schematic diagram of apparatus for MFI zeolite membrane pervaporation

| TMCS含量/%(质量) | 修饰前 | 修饰后 | ||

|---|---|---|---|---|

渗透通量/ (kg·m-2·h-1) | 分离因子 | 渗透通量/ (kg·m-2·h-1) | 分离因子 | |

| 0.2 | 3.47 | 35 | 2.91 | 34 |

| 0.4 | 3.66 | 37 | 2.16 | 28 |

| 0.6 | 3.41 | 35 | 1.76 | 21 |

| 0.8 | 3.59 | 34 | 1.05 | 13 |

| 1.0 | 3.29 | 39 | 0.62 | 7 |

表1 不同TMCS浓度溶液修饰前后MFI分子筛膜的渗透汽化性能

Table 1 Pervaporation performance of MFI zeolite membrane after modification in TMCS solutions with different concentration

| TMCS含量/%(质量) | 修饰前 | 修饰后 | ||

|---|---|---|---|---|

渗透通量/ (kg·m-2·h-1) | 分离因子 | 渗透通量/ (kg·m-2·h-1) | 分离因子 | |

| 0.2 | 3.47 | 35 | 2.91 | 34 |

| 0.4 | 3.66 | 37 | 2.16 | 28 |

| 0.6 | 3.41 | 35 | 1.76 | 21 |

| 0.8 | 3.59 | 34 | 1.05 | 13 |

| 1.0 | 3.29 | 39 | 0.62 | 7 |

图5 MFI及采用不同TMCS浓度溶液修饰后MFI分子筛膜的渗透汽化性能

Fig.5 The pervaporation performance of MFI zeolite membrane and those after modified in TMCS solutions with different concentration

| 修饰时间/h | 修饰前 | 修饰后 | ||

|---|---|---|---|---|

渗透通量/ (kg·m-2·h-1) | 分离 因子 | 渗透通量/ (kg·m-2·h-1) | 分离 因子 | |

| 1 | 3.29 | 36 | 2.94 | 34 |

| 2 | 3.40 | 30 | 1.83 | 27 |

| 3 | 3.15 | 34 | 1.42 | 14 |

| 4 | 3.24 | 34 | 0.97 | 9 |

表2 经TMCS不同修饰时间后的MFI分子筛膜的渗透汽化性能

Table 2 Pervaporation performance of MFI zeolite membrane after TMCS modification for different time

| 修饰时间/h | 修饰前 | 修饰后 | ||

|---|---|---|---|---|

渗透通量/ (kg·m-2·h-1) | 分离 因子 | 渗透通量/ (kg·m-2·h-1) | 分离 因子 | |

| 1 | 3.29 | 36 | 2.94 | 34 |

| 2 | 3.40 | 30 | 1.83 | 27 |

| 3 | 3.15 | 34 | 1.42 | 14 |

| 4 | 3.24 | 34 | 0.97 | 9 |

| 1 | Aditiya H B, Mahlia T M I, Chong W T, et al. Second generation bioethanol production: a critical review [J]. Renewable & Sustainable Energy Reviews, 2016, 66: 631-653. |

| 2 | Kiuchi T, Yoshida M, Kato Y. Energy saving bioethanol distillation process with self-heat recuperation technology [J]. Journal of the Japan Institute of Metals, 2015, 58(3): 135-140. |

| 3 | Cao Z Q, Xia C J, Jia W, et al. Enhancing bioethanol productivity by a yeast-immobilized catalytically active membrane in a fermentation-pervaporation coupling process [J]. Journal of Membrane Science, 2020, 595(9): 117485-117493. |

| 4 | Bai F W, Anderson W A, Moo-young M. Ethanol fermentation technologies from sugar and starch feedstocks [J]. Biotechnology Advances, 2008, 26(1): 89-105. |

| 5 | 姚迅, 彭莉, 徐晓涵, 等. 多级孔道ZSM-5分子筛超滤膜的制备[J]. 化工学报, 2017, 68(11): 4351-4358. |

| Yao X, Peng L, Xu X H, et al. Fabrication of hierarchical ZSM-5 zeolite membranes for ultrafiltration[J]. CIESC Journal, 2017, 68(11): 4351-4358. | |

| 6 | 任建新. 膜分离技术及其应用 [M]. 北京: 化学工业出版社, 2003: 513. |

| Ren J X. Membrane Separation Technology and Application [M]. Beijing: Chemical Industry Press, 2003: 513. | |

| 7 | 徐南平, 邢卫红, 赵宜江. 无机膜分离技术与应用 [M]. 北京: 化学工业出版社, 2003: 347. |

| Xu N P, Xing W H, Zhao Y J. Inorganic Membrane Separation Technology and Application [M]. Beijing: Chemical Industry Press, 2003: 347. | |

| 8 | Chapman P D, Oliveira T, Livingston A G, et al. Membranes for the dehydration of solvents by pervaporation [J]. Journal of Membrane Science, 2008, 318(1/2): 5-37. |

| 9 | Vane L M. Separation technologies for the recovery and dehydration of alcohols from fermentation broths [J]. Biofuels, Bioproducts and Biorefining, 2008, 2(6): 553-588. |

| 10 | Zheng P Y, Li C, Wang N X, et al. The potential of pervaporation for biofuel recovery from fermentation: an energy consumption point of view [J]. Chinese Journal of Chemical Engineering, 2019, 27(6): 1296-1306. |

| 11 | 孔晴晴, 张春, 王学瑞, 等. 含氟体系中MFI型分子筛膜的制备及其乙醇/水分离性能 [J]. 化工学报, 2014, 65(12): 5061-5066. |

| Kong Q Q, Zhang C, Wang X R, et al. Preparation of MFI zeolite membranes in fluoride media and separation performance for ethanol/water mixture [J]. CIESC Journal, 2014, 65(12): 5061-5066. | |

| 12 | Wu Z Q, Zhang C, Peng L, et al. Enhanced stability of MFI zeolite membranes for separation of ethanol/water by eliminating surface Si—OH groups [J]. ACS Applied Materials & Interfaces, 2018, 10(4): 3175-3180. |

| 13 | Kuhn J, Sutanto S, Gascon J, et al. Performance and stability of multi-channel MFI zeolite membranes detemplated by calcination and ozonication in ethanol/water pervaporation [J]. Journal of Membrane Science, 2009, 339(1/2): 261-274. |

| 14 | Yu L, Korelskiy D, Grahn M. Very high flux MFI membranes for alcohol recovery via pervaporation at high temperature and pressure [J]. Separation and Purification Technology, 2015, 153: 138-145. |

| 15 | Charlotte A, Jonas H. Effects of exposure to water and ethanol on silicalite-1 membranes [J]. Journal of Membrane Science, 2008, 313(1/2): 120-126. |

| 16 | Zapata P A, Huang Y, Gonzalez-borja M A, et al. Silylated hydrophobic zeolites with enhanced tolerance to hot liquid water [J]. Journal of Catalysis, 2013, 308: 82-97. |

| 17 | Prodinger S, Derewinski M A, Vjunov A, et al. Improving stability of zeolites in aqueous phase via selective removal of structural defects [J]. Journal of the American Chemical Society, 2016, 138(13): 4408-4415. |

| 18 | Zhou H, Korelskiy D, Sjöberg E, et al. Ultrathin hydrophobic MFI membranes [J]. Microporous and Mesoporous Materials, 2014, 192: 76-81. |

| 19 | Han X L, Wang L, Li J D, et al. Tuning the hydrophobicity of ZSM-5 zeolites by surface silanization using alkyltrichlorosilane [J]. Applied Surface Science, 2011, 257(22): 9525-9531. |

| 20 | Sano T, Hasegawa M, Ejiri S, et al. Improvement of the pervaporation performance of silicalite membranes by modification with a silane coupling reagent [J]. Microporous Materials, 1995, 5(3): 179-184. |

| 21 | Kosinov N, Sripathi V G P, Hensen E J M. Improving separation performance of high-silica zeolite membranes by surface modification with triethoxyfluorosilane [J]. Microporous and Mesoporous Materials, 2014, 194: 24-30. |

| 22 | Kuwahara Y, Maki K, Kamegawa T, et al. Simple design of hydrophobic zeolite material by modification using tefs and its application as a support of TiO2 photocatalyst [J]. Topics in Catalysis, 2010, 52(1/2): 193-196. |

| 23 | Kuwahara Y, Kamegawa T, Mori K, et al. Fabrication of hydrophobic zeolites using triethoxyfluorosilane and their application as supports for TiO2 photocatalysts [J]. Chemical Communications, 2008, 39: 4783-4785. |

| 24 | Chaouati N, Soualah A, Chater M. Adsorption of phenol from aqueous solution onto zeolites Y modified by silylation [J]. Comptes Rendus Chimie, 2013, 16(3): 222-228. |

| 25 | Mhaisagar Y S, Joshi B N, Mahajan A M. Surface texture modification of spin-coated SiO2 xerogel thin films by TMCS silylation [J]. Bulletin of Materials Science, 2012, 35(2): 151-155. |

| 26 | Negishi H, Okamoto M, Sano T, et al. Surface silylation of silicalite membranes and their pervaporation performance for the separation of ethanol from ethanol-water mixtures [J]. Journal of the Ceramic Society of Japan, 2014, 122(1425): 357-360. |

| 27 | 解林坤, 杜官本, 代沁伶, 等. TMCS等离子体对西南桦木材表面的修饰[J]. 中南林业科技大学学报, 2016, 36(3): 96-100. |

| Xie L K, Du G B, Dai Q L, et al. Surface modification of Betula alnoides wood by trimethylchlorosilane plasma [J]. Journal of Central South University of Forestry & Technology, 2016, 36(3): 96-100. | |

| 28 | Deng L F, Zuo X R, Lu B, et al. Effection of surface modification of silica aerogels with mixed modifier(TMCS/HMDSO) at ambient pressure [J]. Materials Review, 2013, 27(2B): 75-78. |

| 29 | 李惠云, 郭金福. 有机氯硅烷修饰的介孔SBA-15及其疏水性[J]. 化学世界, 2011, 52(7): 389-392. |

| Li H Y, Guo J F. Study on mesoporous SBA-15 modified by organochlorosilane and its hydrophobicity [J]. Chemical World, 2011, 52(7): 389-392. | |

| 30 | Shu X J, Wang X R, Kong Q Q. High-flux MFI zeolite membrane supported on ysz hollow fiber for separation of ethanol/water [J]. Industrial & Engineering Chemistry Research, 2012, 51(37): 12073-12080. |

| 31 | Yuan J J, Zhu P X, Fukazawa N, et al. Synthesis of nanofiber-based silica networks mediated by organized poly(ethylene imine): structure, properties, and mechanism [J]. Advanced Functional Materials, 2006, 16(17): 2205-2212. |

| 32 | Khedkar M V, Somvanshi S B, Humbe A V, et al. Surface modified sodium silicate based superhydrophobic silica aerogels prepared via ambient pressure drying process [J]. Journal of Non-Crystalline Solids, 2019, 511: 140-146. |

| [1] | 邵苛苛, 宋孟杰, 江正勇, 张旋, 张龙, 高润淼, 甄泽康. 水平方向上冰中受陷气泡形成和分布实验研究[J]. 化工学报, 2023, 74(S1): 161-164. |

| [2] | 江河, 袁俊飞, 王林, 邢谷雨. 均流腔结构对微细通道内相变流动特性影响的实验研究[J]. 化工学报, 2023, 74(S1): 235-244. |

| [3] | 吴延鹏, 李晓宇, 钟乔洋. 静电纺丝纳米纤维双疏膜油性细颗粒物过滤性能实验分析[J]. 化工学报, 2023, 74(S1): 259-264. |

| [4] | 李艺彤, 郭航, 陈浩, 叶芳. 催化剂非均匀分布的质子交换膜燃料电池操作条件研究[J]. 化工学报, 2023, 74(9): 3831-3840. |

| [5] | 何松, 刘乔迈, 谢广烁, 王斯民, 肖娟. 高浓度水煤浆管道气膜减阻两相流模拟及代理辅助优化[J]. 化工学报, 2023, 74(9): 3766-3774. |

| [6] | 胡建波, 刘洪超, 胡齐, 黄美英, 宋先雨, 赵双良. 有机笼跨细胞膜易位行为的分子动力学模拟研究[J]. 化工学报, 2023, 74(9): 3756-3765. |

| [7] | 齐聪, 丁子, 余杰, 汤茂清, 梁林. 基于选择吸收纳米薄膜的太阳能温差发电特性研究[J]. 化工学报, 2023, 74(9): 3921-3930. |

| [8] | 胡亚丽, 胡军勇, 马素霞, 孙禹坤, 谭学诣, 黄佳欣, 杨奉源. 逆电渗析热机新型工质开发及电化学特性研究[J]. 化工学报, 2023, 74(8): 3513-3521. |

| [9] | 孟令玎, 崇汝青, 孙菲雪, 孟子晖, 刘文芳. 改性聚乙烯膜和氧化硅固定化碳酸酐酶[J]. 化工学报, 2023, 74(8): 3472-3484. |

| [10] | 张佳怡, 何佳莉, 谢江鹏, 王健, 赵鹬, 张栋强. 渗透汽化技术用于锂电池生产中N-甲基吡咯烷酮回收的研究进展[J]. 化工学报, 2023, 74(8): 3203-3215. |

| [11] | 郑玉圆, 葛志伟, 韩翔宇, 王亮, 陈海生. 中高温钙基材料热化学储热的研究进展与展望[J]. 化工学报, 2023, 74(8): 3171-3192. |

| [12] | 张贲, 王松柏, 魏子亚, 郝婷婷, 马学虎, 温荣福. 超亲水多孔金属结构驱动的毛细液膜冷凝及传热强化[J]. 化工学报, 2023, 74(7): 2824-2835. |

| [13] | 韩奎奎, 谭湘龙, 李金芝, 杨婷, 张春, 张永汾, 刘洪全, 于中伟, 顾学红. 四通道中空纤维MFI分子筛膜用于二甲苯异构体分离[J]. 化工学报, 2023, 74(6): 2468-2476. |

| [14] | 蔡斌, 张效林, 罗倩, 党江涛, 左栗源, 刘欣梅. 导电薄膜材料的研究进展[J]. 化工学报, 2023, 74(6): 2308-2321. |

| [15] | 毛磊, 刘冠章, 袁航, 张光亚. 可捕集CO2的纳米碳酸酐酶粒子的高效制备及性能研究[J]. 化工学报, 2023, 74(6): 2589-2598. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号